The Production Line Schedule Excel Template for Manufacturing Plants streamlines workflow management by organizing tasks, shifts, and resource allocation efficiently. This template enhances productivity by providing a clear visual timeline for production activities, reducing downtime and minimizing errors. It is customizable to fit the specific needs of different manufacturing processes, ensuring optimal use of manpower and machinery.

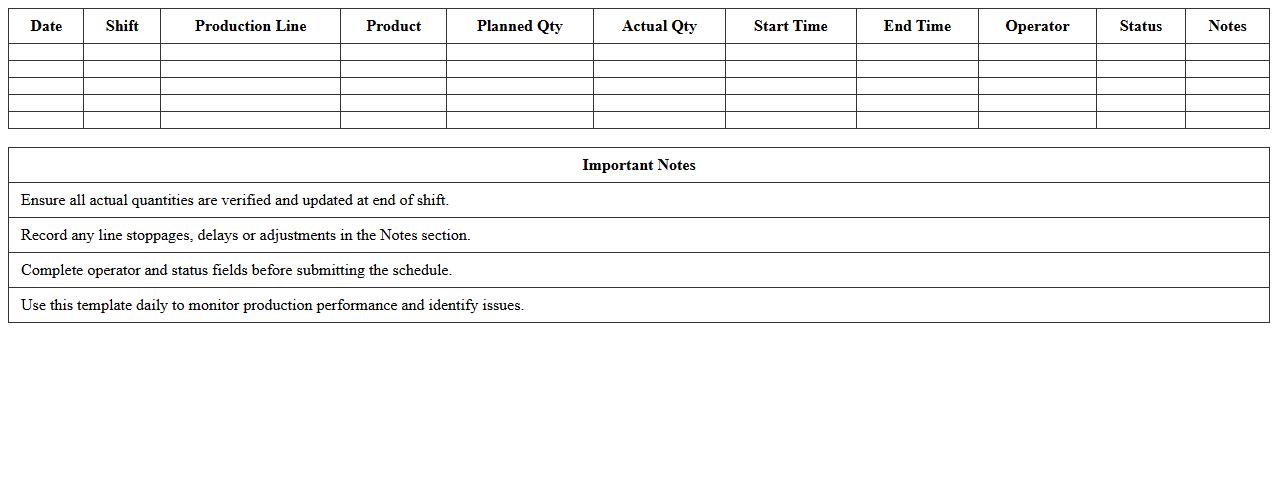

Daily Production Line Schedule Excel Template

The

Daily Production Line Schedule Excel Template is a structured document designed to organize and track daily manufacturing activities, including shift assignments, machine utilization, and output targets. It helps managers monitor production efficiency, reduce downtime, and ensure timely delivery by providing real-time insights into workflow and resource allocation. Utilizing this template supports streamlined operations, improved communication, and data-driven decision-making in manufacturing environments.

