The Material Cost Calculation Excel Template for Manufacturing streamlines the process of estimating expenses by organizing raw material data efficiently. This template allows manufacturers to input quantities, unit prices, and total costs, facilitating accurate budgeting and cost control. Designed for user-friendliness, it enhances financial planning and improves decision-making in production workflows.

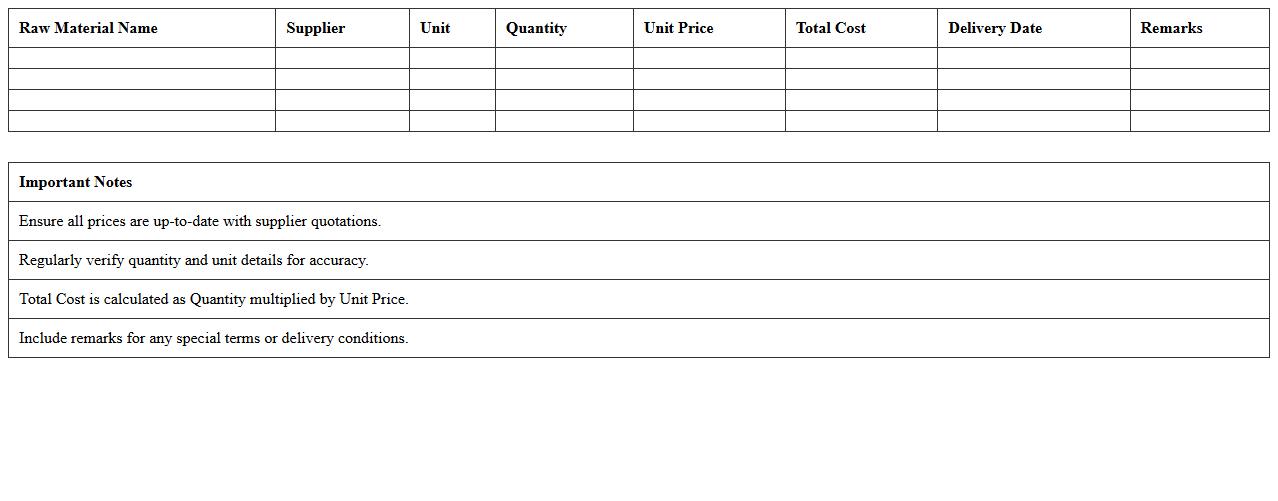

Raw Material Cost Analysis Excel Template

A

Raw Material Cost Analysis Excel Template is a structured spreadsheet designed to track and evaluate the expenses associated with purchasing and using raw materials in production. It allows businesses to monitor cost fluctuations, calculate total material costs, and identify areas for cost reduction, enhancing budget control and operational efficiency. Utilizing this template improves financial planning and supports data-driven decision-making for procurement and inventory management.

Manufacturing Material Expense Tracker

A

Manufacturing Material Expense Tracker document is a tool designed to record and monitor the costs associated with raw materials used in production. It provides detailed insights into material consumption, helping businesses manage budgets effectively and identify cost-saving opportunities. By maintaining accurate expense records, companies can enhance financial planning and improve operational efficiency.

