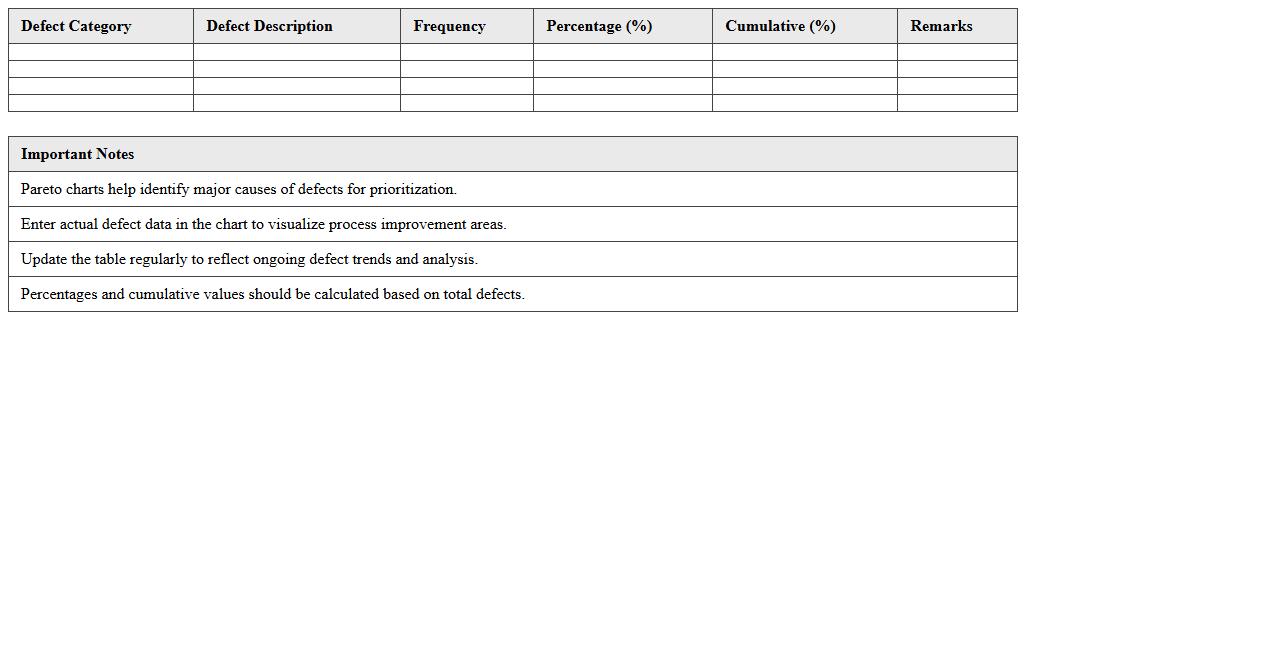

The Pareto Chart Excel Template for Production Defects helps identify and prioritize the most common defects affecting manufacturing processes. This tool visually highlights the frequency and impact of each defect type, enabling efficient quality control and problem-solving. Using the template streamlines data analysis, promoting targeted improvements and reducing overall production errors.

