The Audit Observation Log Excel Template for Manufacturing provides a structured format to systematically record and track audit findings within manufacturing processes. It enhances transparency and accountability by organizing observations, corrective actions, and responsible personnel in one accessible file. This template streamlines the audit process, ensuring compliance with industry standards and improving overall operational efficiency.

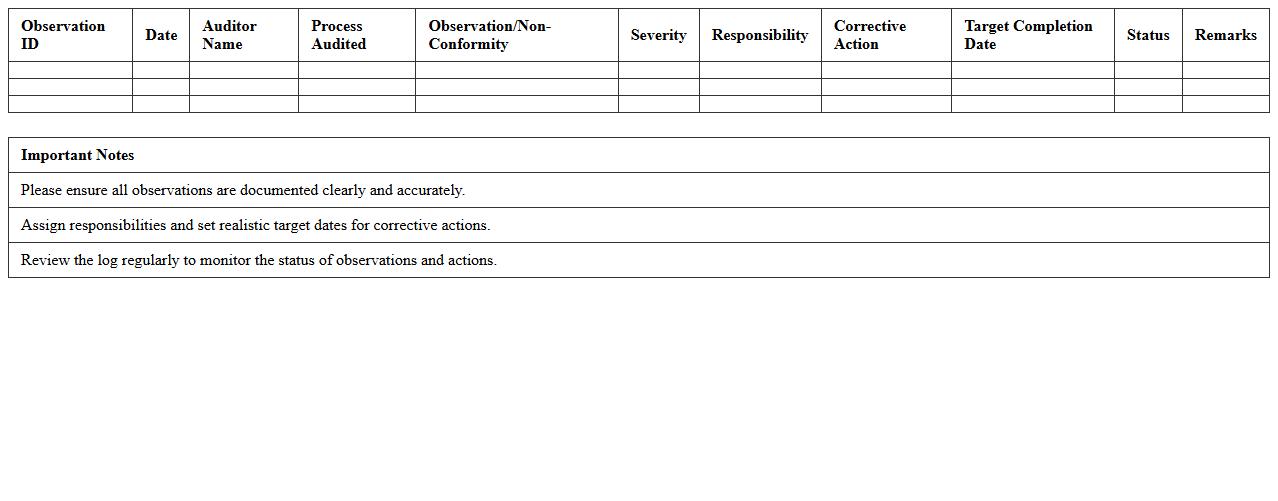

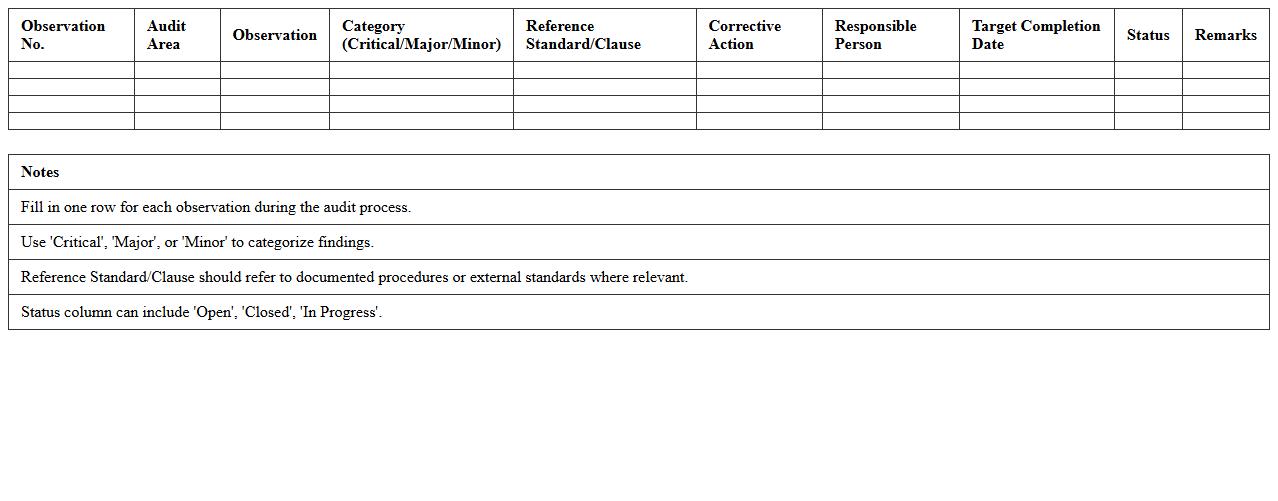

Internal Audit Observation Tracker for Manufacturing

The

Internal Audit Observation Tracker for manufacturing is a systematic tool designed to record, monitor, and manage audit findings within the production process. It helps identify compliance gaps, operational inefficiencies, and safety concerns by documenting audit observations and tracking corrective actions. Using this tracker enhances accountability, ensures timely resolution of issues, and supports continuous improvement in manufacturing quality and regulatory compliance.

