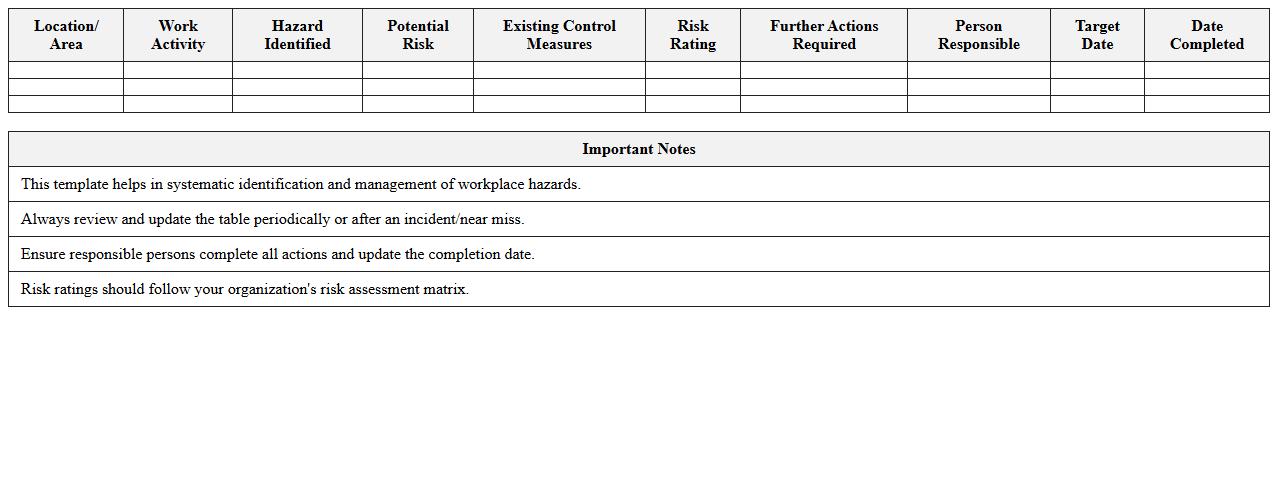

Workplace Hazard Identification Excel Template

The

Workplace Hazard Identification Excel Template document is a structured tool designed to systematically record and assess potential hazards in a work environment. It enables organizations to categorize risks, assign priority levels, and implement corrective actions efficiently, enhancing overall workplace safety. Using this template helps reduce accidents and ensures compliance with occupational health and safety regulations by maintaining clear and accessible hazard documentation.

Manufacturing Incident Tracking Log Template

A

Manufacturing Incident Tracking Log Template document systematically records and monitors incidents occurring during the production process, ensuring accurate documentation of event details such as date, time, cause, and resolution. This template enhances operational efficiency by facilitating quick identification of recurring issues, supporting root cause analysis, and enabling preventive measures that minimize downtime and improve product quality. By maintaining comprehensive incident logs, manufacturers can demonstrate compliance with industry standards and improve workplace safety across all production stages.

