The Root Cause Analysis Excel Template for Manufacturing Processes enables systematic identification of underlying issues affecting production efficiency. This template allows users to organize data, track problem occurrences, and analyze patterns quickly within a familiar spreadsheet format. Streamlining troubleshooting efforts, it supports continuous improvement and reduces downtime in manufacturing operations.

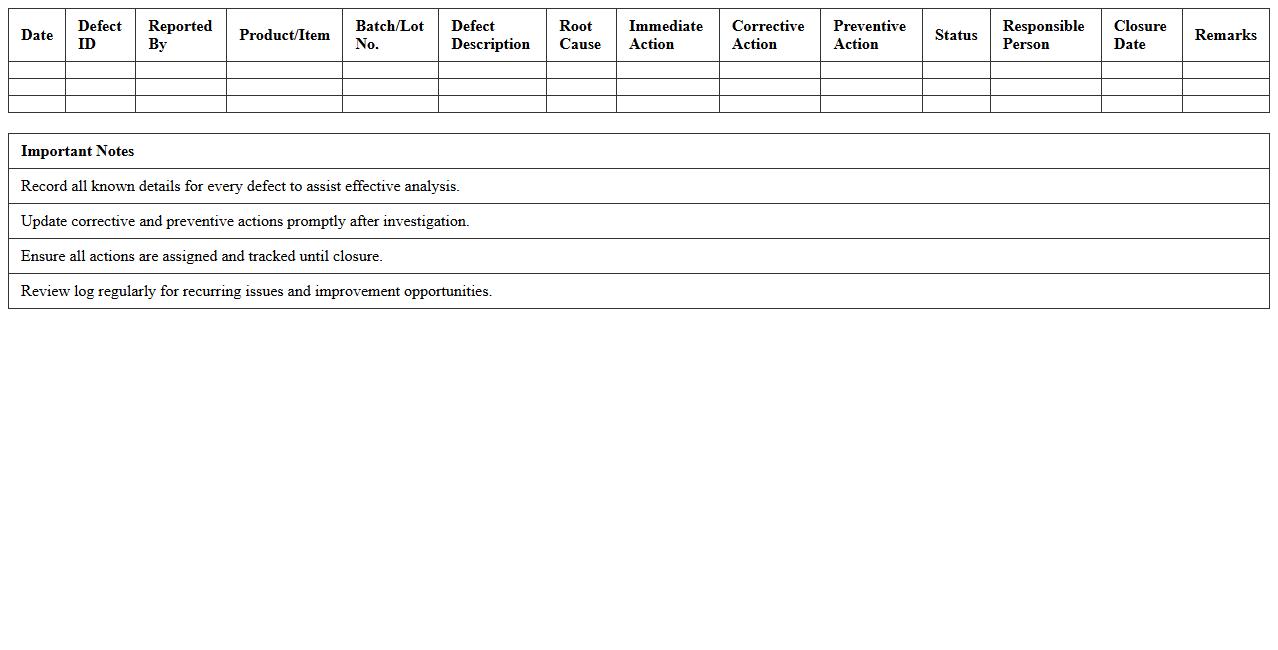

Production Defect Root Cause Analysis Log

A

Production Defect Root Cause Analysis Log document systematically records identified defects in production along with their underlying causes, facilitating detailed tracking and management. This log enables teams to pinpoint recurring issues, streamline troubleshooting processes, and implement targeted corrective actions to enhance product quality. It serves as a critical tool for continuous improvement by providing data-driven insights that reduce defect rates and improve operational efficiency.

Manufacturing Process Incident Tracking Sheet

The

Manufacturing Process Incident Tracking Sheet is a crucial document used to record and monitor incidents that occur during the manufacturing process, capturing details such as the nature of the incident, time, location, and personnel involved. It enables manufacturers to identify patterns, analyze root causes, and implement corrective actions to prevent recurrence, thereby enhancing product quality and operational efficiency. This systematic tracking supports compliance with industry standards and regulatory requirements, ultimately reducing downtime and improving overall safety in the production environment.