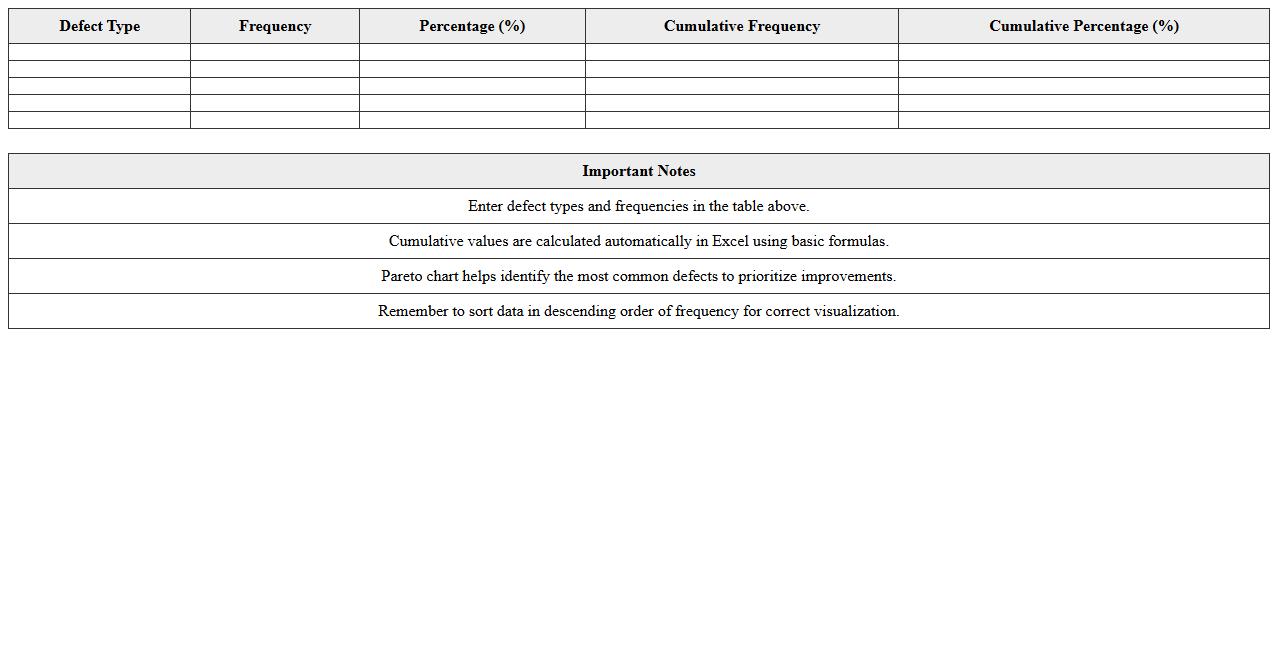

Pareto Chart Excel Template for Manufacturing Quality Defects

A

Pareto Chart Excel Template for Manufacturing Quality Defects is a structured tool that visually represents defect categories and their frequencies, helping to identify the most critical quality issues. By using this template, manufacturers can prioritize defect resolution efforts based on the 80/20 rule, focusing on the few defects that cause the majority of problems. This data-driven approach enhances quality control, reduces waste, and improves overall production efficiency.

