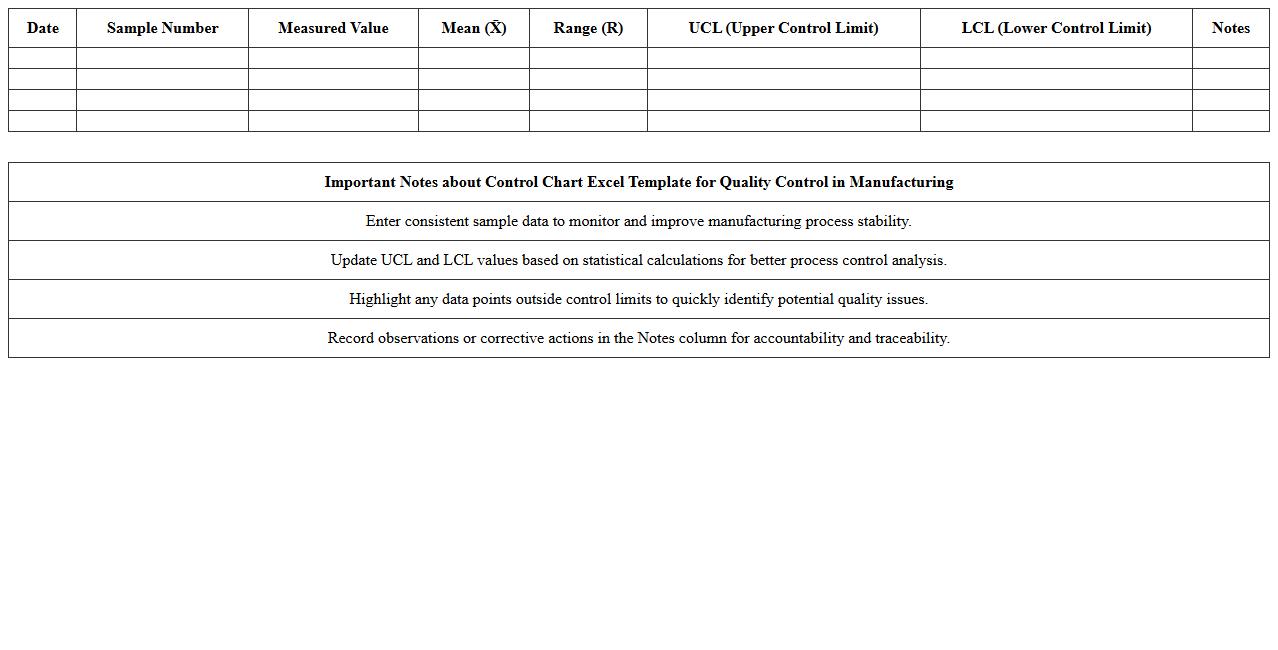

Control Chart Excel Template for Quality Control in Manufacturing

A

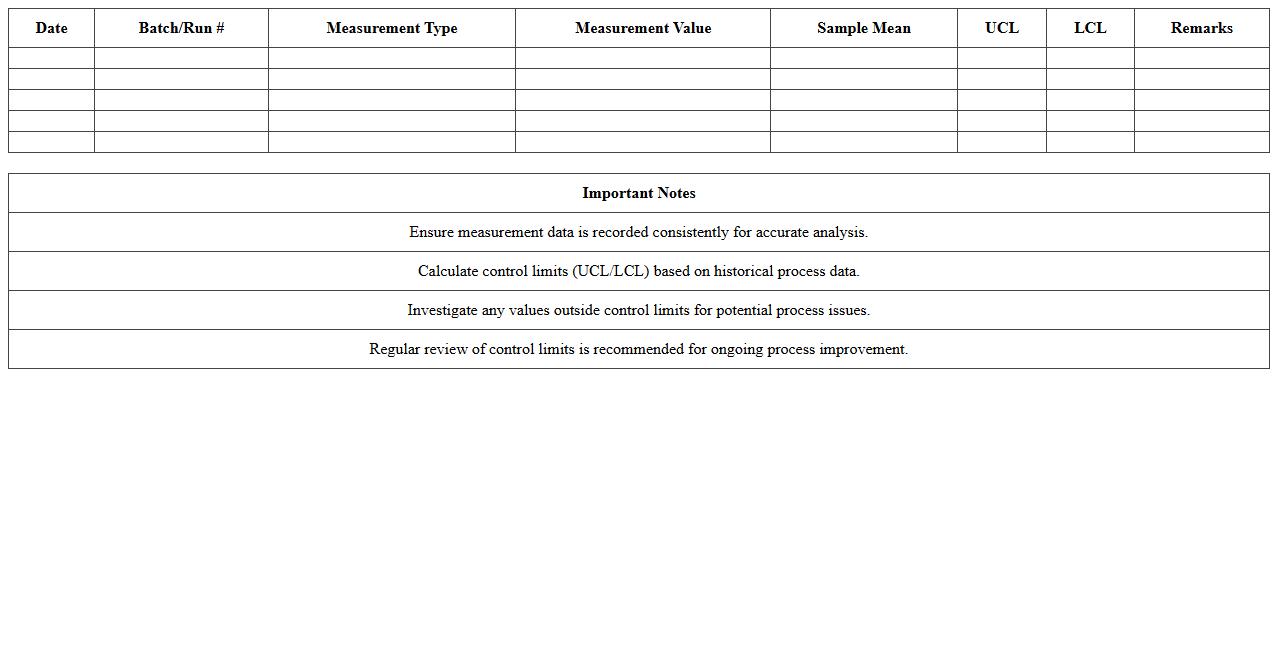

Control Chart Excel Template for Quality Control in Manufacturing is a pre-designed spreadsheet that helps track process variations and maintain product consistency by plotting data points against control limits. It enables manufacturers to identify trends, detect anomalies, and implement corrective actions before defects occur, ensuring compliance with quality standards like Six Sigma or ISO 9001. This tool simplifies data visualization and enhances decision-making, leading to improved operational efficiency and reduced production costs.