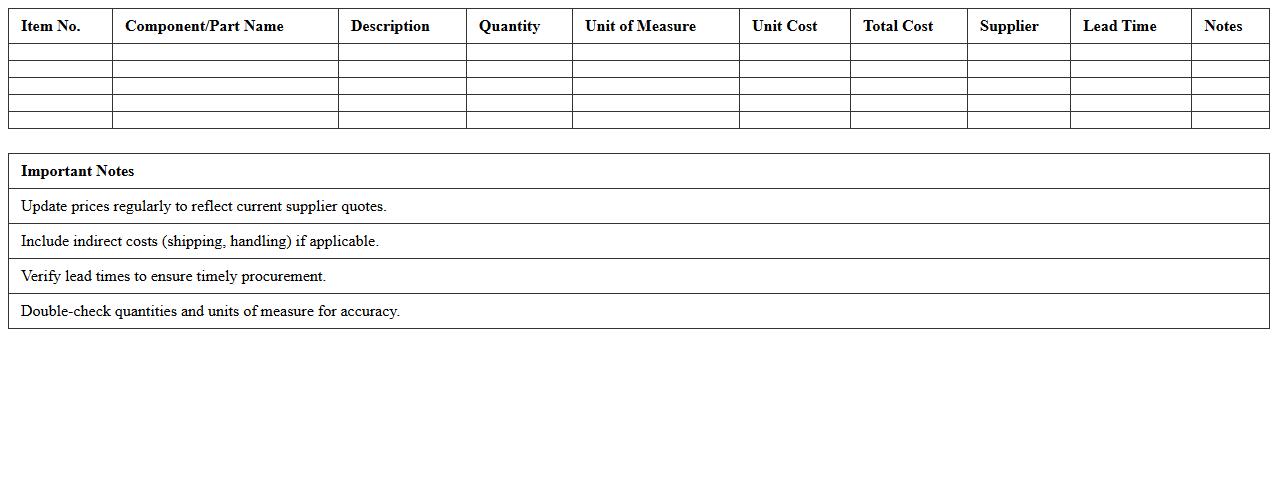

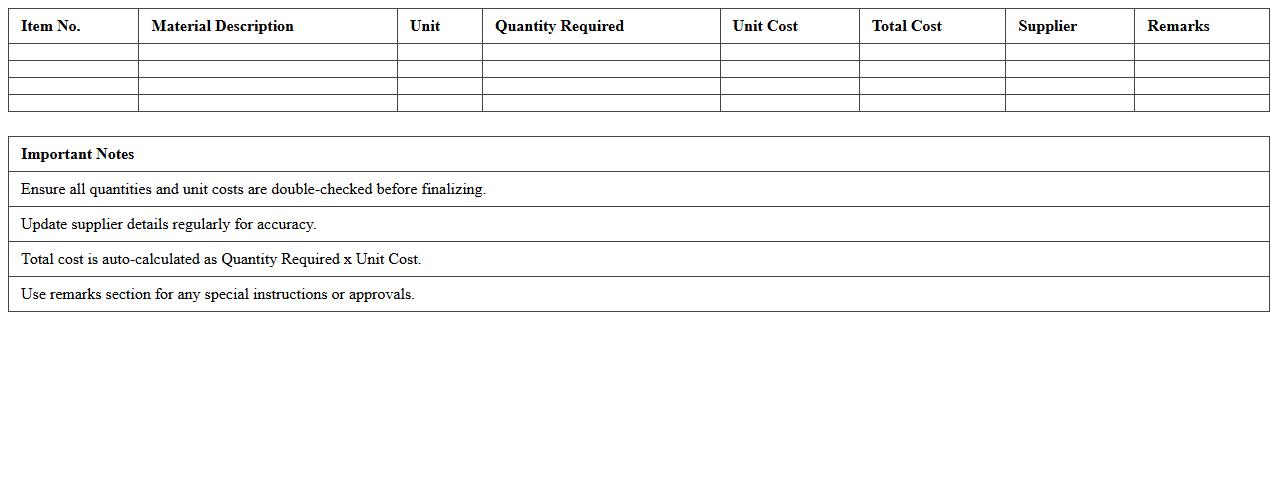

Bill of Materials Costing Spreadsheet

A

Bill of Materials Costing Spreadsheet is a detailed document that itemizes all components, quantities, and associated costs required to manufacture a product. This spreadsheet helps businesses accurately calculate total production expenses, optimize budgeting, and manage inventory effectively. By providing clear visibility into material costs, it supports informed decision-making and enhances cost control throughout the manufacturing process.

