The Manufacturing Output Dashboard Excel Template for Small Factories provides a comprehensive and user-friendly tool to track production efficiency, monitor output levels, and analyze key performance indicators in real-time. Designed specifically for small factories, this template enhances decision-making by visualizing data through customizable charts and graphs. It streamlines workflow management and helps identify bottlenecks to optimize manufacturing processes.

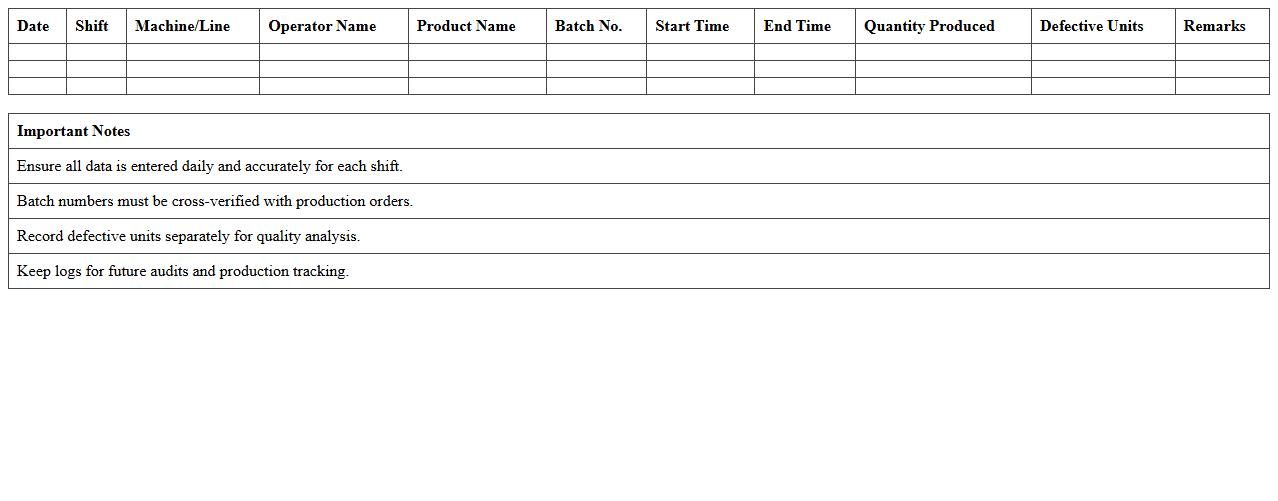

Daily Production Output Log Excel Template

The

Daily Production Output Log Excel Template is a structured spreadsheet designed to record and track daily manufacturing or production data efficiently. It helps businesses monitor output quantities, identify trends, and manage workforce productivity by organizing data in a clear, accessible format. Using this template enhances operational insights, supports decision-making, and promotes timely reporting for improved production management.

Shift-wise Manufacturing Performance Tracker

The

Shift-wise Manufacturing Performance Tracker document systematically records production metrics for each manufacturing shift, enabling precise monitoring of output, efficiency, and downtime. It facilitates real-time analysis of shift-specific performance variations, helping identify bottlenecks and areas for process improvement. This allows managers to optimize resource allocation, enhance productivity, and maintain consistent quality standards across different shifts.

