A Cycle Time Chart Excel Template for Production Lines provides a visual representation of the time taken for each step in the manufacturing process, helping to identify bottlenecks and improve efficiency. The customizable template allows users to input data easily and track cycle times across different production stages. Effective use of this tool leads to streamlined operations and optimized workflow management.

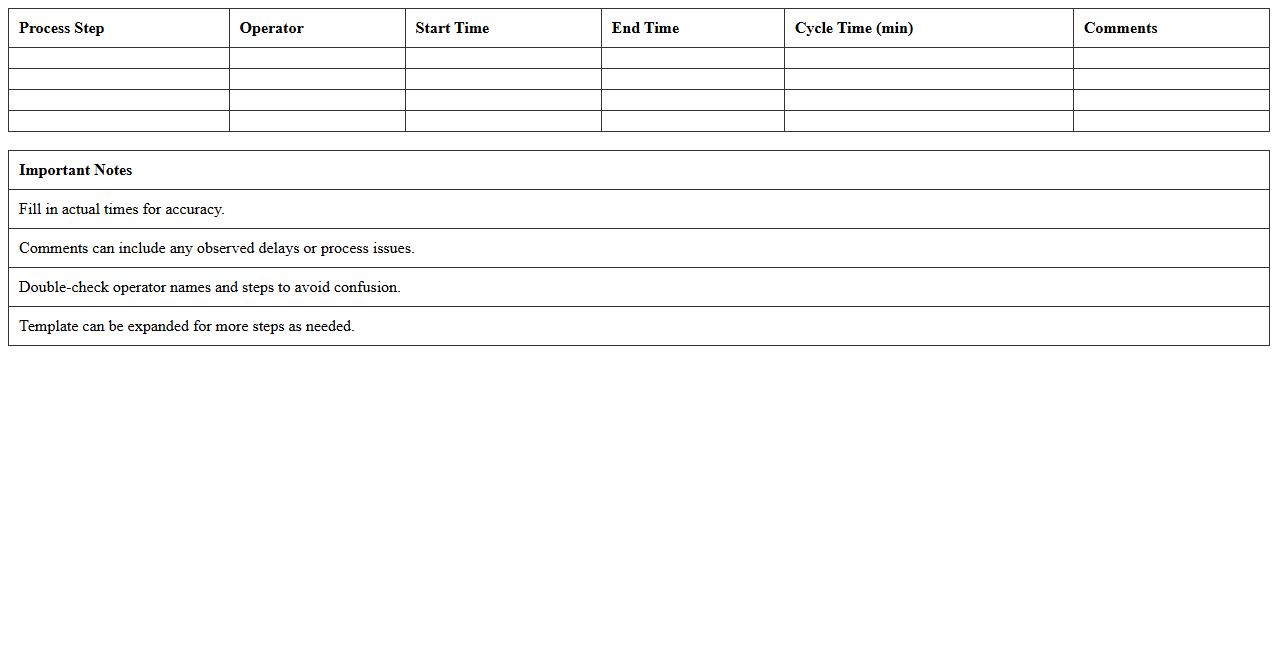

Daily Production Cycle Time Tracker Excel Template

The

Daily Production Cycle Time Tracker Excel Template is a powerful tool designed to monitor and analyze the time taken for each production cycle in a manufacturing process. By recording cycle times daily, it helps identify bottlenecks, improve operational efficiency, and optimize resource allocation. This template enhances decision-making by providing clear insights into production performance and enabling timely interventions to reduce delays.