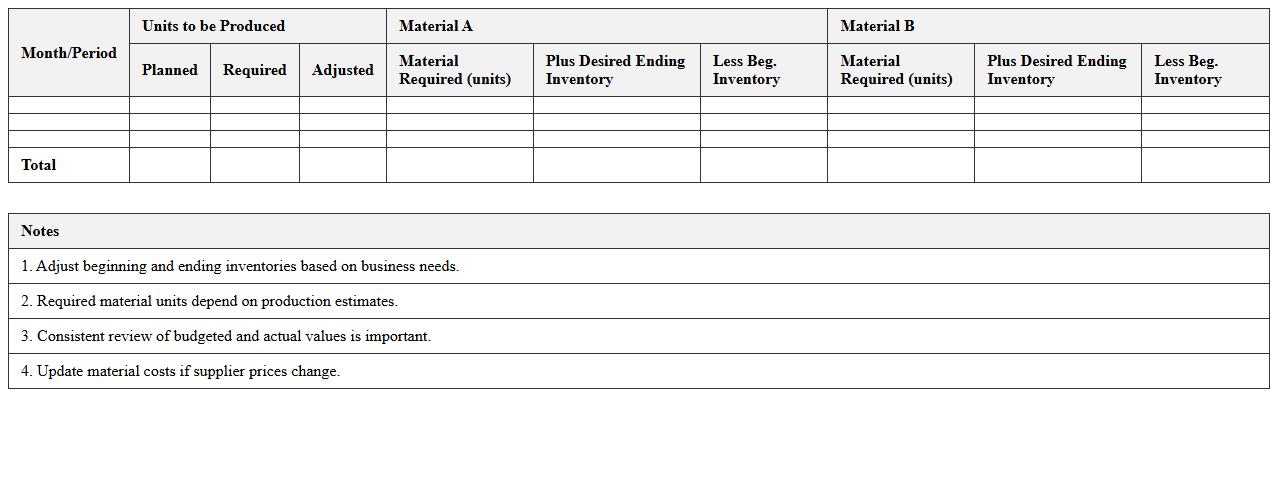

Production Material Budget Calculator

The

Production Material Budget Calculator document is a tool designed to estimate and manage the costs of raw materials required for manufacturing processes. It helps businesses accurately forecast material expenses by analyzing production volumes, material prices, and inventory levels, enabling better financial planning and resource allocation. This calculator ensures cost control, reduces waste, and supports efficient budgeting, ultimately improving overall production profitability.

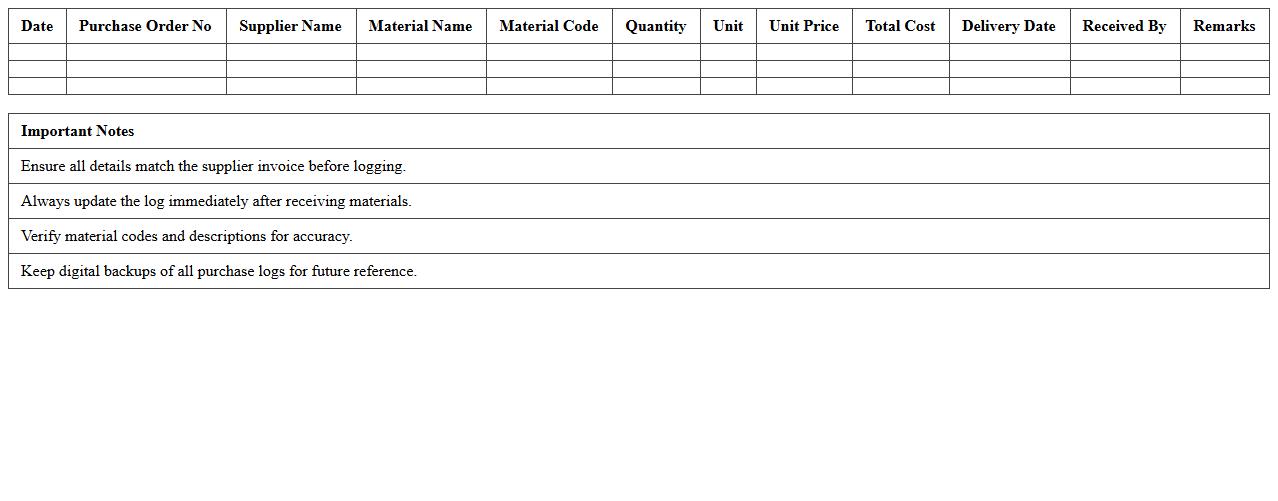

Factory Material Purchase Log Template

The

Factory Material Purchase Log Template is a structured document used to systematically record details of materials procured for factory operations, including item descriptions, quantities, supplier information, prices, and purchase dates. This template helps maintain accurate purchase records, streamline inventory management, and monitor expenditure effectively, ensuring transparency and accountability in the procurement process. Using this log template enhances operational efficiency by facilitating timely material tracking and minimizing supply chain disruptions.

