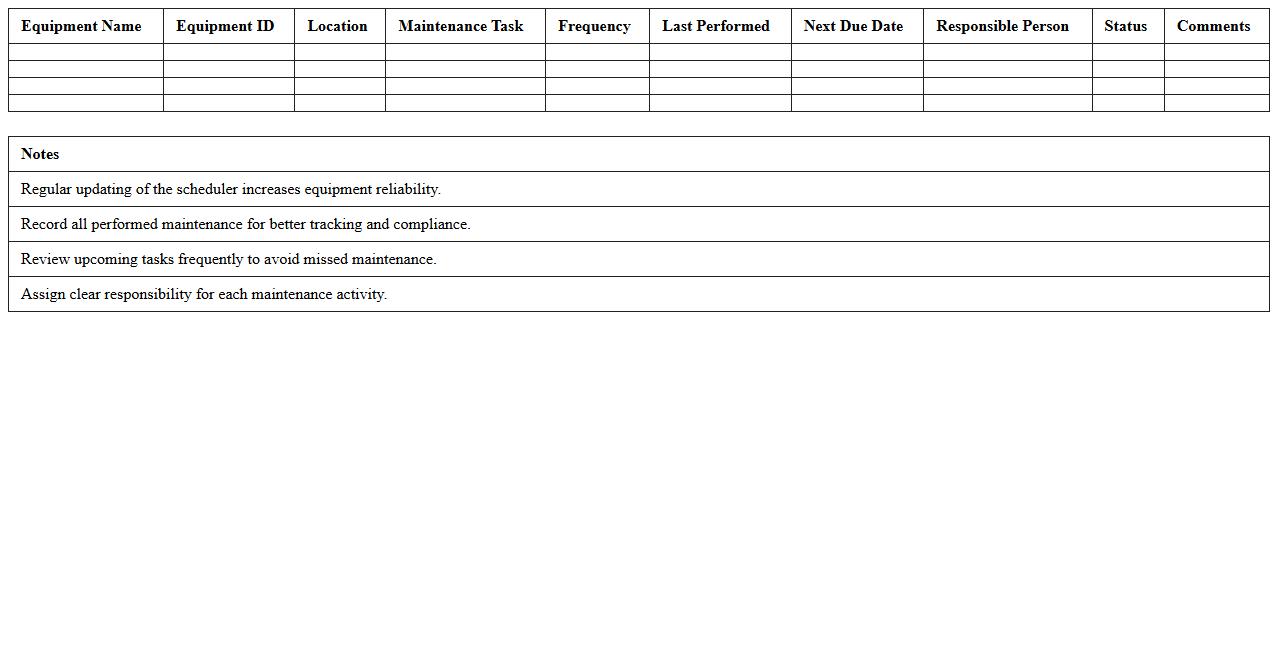

Preventive Maintenance Scheduler Excel Template for Manufacturing Equipment

The

Preventive Maintenance Scheduler Excel Template for manufacturing equipment is a tool designed to organize and track maintenance tasks systematically, ensuring timely inspections and repairs. It helps reduce unexpected downtime by scheduling routine checks and documenting equipment performance, which enhances operational efficiency and extends machinery lifespan. Utilizing this template improves resource planning and supports compliance with safety standards, ultimately optimizing production continuity.

Manufacturing Plant Equipment Downtime Log Excel Template

The

Manufacturing Plant Equipment Downtime Log Excel Template is a structured document that tracks machinery stoppages, recording the duration, causes, and impact on production. This template enables efficient identification of recurring problems, facilitating maintenance scheduling and minimizing unplanned downtime. By analyzing downtime data, manufacturers can enhance equipment reliability, optimize workflows, and improve overall operational efficiency.