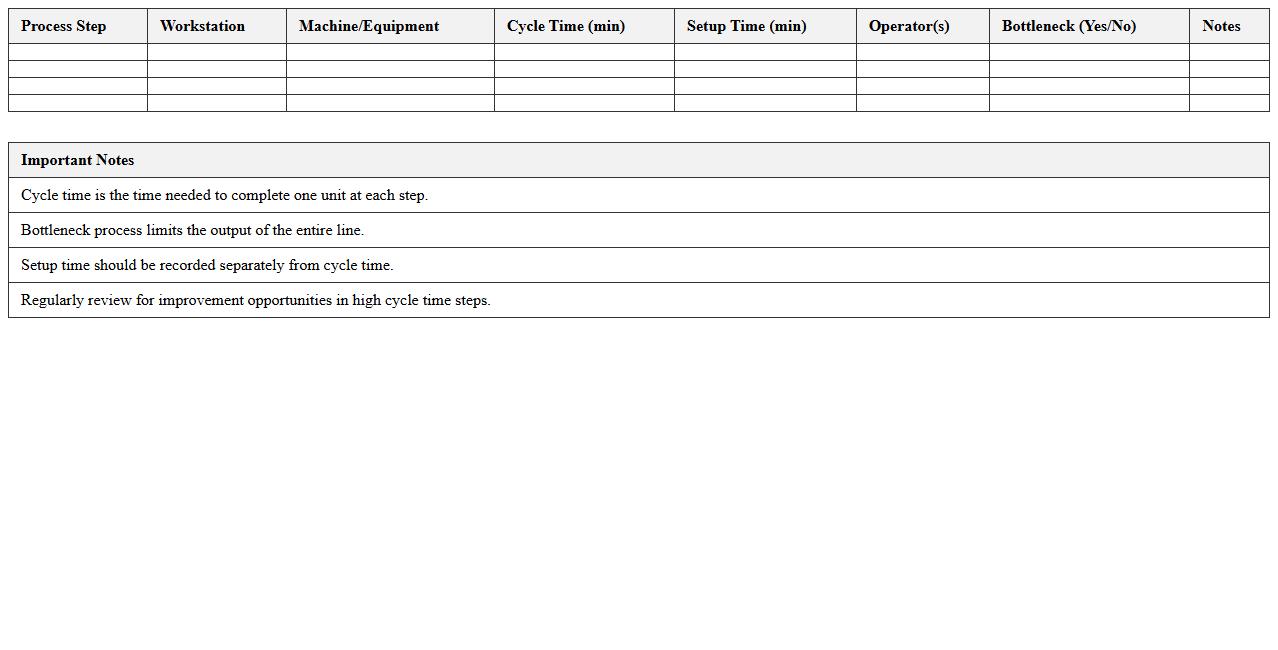

Manufacturing Line Cycle Time Analysis Spreadsheet

A

Manufacturing Line Cycle Time Analysis Spreadsheet is a detailed document that tracks and analyzes the time taken for each step in a production process to identify bottlenecks and optimize efficiency. It helps manufacturers calculate average cycle times, monitor throughput, and pinpoint delays, enabling data-driven decisions to enhance productivity and reduce lead times. Using this tool improves workflow consistency and supports continuous improvement initiatives across the production line.