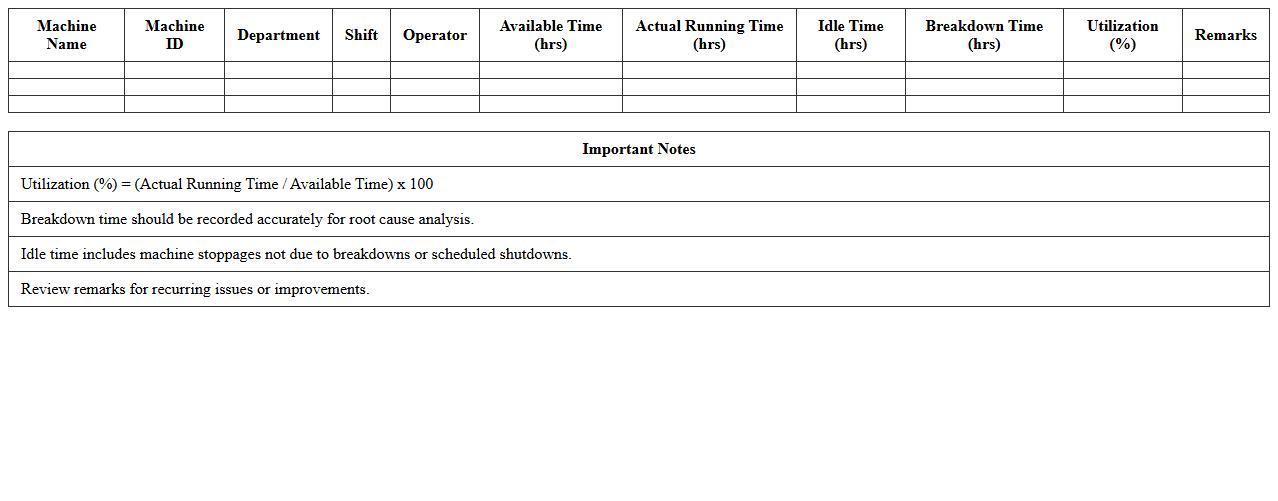

Machine Utilization Analysis Dashboard

The

Machine Utilization Analysis Dashboard document provides a comprehensive overview of equipment performance metrics, including operational time, downtime, and efficiency rates. This dashboard helps identify bottlenecks and underutilized machinery, enabling data-driven decisions to optimize production schedules and increase overall equipment effectiveness (OEE). By tracking real-time and historical machine usage, businesses can reduce maintenance costs and improve asset longevity.

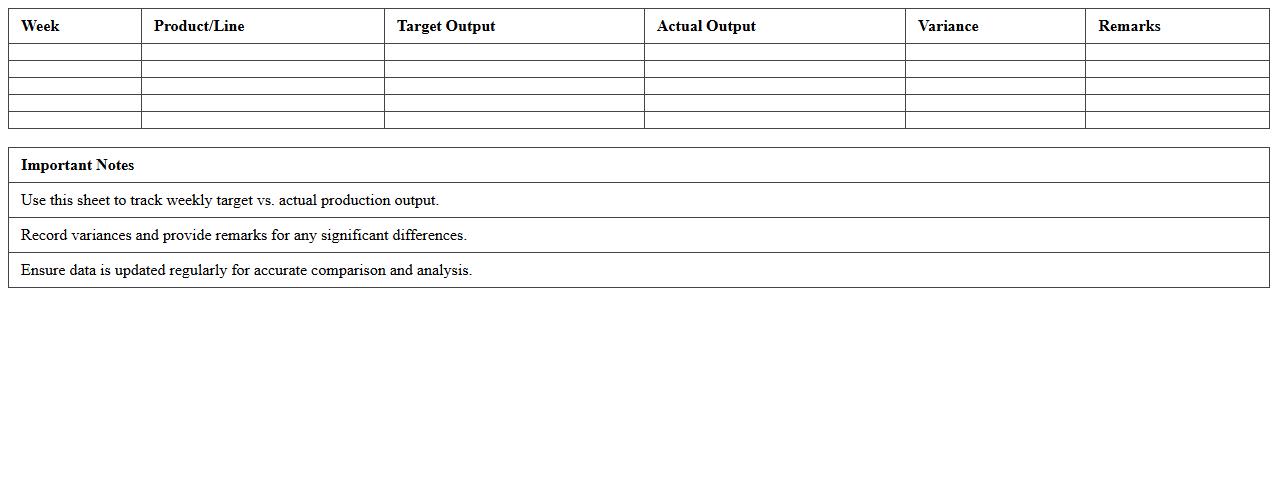

Weekly Production Output Comparison Sheet

The

Weekly Production Output Comparison Sheet is a document that tracks and compares the quantity of goods produced across different weeks, highlighting variations in productivity. It is useful for identifying trends, pinpointing inefficiencies, and enabling data-driven decisions to optimize manufacturing processes. By providing clear visual insights into production performance, this document supports continuous improvement and operational efficiency.