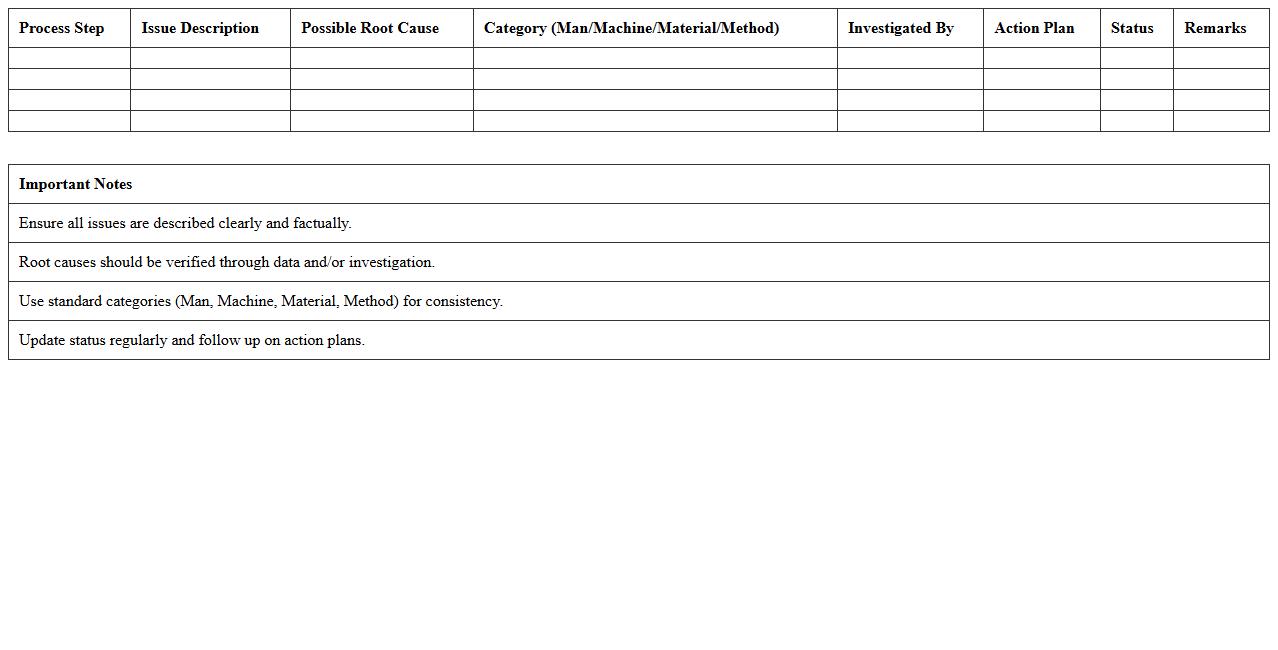

Assembly Line Failure Mode Analysis Tracker

The

Assembly Line Failure Mode Analysis Tracker document systematically records and categorizes potential failure modes occurring in the assembly process, enabling early identification of issues that could disrupt production. By capturing detailed data on failure types, root causes, and frequency, this tracker supports targeted corrective actions and continuous improvement efforts. Utilizing this document enhances operational efficiency, reduces downtime, and improves product quality by preventing repeated assembly line failures.

