The Quality Control Audit Excel Template for Food Processing Plants streamlines the evaluation of production processes by organizing inspection data clearly and efficiently. This template helps identify compliance gaps, track corrective actions, and ensure food safety standards are consistently met. Customizable fields allow seamless adaptation to specific plant requirements, enhancing operational quality management.

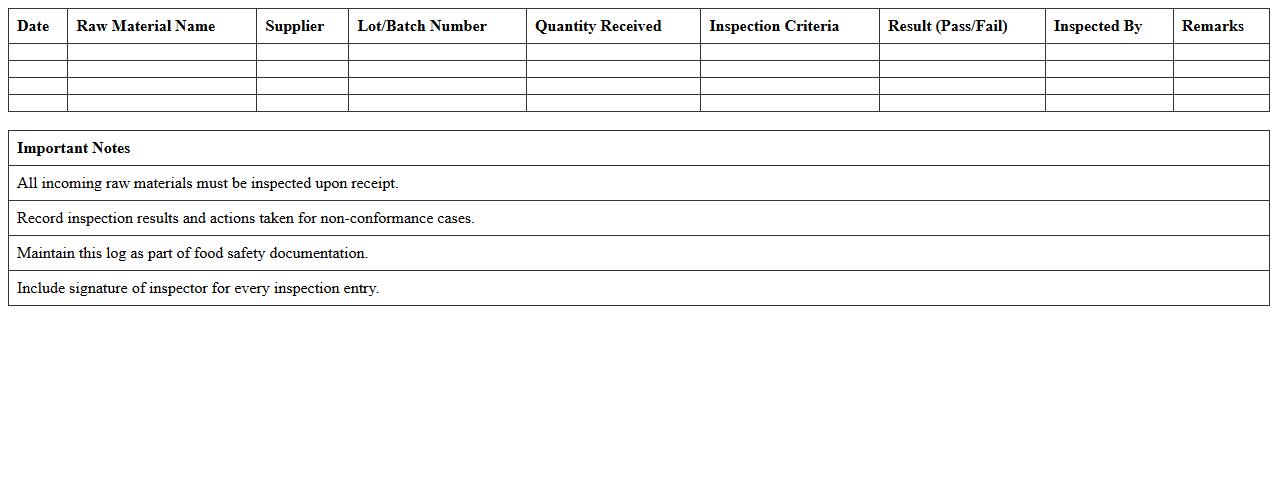

Raw Material Inspection Log Excel Template for Food Plants

The

Raw Material Inspection Log Excel Template for Food Plants is a structured document designed to record and track the quality and compliance of raw materials received at food manufacturing facilities. It facilitates systematic documentation of inspection dates, supplier details, batch numbers, and quality parameters, ensuring adherence to safety standards and regulatory requirements. Utilizing this template enhances traceability, minimizes contamination risks, and supports efficient inventory management in food production processes.

