The Downtime Chart Excel Template for Maintenance Logs is designed to track and visualize equipment downtime efficiently. It helps maintenance teams identify patterns, schedule preventive actions, and improve overall operational productivity. With customizable features, this template simplifies data entry and generates clear reports for better decision-making.

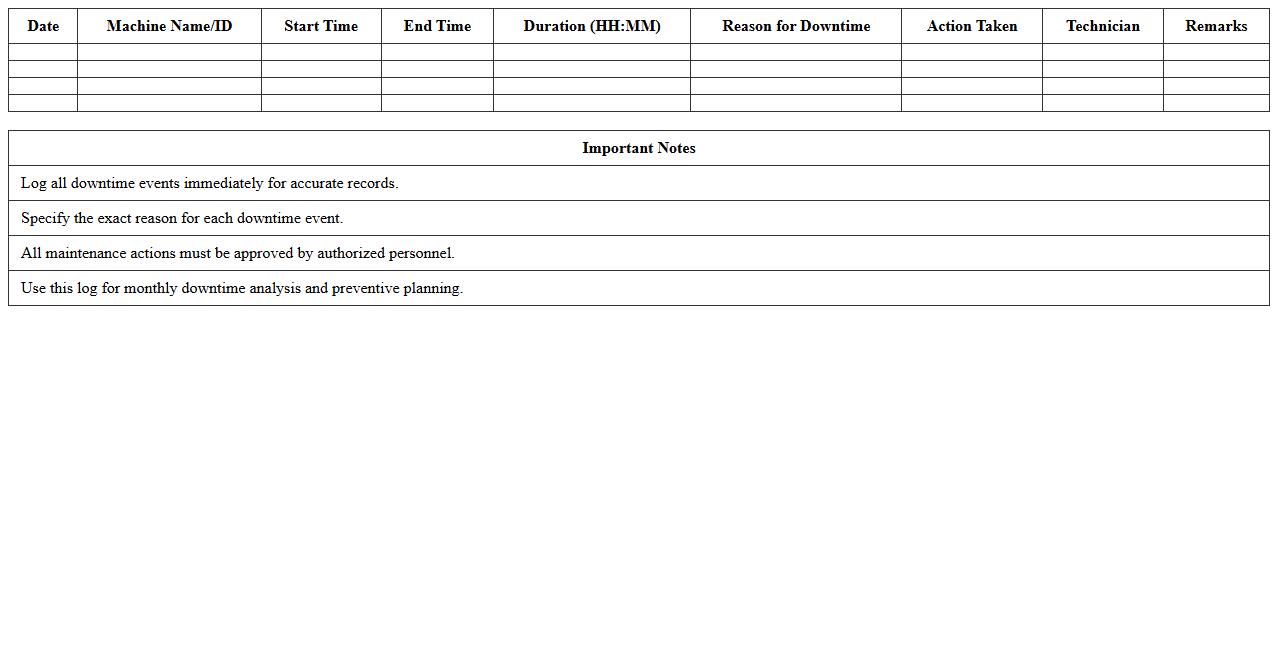

Equipment Downtime Tracking Excel Template

The

Equipment Downtime Tracking Excel Template is a structured spreadsheet designed to monitor and record the periods when machinery or equipment is not operational. It helps businesses identify patterns in equipment failures, schedule preventive maintenance, and improve overall operational efficiency by minimizing unplanned downtime. This tool is essential for enhancing asset management and reducing costs associated with equipment inactivity.