Machine Maintenance Checklist Tracker Excel Sheet

A

Machine Maintenance Checklist Tracker Excel Sheet document is a structured tool designed to systematically record and monitor the maintenance schedules and tasks for machinery. It allows users to log details such as inspection dates, maintenance activities, parts replacements, and operational status, ensuring timely upkeep and minimizing downtime. Utilizing this tracker improves equipment reliability, extends machine lifespan, and supports proactive management of maintenance workflows.

Spare Parts Inventory and Maintenance Log Excel Template

The

Spare Parts Inventory and Maintenance Log Excel Template is a comprehensive tool designed to organize and track spare parts and maintenance activities efficiently. It allows users to monitor stock levels, record usage, schedule maintenance tasks, and maintain detailed logs, ensuring timely replacements and reducing downtime. This template enhances operational efficiency by providing clear visibility into inventory status and maintenance history, aiding in cost control and asset management.

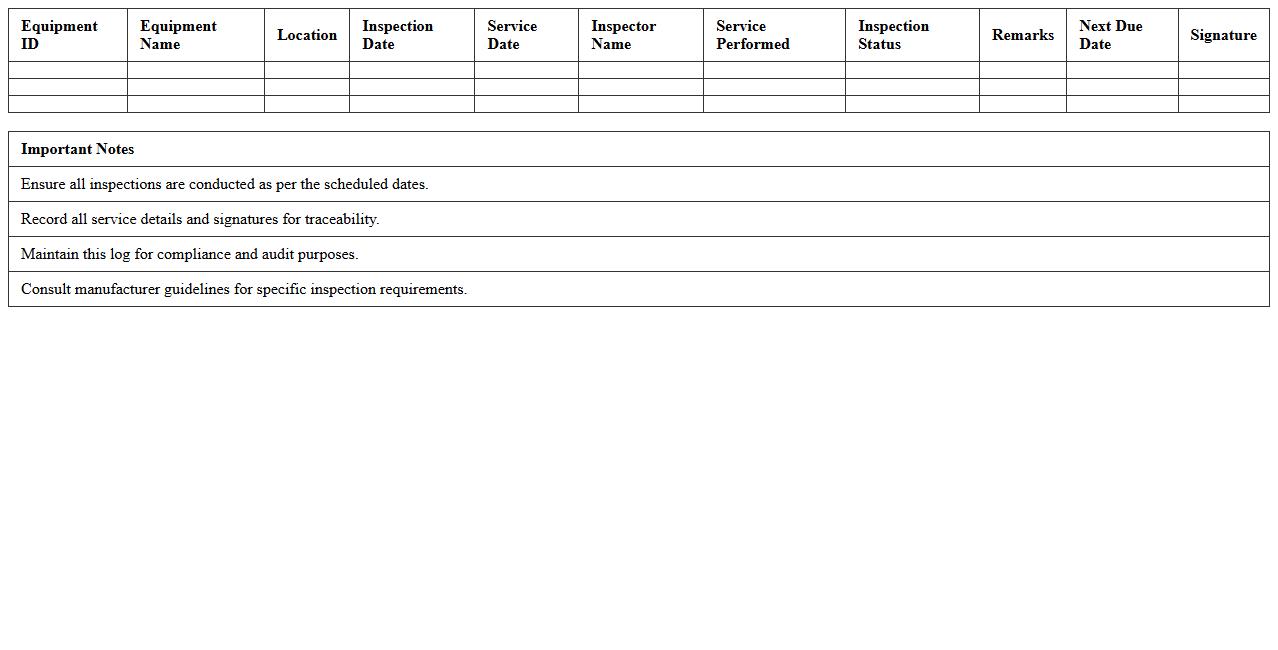

Equipment Inspection and Service Record Excel Template for Manufacturing

The

Equipment Inspection and Service Record Excel Template for manufacturing is a structured document designed to track the maintenance, inspection dates, and service history of machinery and equipment. It helps ensure compliance with safety standards, reduces downtime by scheduling timely inspections, and extends the lifespan of manufacturing assets. By organizing data in a clear, customizable format, this template enhances operational efficiency and supports preventive maintenance strategies.

