The Pareto Chart Excel Template for Defect Prioritization helps identify and focus on the most significant defects impacting product quality. By visually ranking defects based on frequency, it enables efficient resource allocation to address the highest priority issues. This tool supports data-driven decision-making for quality improvement and defect reduction initiatives.

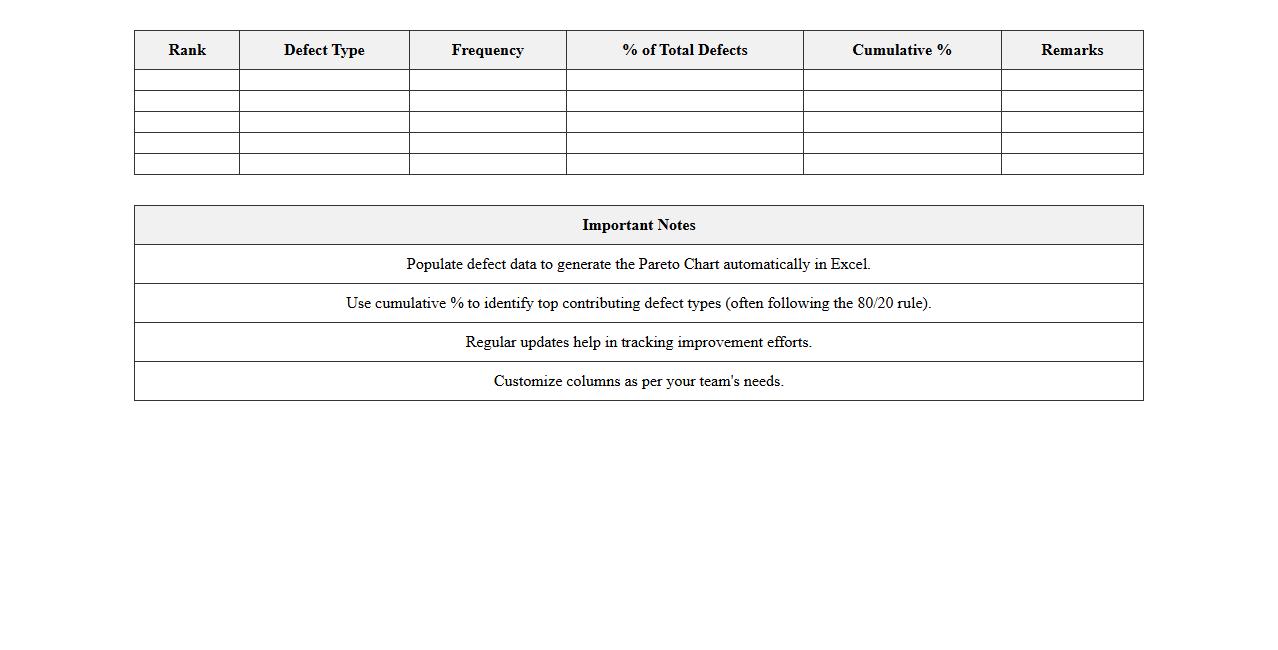

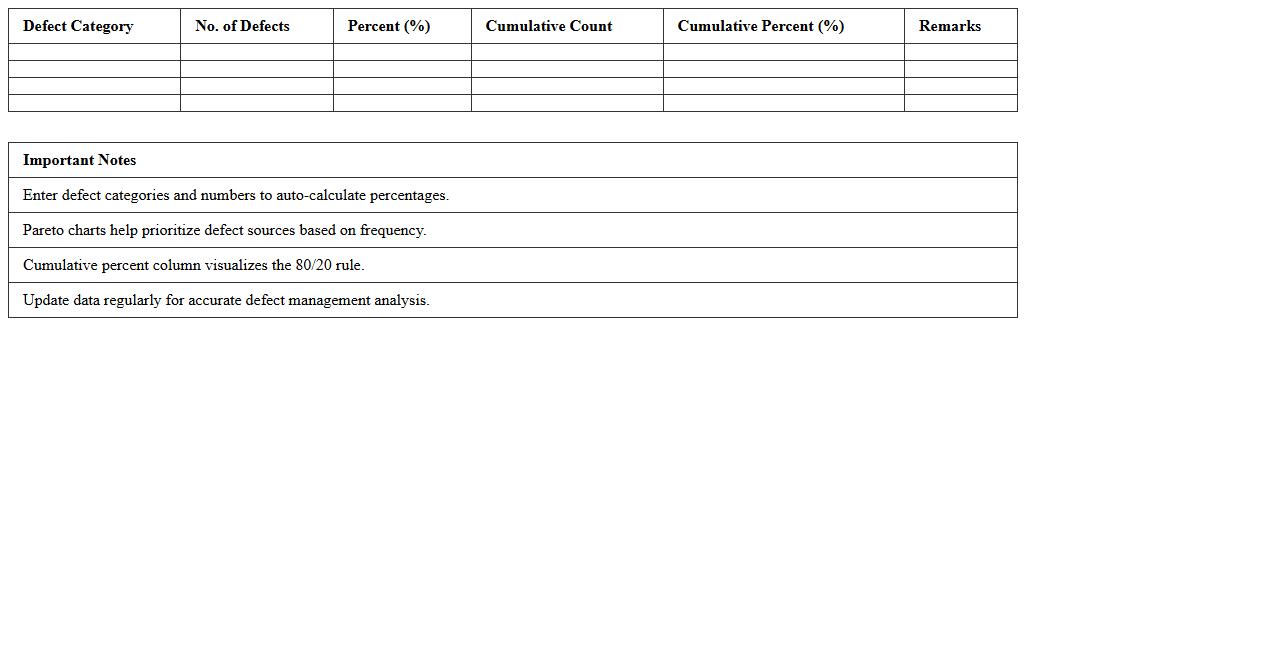

Top Defect Analysis Pareto Chart Excel Template

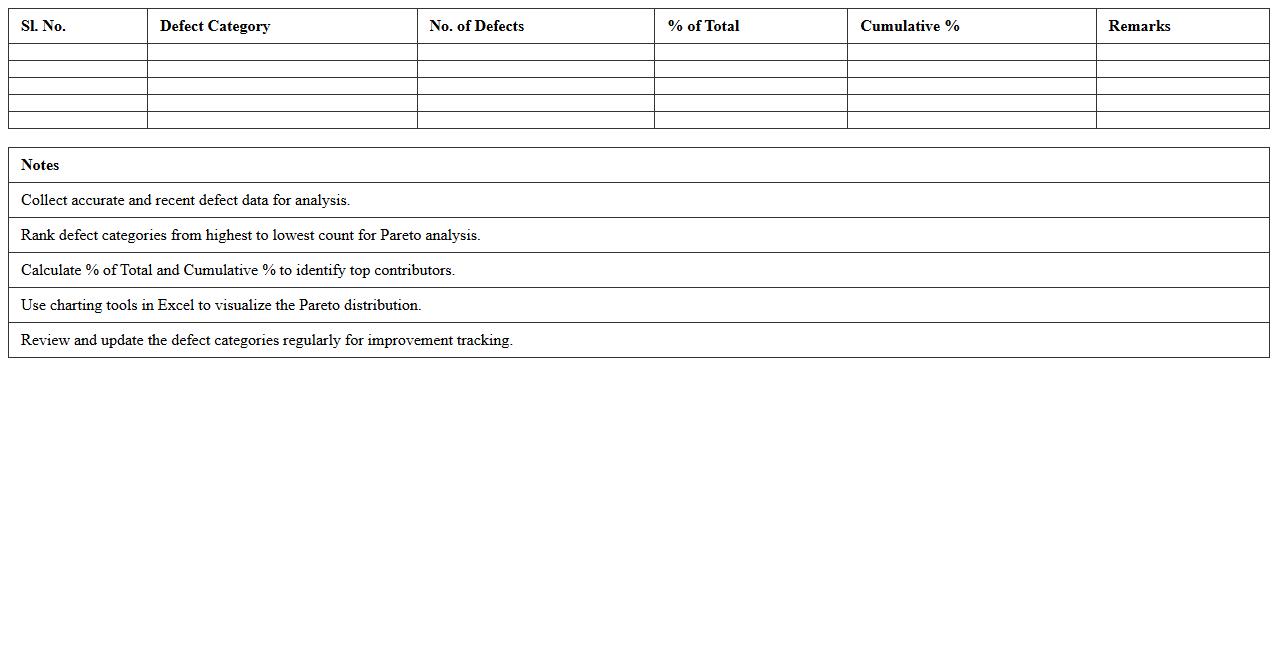

The