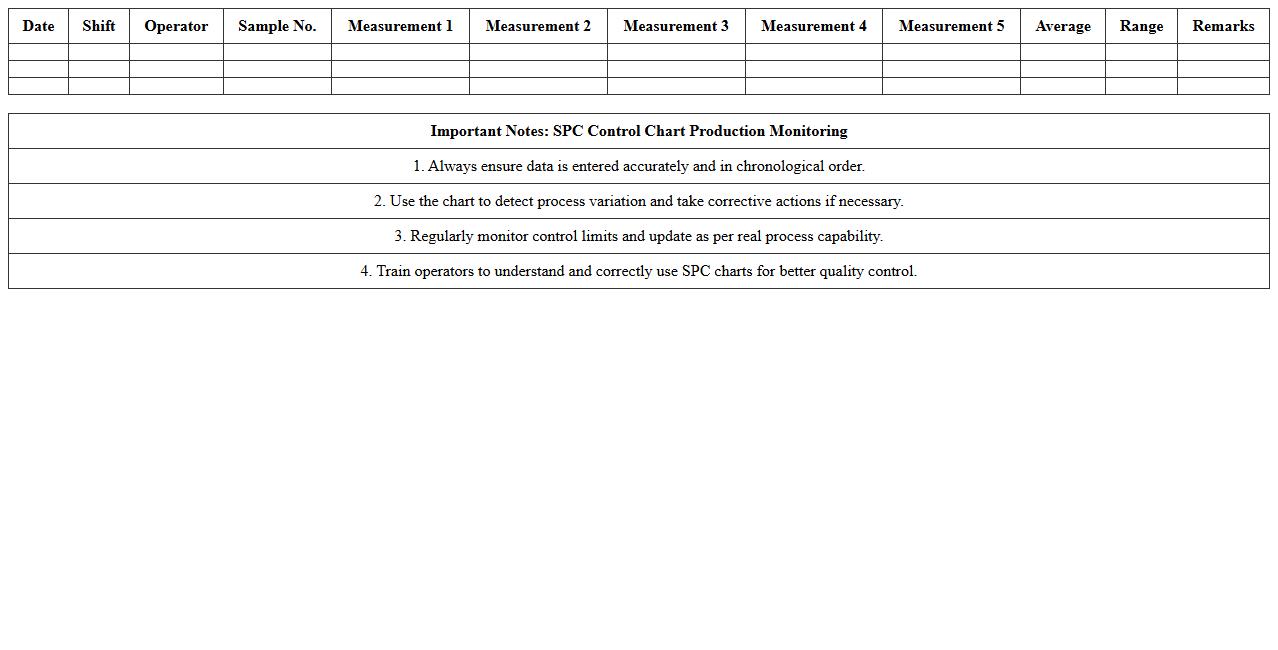

SPC Control Chart Excel Template for Production Monitoring

The SPC Control Chart Excel Template for Production Monitoring document is a powerful tool designed to track and analyze process performance using Statistical Process Control techniques. It enables manufacturers to identify variations, monitor consistency, and improve product quality by visually representing data through control charts. Utilizing this

SPC Control Chart template helps reduce defects, optimize production efficiency, and facilitate data-driven decision-making in real-time.