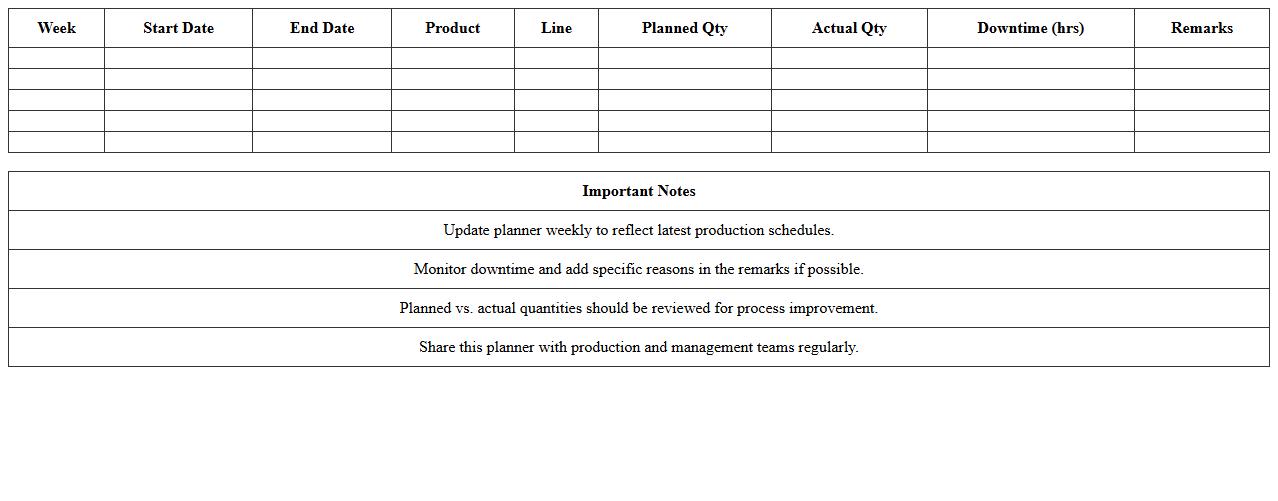

Weekly Manufacturing Line Planner Spreadsheet

The

Weekly Manufacturing Line Planner Spreadsheet is a detailed document designed to organize and track production schedules, resource allocation, and workflow efficiency in manufacturing lines. It enables managers to monitor daily tasks, balance workloads, and predict potential bottlenecks, ensuring smooth operations and timely product delivery. Utilizing this spreadsheet improves productivity by providing a clear overview of manufacturing processes and facilitating data-driven decision-making.

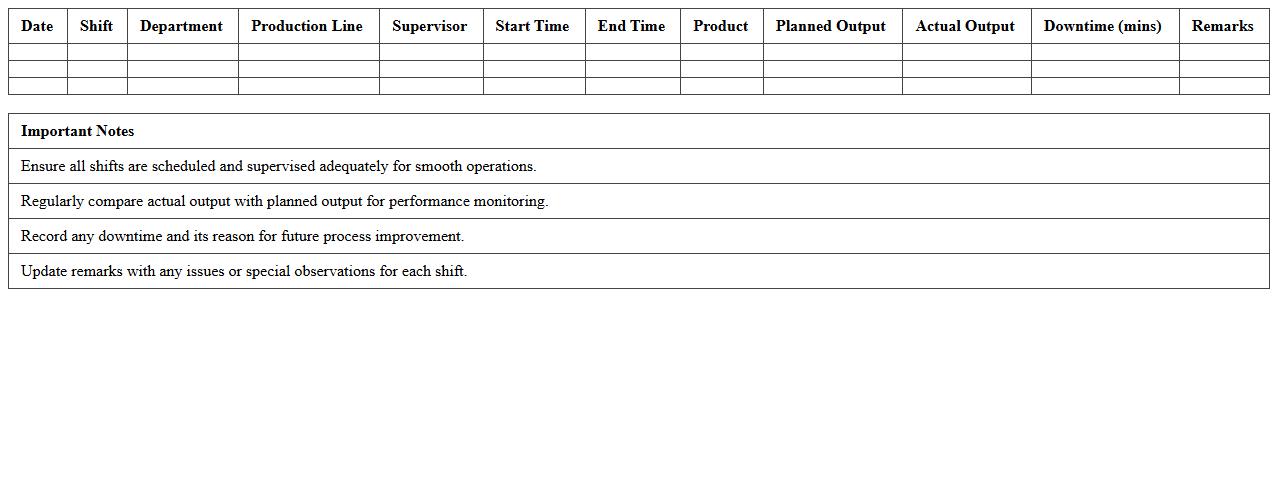

Shift-Based Production Schedule Sheet for Factories

A

Shift-Based Production Schedule Sheet for factories is a detailed document that outlines the allocation of production tasks across different time shifts, ensuring efficient use of labor and machinery. It helps managers monitor workflow, track output, and optimize resource distribution to meet production targets. This schedule sheet improves communication between shifts, reduces downtime, and enhances overall factory productivity.