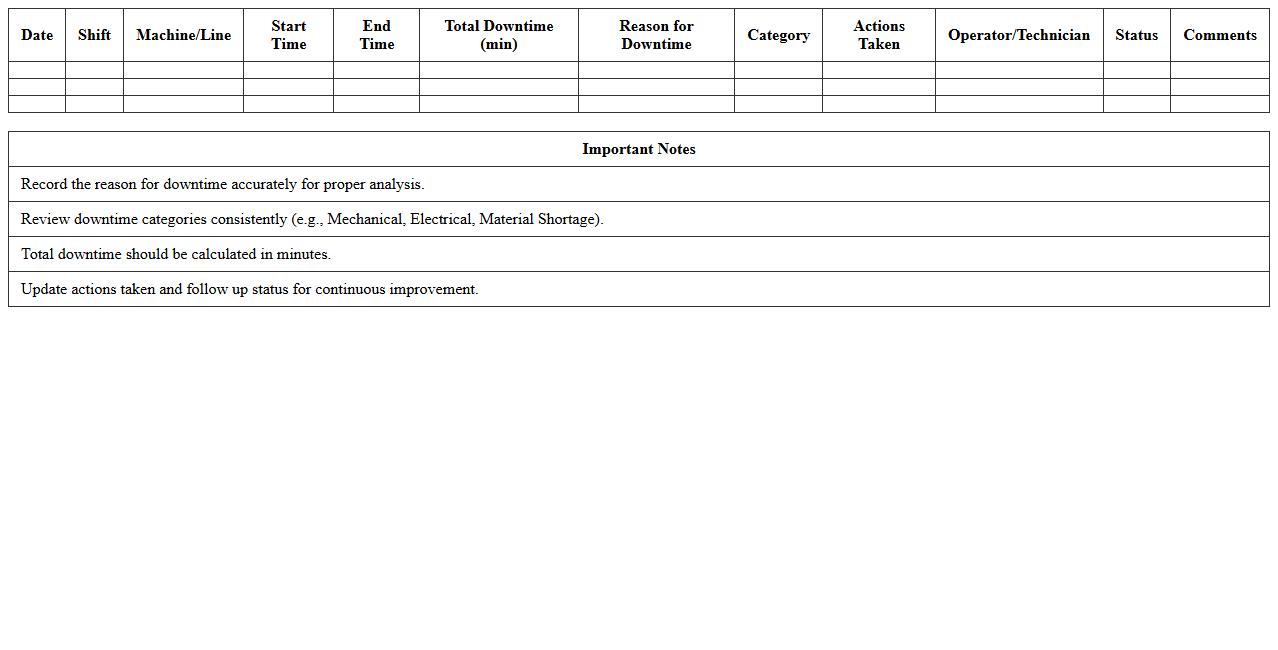

Machine Maintenance Log Downtime Report

A

Machine Maintenance Log Downtime Report is a detailed record documenting periods when machinery is non-operational due to maintenance or unexpected failures. This report helps identify patterns in equipment performance, enabling timely interventions to reduce downtime and improve operational efficiency. Analyzing these logs enhances predictive maintenance strategies and supports informed decision-making to optimize production workflows.