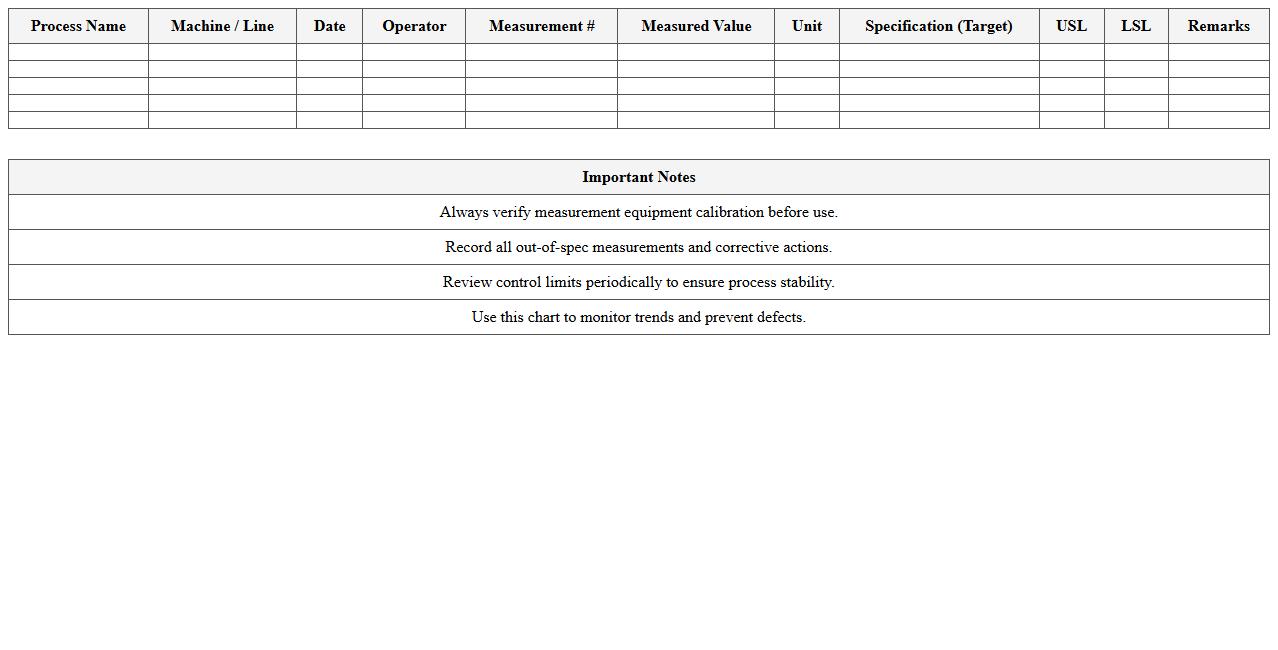

Manufacturing Process Control Chart Excel Sheet

A

Manufacturing Process Control Chart Excel Sheet is a digital tool designed to monitor and analyze production processes by tracking key performance metrics such as defect rates, cycle times, and output consistency. It helps identify variations in manufacturing operations, enabling timely interventions to maintain quality standards and reduce waste. This document is essential for improving operational efficiency, ensuring product quality, and supporting data-driven decision-making in manufacturing environments.