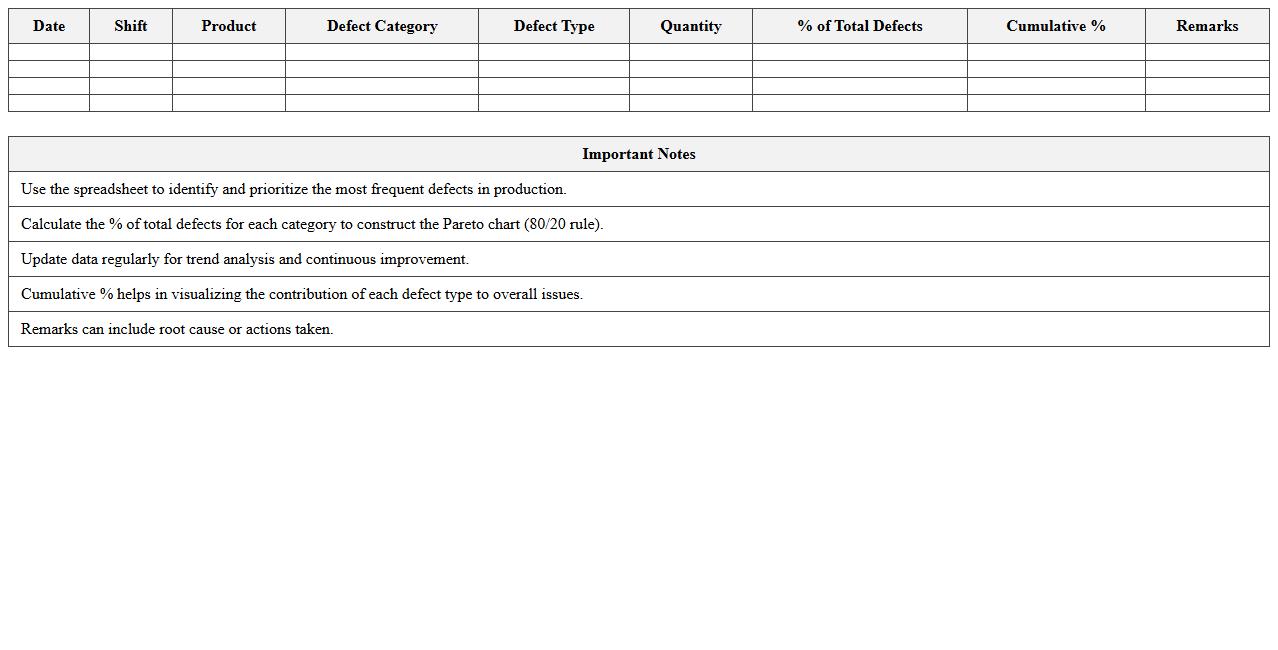

Production Line Defects Pareto Analysis Spreadsheet

The

Production Line Defects Pareto Analysis Spreadsheet is a powerful tool designed to identify and prioritize the most frequent defects occurring in a manufacturing process. By organizing defect data into a Pareto chart, it highlights critical issues causing the majority of quality problems, enabling targeted improvements. This analysis helps streamline defect resolution, reduce waste, and improve overall production efficiency.

