The Quality Control Summary Excel Template for Manufacturing Units streamlines the process of tracking inspection results and identifying defects efficiently. It offers customizable fields to record product details, test dates, and compliance status, ensuring consistent quality standards. This template enhances decision-making by providing clear visual summaries through charts and reports.

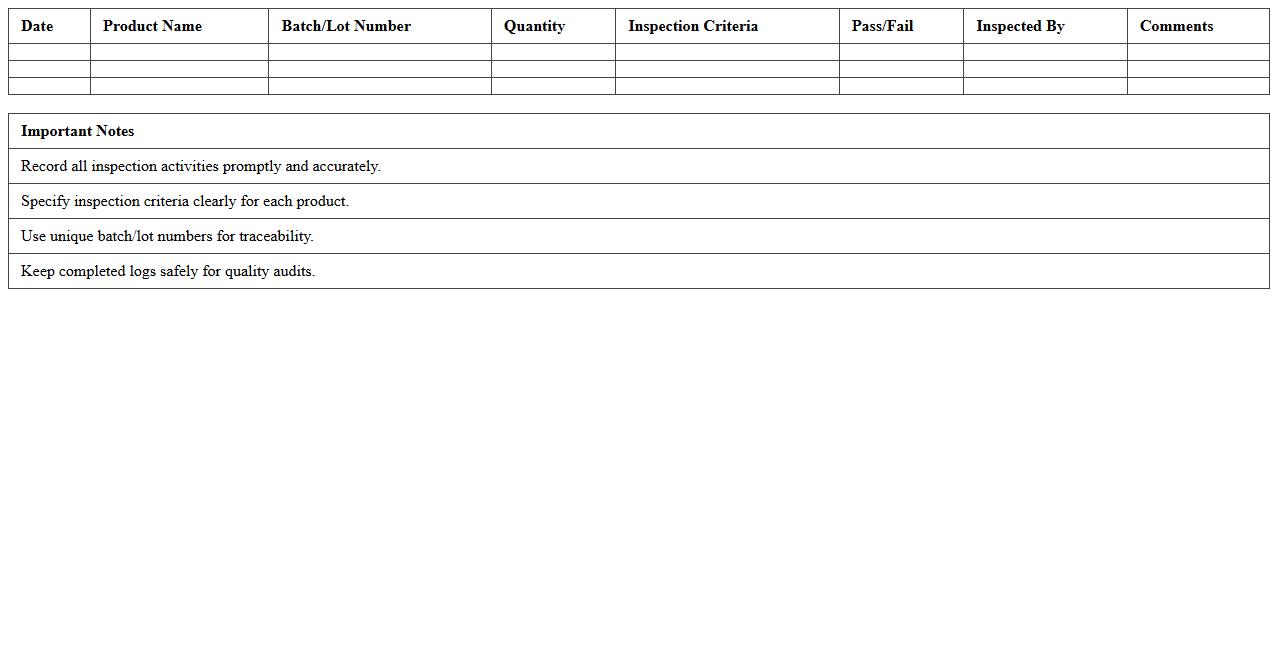

Product Quality Control Log Excel Template

The

Product Quality Control Log Excel Template document is a structured tool designed to track and monitor product quality metrics consistently. It enables manufacturers and quality assurance teams to record inspection results, identify defects, and analyze trends over time, ensuring compliance with industry standards. This template improves accuracy, streamlines quality control processes, and facilitates data-driven decision-making to enhance overall product reliability.

