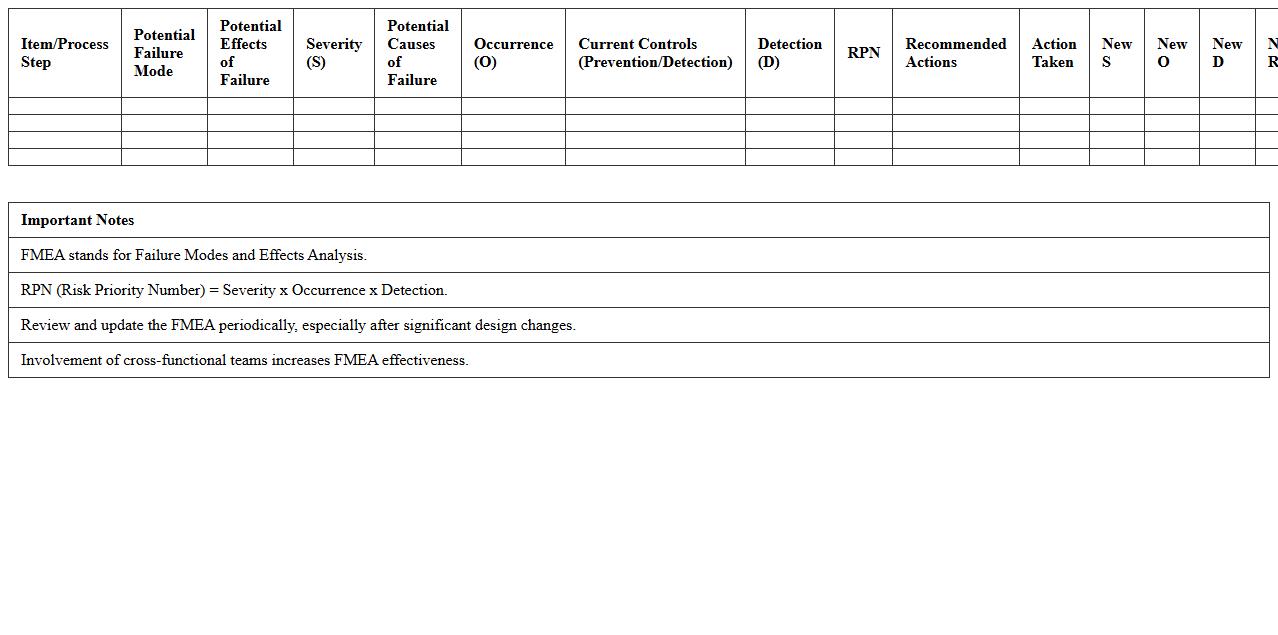

Product Design FMEA Template Excel

A

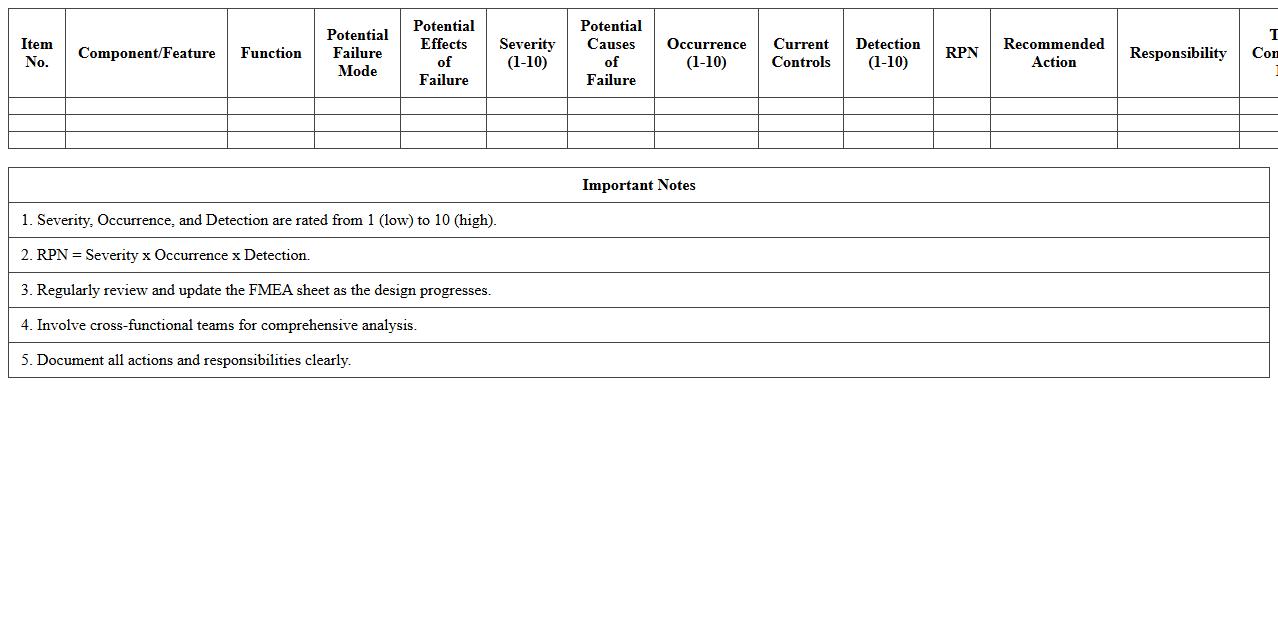

Product Design FMEA Template Excel document is a structured tool that helps identify and analyze potential failure modes in product designs, assessing their impact on performance and safety. It enables teams to prioritize risks based on severity, occurrence, and detection ratings, facilitating targeted corrective actions to improve product reliability. Using this template enhances collaboration, streamlines risk management processes, and ensures more robust and quality-driven product development.