Multi-Line Production Timeline Excel Template

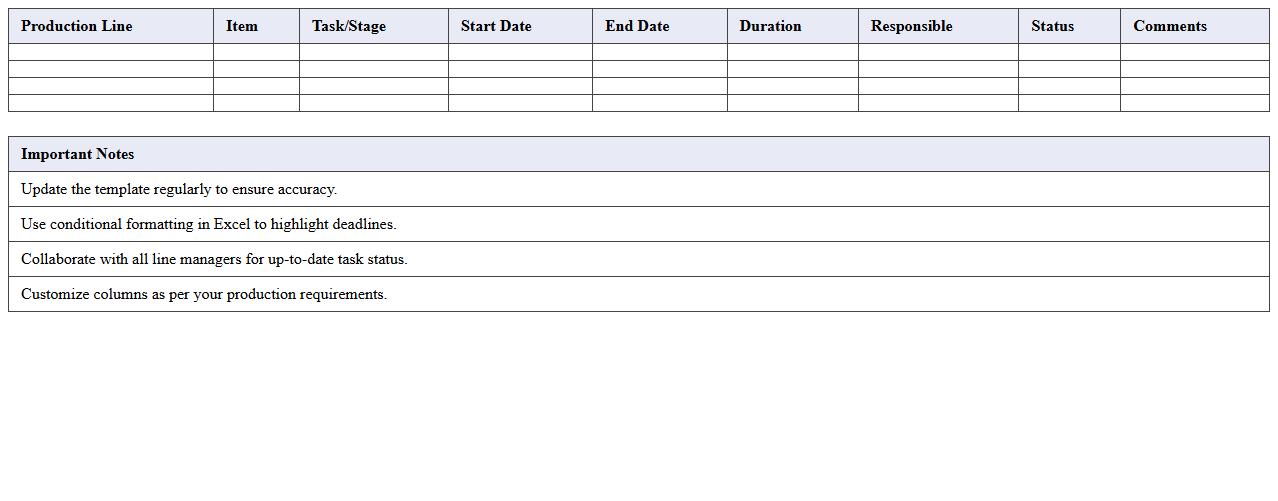

The

Multi-Line Production Timeline Excel Template is a structured tool designed to manage and visualize multiple production schedules simultaneously within a single spreadsheet. It allows users to track progress, deadlines, and resource allocation across various production lines, enhancing project coordination and efficiency. This template improves workflow management by providing clear, customizable timelines that facilitate timely decision-making and reduce production delays.