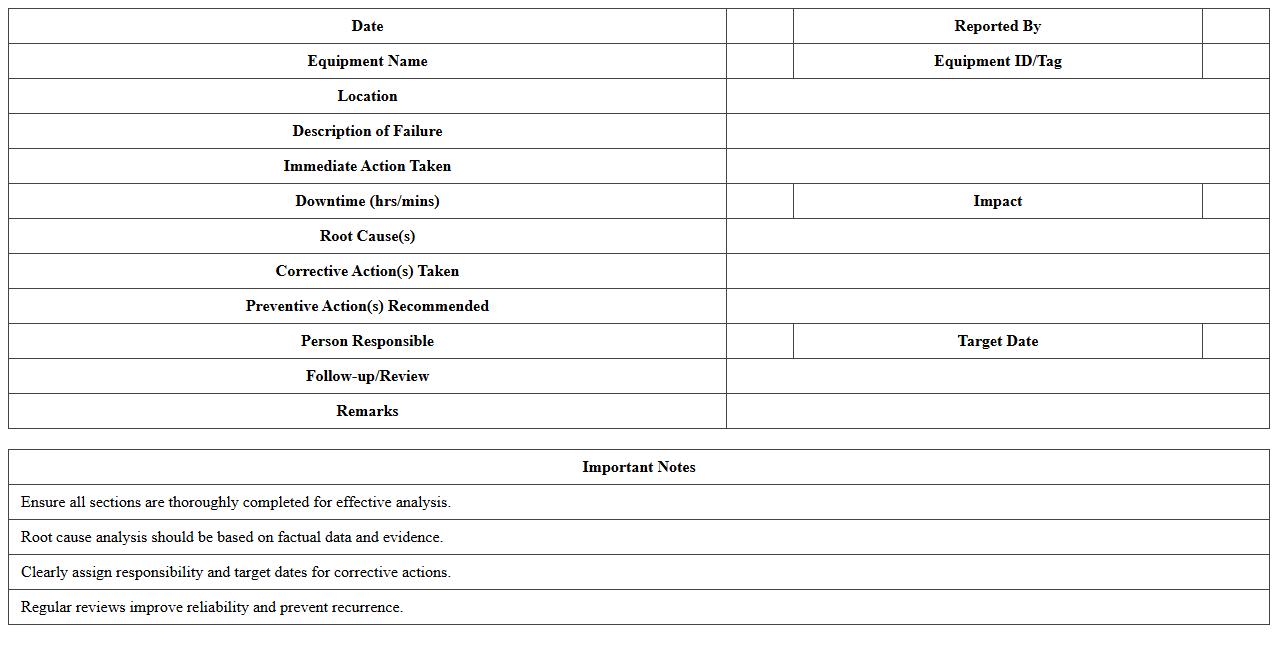

Equipment Breakdown RCA Worksheet

The

Equipment Breakdown RCA Worksheet is a structured document designed to systematically analyze the root causes of equipment failures. It helps organizations identify technical issues, human errors, and environmental factors contributing to breakdowns, enabling targeted corrective actions. Using this worksheet improves maintenance strategies, reduces downtime, and enhances overall operational efficiency.

Manufacturing Quality Issue Root Cause Matrix

A

Manufacturing Quality Issue Root Cause Matrix document systematically categorizes and analyzes the underlying causes of quality problems in manufacturing processes. This tool enables teams to identify, prioritize, and address defects or inefficiencies by mapping issues to specific root causes such as equipment failure, material defects, or human error. Utilizing this matrix enhances problem-solving efficiency, reduces production downtime, and improves overall product consistency and compliance with quality standards.