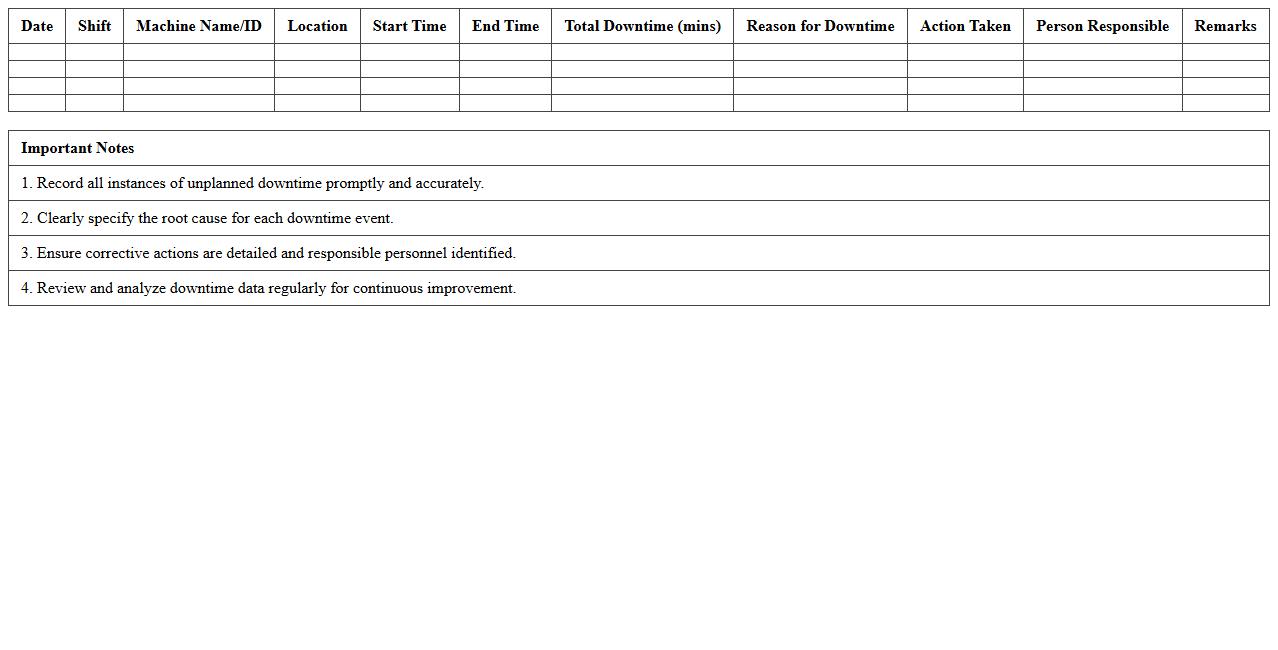

Production Downtime Analysis Spreadsheet

A

Production Downtime Analysis Spreadsheet is a detailed document that tracks and analyzes periods when manufacturing operations halt, capturing data such as duration, cause, and frequency of downtime events. This tool is essential for identifying patterns and root causes of interruptions, enabling businesses to implement targeted improvements and enhance overall equipment effectiveness (OEE). By systematically monitoring downtime, companies can reduce losses, optimize maintenance schedules, and improve production efficiency.