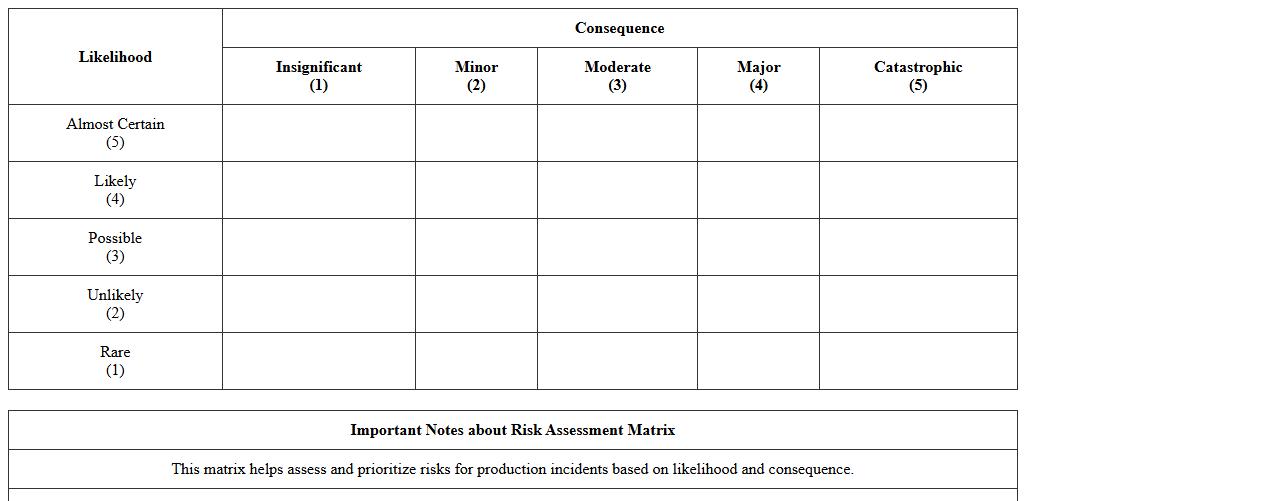

Risk Assessment Matrix for Production Incidents

The

Risk Assessment Matrix for Production Incidents document is a tool used to evaluate and categorize potential risks based on their severity and likelihood in production environments. It helps prioritize incident response efforts by identifying high-impact, high-probability issues, enabling more efficient allocation of resources. This structured approach reduces downtime, improves safety protocols, and supports proactive decision-making in managing production risks.

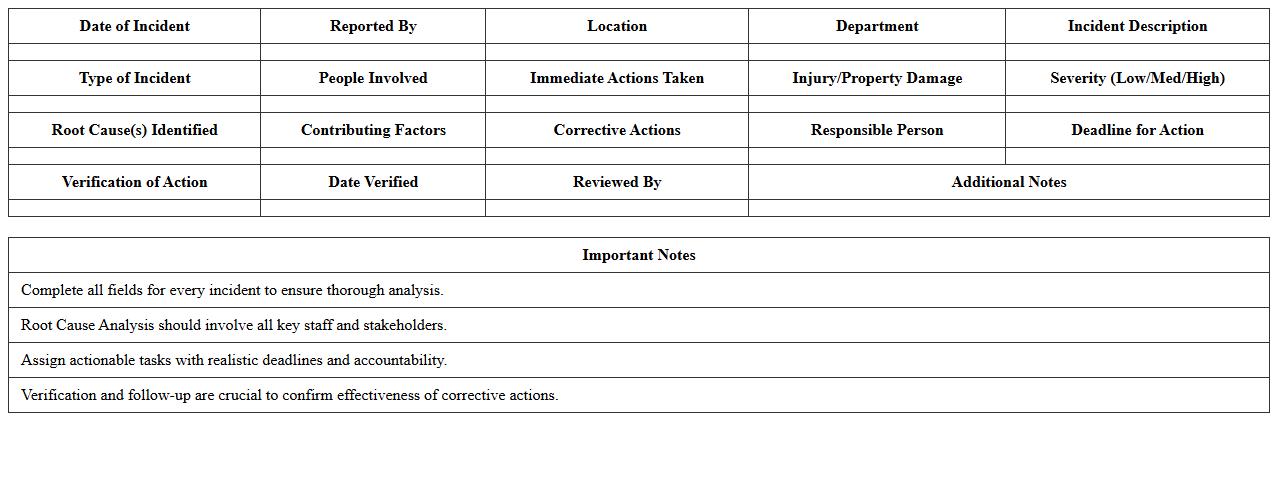

Safety Incident Root Cause Analysis Sheet

A

Safety Incident Root Cause Analysis Sheet is a documented tool used to systematically identify the underlying causes of safety incidents in the workplace. It helps organizations pinpoint not just the immediate errors but the fundamental process failures or environmental conditions leading to an incident. This document is essential for implementing effective corrective actions, reducing future risks, and enhancing overall workplace safety management.