Top Defect Analysis Pareto Chart Excel Template document is a powerful tool designed to identify and prioritize the most significant defects within a process or product using the Pareto principle. By visually representing defect frequency and their cumulative impact, it enables quality managers and teams to focus on the critical few issues causing the majority of problems, leading to targeted improvements. This template streamlines defect tracking, facilitates data-driven decision-making, and enhances overall quality control efficiency.

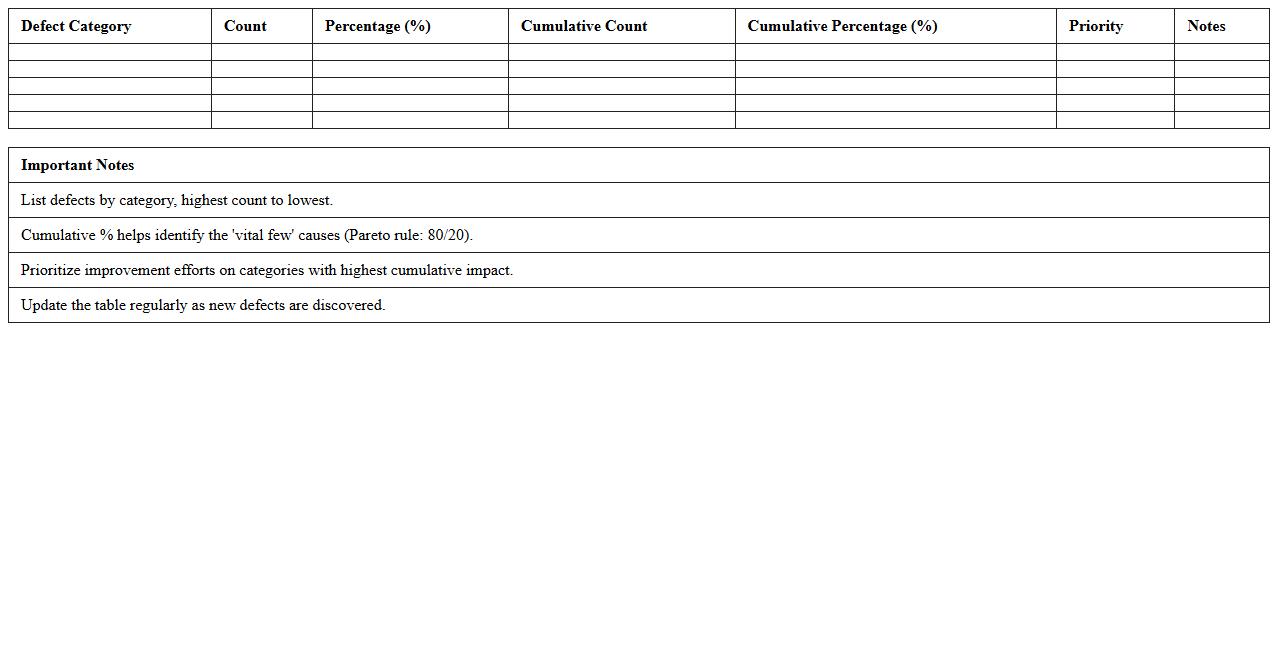

Defect Prioritization Pareto Diagram Spreadsheet

The

Defect Prioritization Pareto Diagram Spreadsheet is a data-driven tool that organizes software defects by frequency and impact, enabling teams to identify the most critical issues affecting product quality. By visualizing defects in descending order, it helps prioritize resolution efforts on the 20% of problems causing 80% of failures, optimizing resource allocation. This spreadsheet enhances decision-making processes, accelerates defect fixes, and improves overall software reliability.