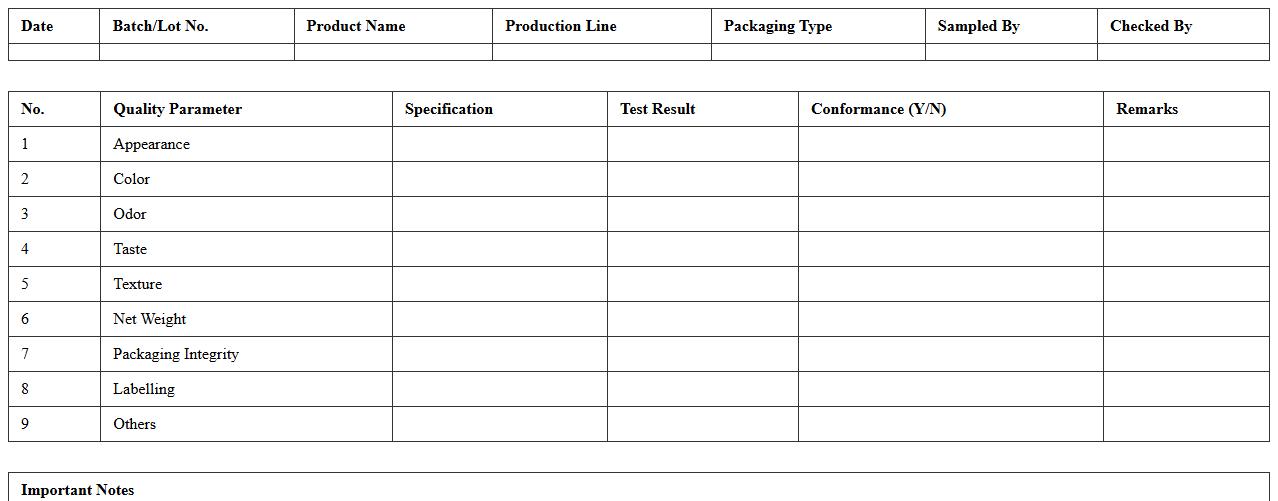

Finished Product Quality Audit Sheet for Food Processing

The

Finished Product Quality Audit Sheet in food processing is a critical document used to systematically evaluate the final product's compliance with established quality standards, including appearance, texture, flavor, and safety parameters. It serves as a comprehensive checklist that helps identify any deviations or defects before product release, ensuring consistency and regulatory compliance. By using this audit sheet, manufacturers can reduce the risk of recalls, improve customer satisfaction, and maintain brand integrity through rigorous quality control.

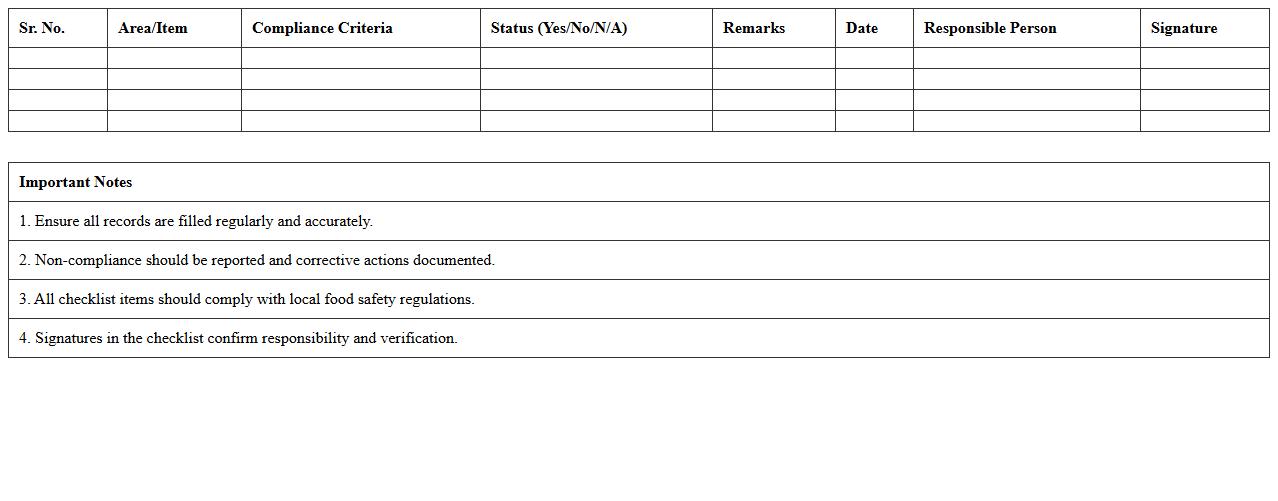

Food Safety Compliance Checklist Excel Format

A

Food Safety Compliance Checklist Excel Format document is a structured template designed to systematically track and ensure adherence to food safety standards and regulations in food handling, storage, and preparation processes. It allows businesses to efficiently monitor critical control points, identify potential hazards, and document corrective actions, thereby reducing the risk of contamination and foodborne illnesses. Utilizing this checklist enhances operational transparency, supports regulatory audits, and promotes a culture of continuous food safety improvement within an organization.