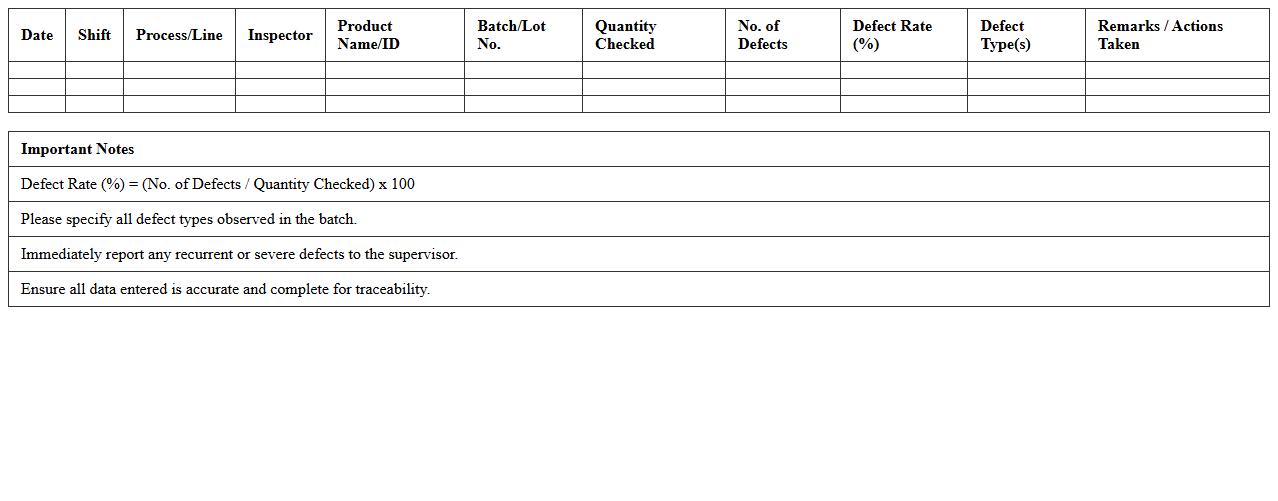

Defect Rate Monitoring Report Template

The

Defect Rate Monitoring Report Template is a structured document designed to track and analyze the frequency of defects in a production or service process. It helps organizations identify patterns, pinpoint root causes, and measure the effectiveness of quality control initiatives. This template is useful for improving product quality, reducing operational costs, and enhancing customer satisfaction by enabling timely corrective actions based on accurate defect data.

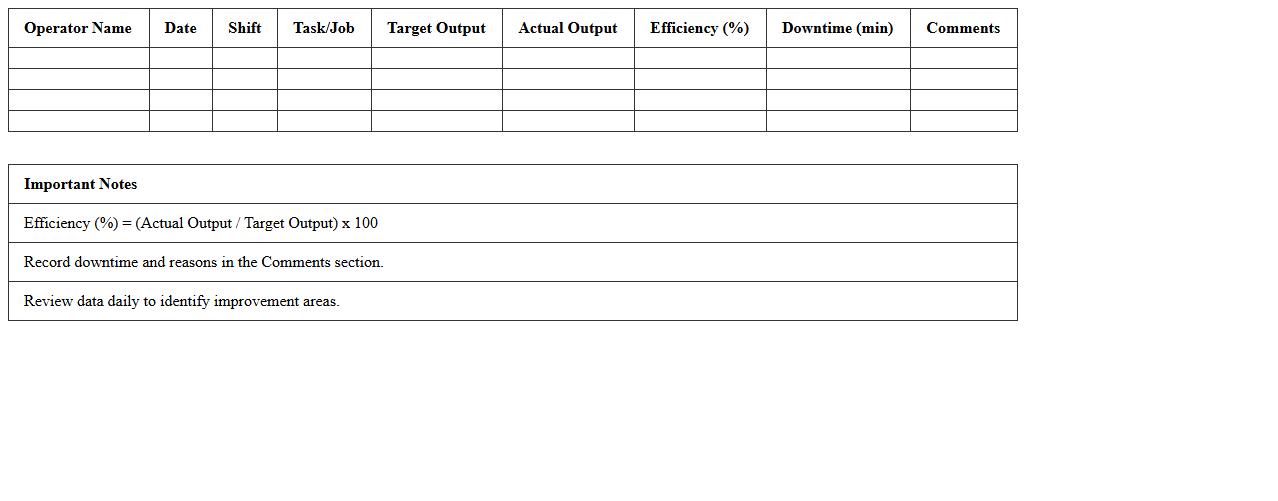

Operator Productivity Summary Excel

The

Operator Productivity Summary Excel document is a comprehensive tool that consolidates data on individual operator performance, including output rates, downtime, and efficiency metrics. It enables managers to identify productivity trends, pinpoint bottlenecks, and make informed decisions to optimize workforce allocation. By providing clear, data-driven insights, this summary enhances operational efficiency and supports continuous improvement initiatives.