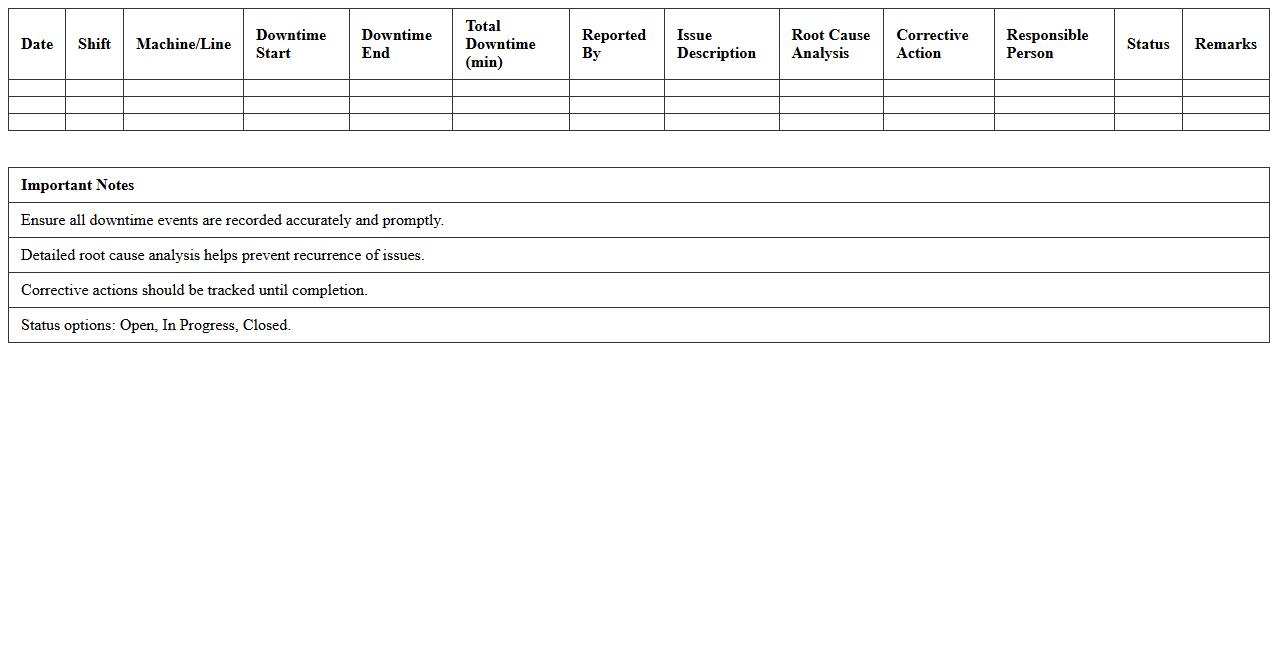

Production Downtime RCA Report Template

The

Production Downtime RCA Report Template is a structured document designed to systematically identify the root causes of production stoppages. It helps organizations analyze downtime events by capturing detailed information such as incident timelines, contributing factors, and corrective actions. Utilizing this template enables companies to reduce future downtime, improve operational efficiency, and increase overall equipment effectiveness (OEE).