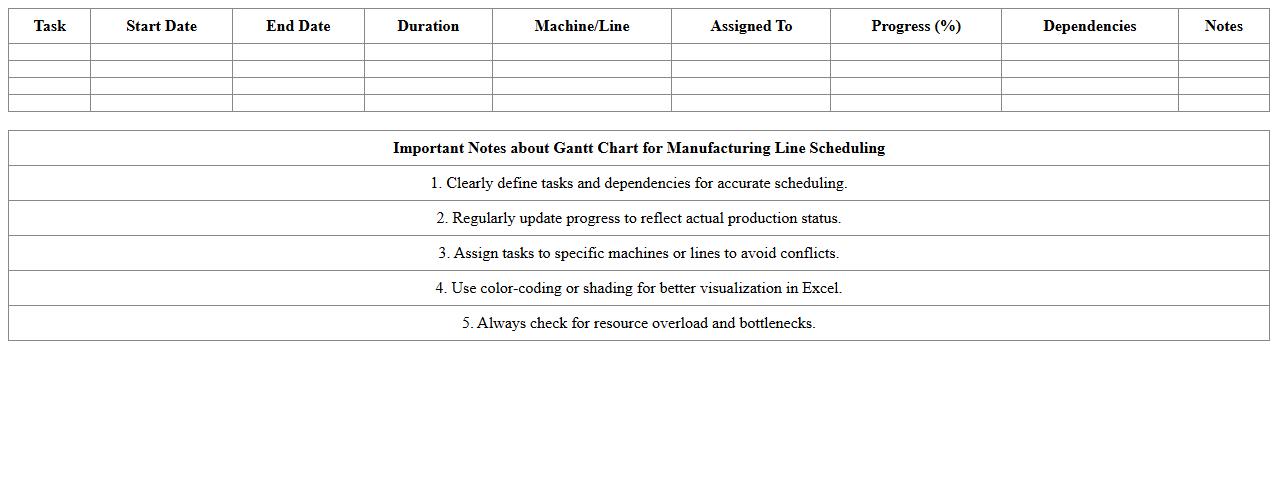

Gantt Chart for Manufacturing Line Scheduling

A

Gantt Chart for Manufacturing Line Scheduling is a visual project management tool that outlines the start and end times of production tasks within a manufacturing process. It helps optimize resource allocation, monitor progress, and identify bottlenecks to ensure deadlines are met efficiently. Using this chart enhances coordination across teams, reduces downtime, and improves overall manufacturing productivity.

Hourly Production Tracking Schedule Excel

The

Hourly Production Tracking Schedule Excel document is a detailed tool designed to monitor and record production output on an hourly basis, allowing for precise measurement of manufacturing efficiency and workflow progress. It helps identify bottlenecks, track labor productivity, and adjust resources in real time to optimize overall production performance. This document is essential for maintaining accurate data, facilitating informed decision-making, and improving operational transparency across production shifts.

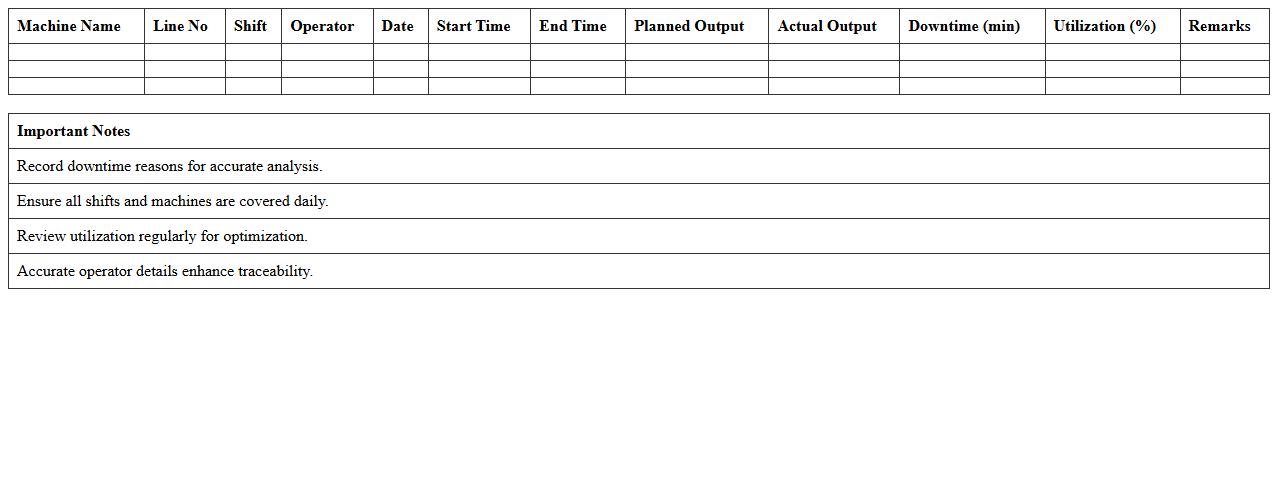

Machine Utilization and Line Schedule Template

Machine Utilization measures the percentage of time a machine is actively used compared to its available operating time, providing critical insights into equipment efficiency. The Line Schedule Template document organizes production tasks, timelines, and resource allocation to ensure smooth workflow and reduce downtime. Using this template enhances productivity by optimizing

machine utilization, improving scheduling accuracy, and facilitating better resource management.