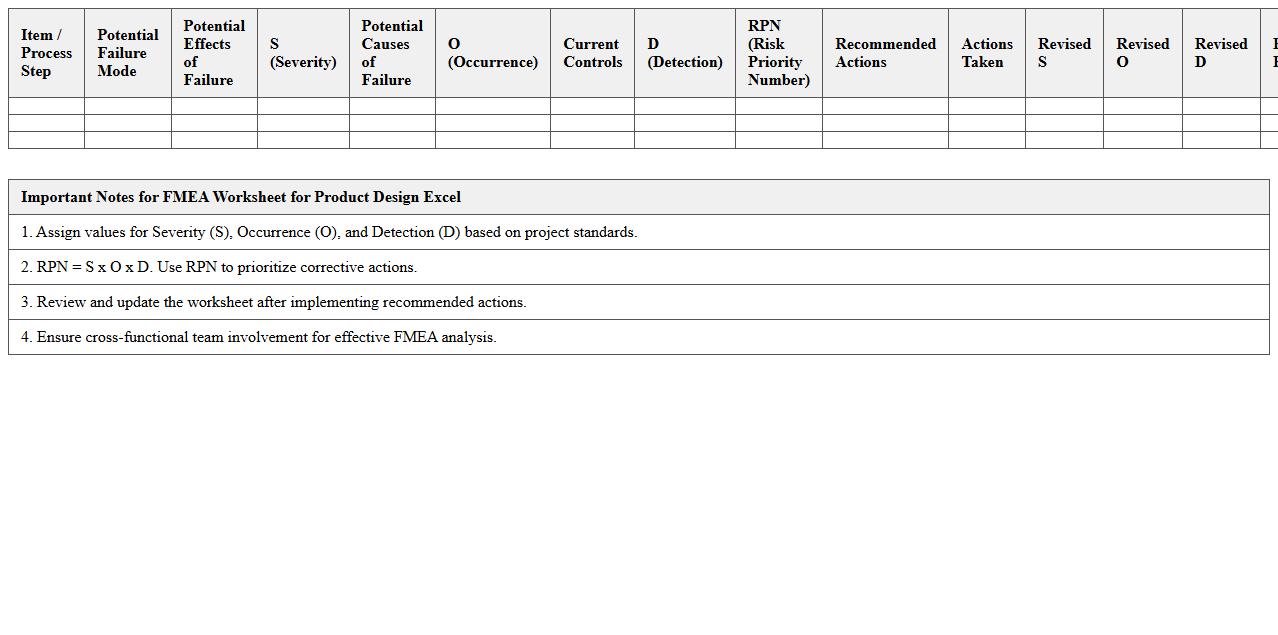

FMEA Worksheet for Product Design Excel

The

FMEA Worksheet for Product Design in Excel is a structured tool used to identify and evaluate potential failure modes in a product's design phase. It helps prioritize risks by assessing the severity, occurrence, and detection of each failure, enabling engineers to implement corrective actions early. This proactive approach reduces product defects, enhances reliability, and improves overall quality while saving time and costs in manufacturing.