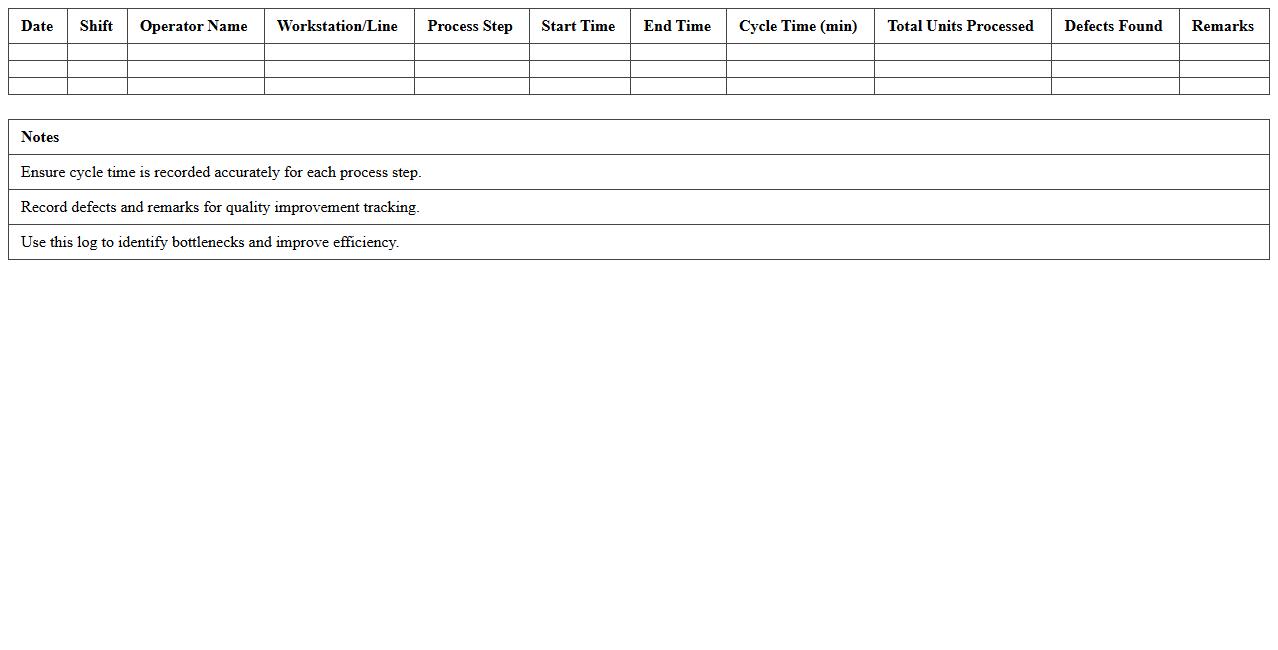

Assembly Line Process Cycle Timing Log Excel

The

Assembly Line Process Cycle Timing Log Excel document tracks and records the time taken for each step in a manufacturing assembly line. It helps identify bottlenecks, optimize workflows, and improve overall production efficiency by providing precise cycle time data. Users gain actionable insights to reduce downtime and increase throughput, making it essential for operational management and continuous improvement initiatives.