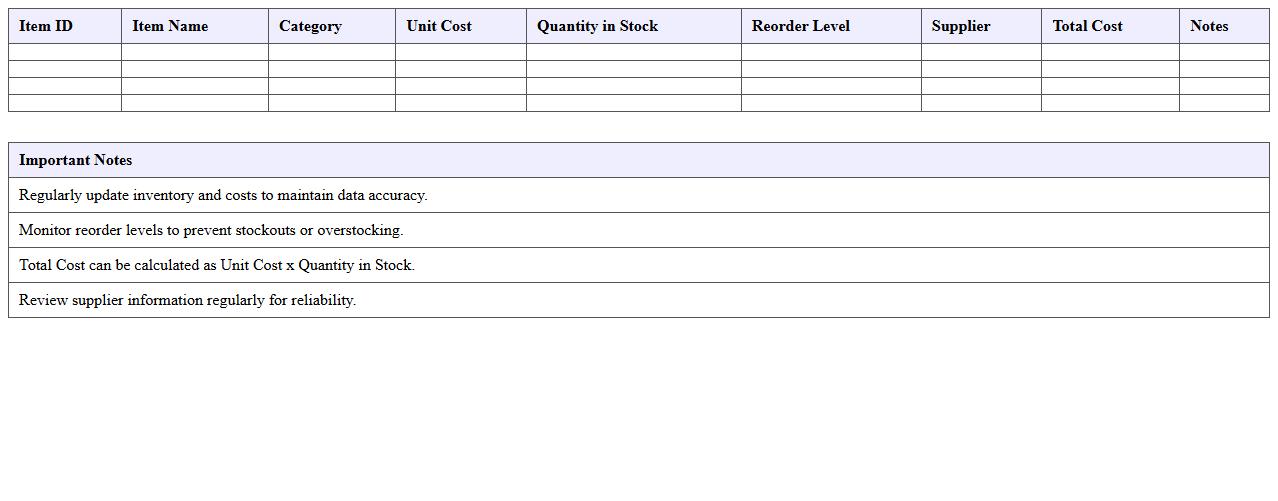

Manufacturing Inventory and Cost Estimator

The

Manufacturing Inventory and Cost Estimator document is a detailed tool that tracks the quantities and costs of raw materials, work-in-progress, and finished goods in a manufacturing process. It helps businesses accurately forecast production expenses, optimize inventory levels, and improve budgeting efficiency. This document is essential for making informed decisions that enhance cost control and resource allocation in manufacturing operations.

Material Cost Breakdown Excel Sheet

A

Material Cost Breakdown Excel Sheet document itemizes the expenses associated with each material used in a project, providing a detailed overview of cost distribution. This sheet helps businesses and project managers accurately track and manage material budgets, ensuring better financial control and forecasting. It is essential for identifying cost-saving opportunities and minimizing resource wastage.

Consumable Material Cost Tracking Template

A

Consumable Material Cost Tracking Template is a structured document that helps monitor and record expenses related to consumable materials used in projects or operations. It enables accurate budget management by providing detailed insights into material usage, costs, and supplier information, facilitating cost control and financial forecasting. This template is useful for businesses aiming to optimize resource allocation and minimize unnecessary expenditure on supplies.

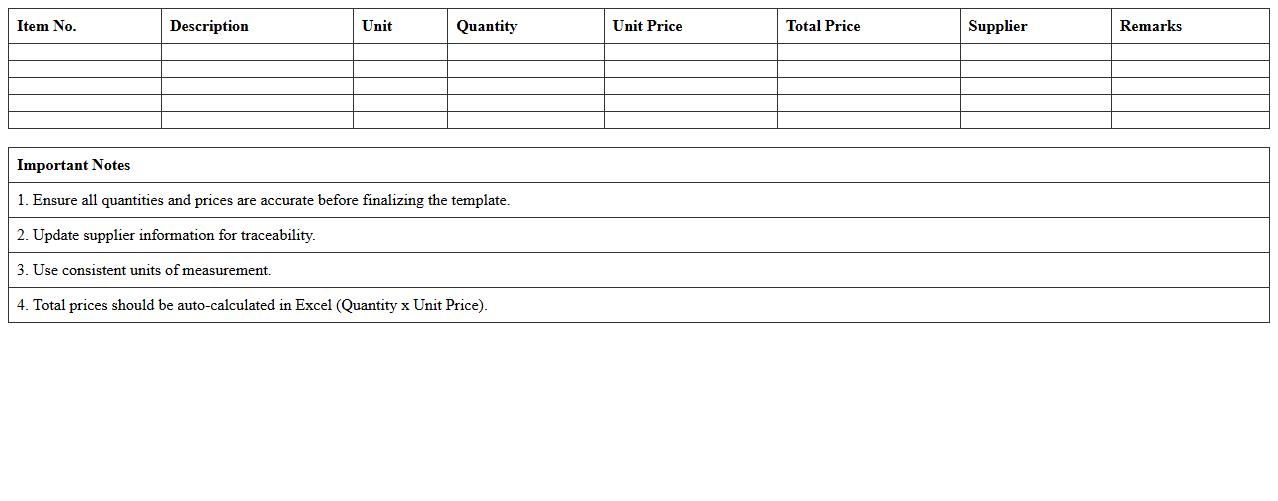

Excel Template for Itemized Material Pricing

An

Excel Template for Itemized Material Pricing is a structured spreadsheet designed to organize and calculate costs for each material used in a project or product. It facilitates precise budgeting by allowing users to input quantities, unit prices, and total costs for individual materials, improving financial tracking and cost management. This template enhances accuracy and efficiency in procurement processes, helping businesses maintain control over expenses and streamline project costing.