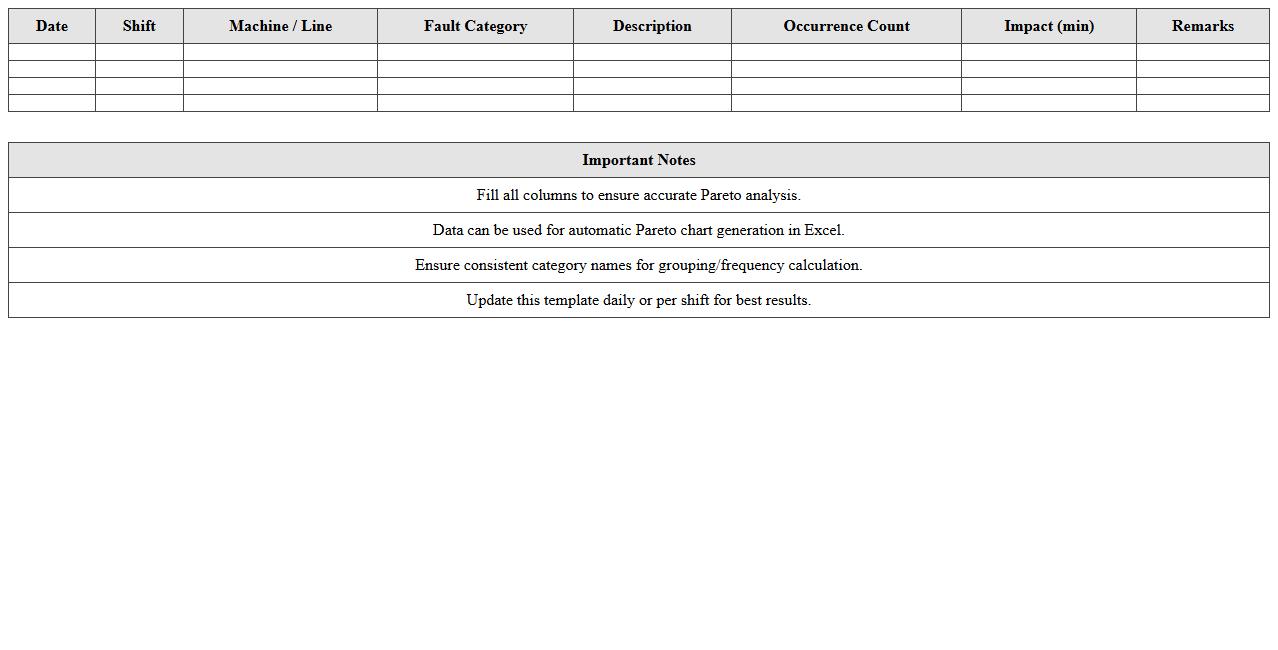

Factory Defect Tracking Pareto Chart Template

A

Factory Defect Tracking Pareto Chart Template document visually represents the frequency and impact of various defects in a manufacturing process, helping to identify the most critical issues affecting product quality. By categorizing defects and highlighting them in descending order, it enables teams to focus on the few key problems that contribute to the majority of defects, supporting efficient quality improvement efforts. This template streamlines data analysis, supports decision-making, and enhances defect reduction strategies to optimize production efficiency and reduce costs.

Excel Template for Production Faults Pareto Visualization

The

Excel Template for Production Faults Pareto Visualization is a pre-formatted spreadsheet designed to analyze and display production defects using Pareto charts. This template helps identify the most significant fault categories by highlighting the frequency and cumulative impact of defects, enabling focused quality improvement efforts. It streamlines data entry and visualization, promoting efficient decision-making in manufacturing process optimization.

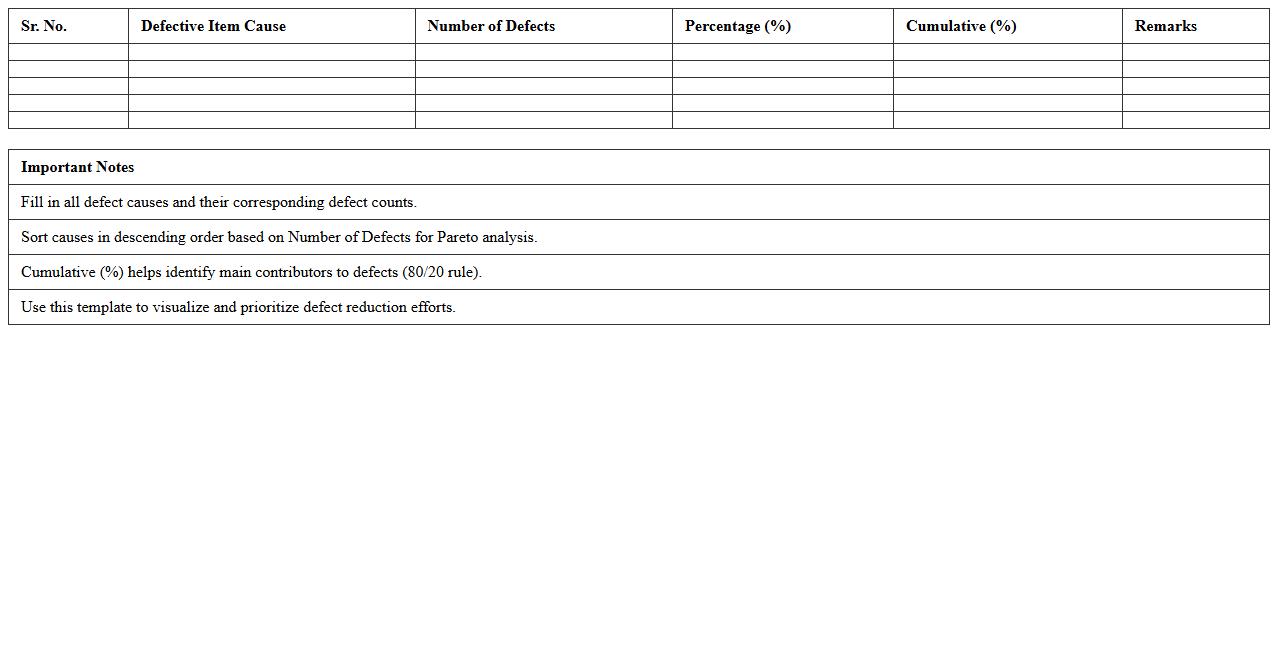

Defective Item Causes Pareto Chart Excel Sheet

The

Defective Item Causes Pareto Chart Excel Sheet document is a tool that visually represents the most frequent causes of defects in a process, helping identify key issues to target for improvement. By organizing defect causes in descending order of frequency, this chart enables users to focus efforts on the problems that have the greatest impact on quality. It is useful for quality control teams and managers seeking data-driven decisions to enhance productivity and reduce defects efficiently.