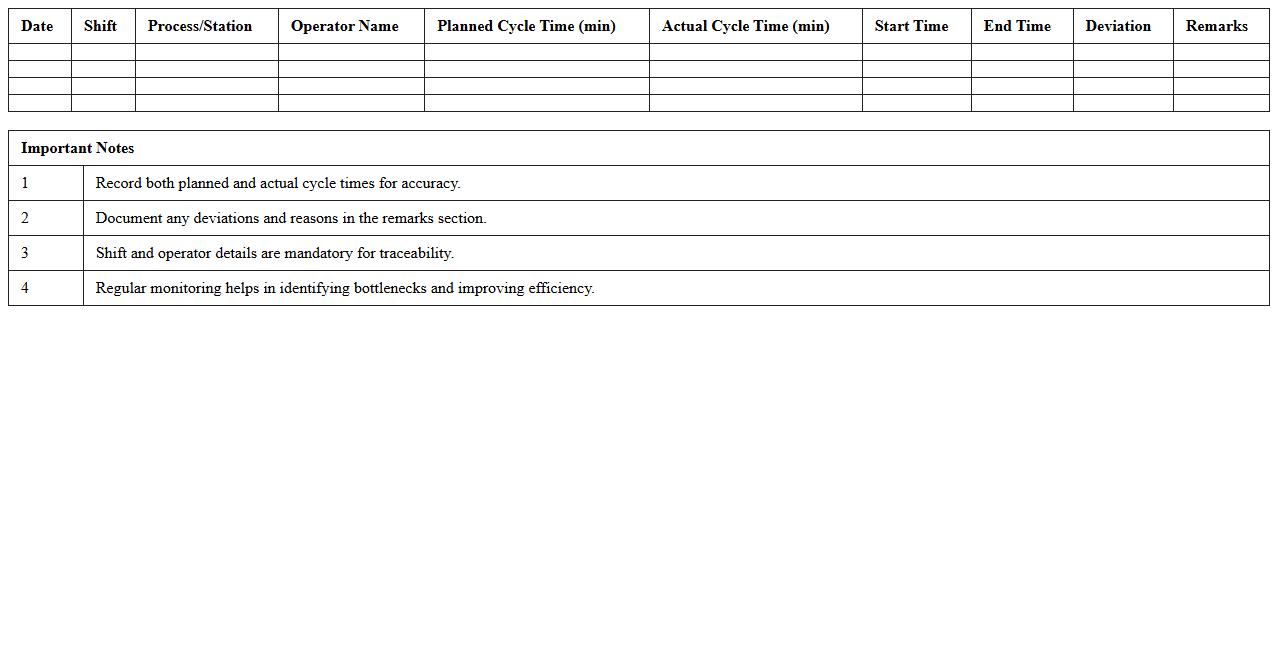

Production Shift Cycle Time Monitoring Sheet

The

Production Shift Cycle Time Monitoring Sheet is a detailed document used to track the duration of each production cycle within a shift, capturing data such as start and end times, downtime, and delays. This sheet helps identify bottlenecks, inefficiencies, and variations in cycle times, enabling teams to optimize workflows and improve overall productivity. By consistently monitoring cycle times, organizations can enhance operational efficiency, reduce waste, and ensure timely delivery of products.

Operations Cycle Time Data Collection Template

The

Operations Cycle Time Data Collection Template is a structured tool designed to capture and analyze the duration of each step within a production or service process. It helps organizations identify bottlenecks, improve efficiency, and optimize workflow by providing precise timing data for every operation involved. Utilizing this template enables data-driven decision-making to enhance productivity and reduce overall cycle time.