Manufacturing Process Audit Observation Log

A

Manufacturing Process Audit Observation Log document systematically records findings and deviations identified during manufacturing process audits, enabling traceability and accountability. It helps organizations monitor compliance with quality standards, identify areas for process improvement, and ensure adherence to regulatory requirements. This log serves as a vital tool for continuous improvement, risk management, and maintaining manufacturing excellence.

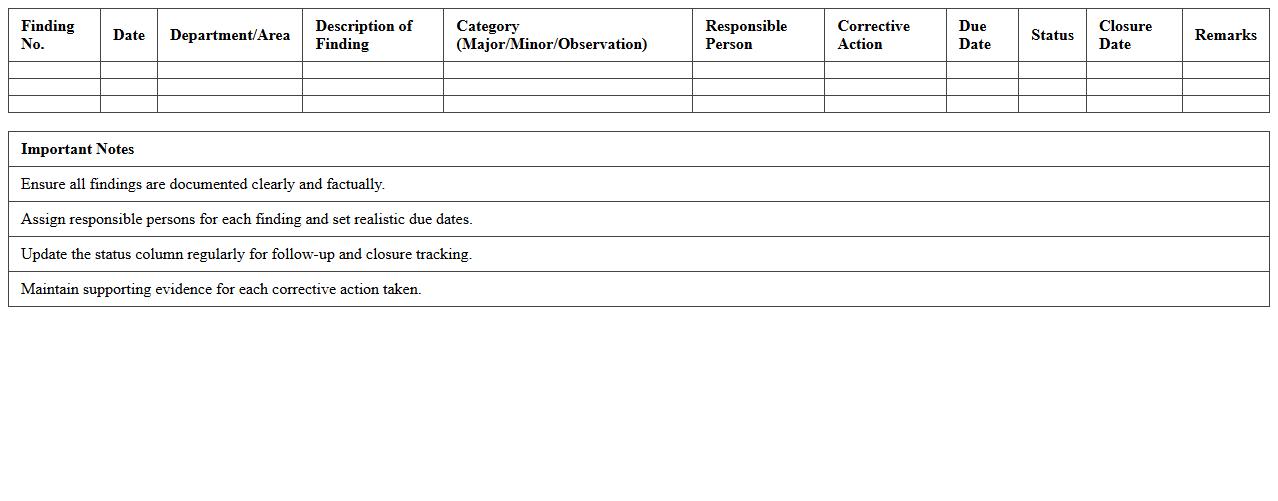

Quality Audit Findings Excel Register

The

Quality Audit Findings Excel Register document is a structured tool designed to systematically record, track, and analyze audit findings related to quality management processes. It helps organizations identify non-conformities, monitor corrective actions, and ensure compliance with industry standards such as ISO 9001. By maintaining this register, businesses can enhance process improvement, streamline quality control, and drive continuous operational excellence.