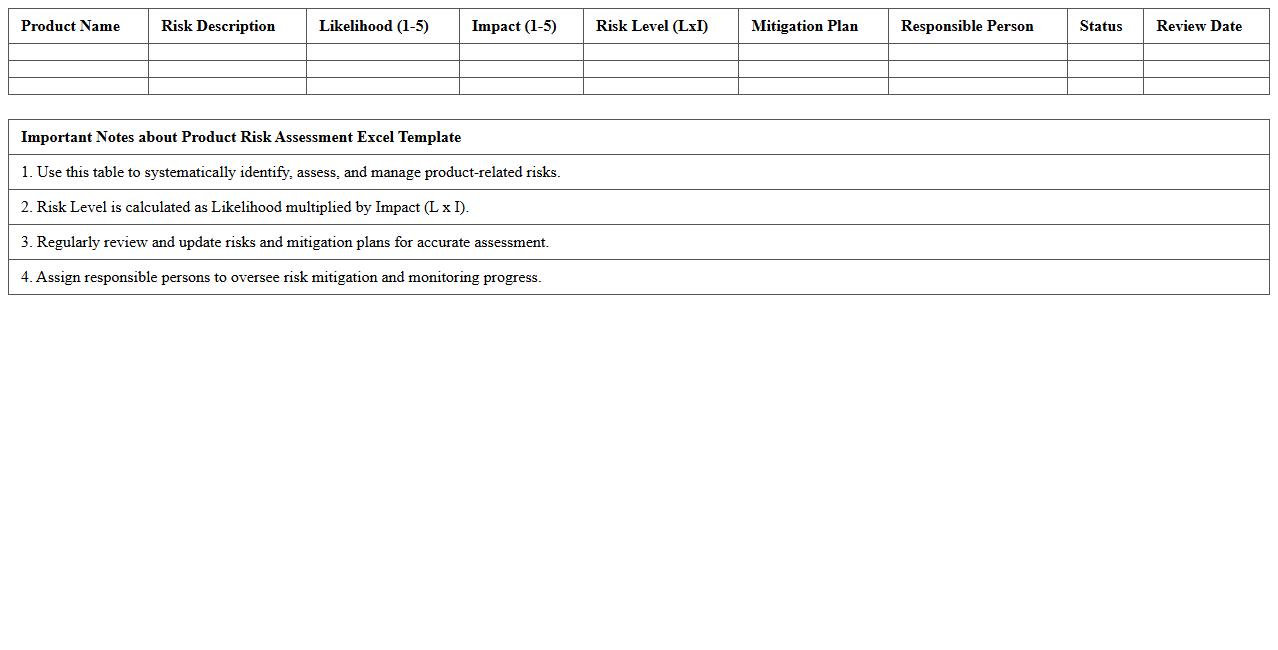

Product Risk Assessment Excel Template

The

Product Risk Assessment Excel Template is a structured document designed to identify, evaluate, and prioritize potential risks associated with a product throughout its development and lifecycle. This template helps teams systematically analyze risk factors such as safety issues, compliance violations, and operational failures by organizing data into clear, actionable categories. It is useful for improving decision-making processes, enhancing product quality, and ensuring regulatory compliance by providing a comprehensive overview of potential vulnerabilities.