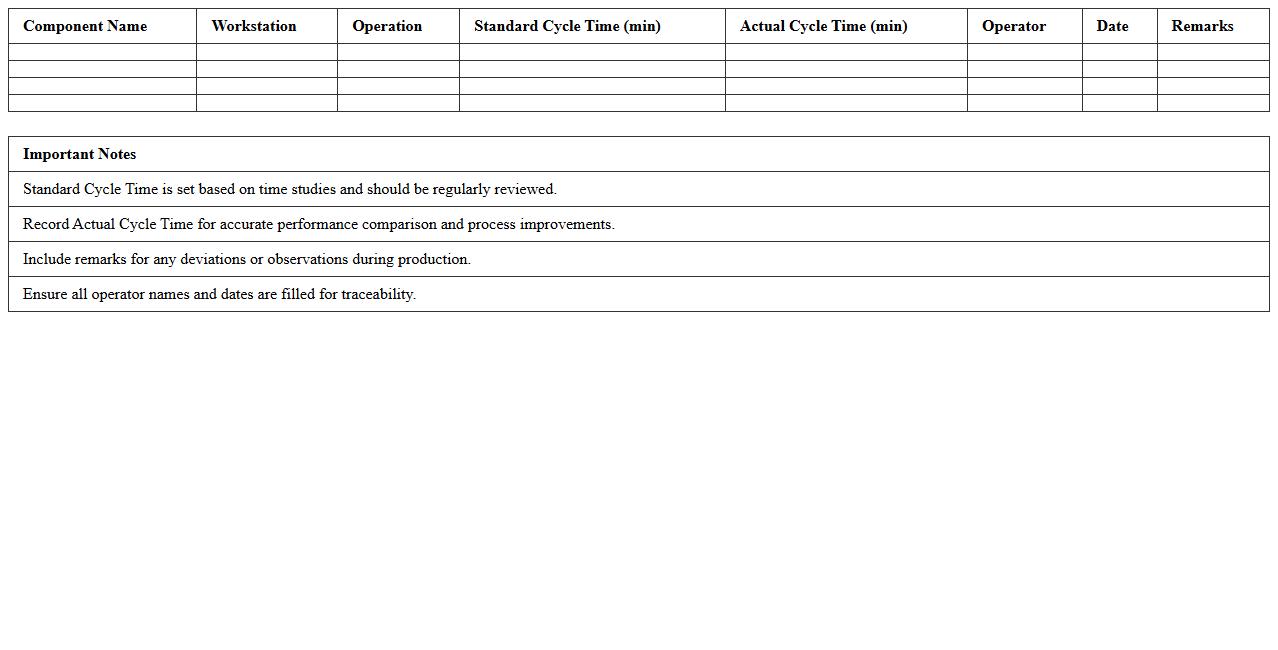

Component Cycle Time Spreadsheet for Production

The

Component Cycle Time Spreadsheet for Production is a detailed tool designed to track and analyze the time taken for each component in the manufacturing process. By recording cycle times, this spreadsheet helps identify bottlenecks, optimize workflows, and improve overall production efficiency. It provides valuable data for reducing downtime and enhancing the accuracy of production planning and scheduling.

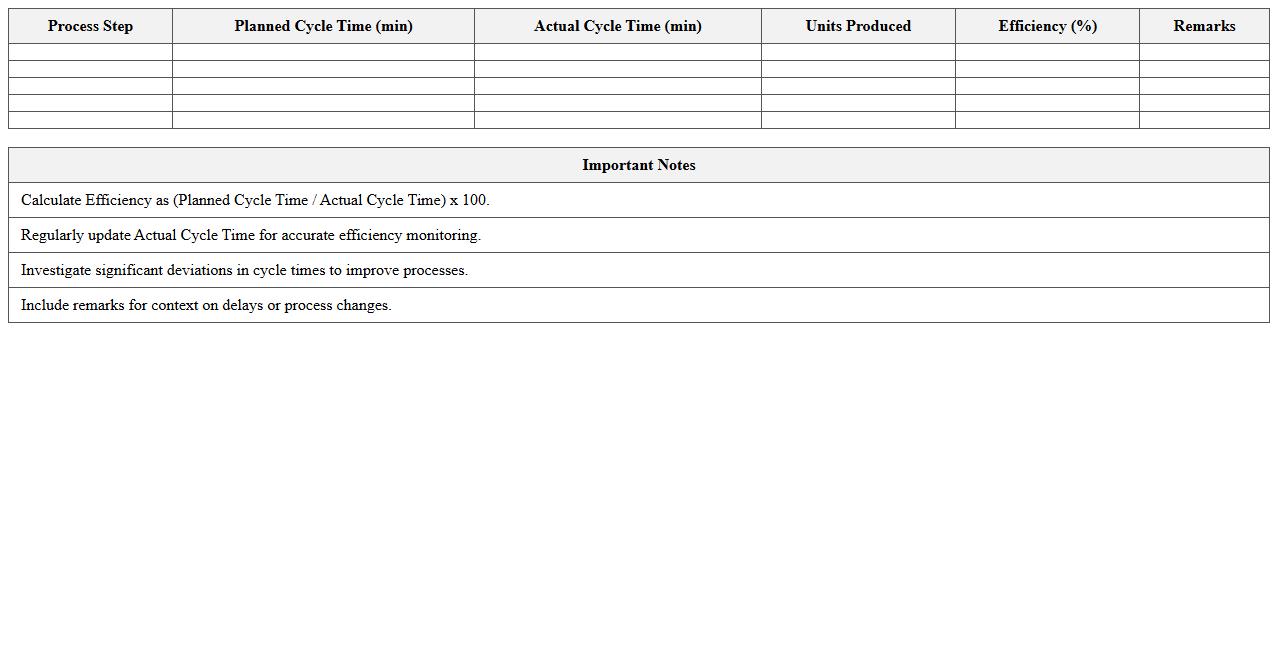

Production Efficiency Cycle Time Chart Excel

The

Production Efficiency Cycle Time Chart Excel document visually represents the time taken for each stage in the production process, enabling precise tracking of cycle times and identifying bottlenecks. It is useful for analyzing process efficiency, optimizing workflow, and reducing downtime by highlighting areas where improvements are necessary. This tool aids manufacturing managers in making data-driven decisions to enhance overall productivity and minimize operational costs.