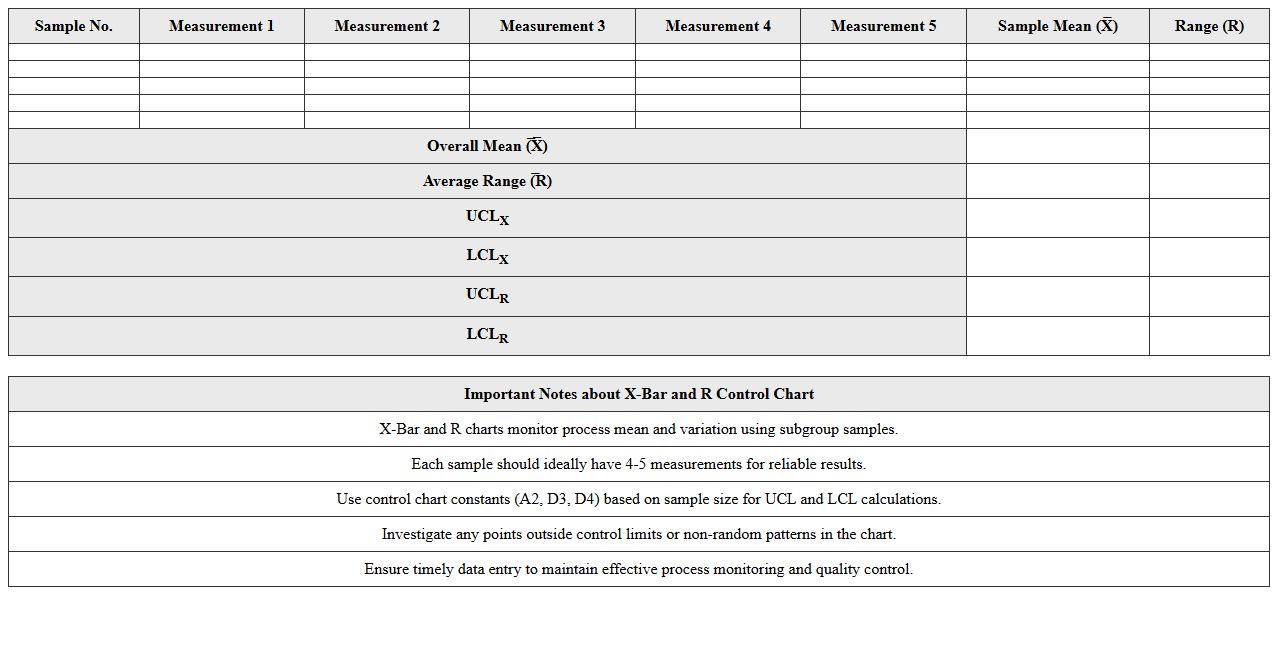

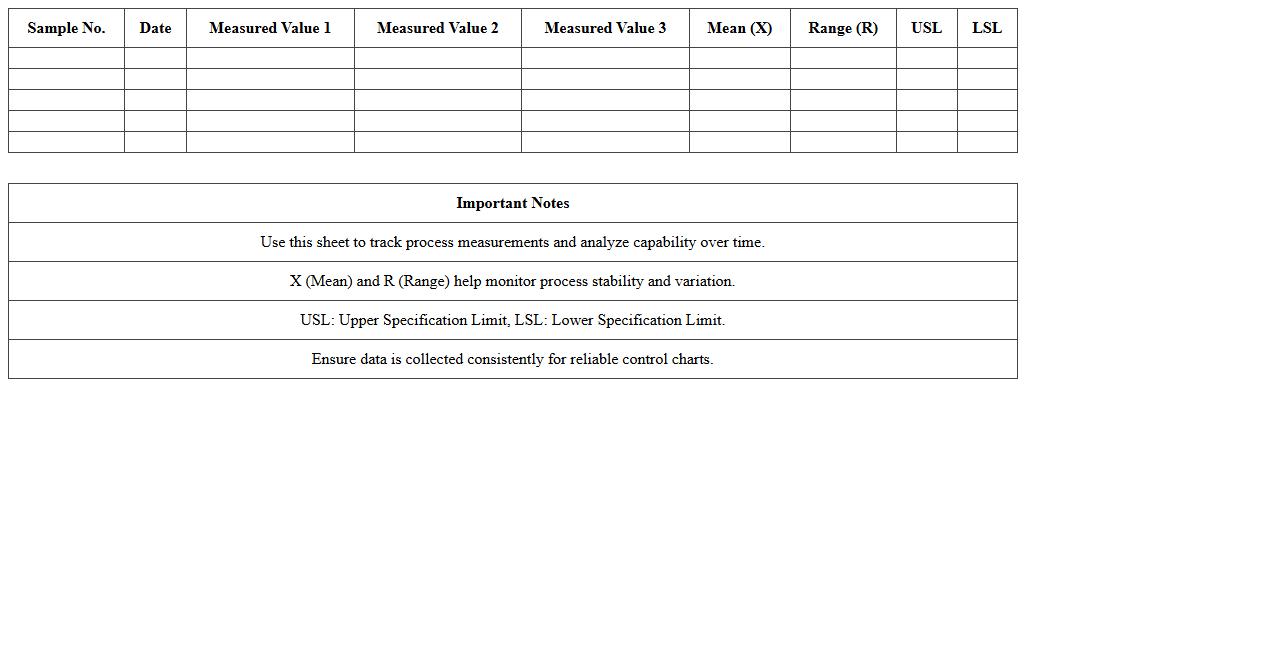

X-Bar and R Control Chart Template for Manufacturing

The

X-Bar and R Control Chart Template for manufacturing is a statistical tool used to monitor the stability and consistency of production processes by tracking sample means (X-Bar) and ranges (R) over time. It helps identify variations within the manufacturing process, allowing for early detection of anomalies or deviations from quality standards. Using this template improves process control, reduces defects, and supports continuous quality improvement in manufacturing operations.