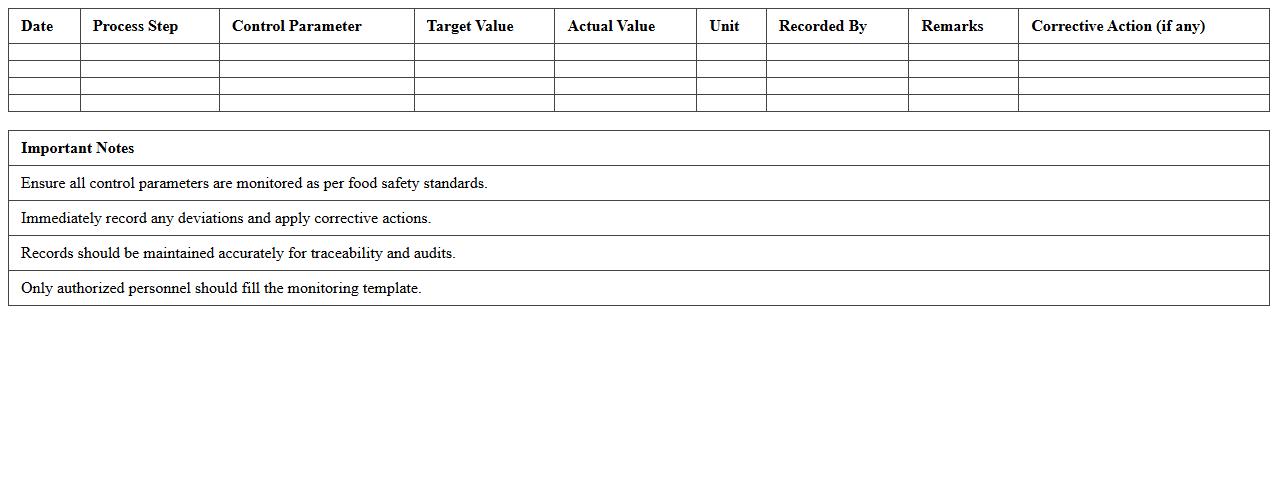

Process Control Monitoring Excel Template for Food Industry

The

Process Control Monitoring Excel Template for Food Industry is a structured tool designed to track and analyze critical production parameters such as temperature, humidity, and sanitation compliance in real-time. This template enables food manufacturers to maintain consistent product quality, ensure regulatory compliance, and identify deviations promptly to prevent contamination or spoilage. Using this document streamlines data collection and reporting, enhancing operational efficiency and food safety management.

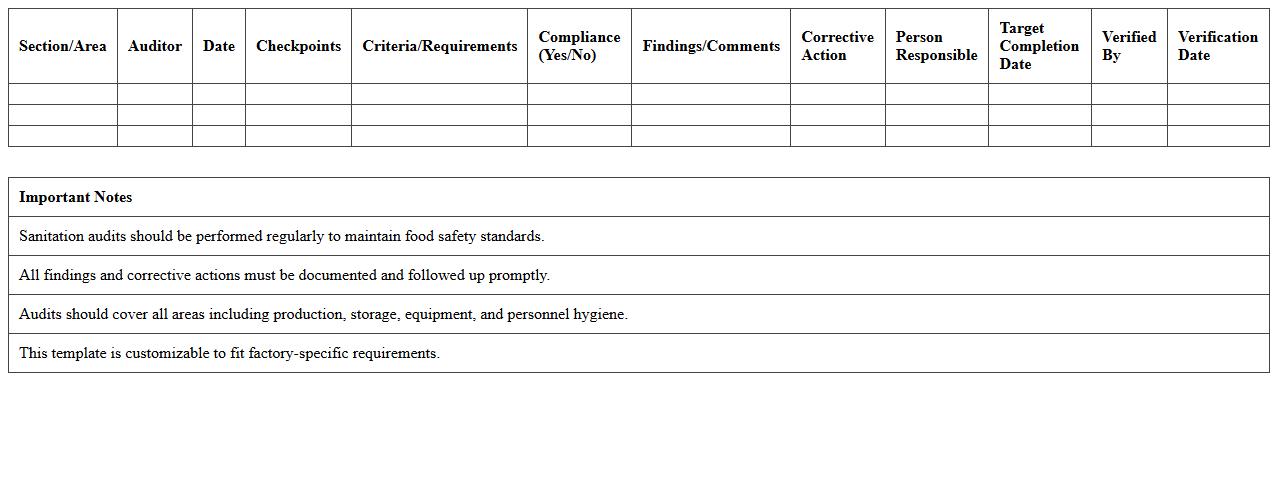

Sanitation Audit Report Excel Template for Food Factories

The

Sanitation Audit Report Excel Template for Food Factories is a structured document designed to systematically evaluate cleanliness and hygiene standards in food production environments. It helps identify potential contamination risks, ensures compliance with food safety regulations, and facilitates organized record-keeping for continuous improvement. Using this template streamlines auditing processes, making it easier to track sanitation performance and implement corrective actions efficiently.