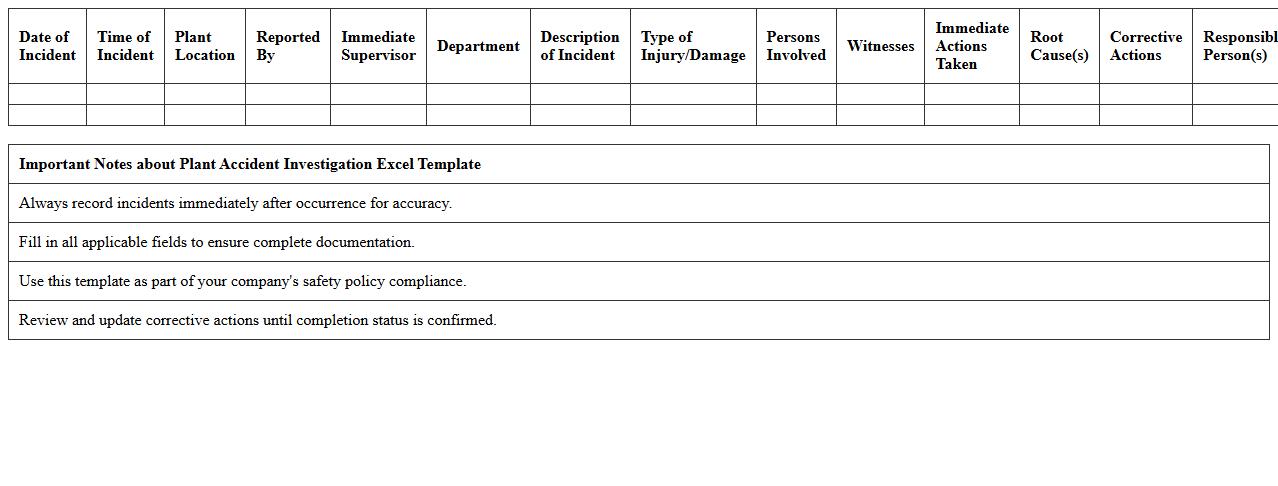

Plant Accident Investigation Excel Template

The

Plant Accident Investigation Excel Template document is designed to systematically record and analyze workplace incidents to identify root causes and prevent future occurrences. It streamlines data entry, categorizes hazards, and documents corrective actions, ensuring thorough and organized reporting. Utilizing this template enhances safety management, compliance with regulatory standards, and supports continuous improvement in plant operations.

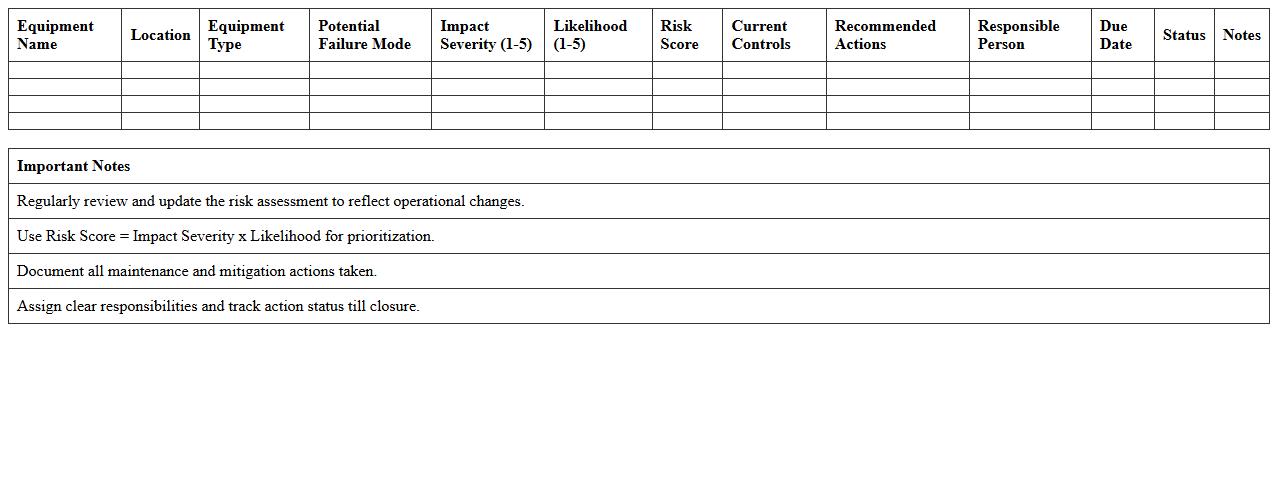

Equipment Failure Risk Assessment Spreadsheet

An

Equipment Failure Risk Assessment Spreadsheet document systematically catalogs potential equipment breakdowns, their causes, and the associated risks, enabling businesses to prioritize maintenance efforts effectively. It integrates failure modes, probabilities, and impact ratings to quantify risk levels, supporting data-driven decision-making in asset management. This tool enhances operational reliability, minimizes downtime, and optimizes resource allocation by providing clear visibility into equipment vulnerabilities.