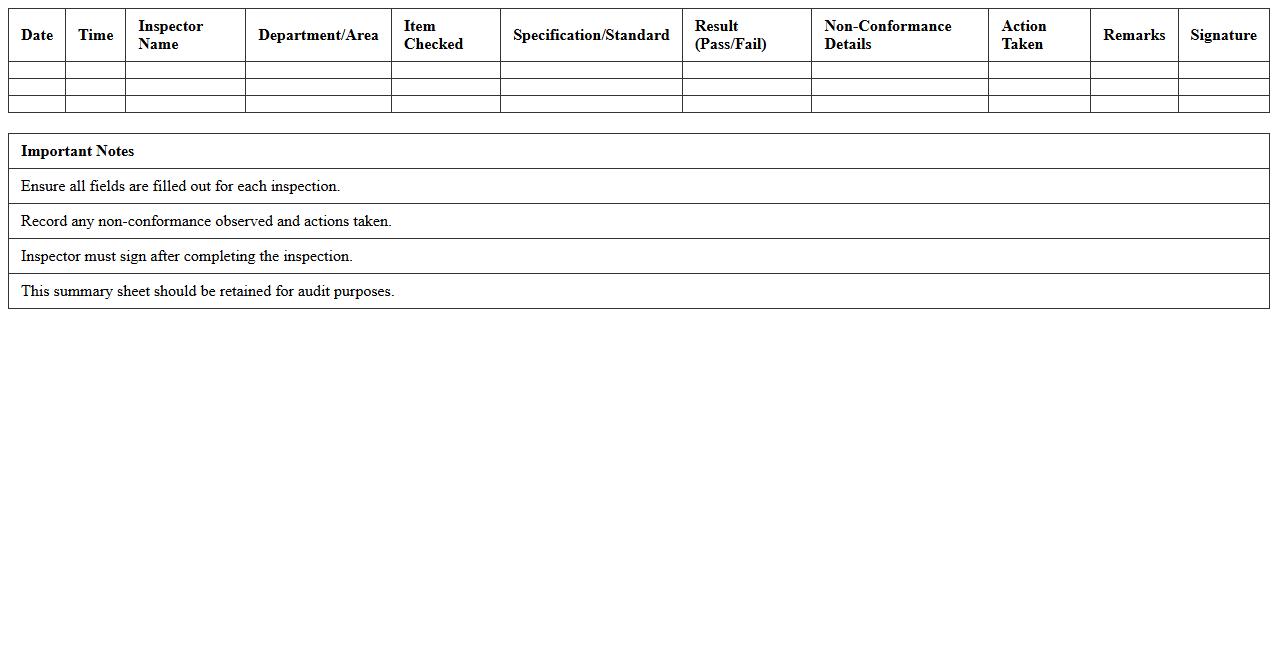

Daily Quality Inspection Summary Sheet

A

Daily Quality Inspection Summary Sheet is a document that records the results of quality checks conducted each day on products, processes, or services. It helps track compliance with quality standards, identify defects early, and ensure corrective actions are implemented promptly. Using this summary sheet improves overall product reliability, reduces rework costs, and supports continuous process improvement.

