The Equipment Maintenance Tracking Excel Template for Manufacturing Units streamlines the monitoring of machinery performance and upkeep schedules. It enables manufacturing teams to log maintenance activities, track equipment status, and predict service needs efficiently. This template enhances operational efficiency by minimizing downtime and extending equipment lifespan.

Preventive Maintenance Schedule Excel Template for Manufacturing Equipment

A

Preventive Maintenance Schedule Excel Template for manufacturing equipment is a structured document designed to plan and track routine maintenance tasks to prevent unexpected breakdowns. It helps ensure equipment longevity, improve operational efficiency, and reduce downtime by scheduling timely inspections, lubrication, adjustments, and part replacements. Utilizing this template enables manufacturers to optimize maintenance workflows, enhance production reliability, and lower repair costs through proactive equipment care.

Equipment Downtime Log Spreadsheet for Manufacturing Plants

An

Equipment Downtime Log Spreadsheet for manufacturing plants is a structured document designed to record and analyze periods when machinery is not operational. It tracks key data such as downtime duration, causes, affected equipment, and maintenance actions, enabling plant managers to identify recurring issues and minimize production interruptions. Utilizing this log improves operational efficiency, supports preventive maintenance planning, and enhances overall equipment effectiveness (OEE).

Asset Maintenance History Tracker Excel Sheet

The

Asset Maintenance History Tracker Excel Sheet is a detailed document designed to record and monitor the maintenance activities of assets over time. It helps organizations track repair dates, maintenance schedules, costs, and asset performance, ensuring timely upkeep and reducing unexpected breakdowns. This tool improves operational efficiency by providing a clear history that supports informed decision-making about asset management and lifecycle optimization.

Spare Parts Inventory and Usage Excel Template

The

Spare Parts Inventory and Usage Excel Template document is a structured spreadsheet designed to track and manage the stock levels, usage rates, and reorder points of spare parts in manufacturing or maintenance operations. It helps businesses maintain optimal inventory levels, reduce downtime caused by part shortages, and improve procurement planning by providing clear insights into consumption patterns and stock availability. Using this template streamlines inventory audits and supports efficient asset management through accurate, real-time data recording and analysis.

Machine Service Record Log Template for Factories

A

Machine Service Record Log Template for factories is a structured document designed to systematically capture maintenance activities, repair history, and operational status of factory machinery. It helps in tracking machine performance, scheduling preventive maintenance, and reducing downtime by ensuring timely interventions. Using this template leads to enhanced equipment reliability, optimized maintenance costs, and improved overall factory productivity.

Manufacturing Equipment Calibration Schedule Excel Sheet

A

Manufacturing Equipment Calibration Schedule Excel Sheet is a structured document designed to track and manage the calibration timelines of various manufacturing tools and machinery. It helps ensure equipment accuracy, compliance with industry standards, and minimizes downtime by scheduling timely calibrations. Using this Excel sheet enables manufacturers to maintain quality control, improve operational efficiency, and reduce the risk of errors caused by uncalibrated equipment.

Equipment Repair Request Form Excel Template

The

Equipment Repair Request Form Excel Template is a standardized document designed to efficiently capture and track repair requests for equipment within an organization. This template streamlines the process by allowing users to input essential details such as equipment identification, description of the issue, request date, and status updates, facilitating transparent communication between employees and maintenance teams. By using this Excel template, businesses can enhance equipment maintenance management, reduce downtime, and maintain accurate repair records for better operational planning.

Maintenance Cost Analysis Excel Worksheet for Manufacturing

A

Maintenance Cost Analysis Excel Worksheet for manufacturing is a detailed spreadsheet designed to track, analyze, and optimize expenses related to equipment upkeep and repairs. It helps identify cost trends, pinpoint high-expense areas, and forecast future maintenance budgets, enabling effective resource allocation and cost control. This tool supports data-driven decision-making to enhance operational efficiency and minimize downtime in manufacturing processes.

Monthly Maintenance Planner Excel Template for Equipment

The

Monthly Maintenance Planner Excel Template for Equipment is a structured tool designed to schedule, track, and organize routine maintenance tasks for various machinery and equipment. It helps businesses optimize asset uptime by providing clear timelines, maintenance history, and resource allocation in an easily accessible format. This template improves operational efficiency, reduces unexpected breakdowns, and supports proactive maintenance strategies.

Equipment Inspection Checklist Excel Sheet for Manufacturing

An

Equipment Inspection Checklist Excel Sheet for manufacturing is a systematic document designed to track and verify the condition and functionality of machinery and tools used in production processes. It enhances maintenance efficiency by providing a structured format for recording inspection dates, identifying defects, and scheduling repairs, thereby minimizing downtime. This tool supports compliance with safety standards and improves overall operational reliability by ensuring all equipment remains in optimal working condition.