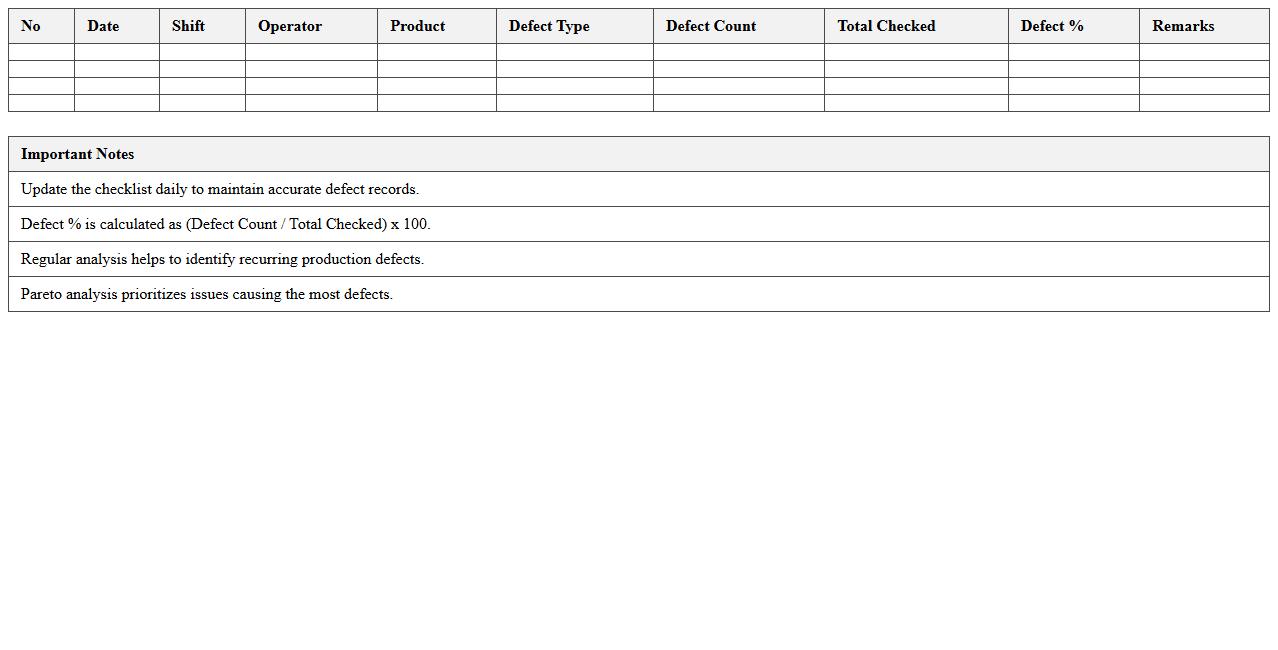

Excel Checklist for Production Defects Pareto Analysis

An

Excel Checklist for Production Defects Pareto Analysis document systematically organizes and categorizes defects to identify the most significant issues impacting production quality. By using this checklist, manufacturers can apply the Pareto principle to focus on the 20% of defects causing 80% of problems, enabling targeted corrective actions. This tool enhances quality control efficiency, reduces downtime, and supports data-driven decision-making in production management.