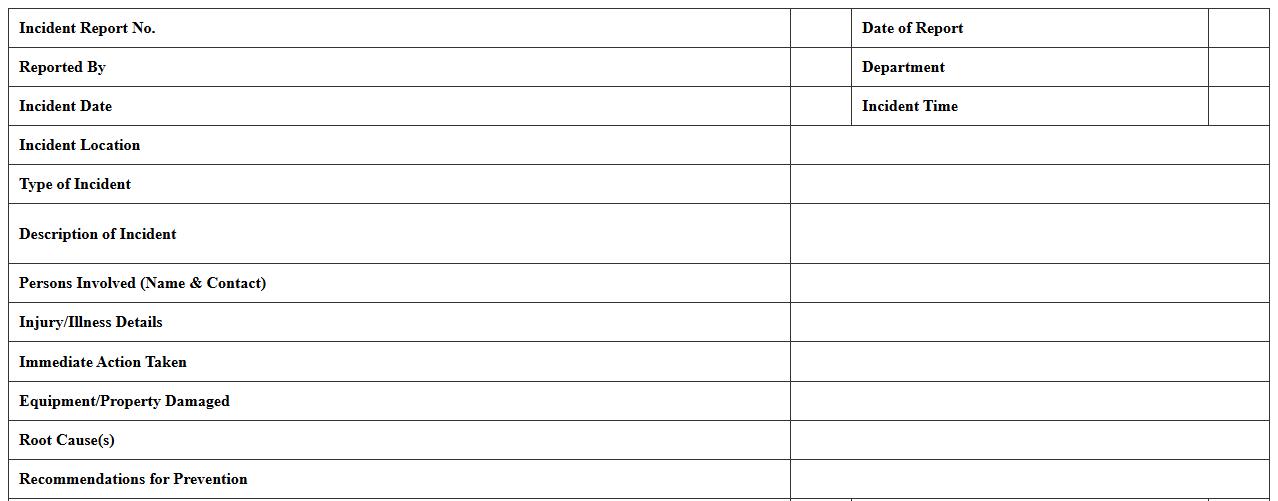

OSHA Compliance Incident Report Template

An

OSHA Compliance Incident Report Template is a structured document designed to capture detailed information about workplace incidents, ensuring adherence to Occupational Safety and Health Administration (OSHA) regulations. It helps organizations systematically record key data such as the nature of the incident, involved parties, causes, and corrective actions taken, facilitating accurate reporting and regulatory compliance. This template streamlines the investigation process, enhances workplace safety management, and supports timely submission of mandatory reports to OSHA authorities.

Corrective Action Plan Tracker Excel Template

The

Corrective Action Plan Tracker Excel Template is a structured spreadsheet designed to monitor, manage, and document corrective actions within projects or processes. It helps organizations systematically identify issues, assign responsibilities, set deadlines, and track progress to ensure timely resolution of problems. This template improves accountability, enhances efficiency in problem-solving, and supports continuous improvement initiatives by providing clear visibility into action status and outcomes.

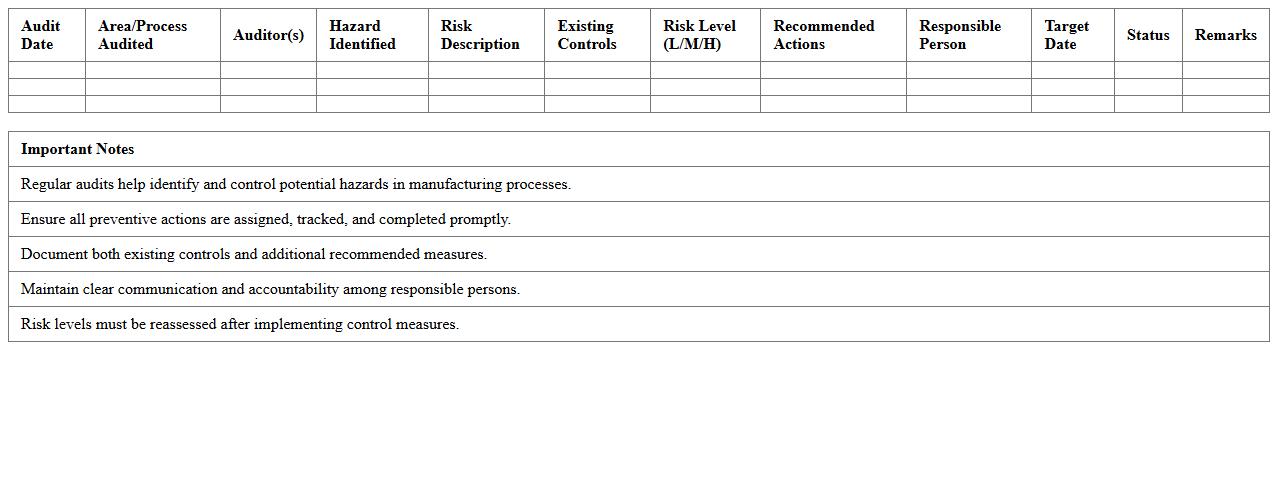

Safety Audit and Risk Register for Manufacturing

A

Safety Audit and Risk Register for Manufacturing documents systematically identify, evaluate, and record potential hazards and risks within manufacturing processes, ensuring compliance with safety standards. This comprehensive tool helps organizations track safety measures, prioritize risks, and implement corrective actions to minimize workplace accidents and operational disruptions. Utilizing these documents enhances overall safety performance, supports regulatory compliance, and promotes a proactive safety culture in manufacturing environments.