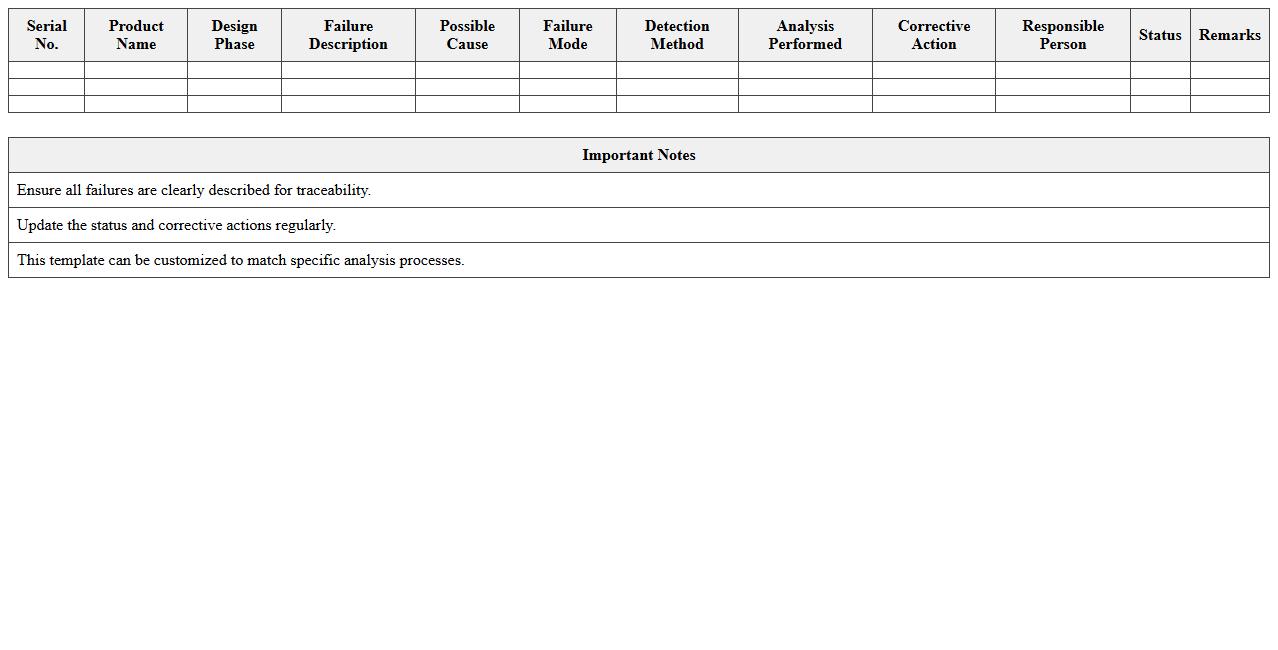

Failure Mode Analysis Product Design Excel Sheet

A

Failure Mode Analysis Product Design Excel Sheet document systematically identifies potential failure points in a product design, helping engineers prioritize risks based on severity, occurrence, and detection ratings. This tool facilitates corrective action planning by organizing failure modes, effects, and recommended improvements in a clear, structured format. Utilizing this sheet enhances product reliability, reduces development costs, and accelerates time-to-market by preventing defects early in the design process.