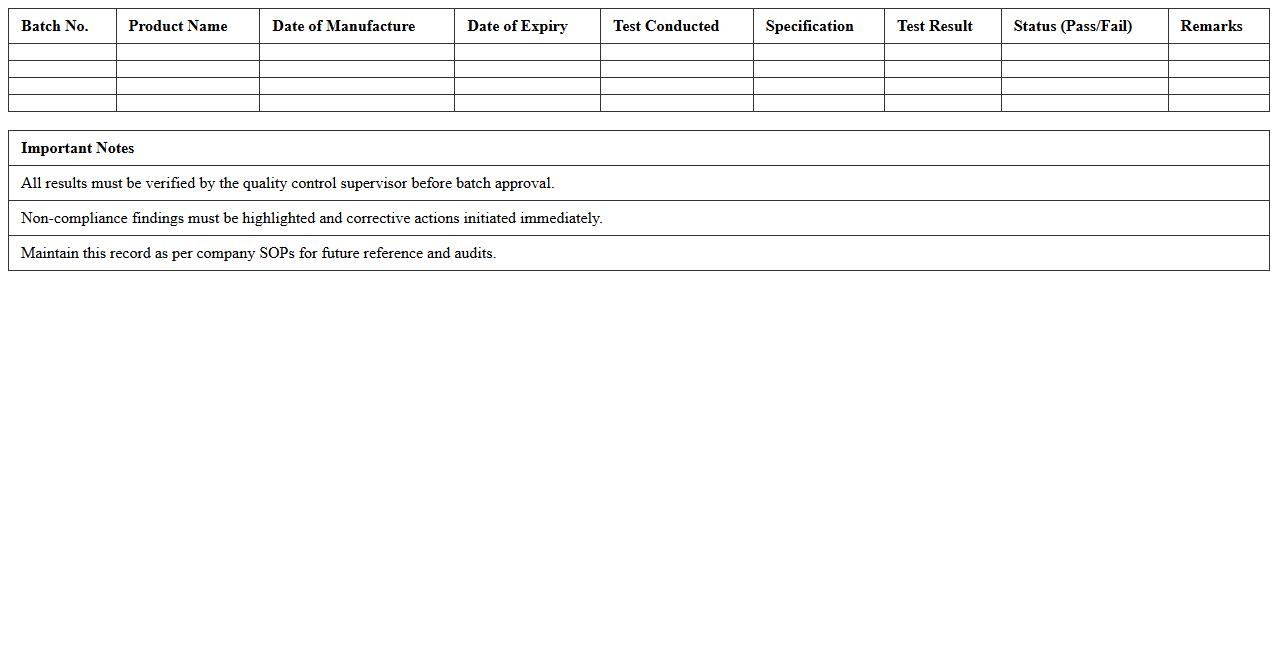

Batch Quality Assessment Report Template

A

Batch Quality Assessment Report Template document standardizes the evaluation of product batches by capturing critical quality parameters, test results, and compliance status. This template streamlines the reporting process, ensuring consistency, accuracy, and traceability in quality control activities. It helps manufacturers quickly identify deviations, maintain regulatory compliance, and improve overall product quality management.

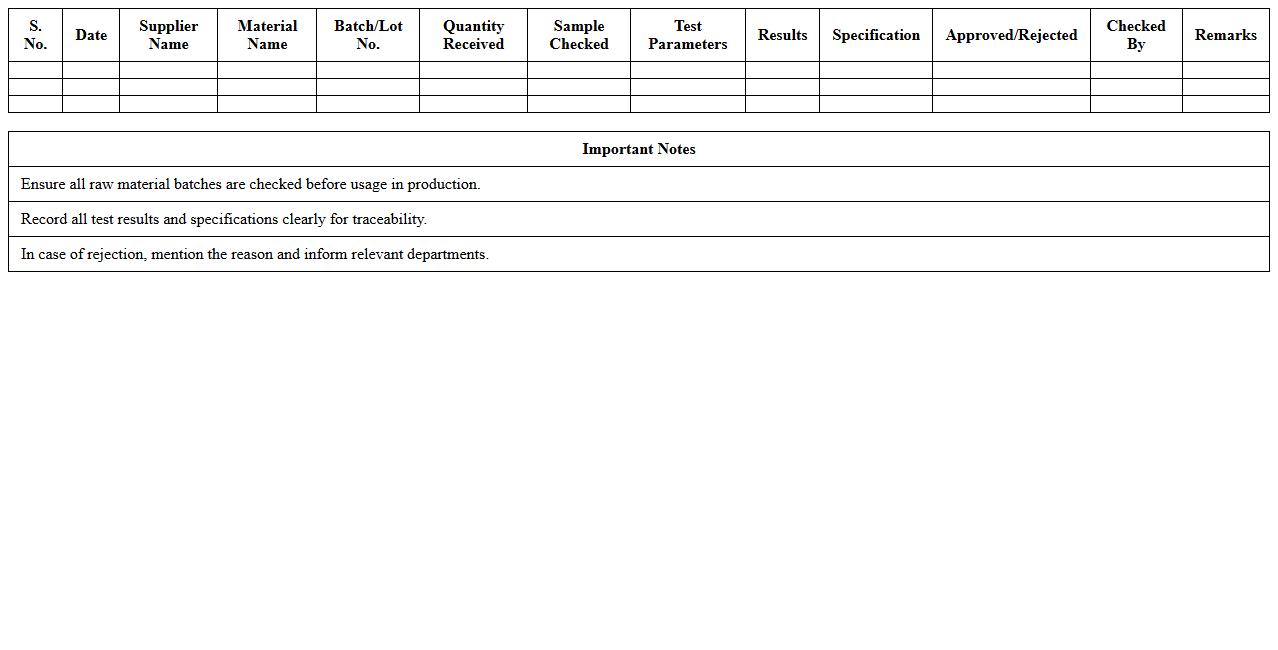

Raw Material Quality Check Register

The

Raw Material Quality Check Register is a crucial document that records and tracks the inspection results of raw materials before they are used in production. It ensures that materials meet specified quality standards, preventing defects and maintaining product consistency. By systematically documenting quality checks, this register helps organizations reduce waste, improve supplier accountability, and maintain compliance with industry regulations.

Defect Tracking Dashboard for Manufacturing

The

Defect Tracking Dashboard for manufacturing is a digital tool that consolidates real-time data on product defects, enabling efficient monitoring and analysis of quality issues across production lines. It allows teams to identify defect patterns, prioritize corrective actions, and reduce manufacturing errors, leading to improved product quality and reduced downtime. By providing visual insights and customizable reports, the dashboard supports data-driven decisions that enhance operational efficiency and customer satisfaction.