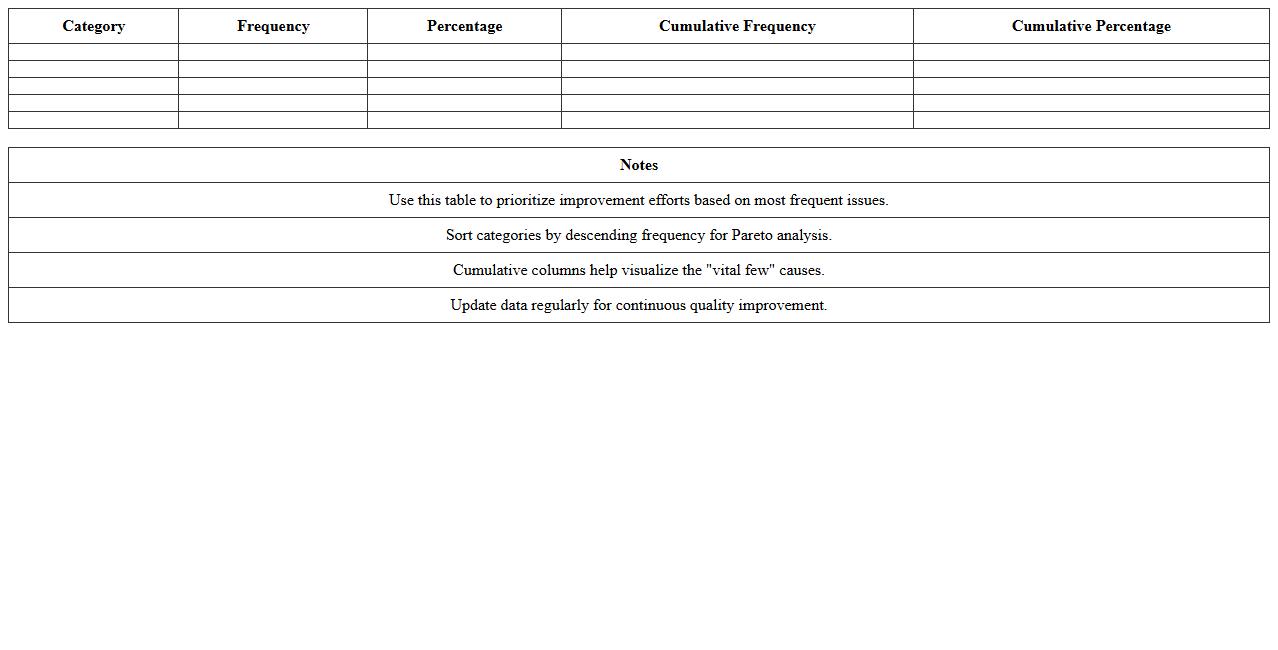

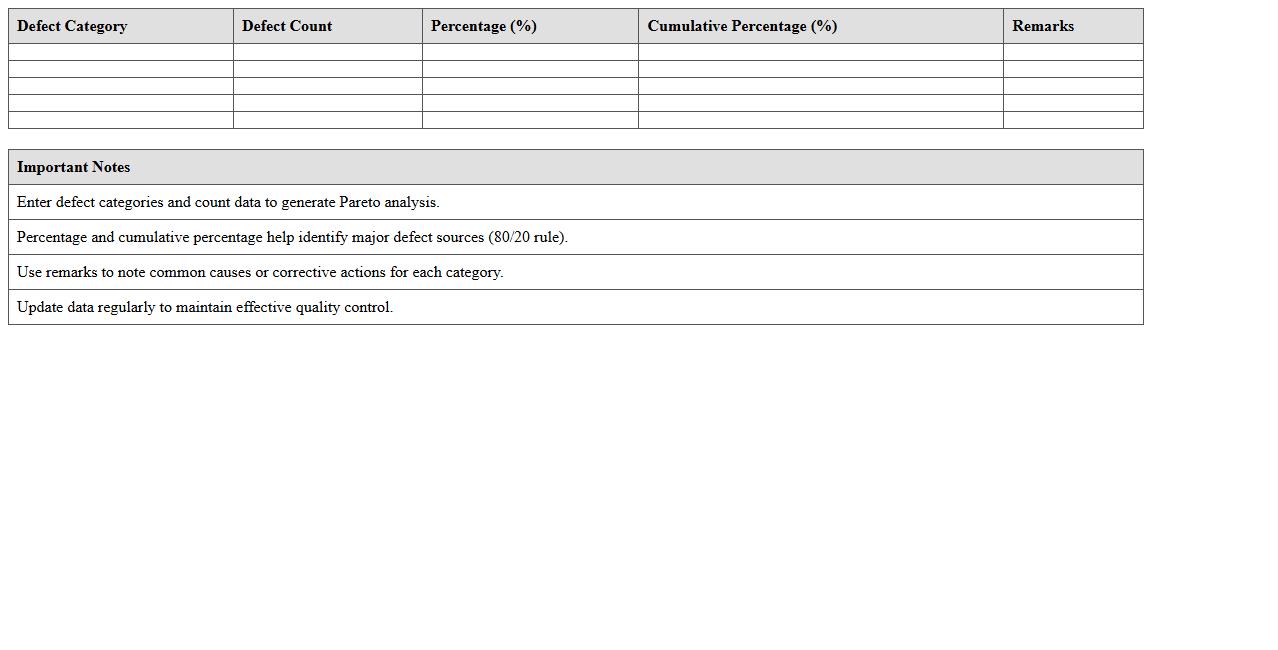

Quality Improvement Pareto Chart Template in Excel

A

Quality Improvement Pareto Chart Template in Excel is a tool designed to visually prioritize causes of problems by displaying their relative frequencies or impacts in descending order. It helps teams focus on the most significant issues by highlighting the vital few factors that contribute to the majority of defects or delays. Using this template streamlines data analysis, supports decision-making, and drives targeted improvements in quality management processes.