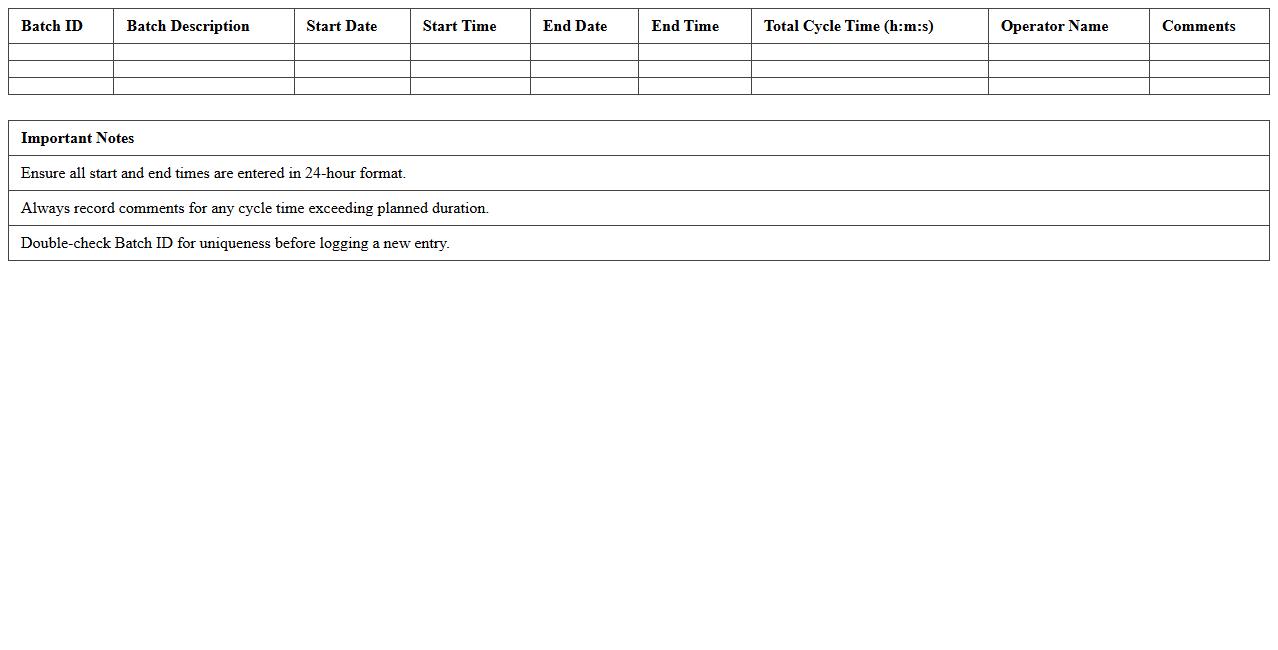

Batch Processing Cycle Time Recorder

The

Batch Processing Cycle Time Recorder document tracks the time taken for each stage in a batch processing workflow, providing precise measurements of cycle durations. This data helps identify bottlenecks and inefficiencies, enabling process optimization and improved throughput. By analyzing recorded cycle times, organizations can enhance productivity, reduce delays, and ensure consistent batch quality.