Product Reliability FMEA Excel Template

The

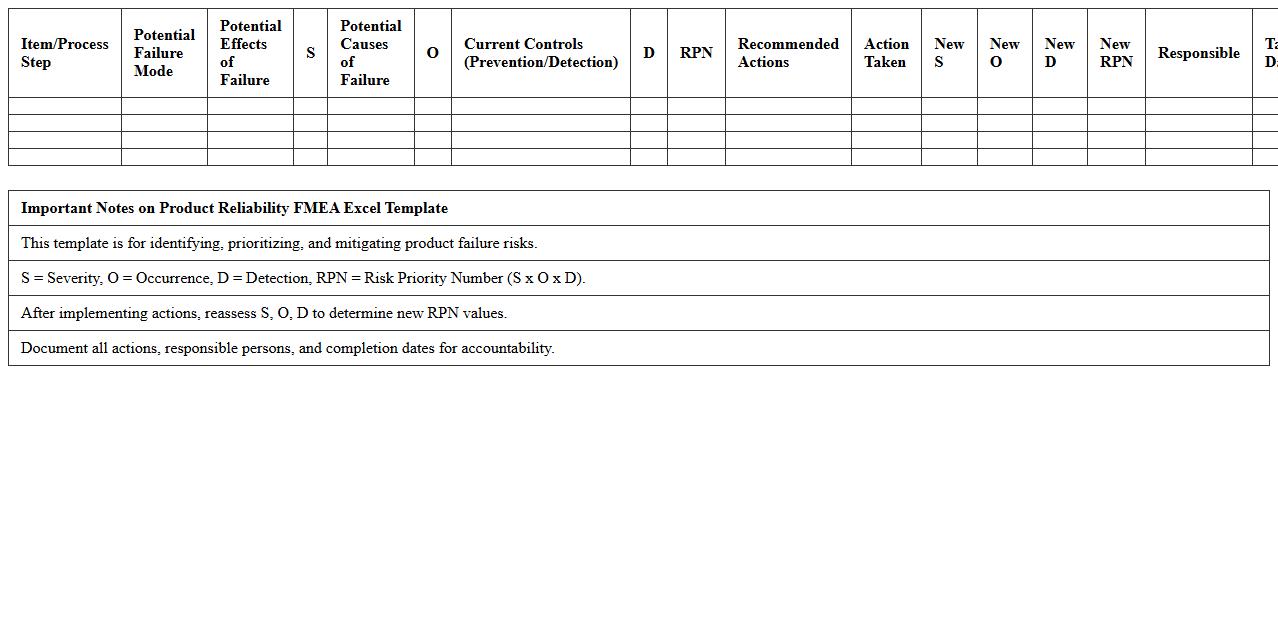

Product Reliability FMEA Excel Template document is a structured tool designed to identify potential failure modes, their causes, and effects within a product's lifecycle. It enables teams to systematically assess risks, prioritize issues based on severity and occurrence, and implement corrective actions to enhance product reliability. Utilizing this template improves decision-making processes, reduces failure rates, and supports continuous quality improvement initiatives.