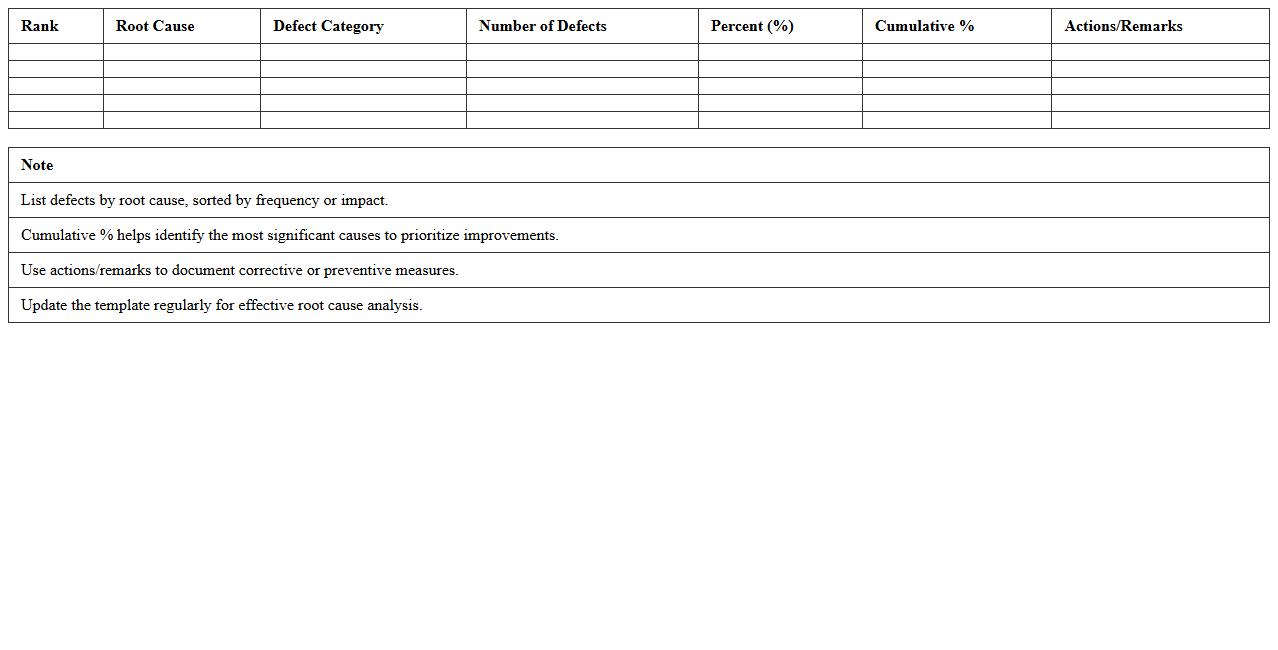

Root Cause Pareto Chart Template for Factory Defects

The

Root Cause Pareto Chart Template for Factory Defects document visually prioritizes the most significant causes of defects by displaying them in descending order of frequency or impact. This template helps manufacturing teams quickly identify critical problem areas, enabling targeted process improvements and efficient resource allocation. Using this document enhances defect reduction strategies, leading to higher product quality and operational efficiency.