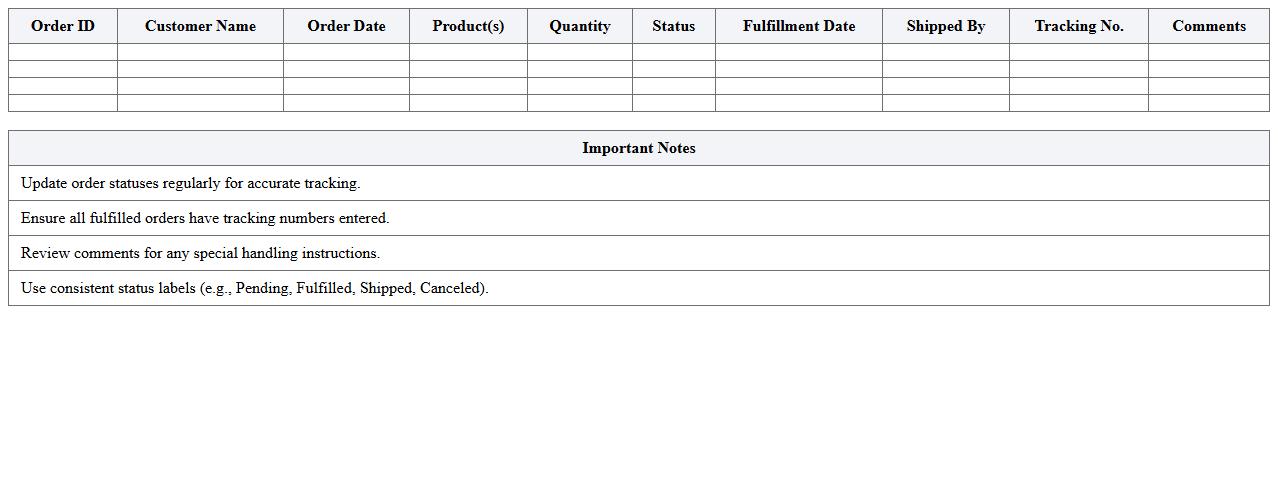

Order Fulfillment Status Dashboard

The

Order Fulfillment Status Dashboard document provides real-time tracking and visualization of order processing stages, including order receipt, packing, shipping, and delivery. This dashboard enables businesses to quickly identify bottlenecks and delays, ensuring timely order completion and improved customer satisfaction. By consolidating fulfillment metrics in one place, it enhances decision-making and operational efficiency across supply chain management.

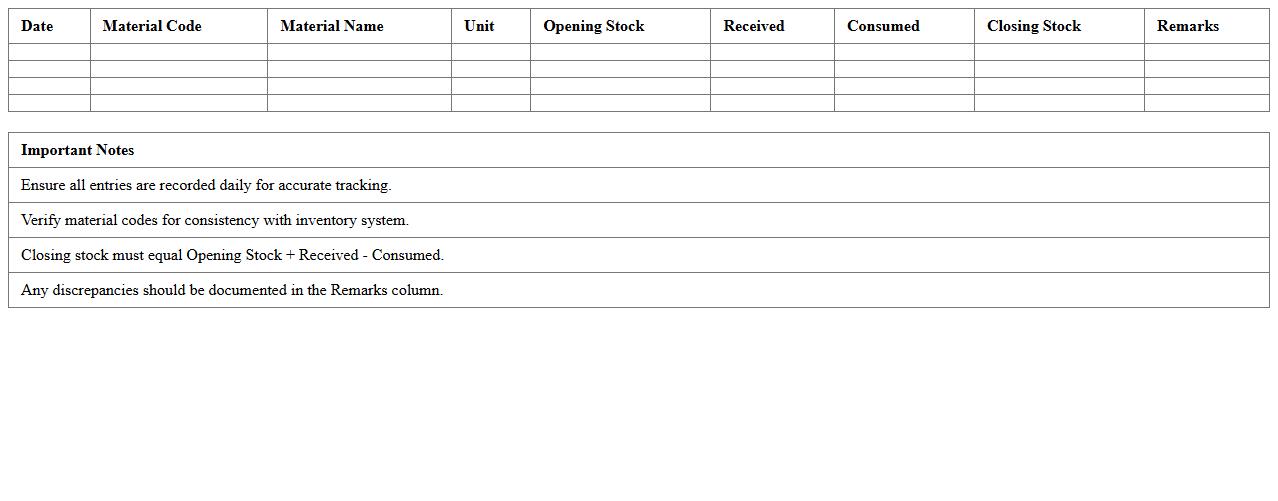

Raw Material Consumption Report Template

The

Raw Material Consumption Report Template is a structured document used to track and analyze the quantity of raw materials utilized in the production process over a specific period. It helps businesses monitor inventory levels, control costs, and identify waste or inefficiencies by providing a clear record of material usage. This template supports accurate forecasting, budgeting, and ensures compliance with manufacturing standards, ultimately improving operational efficiency.