Product Failure Effect Matrix Excel

The

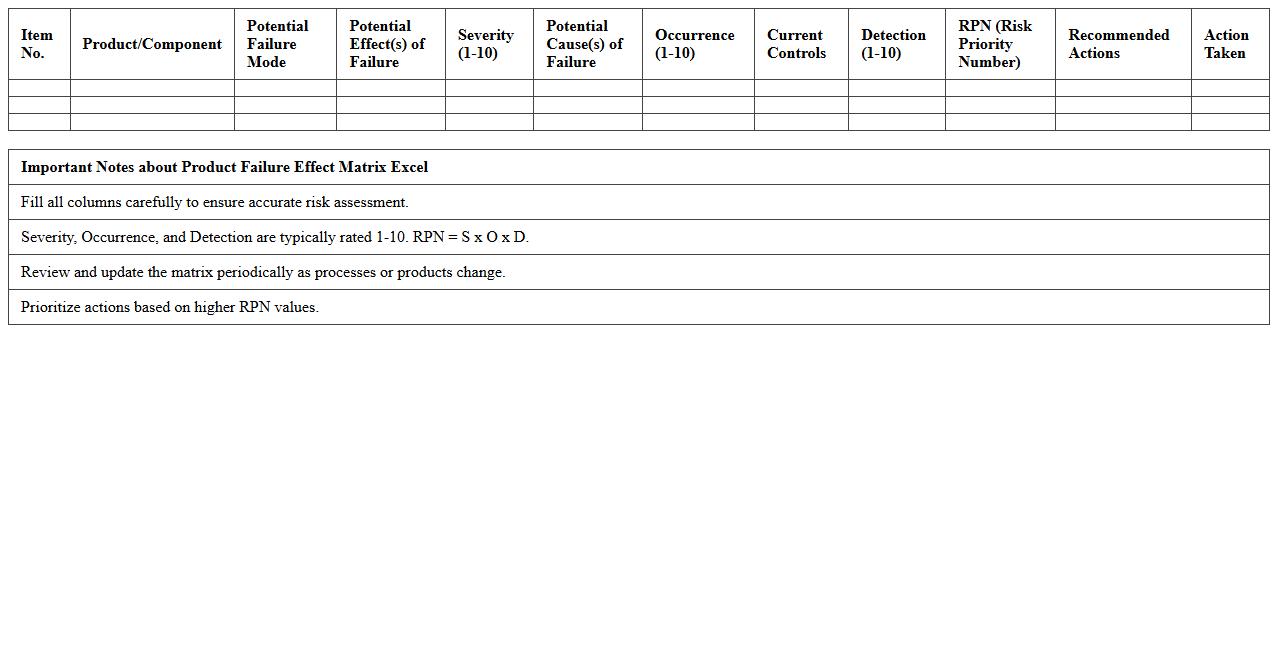

Product Failure Effect Matrix Excel document systematically evaluates potential product failures by analyzing their causes and impacts, enabling effective risk management. It helps prioritize corrective actions by assigning severity, occurrence, and detection ratings, streamlining quality control processes. This tool enhances decision-making and improves product reliability throughout the development lifecycle.

Product Design FMEA Risk Priority Template

The

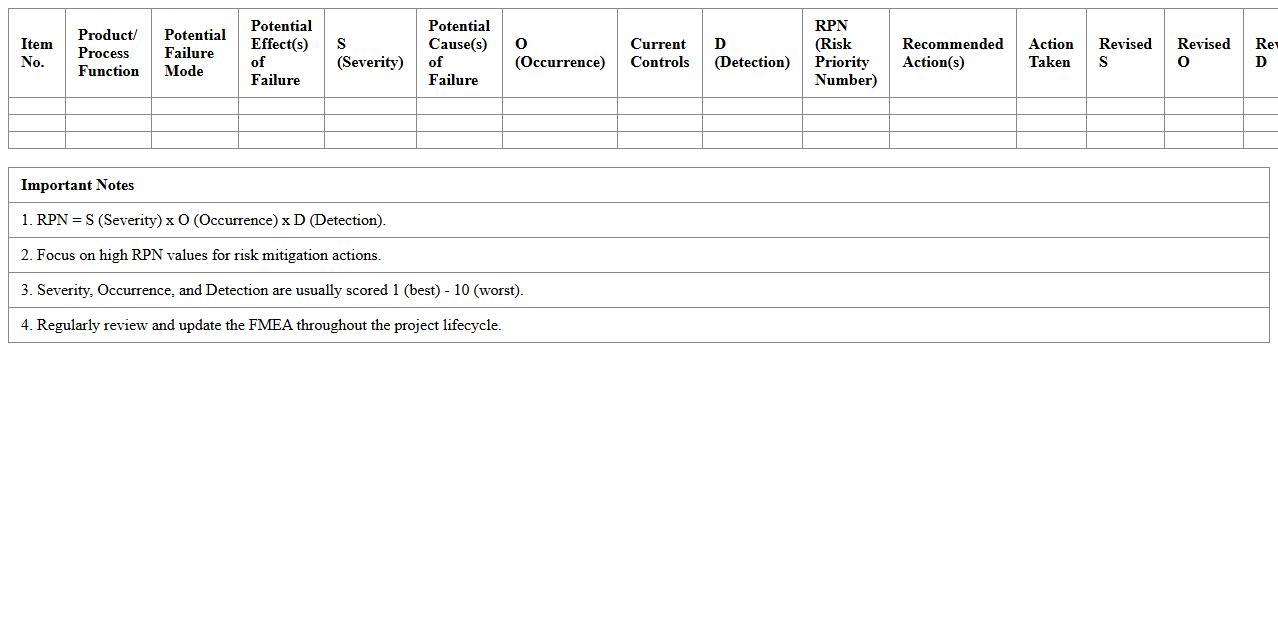

Product Design FMEA Risk Priority Template document systematically identifies and prioritizes potential failure modes in product design by analyzing their severity, occurrence, and detection ratings. This tool helps teams focus on high-risk areas, enabling targeted improvements that enhance product reliability and safety. By providing a structured approach to risk assessment, it supports informed decision-making and efficient allocation of resources during the design process.