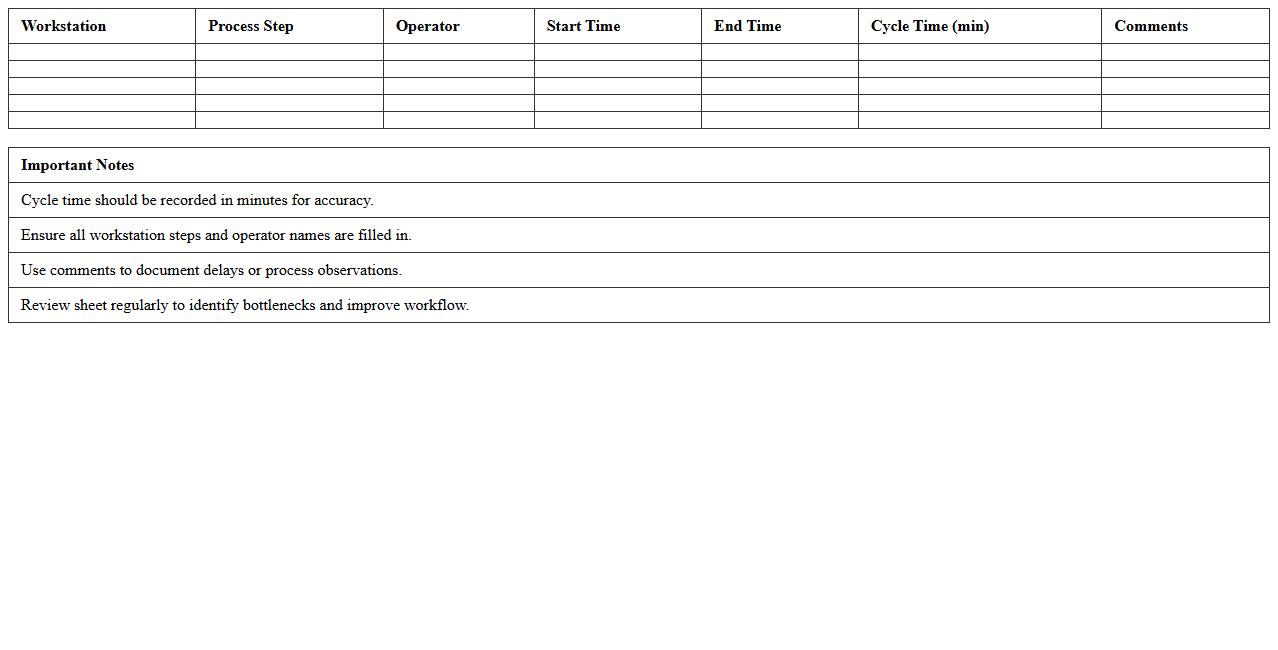

Workstation Cycle Timing Excel Sheet

The

Workstation Cycle Timing Excel Sheet document is a detailed tool used to record and analyze the time taken for each task within a workstation process. It helps identify bottlenecks, optimize workflow efficiency, and improve overall production scheduling by providing precise cycle time data. Utilizing this sheet enables businesses to streamline operations, reduce downtime, and enhance productivity through data-driven decision making.