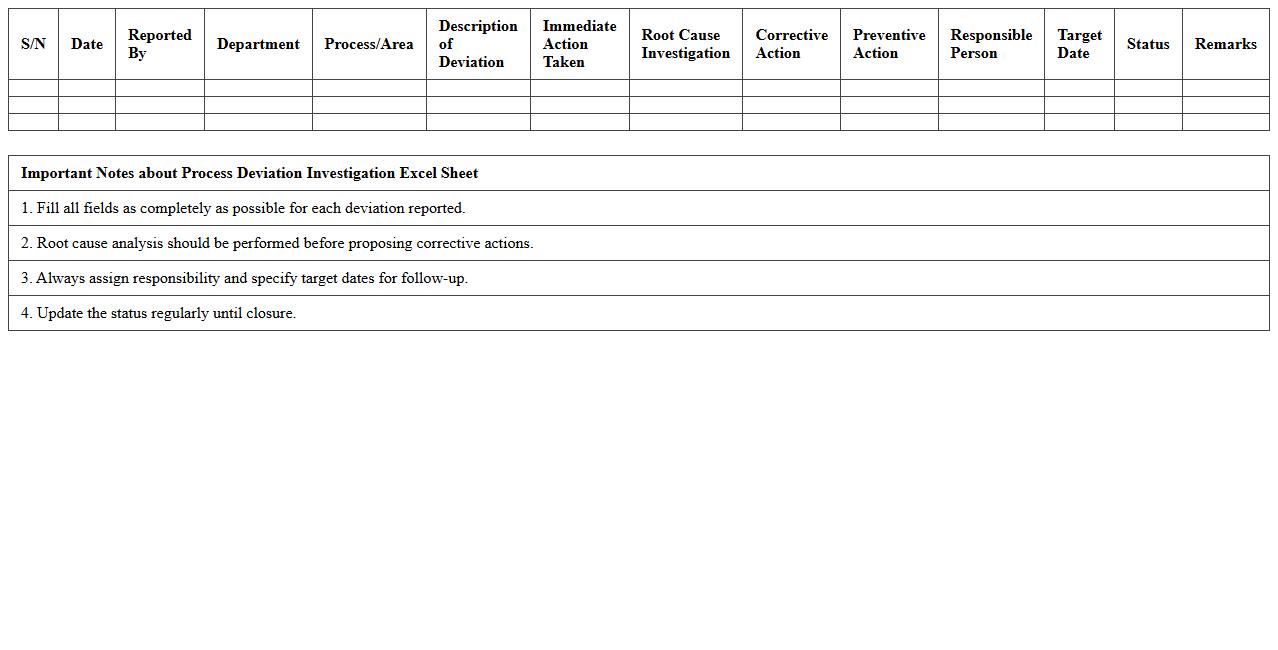

Process Deviation Investigation Excel Sheet

The

Process Deviation Investigation Excel Sheet is a structured document used to systematically record, analyze, and track deviations from standard operating procedures in manufacturing or business processes. It helps teams identify root causes, implement corrective actions, and prevent recurrence by providing a clear visual overview of deviation data and investigation progress. Utilizing this tool improves process compliance, quality control, and operational efficiency through data-driven decision-making and continuous improvement efforts.

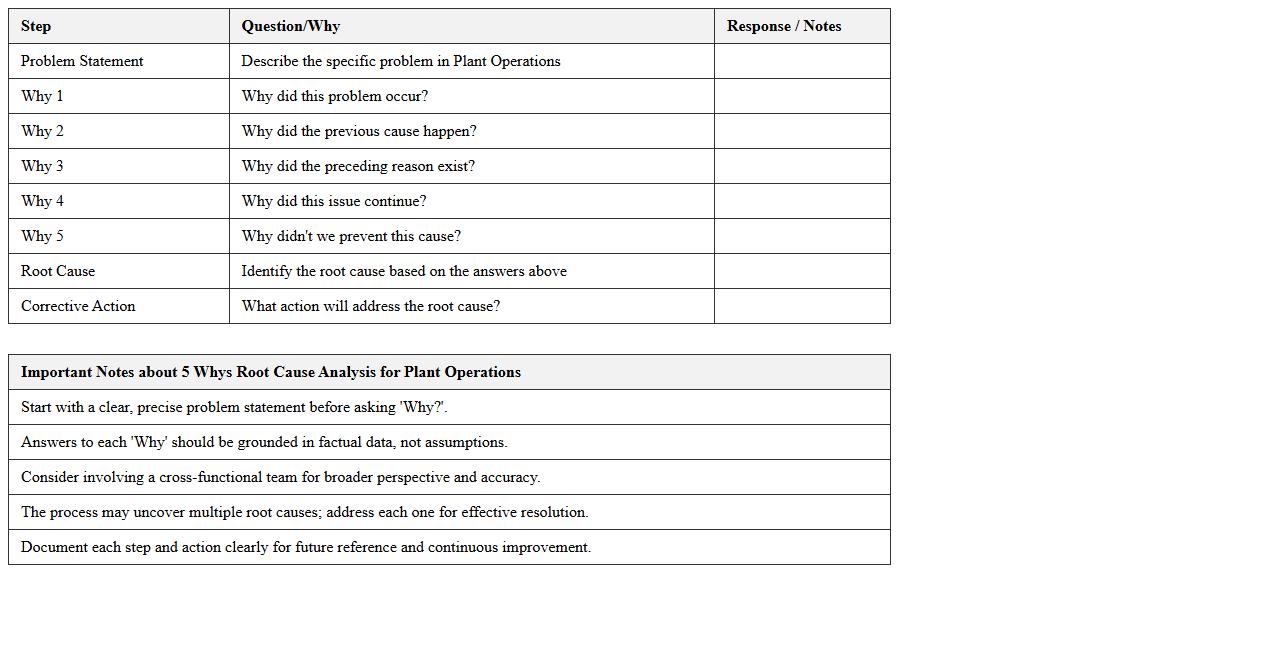

5 Whys Root Cause Analysis for Plant Operations

The

5 Whys Root Cause Analysis is a problem-solving technique used in plant operations to identify the underlying cause of equipment failures or process issues by repeatedly asking "why" until the root cause is determined. This document provides a structured approach to systematically investigate problems, reducing downtime and improving operational efficiency. By implementing this method, plants can prevent recurrence of issues, optimize maintenance strategies, and enhance overall productivity.