Excel Template for Product Design Failure Analysis

An

Excel Template for Product Design Failure Analysis is a structured spreadsheet tool used to systematically identify, document, and evaluate potential design failures in products. It helps teams analyze failure modes, assess risks based on severity, occurrence, and detection ratings, and prioritize corrective actions to enhance product reliability. This template streamlines failure analysis, improves communication among engineers, and supports data-driven decision-making to reduce costly design flaws.

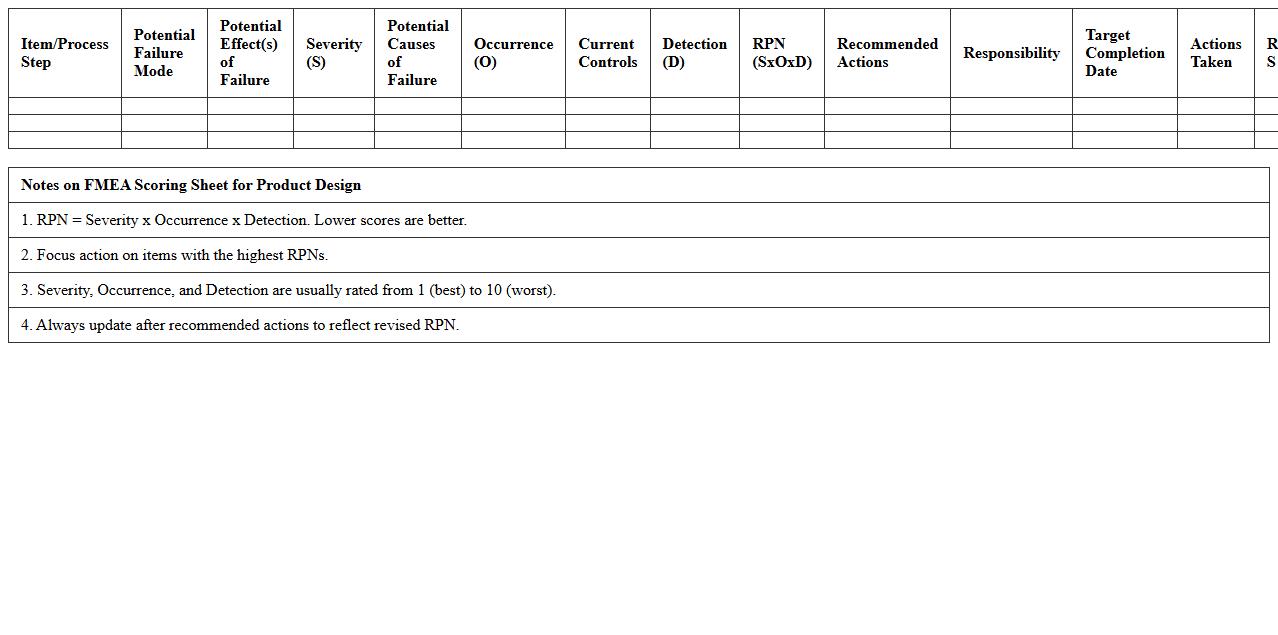

FMEA Scoring Sheet for Product Design Excel

The

FMEA Scoring Sheet for Product Design Excel document is a structured tool used to evaluate potential failure modes, their causes, and effects within a product design process. It helps prioritize risks by assigning scores based on severity, occurrence, and detection, enabling teams to focus on critical issues that require immediate attention. This systematic approach improves product reliability, reduces defects, and supports informed decision-making throughout the design lifecycle.