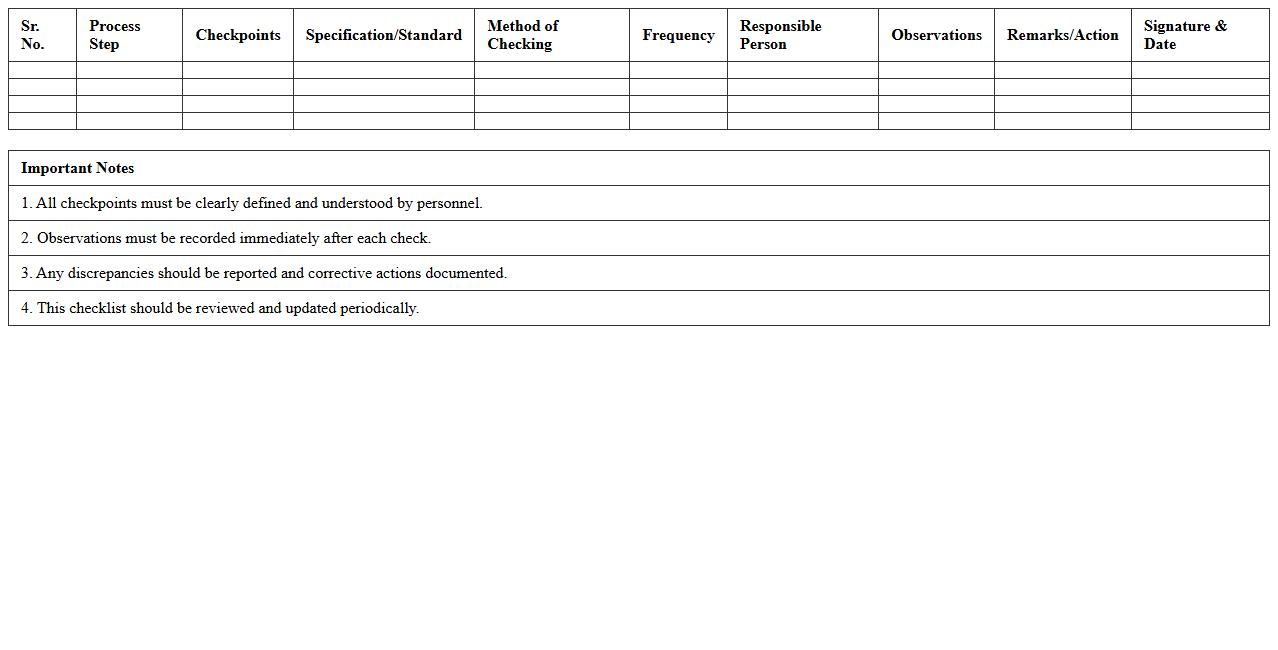

In-Process Quality Control Checklist

An

In-Process Quality Control Checklist document is a detailed tool used during manufacturing or production to systematically verify that each step meets predefined quality standards. It helps identify defects early, ensuring consistent product quality and reducing costly rework or recalls. This checklist streamlines compliance with industry regulations and enhances overall operational efficiency by promoting continuous monitoring and documentation of quality metrics.