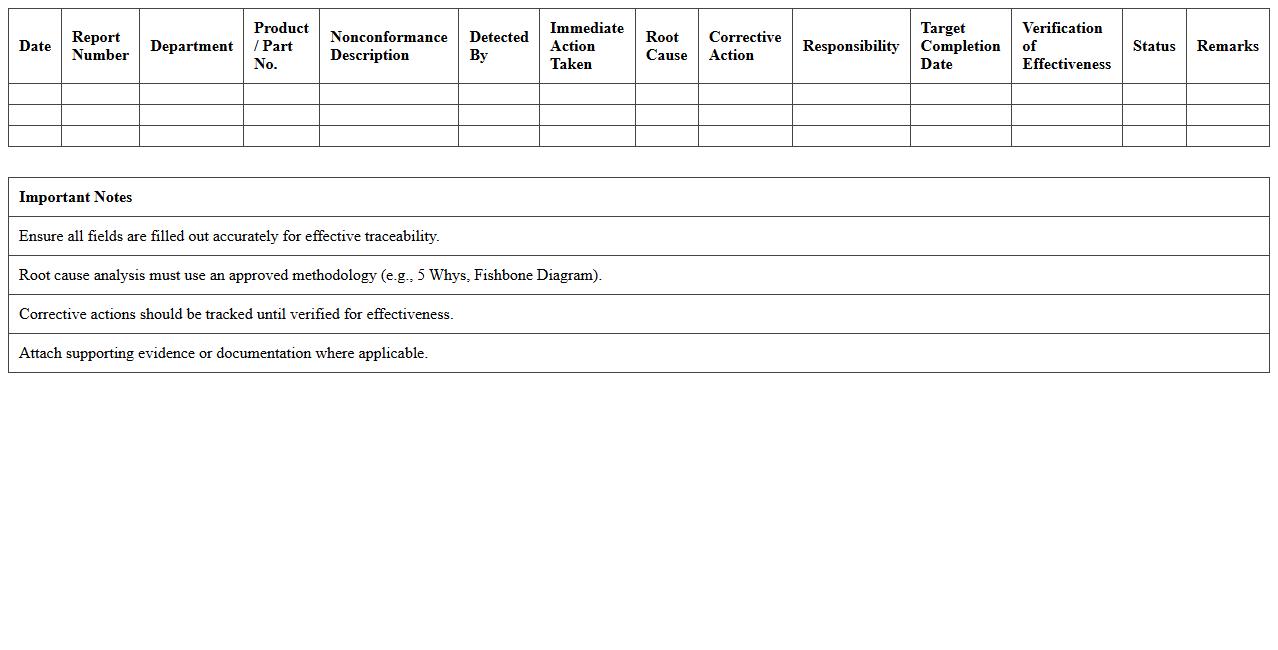

Manufacturing Nonconformance RCA Checklist

The

Manufacturing Nonconformance RCA Checklist document is a structured tool designed to systematically identify the root causes of defects or deviations in manufacturing processes. It helps quality and production teams pinpoint specific issues, streamline corrective actions, and prevent recurrence by ensuring thorough analysis. Utilizing this checklist enhances product quality, reduces downtime, and supports continuous improvement initiatives within manufacturing operations.