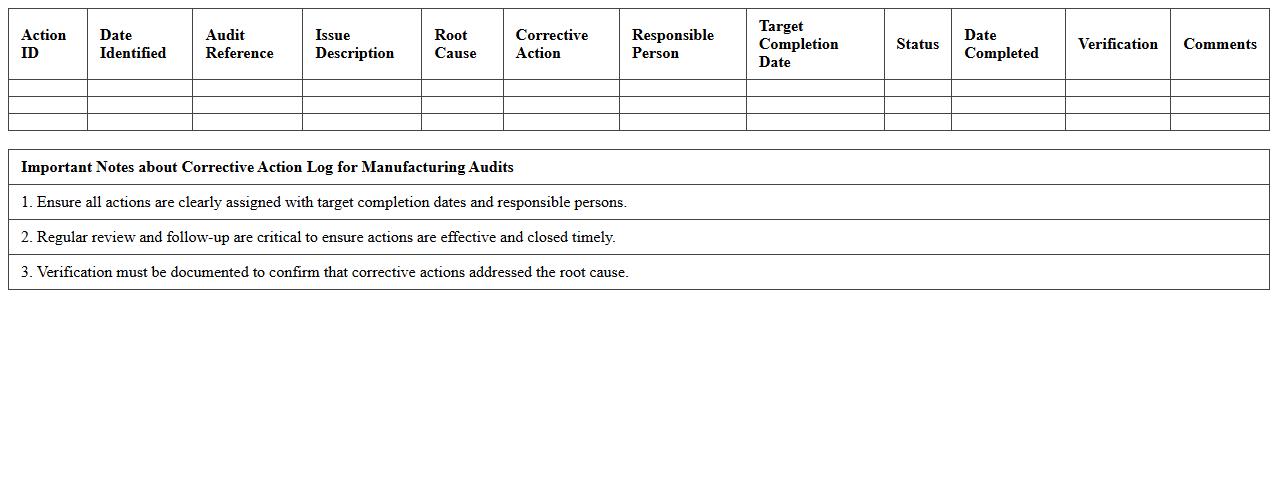

Corrective Action Log for Manufacturing Audits

The

Corrective Action Log for Manufacturing Audits is a critical document that records identified non-conformities, assigned responsibilities, and deadlines for remediation in the production process. This log ensures systematic tracking and verification of corrective measures, promoting continuous improvement and regulatory compliance. By maintaining this record, manufacturers can reduce defects, enhance product quality, and prevent recurrence of issues during future audits.

Production Audit Issue Tracking Template

The

Production Audit Issue Tracking Template document is a structured tool designed to record, monitor, and manage issues identified during production audits. It facilitates organized documentation of non-conformities, corrective actions, and responsible personnel, enhancing transparency and accountability. Using this template improves issue resolution efficiency, supports compliance with quality standards, and drives continuous improvement in production processes.

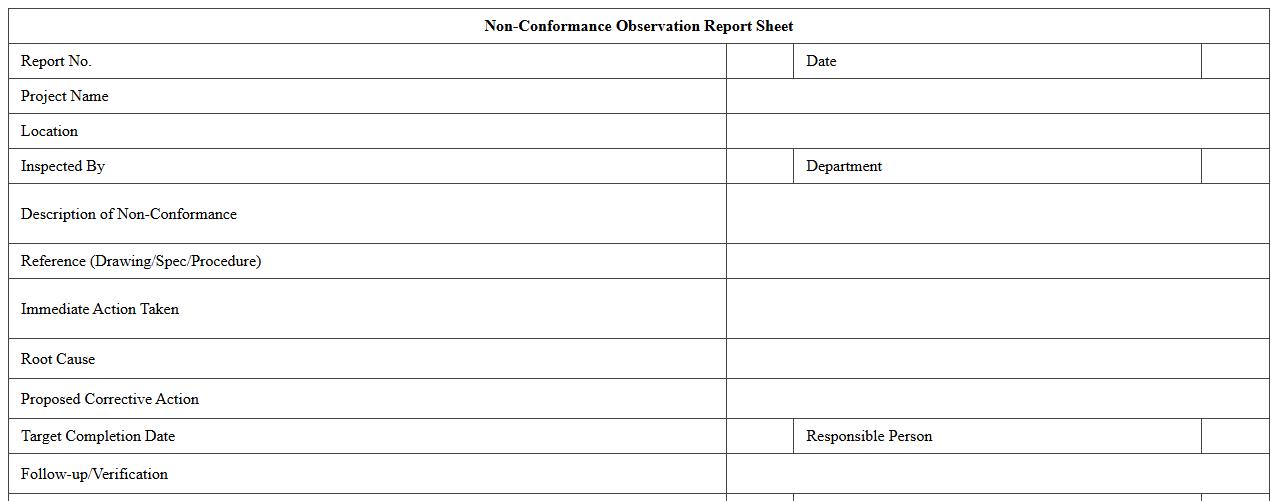

Non-Conformance Observation Report Sheet

A

Non-Conformance Observation Report Sheet is a document used to record deviations from standard processes or specifications in quality management systems. It provides detailed information on the nature of the non-conformance, its causes, and the corrective actions taken to prevent recurrence. This report enhances process control, ensures compliance with industry standards, and supports continuous improvement by systematically tracking and addressing non-compliant issues.

Manufacturing Site Audit Observation Matrix

The

Manufacturing Site Audit Observation Matrix document systematically compiles and categorizes audit findings from manufacturing sites, enabling precise tracking of compliance and quality issues. It facilitates identifying patterns and prioritizing corrective actions by providing a clear overview of non-conformities and areas for improvement. This matrix enhances audit efficiency, supports regulatory adherence, and drives continuous operational excellence in manufacturing processes.