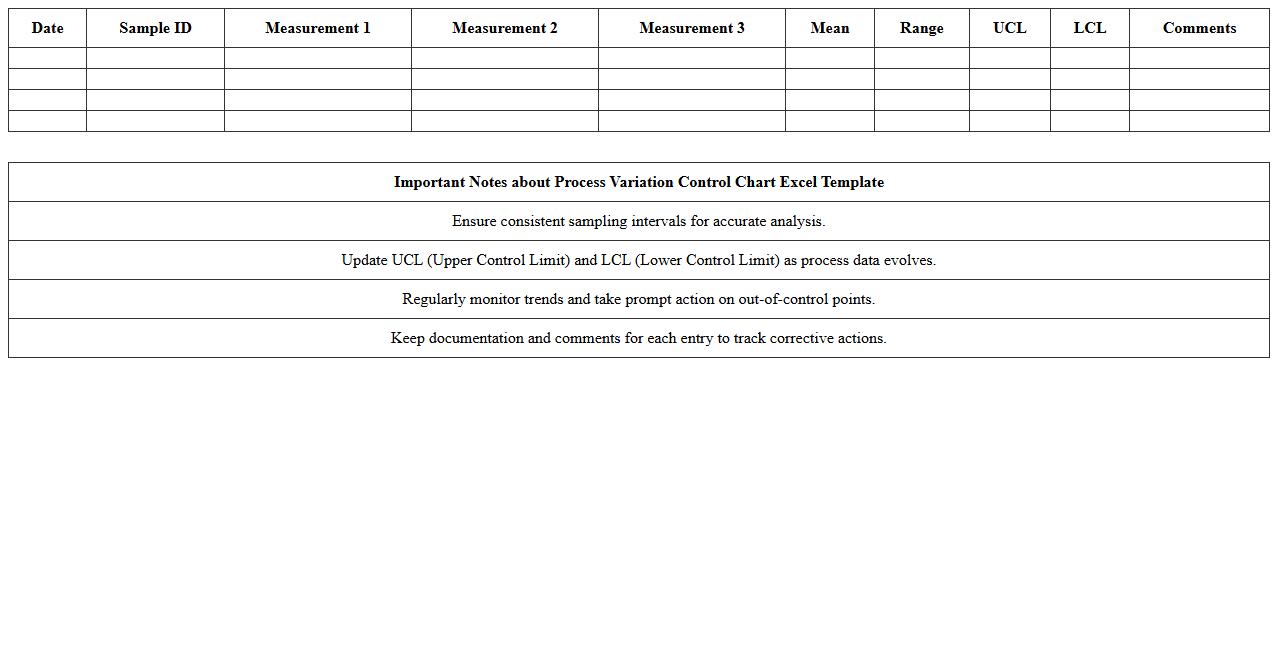

Process Variation Control Chart Excel Template

The

Process Variation Control Chart Excel Template document is a tool designed to monitor and analyze variations in manufacturing or business processes using control charts. It helps identify trends, shifts, or any unusual patterns in process data, enabling proactive quality management and timely corrective actions. By visualizing process stability and detecting variation sources, this template supports improved decision-making and consistent product or service quality.