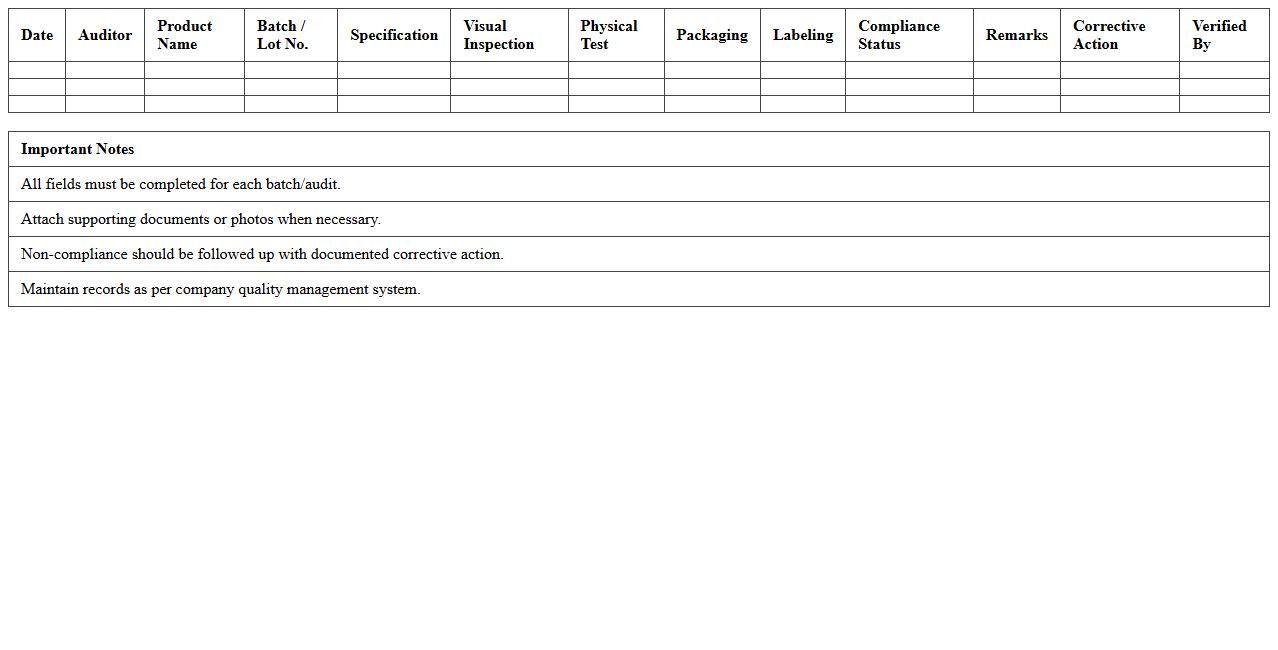

Final Product Quality Audit Summary

The

Final Product Quality Audit Summary document provides a comprehensive review of the product's compliance with quality standards, identifying any defects or deviations before market release. It helps organizations ensure product reliability, meet regulatory requirements, and improve overall quality control processes. This document serves as a critical reference for continuous improvement and customer satisfaction initiatives.