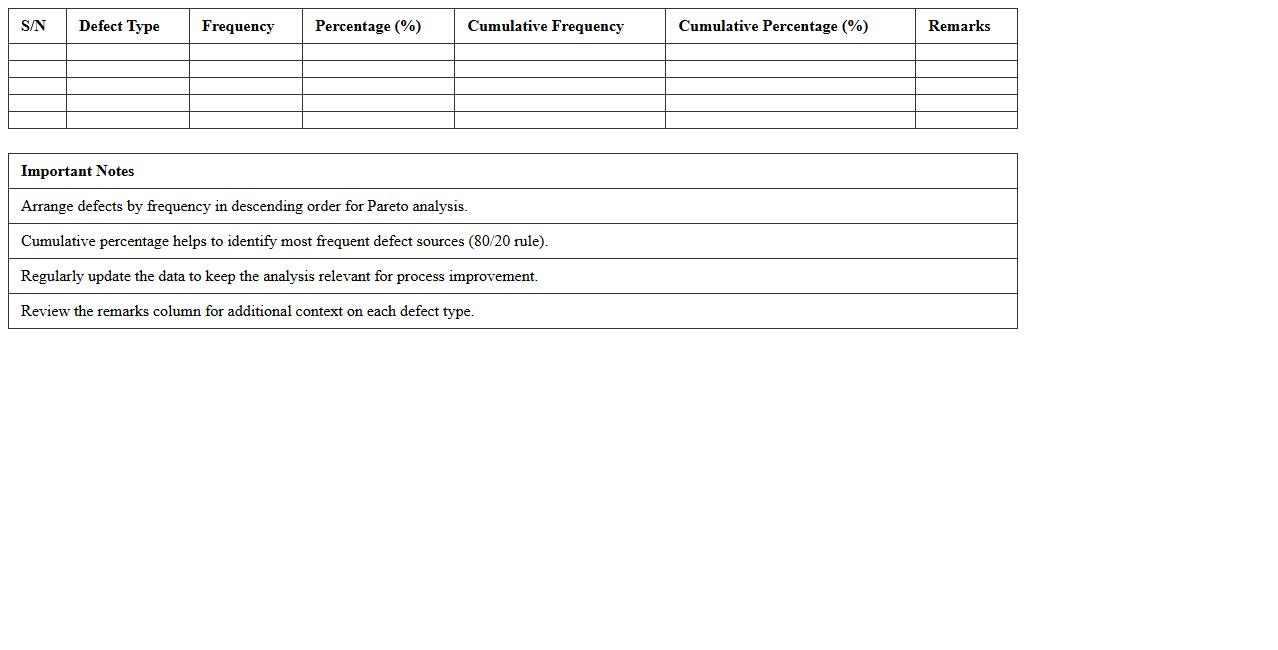

Defect Frequency Pareto Analysis Excel Sheet

A

Defect Frequency Pareto Analysis Excel Sheet document is a tool that organizes and visualizes defect data by frequency, applying the Pareto principle to identify the most common issues causing quality problems. It helps prioritize efforts by highlighting the vital few defects that contribute to the majority of problems, enabling targeted improvements in manufacturing or service processes. Using this analysis leads to more efficient resource allocation and enhanced product quality by focusing on high-impact defects.