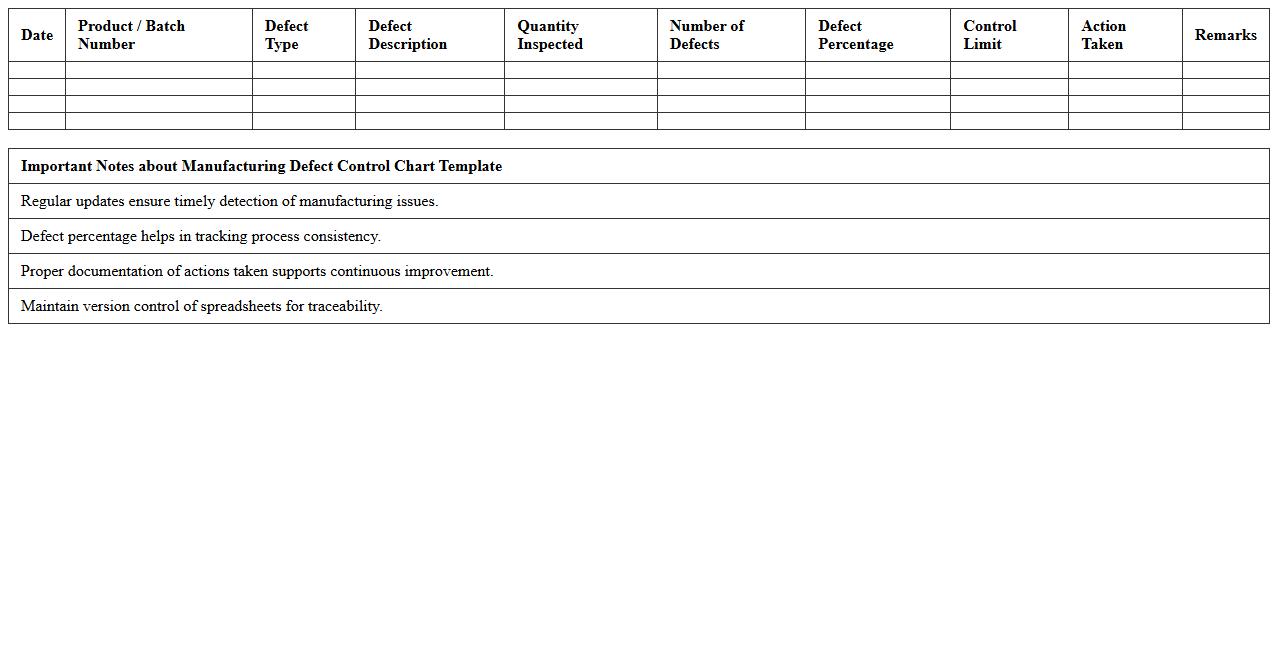

Manufacturing Defect Control Chart Excel Spreadsheet

The

Manufacturing Defect Control Chart Excel Spreadsheet is a tool designed to monitor and analyze defect rates in production processes, enabling quality control teams to identify variations and trends over time. This document provides a visual representation of defect data, facilitating quick detection of out-of-control processes and helping maintain consistent product quality. By leveraging this spreadsheet, manufacturers can implement timely corrective actions, reduce waste, and improve overall operational efficiency.