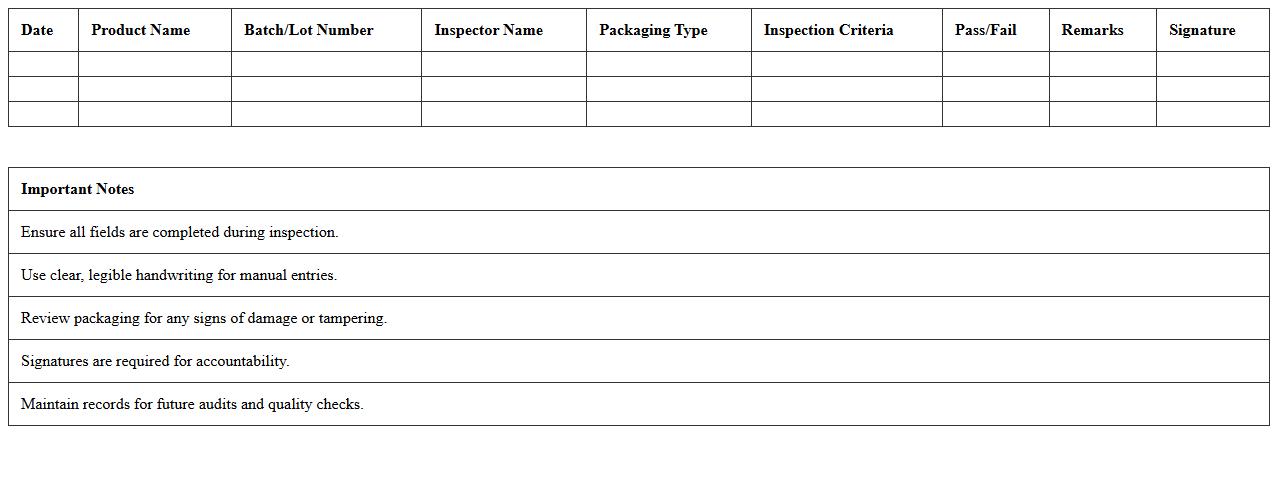

Packaging Quality Inspection Excel Spreadsheet

The

Packaging Quality Inspection Excel Spreadsheet document is a structured tool designed to systematically record and evaluate packaging components against predefined quality standards. It enables easier tracking of defects, consistency in inspection processes, and quick data analysis for ensuring compliance with industry regulations. This spreadsheet enhances decision-making by providing clear insights into packaging quality, ultimately reducing product returns and improving customer satisfaction.

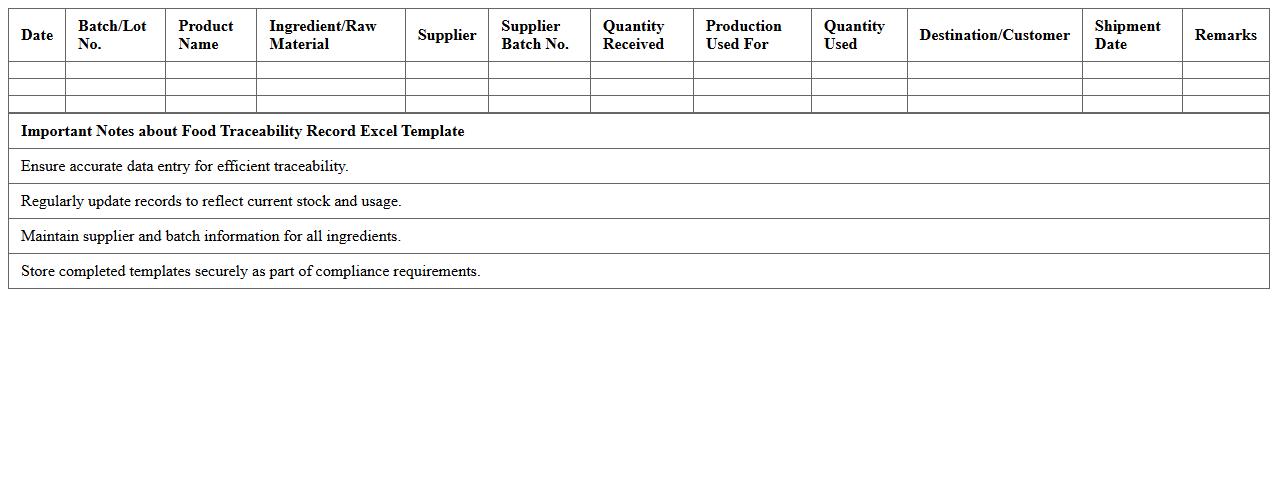

Food Traceability Record Excel Template

The

Food Traceability Record Excel Template is a structured document designed to track and document the movement of food products through the supply chain from origin to final destination. It helps ensure compliance with food safety standards, enhances transparency, and facilitates quick identification of contaminated batches during recalls. Using this template improves inventory management, supports regulatory audits, and strengthens consumer trust by maintaining accurate and accessible traceability data.