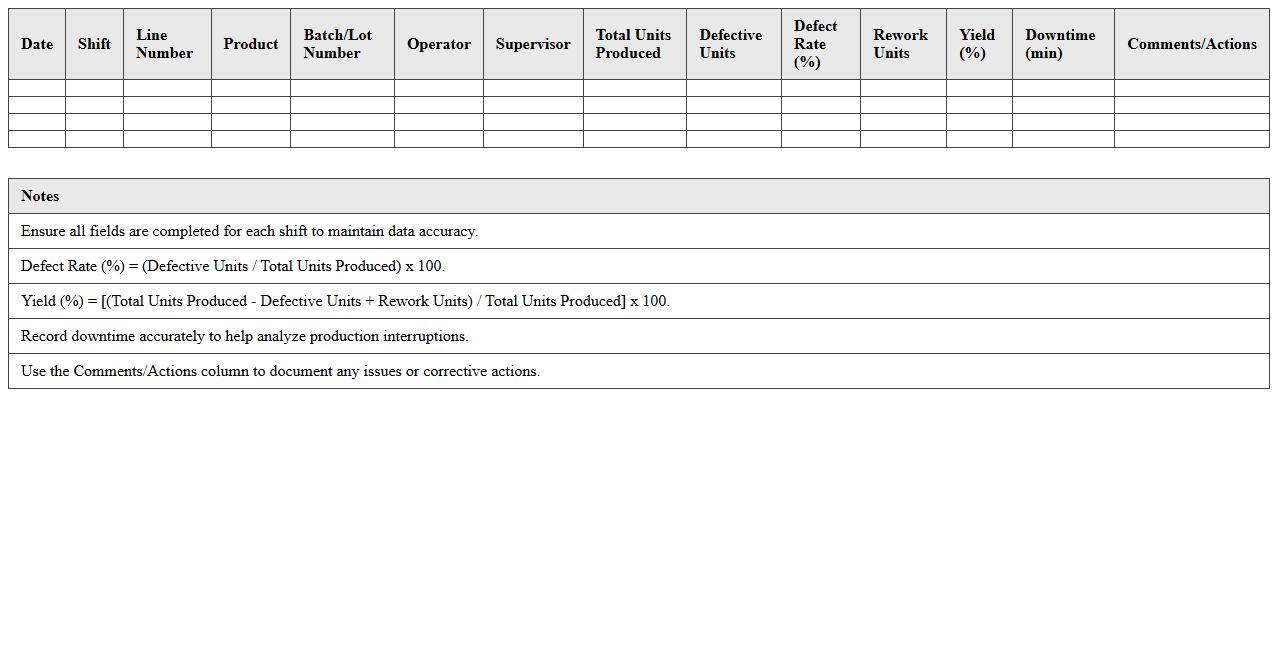

Production Line Quality Metrics Sheet

The

Production Line Quality Metrics Sheet is a detailed document that tracks the performance and quality indicators of a manufacturing production line, including defect rates, cycle times, and equipment efficiency. This sheet enables manufacturers to identify bottlenecks, maintain consistent product quality, and implement data-driven improvements to reduce waste and increase operational efficiency. Using this document ensures accountability and helps in meeting compliance standards by providing transparency into production quality processes.

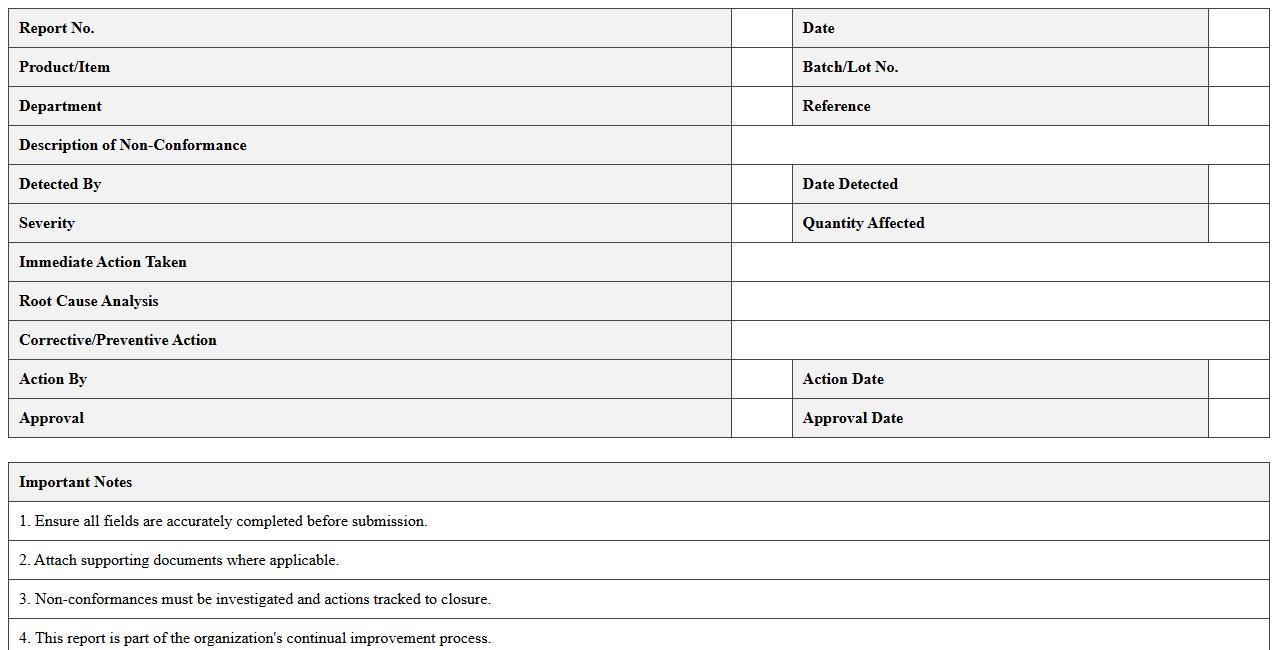

Quality Control Non-Conformance Report

A

Quality Control Non-Conformance Report document records instances where products or processes fail to meet specified standards or requirements. It helps identify defects or deviations, enabling corrective actions and preventing recurrence, thus improving overall product quality and operational efficiency. This report serves as a vital tool for continuous quality improvement and regulatory compliance in manufacturing and service industries.