Factory Maintenance Downtime Record Sheet

A

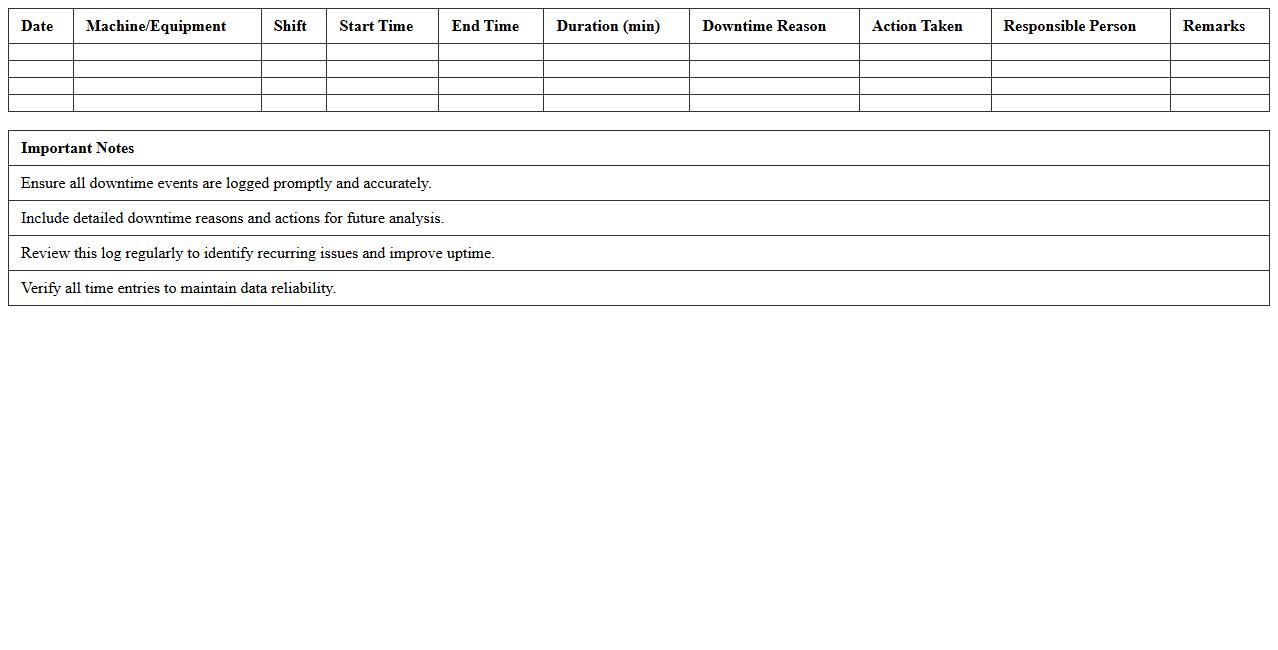

Factory Maintenance Downtime Record Sheet is a detailed document used to log periods when machinery or production lines are non-operational due to maintenance activities. It captures essential data such as start and end times of downtime, reasons for stoppage, and maintenance actions taken, enabling accurate tracking of equipment availability and efficiency. This record sheet is useful for identifying recurring issues, planning preventive maintenance, minimizing production losses, and optimizing overall factory productivity.

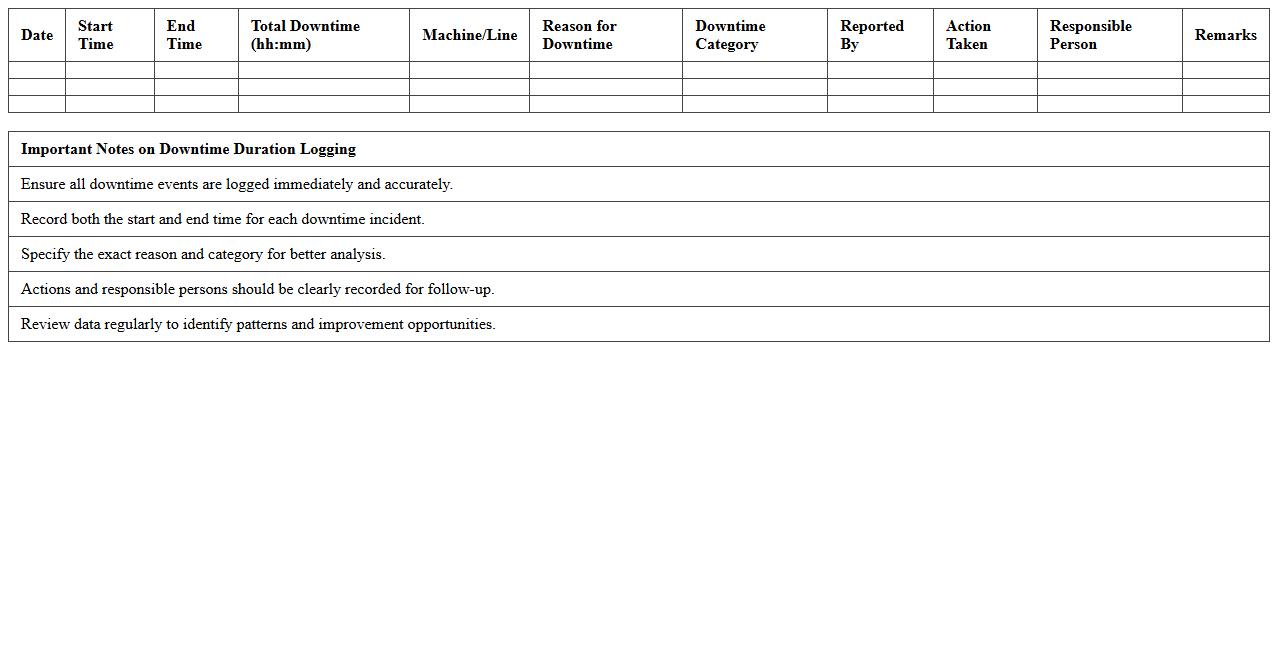

Downtime Duration Logging Excel Sheet

The

Downtime Duration Logging Excel Sheet document is a tool designed to record and track periods of operational inactivity in machinery or processes. By systematically logging downtime durations, it helps identify patterns and causes of equipment failure, enabling data-driven maintenance scheduling and productivity optimization. This sheet enhances operational efficiency by providing clear insights into downtime trends, facilitating timely interventions and reducing overall losses.