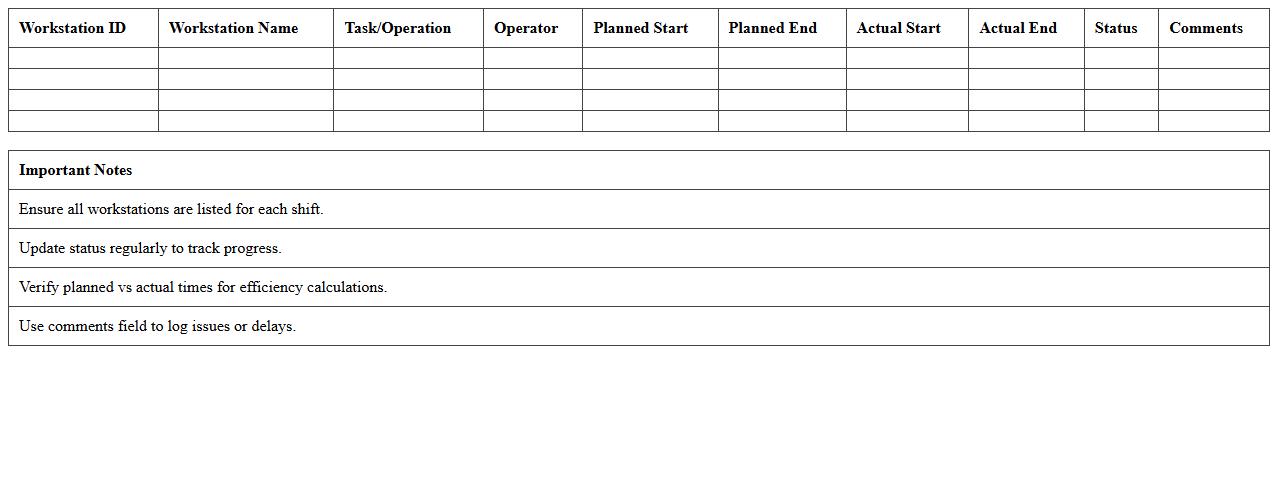

Automated Workstation Production Planner Spreadsheet

The

Automated Workstation Production Planner Spreadsheet is a dynamic tool designed to streamline production scheduling by automating task allocation and resource management within a manufacturing environment. It enhances operational efficiency by providing real-time updates on workstation availability, production timelines, and capacity utilization, reducing manual errors and improving decision-making accuracy. This spreadsheet is invaluable for optimizing workflow, minimizing downtime, and ensuring timely project completion in complex production setups.