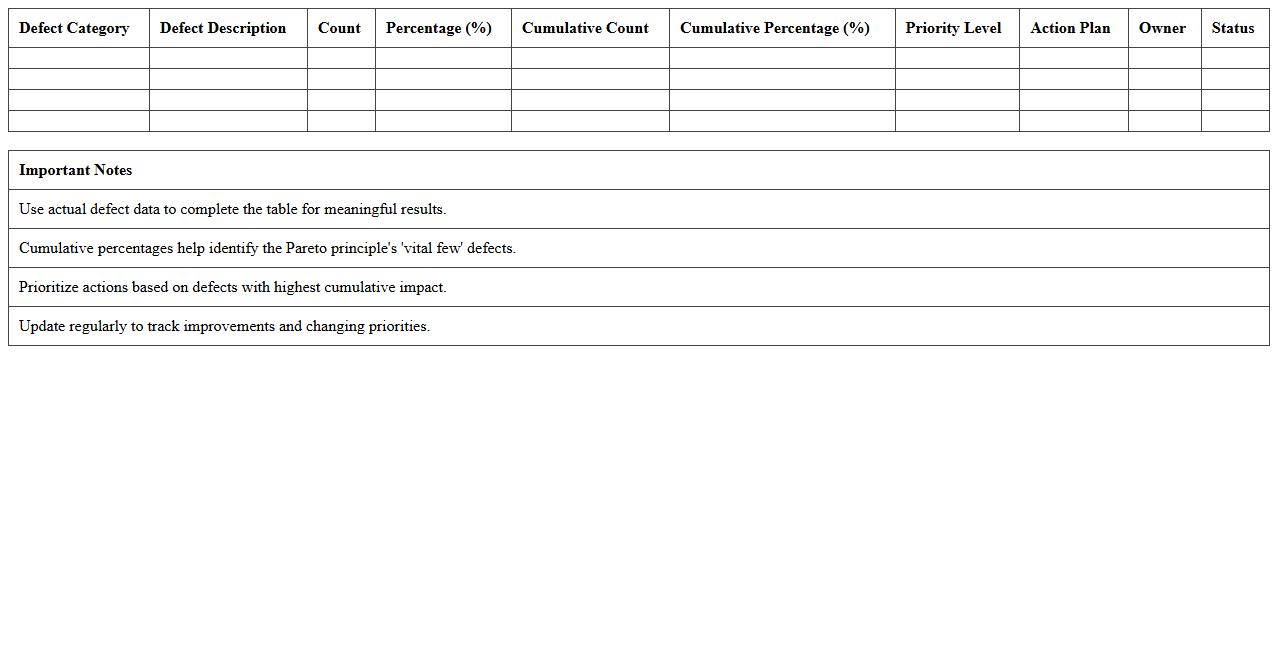

Excel Defect Management Pareto Chart Template

The

Excel Defect Management Pareto Chart Template is a powerful tool designed to visually display and prioritize defects by frequency, enabling users to focus on the most critical issues affecting product quality. It leverages the Pareto principle by highlighting the vital few defects that cause the majority of problems, streamlining the defect resolution process. This template aids teams in data-driven decision-making, improving quality control, and enhancing overall project efficiency.