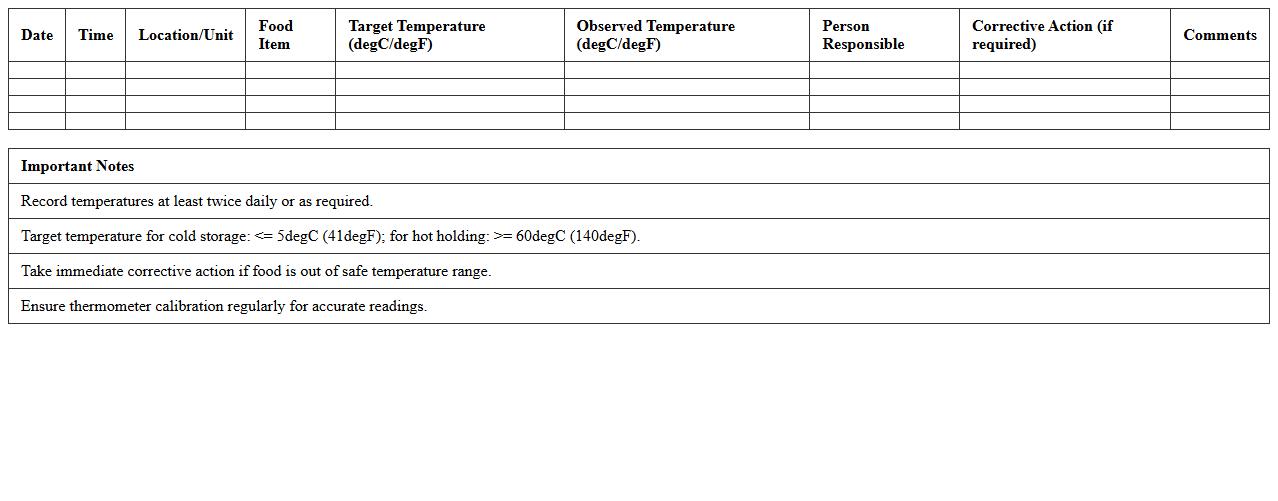

Temperature Control Log Sheet Excel for Food Storage

A

Temperature Control Log Sheet Excel for Food Storage is a digital document designed to record and monitor temperature readings of food storage units consistently. It helps ensure compliance with food safety regulations by tracking temperature fluctuations, preventing food spoilage, and maintaining optimal storage conditions. This tool is essential for food businesses to maintain hygiene standards, reduce waste, and protect consumer health.

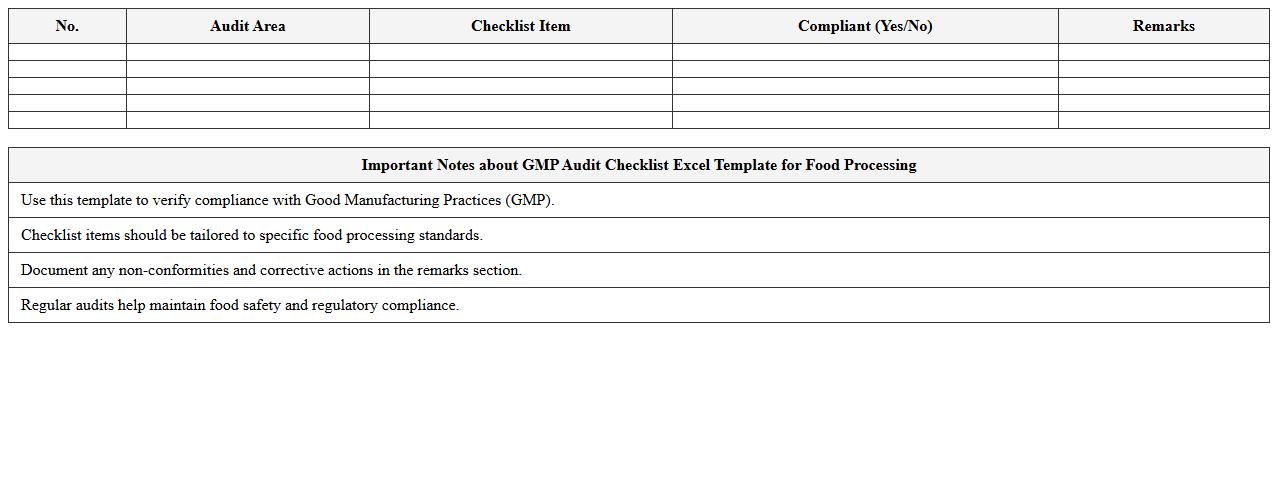

GMP Audit Checklist Excel Template for Food Processing

The

GMP Audit Checklist Excel Template for Food Processing is a structured tool designed to ensure compliance with Good Manufacturing Practices in food production facilities. It systematically guides users through critical checkpoints such as hygiene standards, equipment maintenance, and safety protocols, facilitating thorough internal audits. This template enhances operational efficiency by identifying potential risks early, ensuring product quality, and supporting regulatory adherence in food processing environments.