Asset Lifecycle Management Excel Template for Plant Machinery

The

Asset Lifecycle Management Excel Template for Plant Machinery is a comprehensive tool designed to track and manage the entire lifespan of machinery assets from acquisition to disposal. It enables organizations to monitor maintenance schedules, downtime, operational costs, and depreciation, ensuring optimal utilization and extended equipment life. By providing data-driven insights, this template supports informed decision-making, reduces unexpected breakdowns, and enhances budgeting accuracy for plant operations.

Maintenance Request and Work Order Excel Tracker

The

Maintenance Request and Work Order Excel Tracker is a comprehensive tool designed to organize, monitor, and manage maintenance activities efficiently. It allows users to log requests, assign tasks, track progress, and record completion details in a centralized spreadsheet format. This tracker improves workflow transparency, enhances response times, and supports data-driven decision-making for facility management and operational teams.

Manufacturing Equipment Calibration Schedule Excel Template

The

Manufacturing Equipment Calibration Schedule Excel Template is a practical tool designed to organize and track calibration dates and details for manufacturing machinery, ensuring precise operation and compliance with industry standards. This template helps maintain equipment accuracy, reduces downtime, and prevents costly production errors by providing a clear timeline for calibration activities. Utilizing this document streamlines maintenance processes and supports quality control initiatives, ultimately improving operational efficiency.

Predictive Maintenance Analysis Dashboard Excel Sheet

The

Predictive Maintenance Analysis Dashboard Excel Sheet is a dynamic tool designed to monitor equipment performance and predict potential failures using historical data and real-time inputs. It helps businesses reduce downtime, optimize maintenance schedules, and extend asset life by providing actionable insights through visual charts and key performance indicators. This dashboard enhances decision-making by enabling proactive maintenance, thereby minimizing unexpected repair costs and improving overall operational efficiency.

Monthly Maintenance Cost Tracking Excel Template for Manufacturing Plant

The

Monthly Maintenance Cost Tracking Excel Template for Manufacturing Plants is a detailed spreadsheet designed to monitor and analyze maintenance expenses on a monthly basis. It helps plant managers track costs related to labor, parts, and equipment downtime, allowing for better budgeting and resource allocation. Utilizing this template enhances financial oversight, reduces unexpected maintenance costs, and supports efficient operational planning.

How can I automate downtime logging for equipment in Excel trackers?

To automate downtime logging in Excel, use VBA macros or Power Query to capture timestamps and calculate duration automatically. Integrate buttons or form controls to start and stop timers for logging downtime events easily. This method reduces manual input errors and improves the accuracy of equipment downtime tracking.

What Excel formulas best calculate preventive maintenance intervals for machinery?

Excel formulas like DATEDIF and EDATE are ideal for calculating preventive maintenance intervals based on last service dates. The formula =EDATE(last_service_date,interval_months) helps predict the next maintenance schedule automatically. Utilizing these functions ensures consistent tracking of preventive maintenance dates across multiple machines.

How do I visualize maintenance cost trends by equipment type within the spreadsheet?

Create pivot tables summarizing maintenance costs by equipment type and use Excel charts such as line or column charts to display trends over time. Conditional formatting can highlight cost spikes or anomalies effectively. This visual approach provides clear insights into cost trends for better budget management.

Which data validation methods improve accuracy in maintenance personnel entries?

Implement dropdown lists and data validation rules to restrict entries to predefined personnel names or IDs. Using Excel's data validation feature reduces input errors and inconsistencies in maintenance logs. This approach enhances data integrity for personnel-related records.

How can I link spare parts inventory tracking directly to equipment maintenance logs in Excel?

Use Excel's VLOOKUP or INDEX-MATCH functions to connect spare parts inventory data with maintenance logs dynamically. Create unique equipment IDs to cross-reference parts usage during repairs and update inventory levels automatically. This linkage improves transparency and streamlines inventory control linked to maintenance activities.

![]()