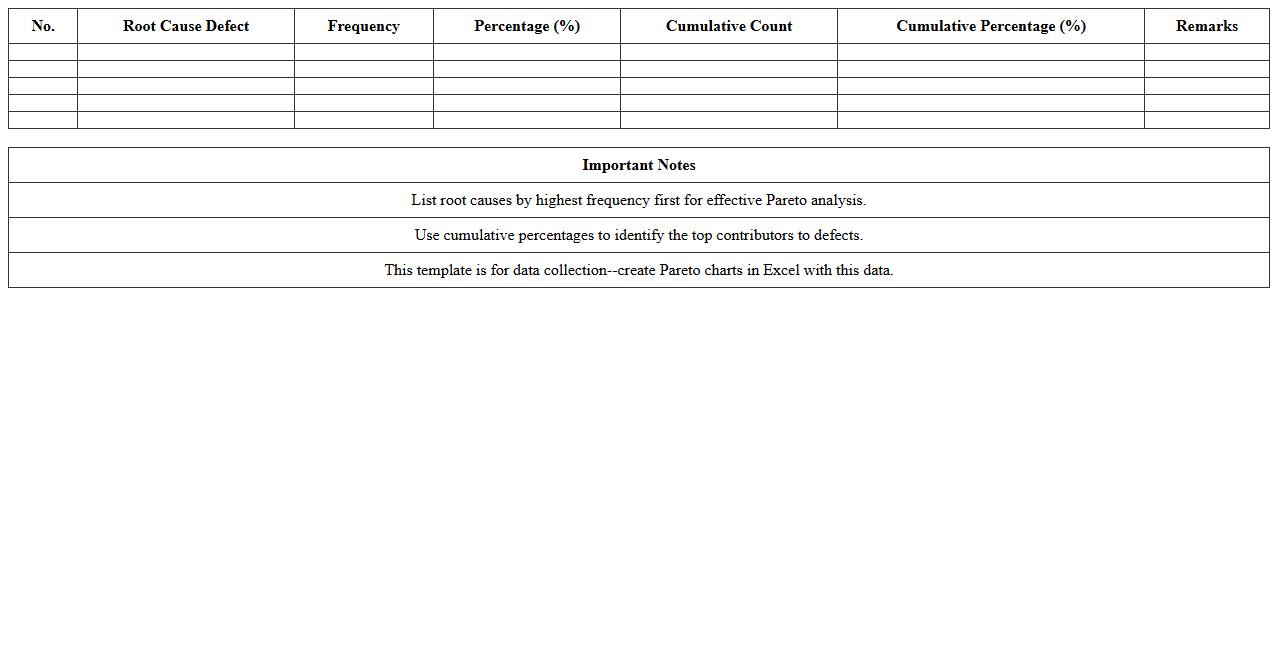

Root Cause Defects Pareto Chart Excel Format

The

Root Cause Defects Pareto Chart Excel Format document is a structured tool that organizes and visually represents defect data to identify the most significant causes of problems. By focusing on the highest impact root causes using the Pareto principle, it helps organizations prioritize quality improvement efforts efficiently. This format streamlines defect analysis, enabling data-driven decision making and reducing resource wastage in troubleshooting.