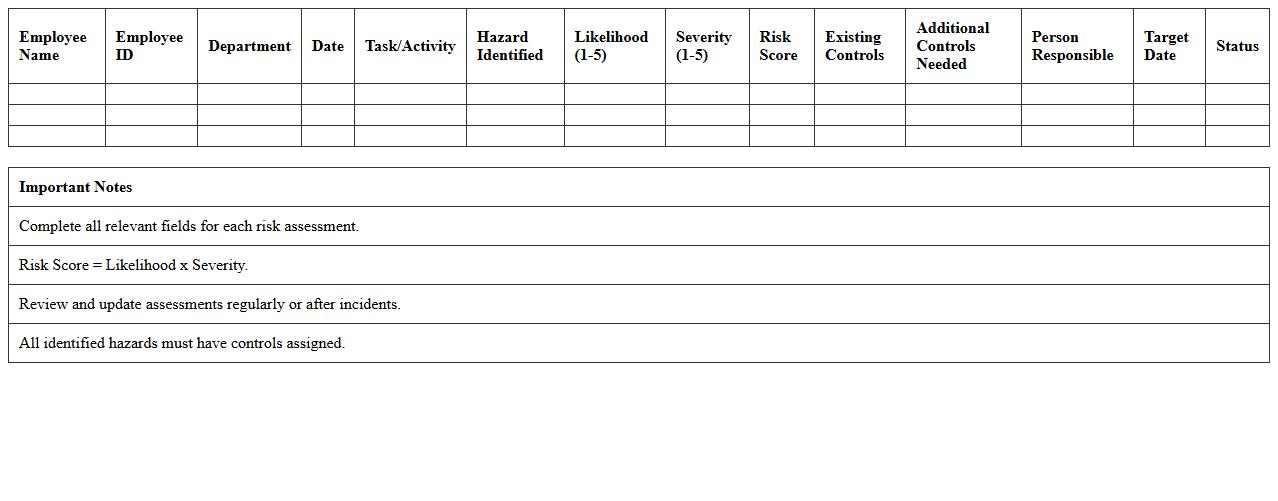

Employee Injury Risk Assessment Sheet

An

Employee Injury Risk Assessment Sheet is a detailed document used to identify and evaluate potential hazards that could cause injuries in the workplace. It systematically records risks associated with specific tasks or environments, helping organizations implement targeted safety measures and reduce workplace accidents. By analyzing this sheet, companies can enhance employee protection protocols, ensure compliance with safety regulations, and minimize injury-related costs.

How does the Incident Risk Assessment Excel template quantify manufacturing process hazards?

The Incident Risk Assessment Excel template quantifies manufacturing process hazards by assigning numerical values to the likelihood and severity of each hazard. These values are then combined to calculate an overall risk score that prioritizes risks. This method ensures a systematic and objective evaluation of potential hazards in the manufacturing process.

What formulas are used to calculate risk priority numbers (RPN) in the document?

The document uses the formula RPN = Likelihood x Severity x Detection to calculate risk priority numbers. Each factor is rated on a predefined scale, and the product provides a quantitative measure of risk. This formula helps in prioritizing risks based on their potential impact and detectability.

Can the Excel sheet auto-generate risk mitigation action plans for identified incidents?

The Excel sheet includes features that assist users in auto-generating risk mitigation action plans once incidents are identified. It uses predefined templates and dropdown menus to suggest appropriate actions based on the risk scores. While it streamlines the process, final plan customization by the user is recommended for accuracy.

Does the assessment template allow linking incident data to specific production lines or equipment?

The assessment template provides options to link incident data directly to specific production lines or equipment via dropdown menus or lookup tables. This integration aids in precise tracking and analysis of risks associated with particular manufacturing assets. It enhances the granularity and relevance of risk management efforts.

How does the Excel document support version control for updated risk assessments?

The Excel document supports version control by enabling users to save copies with timestamps or version numbers in the filename. Additionally, some templates may include logs or sheets that record changes and updates within the file. This ensures a clear history of modifications to risk assessments over time.