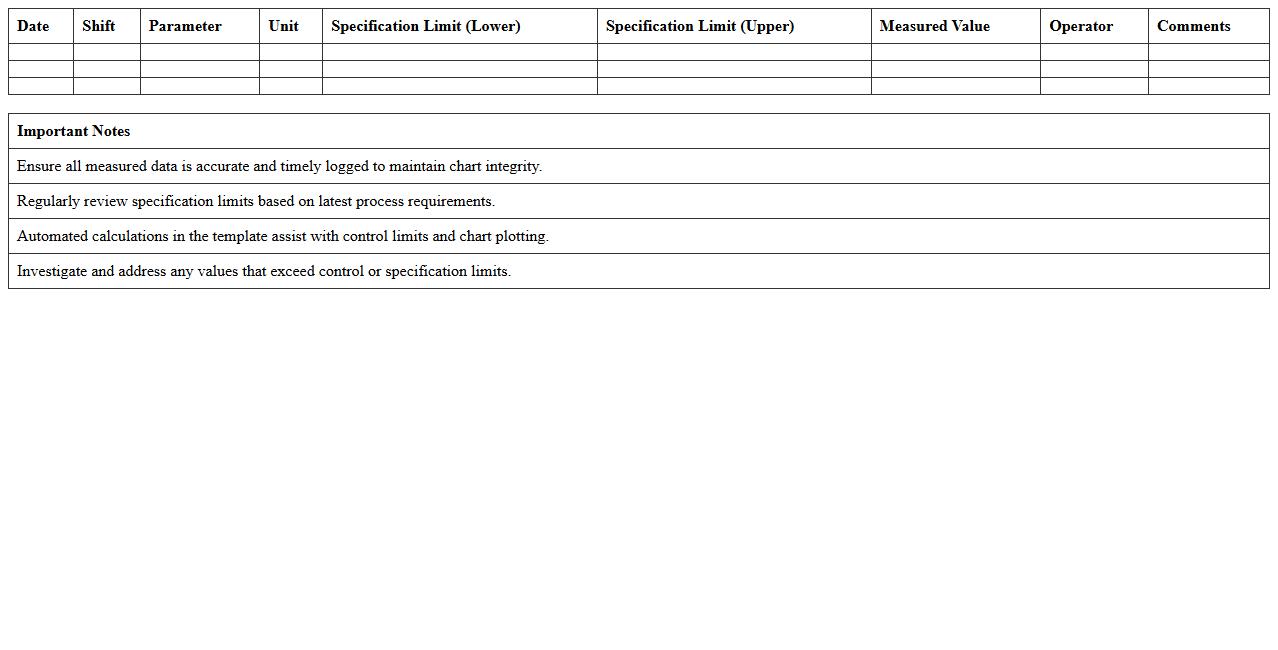

Automated Control Chart Excel Template for Factories

The

Automated Control Chart Excel Template for factories is a pre-designed spreadsheet tool that streamlines the process of monitoring production quality by automatically plotting control charts based on real-time data inputs. This template helps identify variations, trends, and outliers in manufacturing processes, enabling rapid decision-making to maintain consistent product standards. By reducing manual chart creation time and minimizing human error, it enhances operational efficiency and supports continuous improvement initiatives in factory settings.

Process Capability Control Chart Excel Template

The

Process Capability Control Chart Excel Template document is a structured tool designed to analyze and monitor manufacturing or business process performance by displaying process capability indices such as Cp, Cpk, and control limits in an easily readable format. It enables users to identify variations, detect trends, and ensure that processes consistently produce outputs within specified tolerance levels, leading to improved quality control and operational efficiency. By automating data visualization and calculations, this template helps organizations make informed decisions to maintain compliance with industry standards and reduce defect rates.

Real-Time Manufacturing Control Chart Excel Tracker

The

Real-Time Manufacturing Control Chart Excel Tracker is a dynamic document designed to monitor and analyze production processes by capturing live data on key manufacturing metrics such as cycle time, defect rates, and output levels. It enables manufacturers to identify trends, detect anomalies, and make data-driven decisions promptly to improve efficiency and reduce downtime. By providing a visual representation of performance metrics in real time, this tool helps maintain quality control, optimize workflows, and boost overall operational productivity.

Control Limits Analysis Excel Template for Manufacturing

The

Control Limits Analysis Excel Template for manufacturing is a specialized tool designed to monitor and analyze production process variations by calculating upper and lower control limits based on real-time data. This template enables manufacturers to identify deviations from standard quality parameters, ensuring timely interventions to maintain product consistency and reduce defects. By visualizing control charts and statistical calculations within Excel, it streamlines decision-making and enhances process capability analysis, ultimately improving operational efficiency.