How can I automate preventive maintenance schedules using Excel formulas in the tracking sheet?

Automate your preventive maintenance schedules by using the Excel DATE and IF functions to calculate next service dates based on the last maintenance. Utilize conditional formatting to highlight upcoming or overdue maintenance tasks automatically. Incorporate dynamic drop-down lists to select equipment and update schedules efficiently.

What are the best Excel templates for logging equipment calibration history in a manufacturing unit?

The best templates for equipment calibration history include fields for date, equipment ID, calibration results, and technician comments. Choose templates that offer built-in data validation and dropdown menus for consistent data entry. Templates with pivot tables or charts help analyze calibration trends over time in manufacturing units.

Which Excel functions help track downtime reasons and link them to specific equipment efficiently?

Excel functions like VLOOKUP or XLOOKUP are essential to link downtime reasons to specific equipment efficiently. SUMIFS and COUNTIFS help summarize downtime duration by reason or machine. Use data validation lists to standardize downtime categories and ensure accurate tracking.

How do I visualize maintenance cost trends by machine type in Excel dashboards?

Use Pivot Tables combined with Pivot Charts to visualize maintenance cost trends by machine type dynamically. Incorporate slicers for filtering by time periods or equipment categories. Conditional formatting highlights cost spikes, making trends easy to identify on dashboards.

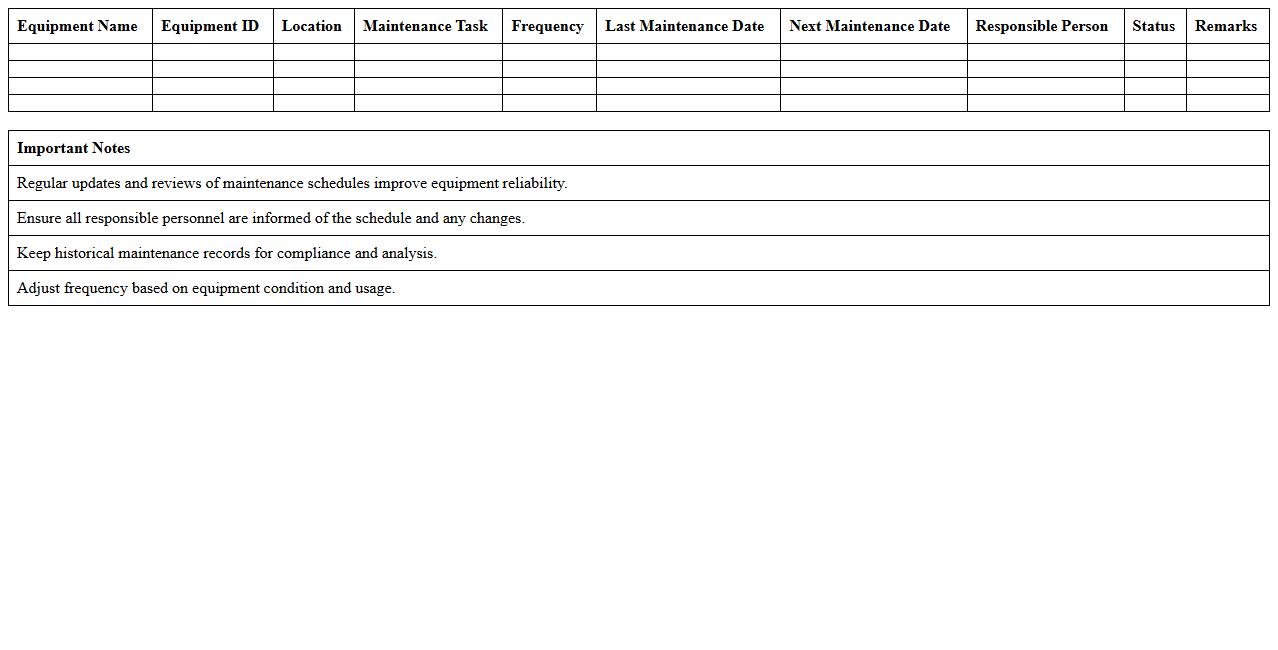

What columns should be included in an Excel log for regulatory compliance in equipment maintenance?

Include columns for equipment ID, maintenance date, technician name, task description, and compliance status to ensure regulatory compliance. Add fields for inspection results, follow-up actions, and documentation references for audit readiness. Properly structured logs enhance traceability and improve maintenance accountability.

More Tracking Excel Templates

![]()