Preventive Maintenance Downtime Tracker

The

Preventive Maintenance Downtime Tracker document systematically records equipment downtime during scheduled maintenance to identify patterns and inefficiencies. It helps organizations optimize maintenance schedules, reduce unexpected breakdowns, and improve overall operational productivity. By analyzing downtime data, businesses can make informed decisions that enhance asset reliability and extend equipment lifespan.

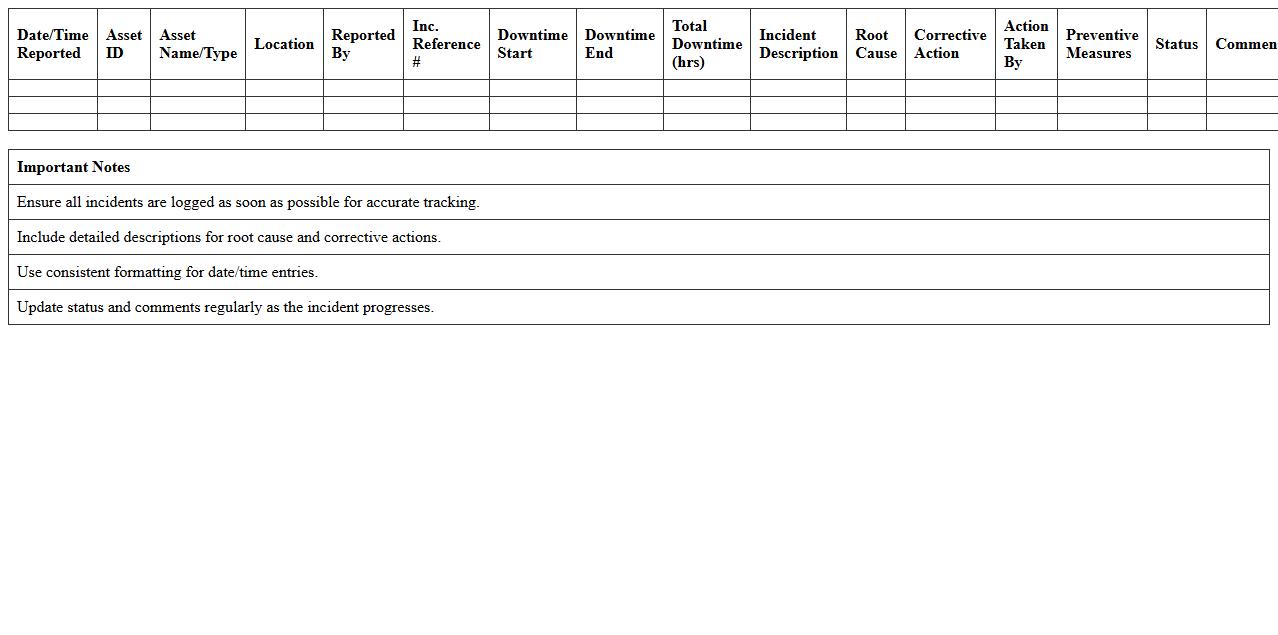

Asset Downtime Incident Log Template

The

Asset Downtime Incident Log Template document is a structured record-keeping tool designed to track and document instances of asset or equipment downtime within an organization. It helps in capturing critical details such as the duration of downtime, causes, affected assets, and resolution steps, enabling effective analysis and reporting. This template is useful for identifying patterns, minimizing future disruptions, improving maintenance schedules, and enhancing overall operational efficiency.