Manufacturing Defect Pareto Tracker Excel Template

The

Manufacturing Defect Pareto Tracker Excel Template document is designed to systematically identify and analyze defects in manufacturing processes using the Pareto principle. It helps prioritize the most critical defects by visually displaying their frequency and impact, enabling targeted improvement efforts. By focusing on the top sources of defects, manufacturers can enhance product quality, reduce waste, and improve overall operational efficiency.

Product Defect Distribution Pareto Chart Spreadsheet

A

Product Defect Distribution Pareto Chart Spreadsheet document visually represents the frequency and impact of various product defects by organizing data into a descending bar graph combined with a cumulative percentage line. This tool helps identify the most critical defects that contribute to the majority of quality problems, enabling targeted improvements in manufacturing or production processes. By focusing on the vital few defects, businesses can efficiently allocate resources to reduce overall product issues and enhance customer satisfaction.

Service Defect Prioritization Pareto Excel Template

The

Service Defect Prioritization Pareto Excel Template is a powerful tool designed to identify and analyze the most critical service defects by applying the Pareto principle, enabling businesses to focus on the 20% of issues causing 80% of problems. This template organizes defect data visually through charts and graphs, facilitating quick decision-making and efficient resource allocation for defect resolution. By prioritizing defects effectively, organizations can significantly improve service quality and customer satisfaction.

Process Defect Analysis Pareto Chart Excel Sheet

A

Process Defect Analysis Pareto Chart Excel Sheet document is a structured tool used to identify and prioritize defects in a process by visually representing their frequency or impact. It applies the Pareto principle, focusing on the most significant defects that contribute to the majority of problems, enabling targeted improvements. This document helps organizations streamline quality control, reduce waste, and enhance overall efficiency by concentrating efforts on the critical few issues.

How do I automatically highlight top defect categories in a Pareto Chart in Excel?

To automatically highlight top defect categories in a Pareto Chart, use a combination of conditional formatting and dynamic ranges. Set up your data so the top categories are identified based on frequency or cumulative impact, then apply a unique color to those bars. This approach ensures your chart visually emphasizes key areas without manual updates.

Which Excel formula best separates cumulative percentage for defect prioritization?

The SUM and SUMIF functions are essential to calculate cumulative percentages for defect prioritization. Use the formula =SUM($B$2:B2)/SUM($B$2:$B$20) to accumulate defect counts and convert to a percentage. This separated cumulative percentage aids in applying the Pareto principle by highlighting the vital few defects.

How can I link defect tracker data directly to a Pareto Chart dashboard?

Link your defect tracker data to the Pareto Chart using Excel's Table feature and dynamic named ranges. By referencing these live data tables in your chart source, the dashboard updates automatically as new defects are logged. This setup minimizes errors and ensures real-time visualization accuracy.

What's an efficient way to update Pareto Charts for recurring defect reports in Excel?

Efficient updating of Pareto Charts requires using dynamic named ranges or Excel Tables that expand with new data. Pair this with PivotTables connected to your data source for instant refreshes. This method streamlines recurring defect report analysis by eliminating manual data adjustments.

How do I present actionable insights from Pareto analysis in an executive summary letter?

Focus your executive summary on key defect categories causing the majority of issues using clear, concise language. Use data-driven insights from the Pareto Chart to recommend targeted actions and resource allocation. Highlight measurable benefits to drive informed decision-making by leadership.

More Chart Excel Templates