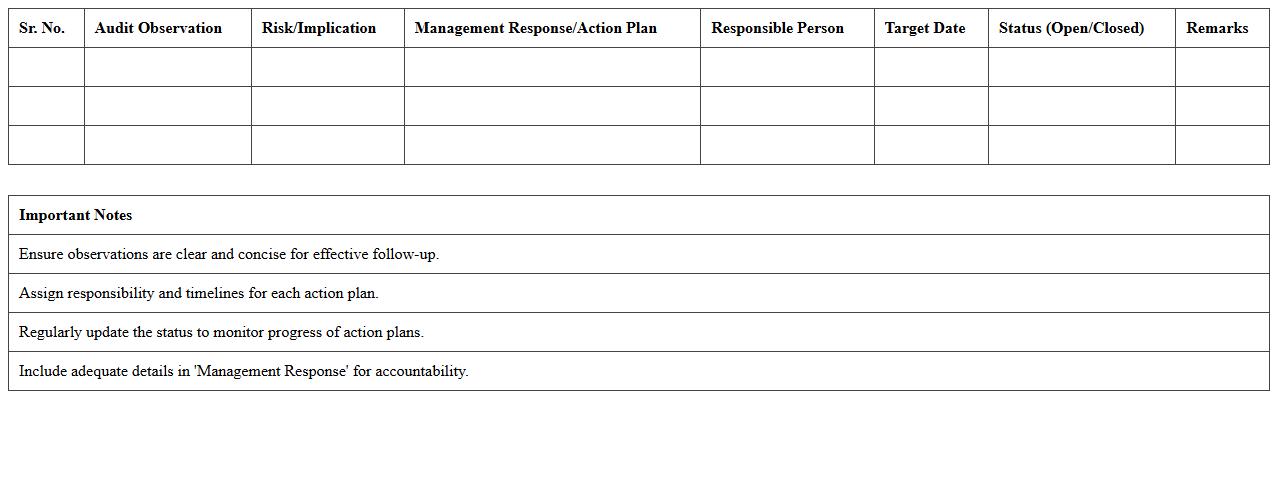

Audit Observation and Action Plan Template

An

Audit Observation and Action Plan Template document systematically records findings from an audit and outlines specific corrective actions to address identified issues. It facilitates clear communication between auditors and management, ensuring accountability and tracking progress on implementing recommendations. By using this template, organizations enhance their compliance efforts, improve operational efficiency, and reduce risks through structured follow-up and continuous improvement.

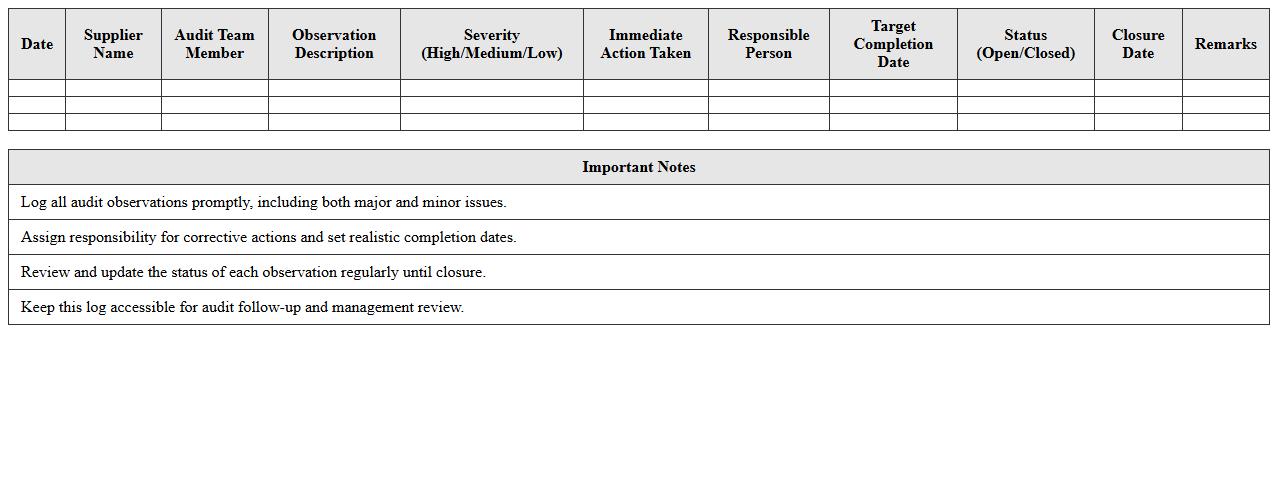

Supplier Audit Observation Log for Manufacturing

The

Supplier Audit Observation Log for manufacturing is a detailed record used to document findings during supplier evaluations, highlighting areas of non-compliance, strengths, and opportunities for improvement. This log helps organizations maintain quality standards, track corrective actions, and ensure supplier adherence to contractual and regulatory requirements. It serves as a critical tool for continuous improvement, risk management, and enhancing supplier performance over time.