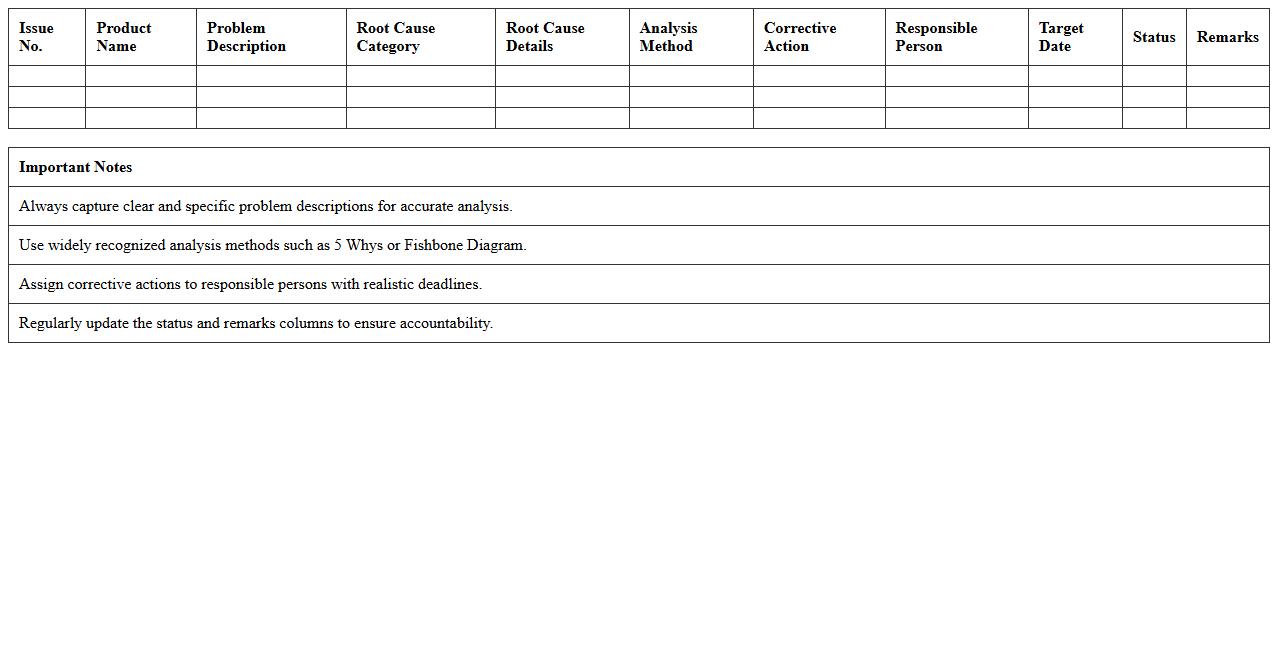

Product Design Root Cause Analysis Excel Template

The

Product Design Root Cause Analysis Excel Template document is a structured tool that helps identify, analyze, and document the fundamental reasons behind product design issues. It streamlines the process of tracing defects or failures back to their origin by organizing data efficiently within Excel sheets, enabling teams to develop targeted corrective actions. This template enhances problem-solving efficiency, improves product quality, and supports continuous improvement efforts in design processes.

How does the FMEA Excel template capture product-specific failure modes during design phase reviews?

The FMEA Excel template captures product-specific failure modes by allowing users to input detailed descriptions for each failure scenario. This ensures that unique design risks are identified early and documented thoroughly. Additionally, the template supports structured inputs that align failure modes directly with corresponding components or processes.

Which columns in the FMEA spreadsheet are essential for documenting detection controls unique to new product designs?

Columns such as Detection Method and Current Controls are crucial for documenting detection controls. These fields provide insights into how potential defects will be identified before the product release. Accurate recording in these columns helps prioritize actions based on the effectiveness of existing detection measures.

What formulas are best used in Excel to automatically calculate Risk Priority Number (RPN) for design-related failures?

The Risk Priority Number is best calculated using the formula =Severity*Occurrence*Detection to multiply key risk factors. This formula automates the RPN calculation and updates dynamically when any input changes. Embedding this formula in the RPN column maintains consistency and accuracy throughout the design FMEA.

How can design change impacts be tracked and updated within an FMEA worksheet for product iterations?

Design change impacts are tracked by maintaining a Change History section in the FMEA worksheet. This area logs modifications, dates, and responsible personnel to ensure traceability. Updating affected failure modes and controls ensures the FMEA reflects the latest product design iterations.

What are the most effective dropdown lists or data validation rules for standardizing effect severity inputs in product design FMEAs?

Effective dropdown lists standardize inputs by providing predefined severity rating options, such as numeric scales from 1 to 10. Using Excel's data validation ensures only valid values are entered, reducing errors and improving data consistency. This approach helps harmonize severity assessments across different design teams.