How to automate control chart updates in Excel for real-time manufacturing data?

To automate control chart updates in Excel for real-time data, use dynamic named ranges linked to your manufacturing data. Incorporate Excel's Table feature to expand data ranges automatically as new data arrives. Combine this with Excel VBA or Power Query to refresh data and charts continuously without manual intervention.

Which Excel formulas are best for calculating control limits in variable manufacturing processes?

The best Excel formulas for control limits involve standard deviation and average calculations, such as =AVERAGE() and =STDEV.P() or =STDEV.S(). Calculate Upper Control Limit (UCL) and Lower Control Limit (LCL) using the formulas: UCL = Average + 3*StdDev, LCL = Average - 3*StdDev. These formulas adapt well to variable manufacturing processes by reflecting process variability accurately.

How can out-of-specification points be flagged automatically in an Excel control chart?

Out-of-specification points can be flagged by applying conditional formatting rules based on control limits in your control chart. Use formulas like =OR(value>UCL, value

What is the most efficient way to import sensor data into Excel for SPC control charts?

The most efficient method to import sensor data into Excel is through Power Query or connecting Excel directly to data sources such as CSV files, databases, or IoT platforms. Automate data refresh schedules for near real-time updates and create streamlined workflows that eliminate manual import errors. Leveraging APIs or ODBC connections ensures reliable and continuous data flow for SPC control charts.

How to create a multi-process control chart dashboard in Excel for different manufacturing lines?

Design a multi-process control chart dashboard by using Excel's PivotTables and PivotCharts to summarize and visualize data from various manufacturing lines. Employ slicers and drop-down menus to filter and switch between different process data dynamically. Integrate VBA macros or Power BI for enhanced interactivity and real-time dashboard automation, providing comprehensive monitoring of multiple processes.