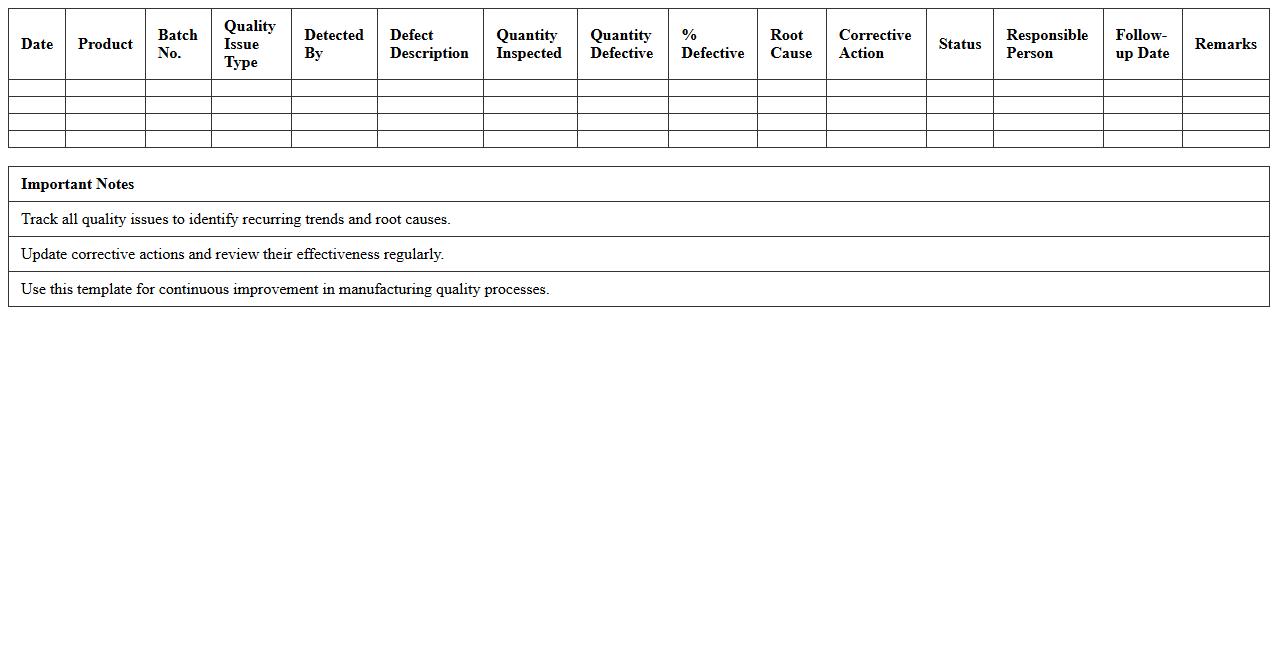

Manufacturing Quality Trends Analysis Template

A

Manufacturing Quality Trends Analysis Template document is a structured tool designed to track and analyze quality performance metrics over time, identifying patterns and deviations in manufacturing processes. It helps manufacturers detect recurring defects, monitor improvement initiatives, and support data-driven decision-making for enhancing product quality. By offering clear visual trends and standardized reporting, this template improves communication across teams and drives continuous quality improvement efforts.

How is defect frequency tracked in the Quality Control Summary Excel for specific production lines?

The Quality Control Summary Excel tracks defect frequency by logging each defect occurrence against specific production lines. Data entry forms capture detailed records, which are then compiled into summary tables. These tables generate automated charts that provide a visual overview of defect trends per line.

What conditional formatting highlights out-of-spec results in the summary sheet?

The summary sheet utilizes conditional formatting to flag out-of-spec results using color-coding rules. Typically, cells with values outside acceptable ranges are highlighted in red or bolded for easy identification. This visual cue helps quality teams quickly detect and address deviations.

Is there a section for recording root cause analysis for recurring quality issues?

The template includes a dedicated section for root cause analysis to document investigations of recurring quality problems. Users can input detailed notes, corrective actions, and responsible parties. This feature supports continuous improvement through systematic problem-solving.

How does the template auto-calculate pass/fail rates across different manufacturing shifts?

The template uses embedded formulas to automatically calculate pass/fail rates for each manufacturing shift based on inspection data. By referencing shift-specific input data, it dynamically updates summary statistics. This functionality enables real-time performance monitoring across shifts.

Are raw material batch numbers linked to finished product quality records for traceability?

Yes, the system links raw material batch numbers to finished product quality records within the template. This traceability feature ensures every product can be tracked back to its material source. It facilitates effective recall management and quality assurance procedures.

More Summary Excel Templates