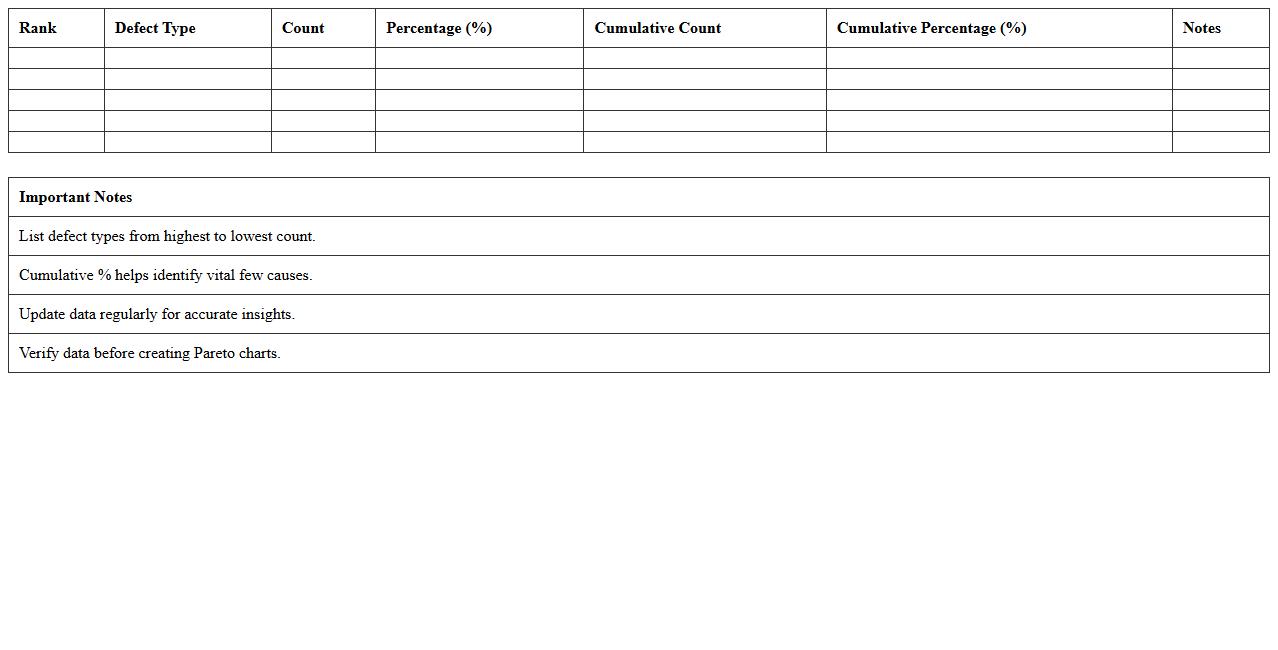

Assembly Line Defects Pareto Chart Excel File

The

Assembly Line Defects Pareto Chart Excel File document visually represents the frequency and impact of various defects in an assembly line, helping identify the most critical issues that need attention. By organizing defect data in descending order of frequency, it enables efficient prioritization of quality control efforts to improve production efficiency and reduce waste. This tool is essential for quality managers and engineers aiming to implement targeted process improvements and achieve higher product reliability.