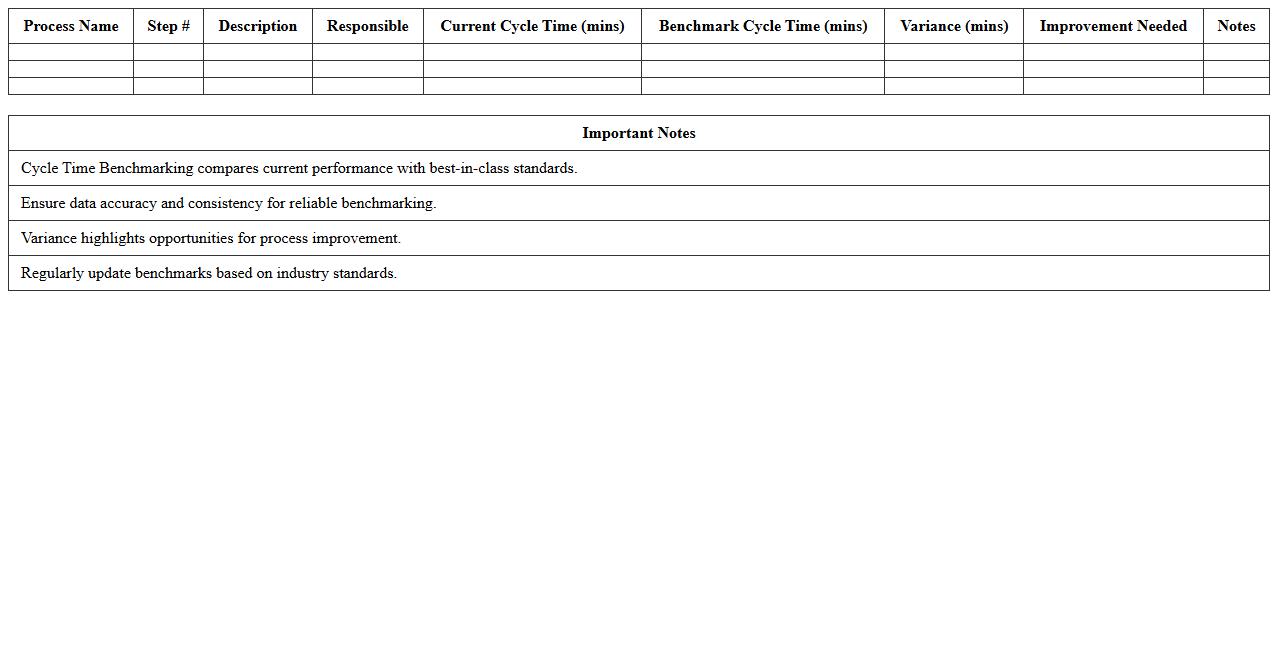

Cycle Time Benchmarking Report Excel Template

The

Cycle Time Benchmarking Report Excel Template is a structured tool designed to track and analyze the efficiency of production or service processes by measuring the time taken for each cycle. This template helps businesses identify bottlenecks and compare performance metrics across different periods or departments, enabling data-driven decisions to enhance operational efficiency. Utilizing this document streamlines workflow analysis and supports continuous improvement initiatives through clear visualization and benchmarking of cycle times.

How to automate cycle time data import into Cycle Time Chart Excel for multiple production lines?

To automate data import for multiple production lines, use Excel's Power Query feature to connect directly to your data sources such as CSV files or databases. Setting up scheduled refreshes ensures cycle time data is updated automatically without manual intervention. Combining Power Query with VBA scripts can further streamline the process, allowing seamless integration into your Cycle Time Chart workbook.

What are the best Excel formulas for calculating average cycle time per work order?

The AVERAGEIFS formula is ideal for calculating the average cycle time per work order by specifying conditions like work order ID and date range. Using SUMIFS combined with COUNTIFS can also provide weighted averages based on quantity or units produced. These formulas ensure accurate and dynamic calculation of average cycle times directly within your dataset.

How to visualize bottlenecks on a Cycle Time Chart Excel dashboard?

To highlight bottlenecks, implement color-coded bar or line charts that display cycle times exceeding target thresholds. Adding data labels and annotations helps identify specific stages or lines causing delays. Integrating conditional formatting with visual elements enhances the dashboard's ability to clearly highlight critical bottlenecks affecting production flow.

How to set up conditional formatting to highlight excess cycle times in Excel?

Use Excel's Conditional Formatting rules to apply color scales or icon sets that flag cycle times above defined benchmarks. Setting rules based on percentage thresholds or absolute values allows dynamic highlighting as data changes. This visual cue immediately draws attention to excess cycle times needing corrective action.

Which Excel chart type best displays cycle time variance across shifts?

A box and whisker chart effectively visualizes cycle time variance across different shifts by showing distribution, median, and outliers. Alternatively, clustered column charts with error bars can highlight variability between shifts. These chart types provide clear insights into cycle time fluctuations, aiding shift performance comparison.

More Chart Excel Templates