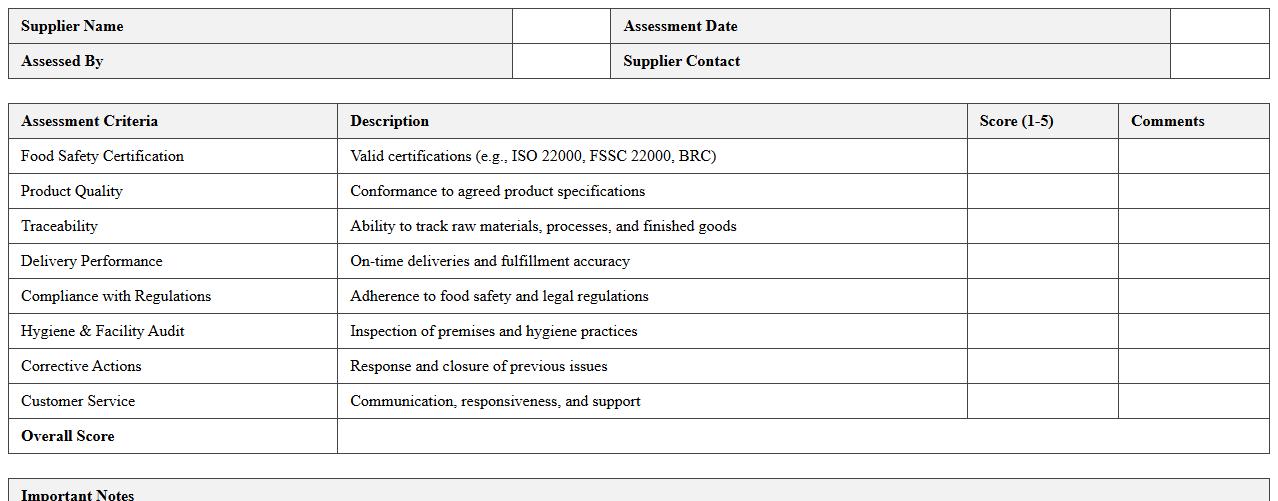

Supplier Quality Assessment Template for Food Manufacturing

A

Supplier Quality Assessment Template for Food Manufacturing is a standardized document designed to evaluate and monitor the quality standards of suppliers in the food industry. It helps ensure that raw materials and ingredients meet regulatory requirements and company specifications, reducing the risk of contamination and non-compliance. This template streamlines supplier audits, facilitates consistent quality control, and supports maintaining high safety standards throughout the supply chain.

How is critical control point data verified for accuracy in QC Audit Excel sheets?

Critical control point data is verified through cross-referencing logged values with preset acceptable limits. Audit trails are maintained to ensure data integrity and support traceability. Automated formulas highlight discrepancies to prompt immediate review.

Which columns track non-conformance trends in finished product inspections?

The columns labeled Defect Type, Frequency, and Inspection Date capture non-conformance trends. These data points help identify recurring issues and their patterns over time. Visual aids like conditional formatting highlight critical deviations.

What formulas are used to calculate defect rates per batch in the audit log?

Defect rates are calculated using formulas like =COUNTIF(range, "Defect")/TotalUnits per batch. This provides a clear percentage measure of defects relative to units inspected. Such formulas are embedded to automate continuous monitoring of quality performance.

How are supplier certificate expiries flagged in QC tracking spreadsheets?

Expiry dates are monitored with conditional formatting rules that highlight certificates nearing expiration. Formulas calculate the days remaining to expiry and trigger alerts if below a threshold. This ensures timely action for certificate renewals.

What data validations prevent entry of incorrect temperature values in process logs?

Data validation rules restrict temperature entries within predefined minimum and maximum thresholds. Dropdown lists and input masks further ensure consistent and accurate data capture. Errors are prevented by immediate warning prompts when invalid data is entered.

More Audit Excel Templates