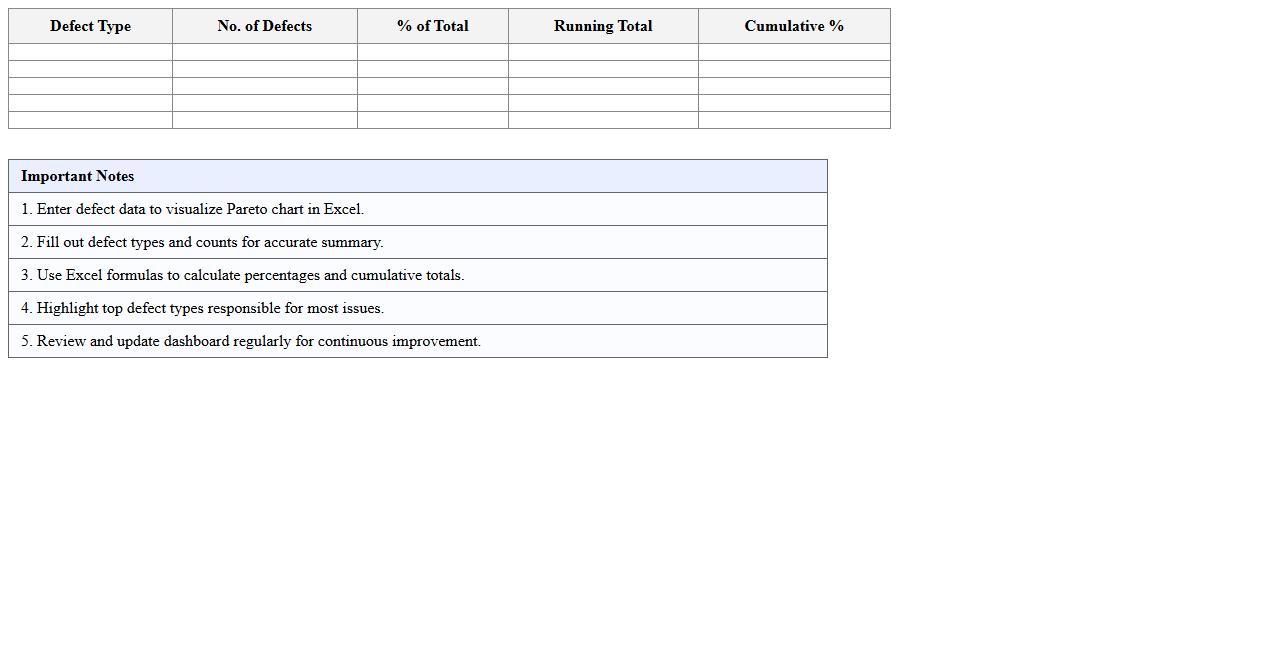

Excel Dashboard for Production Defect Types Pareto

The

Excel Dashboard for Production Defect Types Pareto document visually represents the frequency and impact of various production defects using Pareto analysis, helping to identify the most significant issues affecting quality. This tool consolidates complex data into clear charts and graphs, enabling quick decision-making and targeted process improvements. By focusing on the critical few defects causing the majority of problems, it drives efficient resource allocation and enhances overall production efficiency.

Process Defect Frequency Pareto Chart Excel Template

The

Process Defect Frequency Pareto Chart Excel Template is a valuable tool designed to help identify and prioritize the most common defects in a process by visually representing their frequency in descending order. This template enables businesses to quickly analyze defect data, focusing improvement efforts on the highest-impact issues to enhance quality and efficiency. Utilizing this chart facilitates data-driven decision-making, streamlining quality control and reducing process variations effectively.

How can I automate defect category grouping in a Pareto Chart using Excel formulas?

Automating defect category grouping in a Pareto Chart can be achieved by using Excel's SUMIF or SUMIFS functions. These formulas sum defect counts based on criteria, grouping similar defects efficiently within the dataset.

Then, use the SORT function to order defect groups by frequency, aiding in visualization. Finally, linking these aggregated values directly into your Pareto Chart updates your chart automatically as data changes.

What Excel functions best highlight cumulative defect impacts in Pareto analysis?

To highlight cumulative defect impacts, the SUM function combined with relative referencing is key. By applying the CUMSUM logic using dynamic ranges, you create a running total illustrating the cumulative percentage of defects.

The PERCENTAGE calculation in Excel also helps normalize data for clear cumulative impact display on a Pareto Chart. These formulas together enhance analytical insight for defect prioritization.

How do you dynamically filter production defect data for real-time Pareto Chart updates?

Dynamically filtering production defect data requires the use of Excel's FILTER function, which extracts data based on set conditions. This real-time filtering adjusts the input range for your Pareto Chart automatically.

Use drop-down slicers or data validation lists coupled with FILTER to allow easy user input. This setup ensures your defect grouping and chart remain current as production data evolves.

Which add-ins enhance Pareto Chart visualization for specific defect types in Excel?

Popular add-ins such as Power BI integration and Excel's Analysis ToolPak provide enhanced visualization options. They allow for better interactivity and customization of Pareto Charts emphasizing specific defect types.

Additionally, third-party tools like XLSTAT offer advanced statistical and visualization features tailored for defect analysis. These add-ins improve the clarity and analytical depth of your Pareto Chart presentations.

How can conditional formatting highlight critical defect bars in Excel Pareto Charts?

Conditional formatting can be applied using data bars or custom rules to emphasize critical defect categories in your Pareto Chart. By setting thresholds based on defect counts or cumulative percentage, Excel highlights the most impactful defects.

Use formula-based formatting with functions such as IF to dynamically change bar colors. This visual cue aids immediate recognition of priority areas in defect reduction efforts.

More Chart Excel Templates