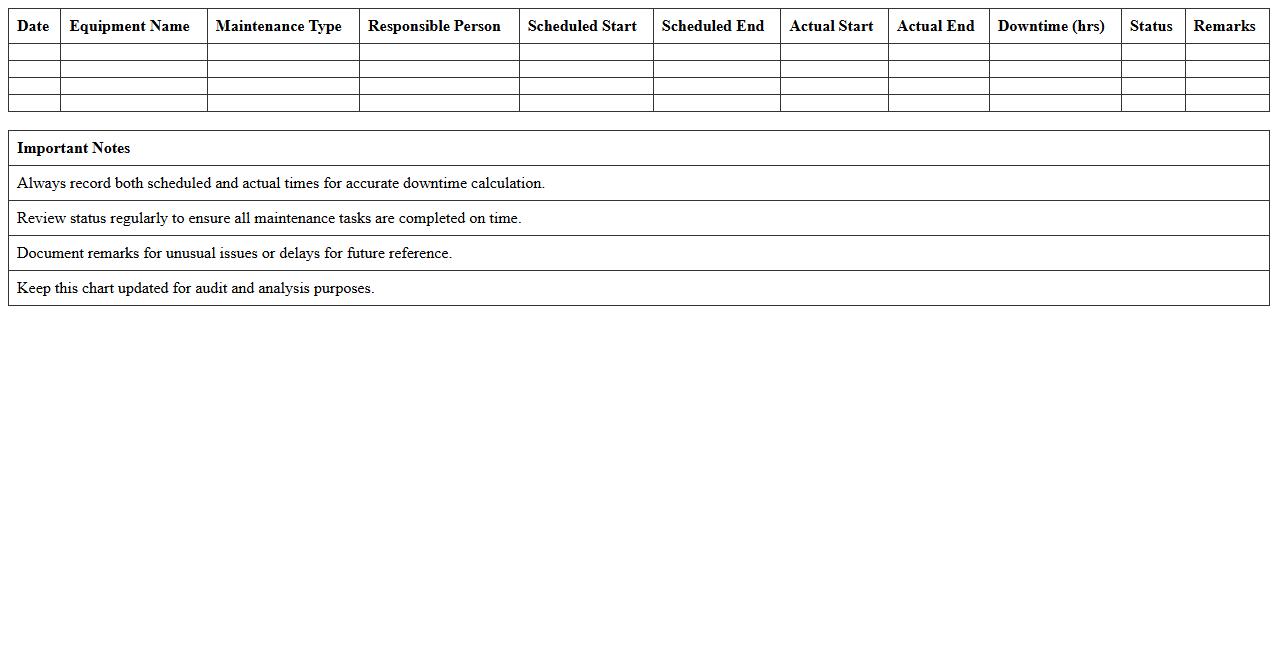

Maintenance Schedule & Downtime Chart

A

Maintenance Schedule & Downtime Chart document outlines planned maintenance activities alongside expected equipment downtime, helping organizations organize and monitor routine servicing tasks efficiently. This document is crucial for minimizing unplanned interruptions by predicting maintenance windows and coordinating team efforts to optimize operational uptime. Access to clear scheduling and downtime data supports informed decision-making, enhances resource allocation, and improves overall asset reliability.