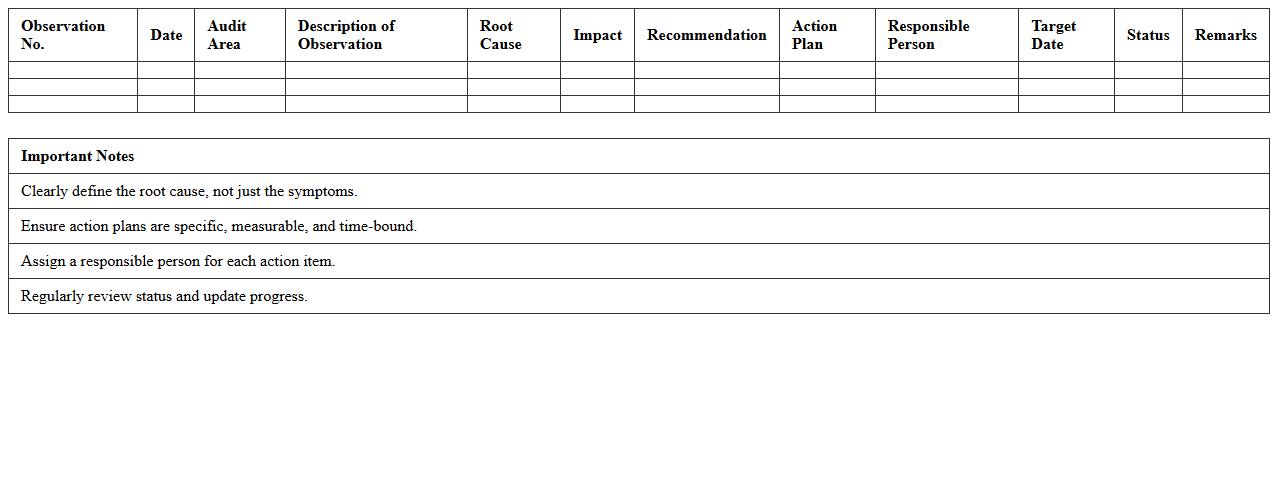

Root Cause Analysis Audit Observations Excel

A

Root Cause Analysis Audit Observations Excel document systematically records and analyzes audit findings to identify underlying issues driving non-compliance or inefficiencies. This structured approach helps teams prioritize corrective actions by linking observed problems directly to their root causes, enabling targeted improvements and preventing recurrence. Utilizing this document enhances decision-making, supports continuous improvement initiatives, and promotes accountability within an organization.

How to customize audit observation categories in an Excel log for manufacturing compliance?

To customize audit observation categories in an Excel log, start by creating a dedicated sheet for all category types relevant to manufacturing compliance. Use data validation dropdown lists linked to this category list, ensuring consistent usage across entries. Regularly update the list as compliance requirements evolve to maintain accuracy in audit records.

What formulas automate risk scoring in a manufacturing audit log spreadsheet?

Formulas such as =IF(), =VLOOKUP(), and arithmetic operations can automate risk scoring effectively. Combine severity, likelihood, and detection scores into a single risk score using a formula like =Severity*Likelihood*Detection. This automated scoring enhances consistency and provides quick insight into audit findings.

Which Excel features best track corrective action deadlines in audit observation logs?

Utilize conditional formatting to highlight approaching or overdue corrective action deadlines visually. Leverage Excel's built-in date functions, such as TODAY() and NETWORKDAYS(), to calculate remaining time accurately. Additionally, incorporating reminder alerts via formulas or VBA helps ensure timely completion of corrective actions.

How to link manufacturing process owners to observations using dropdown lists in Excel?

Create a master list of process owners on a separate sheet and name the range for easy reference. Use data validation dropdowns in the observation log to link each finding to a specific owner, enabling clear accountability. This method streamlines assignment tracking and fosters responsibility for corrective measures.

What Excel templates support trend analysis of recurring audit findings in manufacturing?

Templates featuring pivot tables and charts are ideal for analyzing trends in audit findings over time. Employ time-series data organized by observation categories and dates to visualize patterns and recurring issues effectively. Many pre-built audit log templates with analytical dashboards simplify ongoing monitoring and reporting.

More Audit Excel Templates