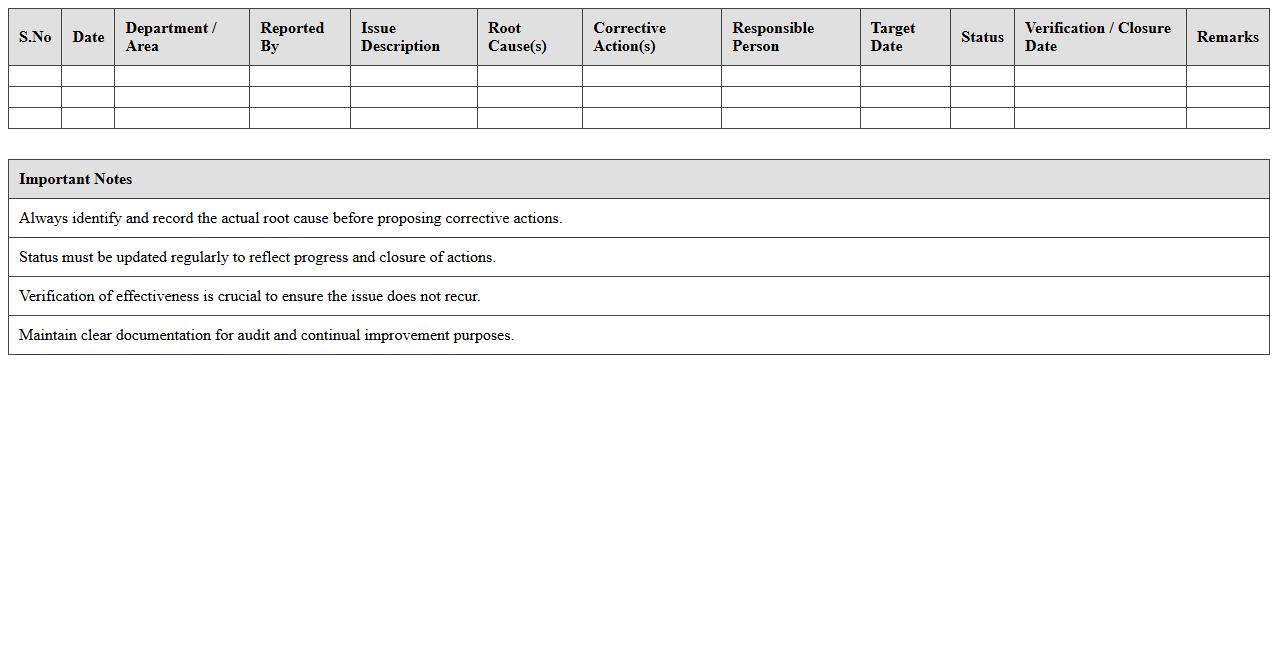

Root Cause and Corrective Action Register for Manufacturing

The

Root Cause and Corrective Action Register is a critical manufacturing document that systematically records identified root causes of defects or process failures alongside the corrective actions implemented to resolve them. It facilitates continuous improvement by providing a centralized reference to track problem resolution effectiveness, prevent recurrence, and enhance product quality. Utilizing this register helps manufacturers reduce downtime, improve operational efficiency, and maintain compliance with quality management standards such as ISO 9001.

How to automate defect trend charts in a Root Cause Analysis Excel template for manufacturing?

To automate defect trend charts, use dynamic named ranges linked to your data source to update charts automatically. Incorporate Excel's PivotTables and PivotCharts to summarize defect data efficiently over time. Utilize VBA macros to refresh data and generate charts instantly with a single click.

Which Excel functions best isolate process variance causes in manufacturing RCAs?

Functions like IF, COUNTIFS, and VLOOKUP effectively identify patterns and anomalies in defect data. Utilize FILTER and SUMPRODUCT to correlate multiple criteria and isolate specific root causes. Statistical functions like STDEV support quantifying process variance within datasets.

What data fields are critical in a manufacturing RCA document letter for Excel tracking?

Essential data fields include Root Cause Description, Defect Type, and Occurrence Date for tracking temporal trends. Fields such as Corrective Actions and Responsibility enable accountability and resolution tracking. Including a Status field helps monitor progress and closure within the RCA template.

How can conditional formatting in Excel highlight recurring root causes in process logs?

Apply conditional formatting rules based on criteria like repeated Root Cause IDs or high-frequency defect types. Use color scales or icon sets to visualize severity or recurrence intensity dynamically. Setting rules with formulas like COUNTIF allows automated highlighting of persistent issues in logs.

What are effective methods to visualize corrective action timelines in Excel RCA sheets?

Gantt charts created via stacked bar charts provide clear visualization of corrective action timelines and deadlines. Utilize Excel's timeline slicers within PivotTables for interactive filtering of action dates. Incorporate conditional formatting to highlight overdue tasks and maintain timely follow-up.

More Analysis Excel Templates