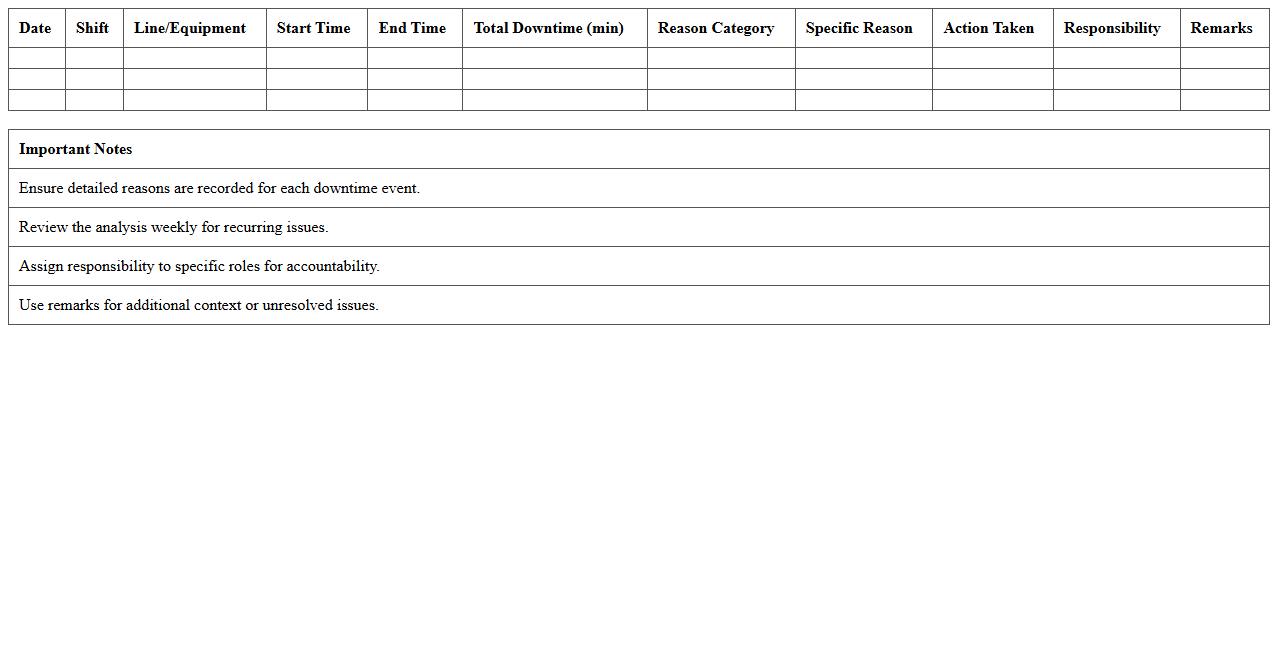

Plant Downtime Reason Analysis Template

The

Plant Downtime Reason Analysis Template document systematically records and categorizes causes of production stoppages, enabling clear identification of recurring issues in manufacturing processes. By analyzing this data, plant managers can prioritize maintenance, streamline operations, and reduce unplanned downtime, leading to improved productivity and cost savings. This template serves as a critical tool for root cause analysis and continuous improvement efforts in industrial environments.

Daily Downtime Log Excel Sheet

A

Daily Downtime Log Excel Sheet document systematically records periods when equipment or processes are non-operational, capturing data such as start and end times, reasons for downtime, and responsible personnel. This log facilitates analysis of recurring issues and downtime patterns, enabling businesses to implement targeted maintenance and operational improvements. Using this document enhances productivity by minimizing unexpected delays and optimizing resource allocation.

How can I automate downtime tracking in an Excel maintenance log chart?

To automate downtime tracking, start by organizing your log with clear start and end time columns. Use Excel formulas like =IF to calculate downtime intervals automatically. Incorporate drop-down lists for downtime reasons to standardize data entry and improve accuracy.

What formulas calculate total downtime duration per machine in my document letter?

Use the SUMIFS formula to sum downtime intervals specific to each machine. Calculate individual downtime by subtracting start time from end time with =EndTime - StartTime. Combine these with the machine filter using =SUMIFS(DurationRange, MachineRange, "MachineName") for precise totals.

Which Excel chart type best visualizes monthly maintenance downtimes from logs?

The stacked column chart is ideal for displaying monthly downtime by various causes. It allows comparison of total downtime while breaking down contributions from each reason. Alternatively, line charts can show downtime trends over time effectively.

How do I link downtime reasons in Excel logs for trend analysis?

Use a pivot table to summarize downtime by reason, making it easy to identify patterns. Link downtime reasons with log entries via consistent data validation lists. This connection enables dynamic trend analysis across multiple machines and periods.

Can conditional formatting flag excessive downtime automatically in my chart?

Yes, apply conditional formatting rules to the downtime duration cells to highlight values exceeding predefined thresholds. Use color scales or icon sets to visually flag excessive downtime instantly. This approach helps maintain focus on critical maintenance issues.

More Chart Excel Templates