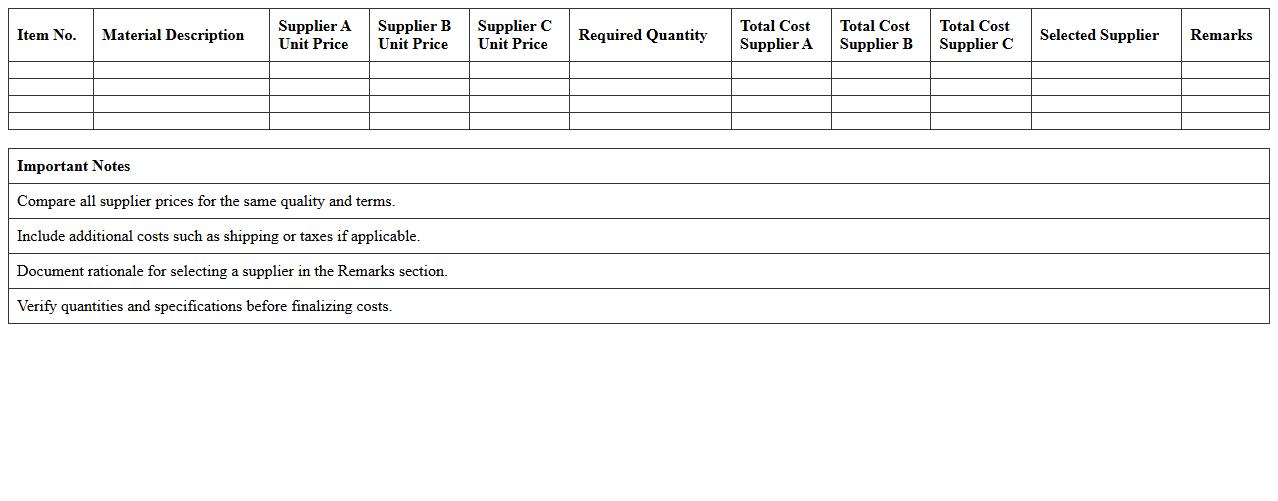

Direct Material Cost Comparison Worksheet

A

Direct Material Cost Comparison Worksheet is a document used to analyze and compare the costs of raw materials across different suppliers or purchase periods. It helps businesses identify cost-saving opportunities by highlighting price variations and assessing quality differences. This worksheet streamlines budgeting and procurement decisions, ensuring more efficient and cost-effective material sourcing.

How can I automate BOM (Bill of Materials) cost roll-ups in Excel for custom products?

To automate BOM cost roll-ups, use Excel's SUMPRODUCT formula to multiply component quantities by unit prices efficiently. Structuring your BOM data in a tabular format enables easy updates and accurate total cost calculations. Additionally, implement named ranges to simplify formula management, especially for custom products with varying components.

Which Excel formulas best track real-time material price fluctuations in manufacturing sheets?

The VLOOKUP and INDEX-MATCH formulas are essential for retrieving up-to-date prices from dynamic material price tables. Incorporating the TODAY() function helps maintain date-sensitive data, ensuring price tracking reflects current market conditions. To handle volatile prices, use conditional formatting for alerts when material costs exceed predefined thresholds.

What is the most efficient way to link supplier price lists to my material cost calculation document?

Link supplier price lists using Excel's Power Query to import and refresh external data sources automatically. Establishing dynamic connections ensures your cost calculations stay synchronized with supplier updates without manual intervention. Furthermore, setting refresh schedules optimizes efficiency and accuracy in your costing document.

How do I handle waste and scrap value adjustments in Excel material costing templates?

Incorporate waste and scrap by adding adjustment columns that calculate percentage-based losses within your costing templates. Use formulas like =(Quantity * Unit Cost) * (1 + Waste Percentage) to factor these costs directly into total material expenses. This systematic approach guarantees that your financial estimates align with actual manufacturing conditions.

Can Excel Power Query streamline import of material data from my ERP into costing sheets?

Excel Power Query is an effective tool for automating the import of material data from ERP systems into your costing sheets. It supports various data formats and enables transformation and cleaning before loading data into Excel, making integration seamless. Utilizing Power Query reduces manual data entry errors and enhances real-time cost analysis accuracy.

More Calculation Excel Templates