Downtime Tracking and Analysis Sheet

A

Downtime Tracking and Analysis Sheet is a structured document used to record and evaluate periods when equipment or processes are not operational, capturing data such as start and end times, reasons for downtime, and impacted systems. This document is essential for identifying patterns, root causes, and areas for improvement, enabling organizations to enhance operational efficiency and reduce lost production time. By systematically analyzing downtime data, companies can implement targeted maintenance strategies and optimize resource allocation.

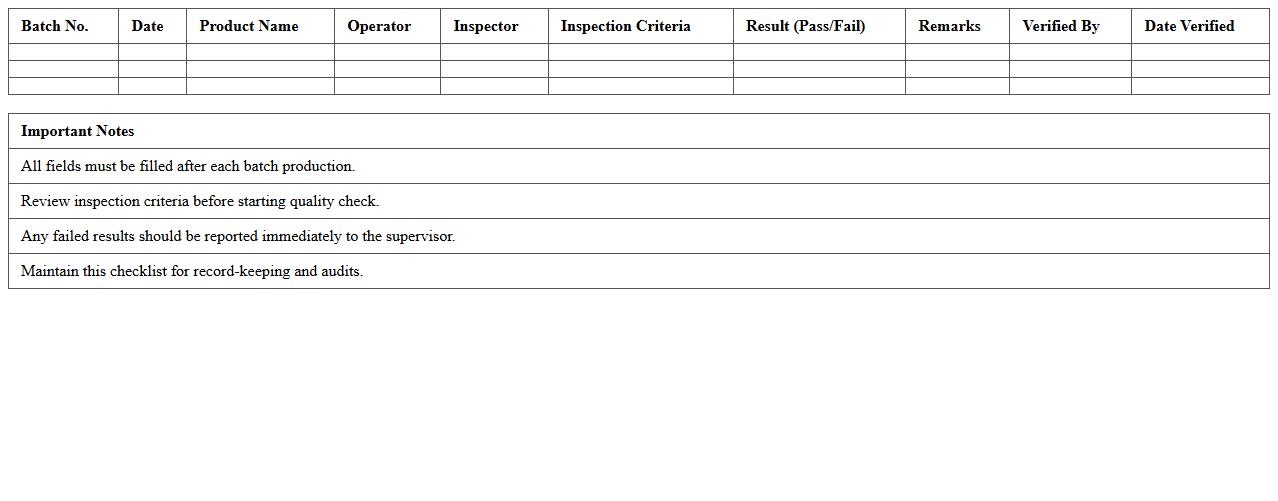

Batch-wise Output Quality Control Checklist

The

Batch-wise Output Quality Control Checklist document is a critical tool used to systematically verify the quality of each production batch against predefined standards. It ensures consistency, identifies defects early, and facilitates compliance with regulatory requirements, thereby reducing risks of product recalls and enhancing customer satisfaction. By providing a structured framework for quality assessment, it streamlines decision-making and supports continuous improvement in manufacturing processes.

How can conditional formatting highlight underperforming production lines in a dashboard?

Conditional formatting in Excel helps visually distinguish underperforming production lines by applying color scales or icon sets based on performance thresholds. This allows quick identification of lines that fall below targets or exceed downtime limits. By customizing the rules to specific KPIs, managers can efficiently monitor production efficiency at a glance.

What formulas best track downtime causes in small factory environments?

SUMIFS and COUNTIFS formulas are effective for tracking downtime by categorizing events based on causes and durations. These formulas aggregate downtime data, filtering by machine or cause, enabling detailed analysis of root downtime reasons. Using these calculations helps factory managers focus on critical issues affecting overall productivity.

Which Excel charts visualize daily versus monthly output variations effectively?

Line chartscolumn charts are ideal for displaying daily and monthly output variations. Line charts show trends over time, highlighting fluctuations, while column charts compare output volumes on specific timeframes. Combining these charts in a dashboard provides a comprehensive view of production performance across periods.

How to automate material usage reports from raw data input in the dashboard?

Automating material usage reports involves creating dynamic tables with PivotTables and using Excel formulas to summarize data. By linking raw data inputs to the dashboard, the reports update automatically when new data is entered. This process streamlines analysis and improves accuracy in tracking material consumption.

What metrics should be included to monitor machine efficiency in small-scale manufacturing?

Key metrics to monitor include Overall Equipment Effectiveness (OEE), downtime frequency, and production cycle times. Tracking these metrics provides insights into machine availability, performance, and quality. Including them in the dashboard enables proactive maintenance and enhances manufacturing efficiency.

More Dashboard Excel Templates