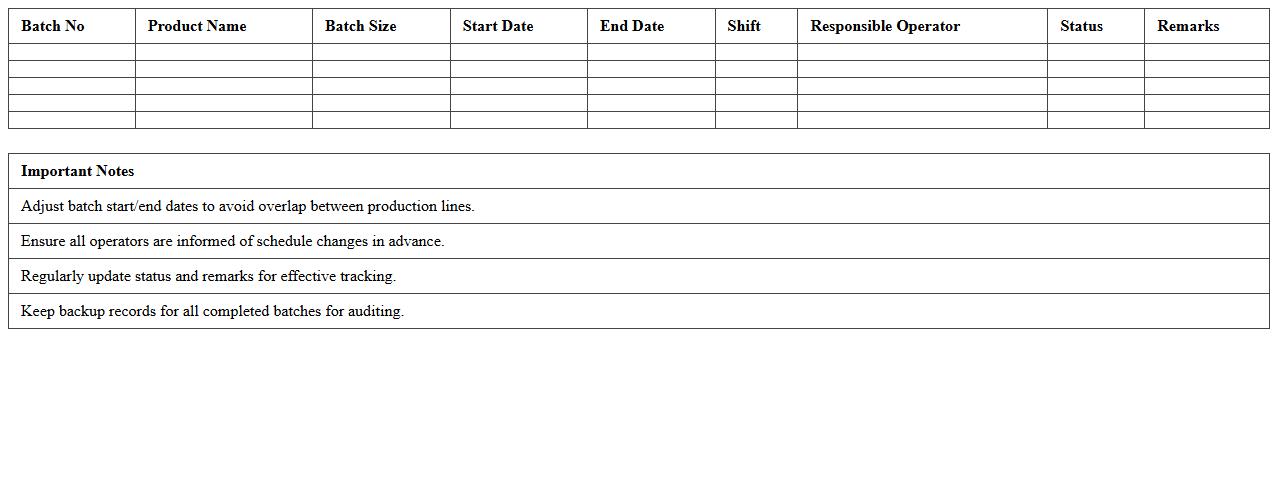

Batch Processing Line Schedule Excel

The

Batch Processing Line Schedule Excel document is a structured tool designed to organize and track production timelines across manufacturing batches efficiently. It allows users to input start and end times, allocate resources, and monitor process flow for each batch, ensuring timely completion and minimizing downtime. This scheduling tool enhances operational control, improves productivity, and enables better forecasting and resource management in batch processing environments.

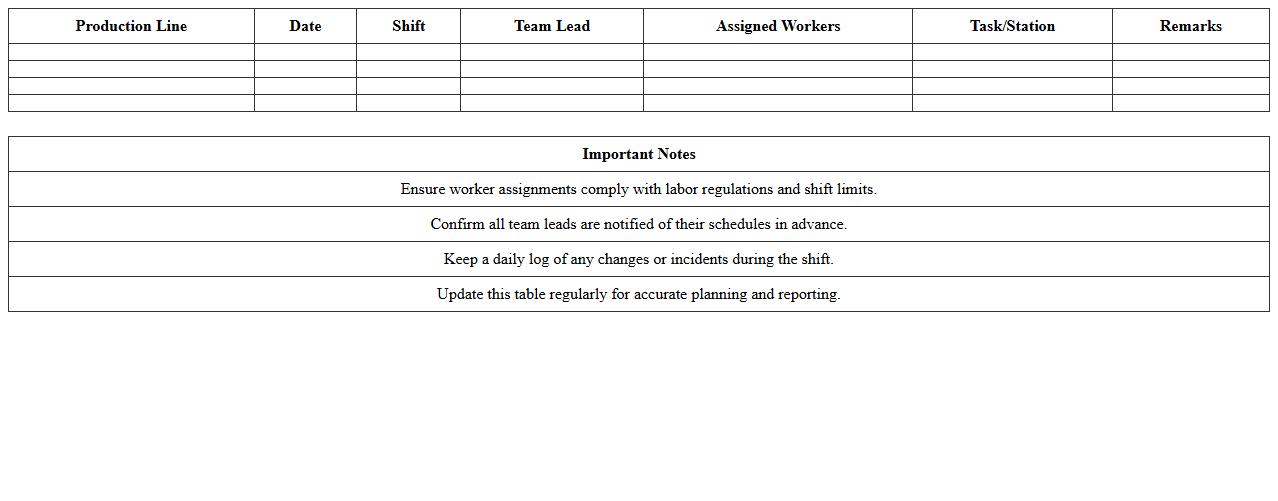

Workforce Assignment Schedule for Production Lines

The

Workforce Assignment Schedule for Production Lines document outlines the detailed allocation of employees to specific tasks and shifts within a manufacturing environment, ensuring optimal coverage and productivity. It helps managers streamline labor resources, minimize downtime, and balance workload distribution across production lines. Utilizing this schedule enhances operational efficiency and supports timely delivery of products by accurately matching workforce capacity with production demands.

How can shift-wise production targets be auto-calculated in a schedule Excel sheet?

To auto-calculate shift-wise production targets, use the SUMIFS function to aggregate production goals based on shift timings and dates. You can link these formulas to a dynamic input table where shift durations, productivity rates, and total daily targets are specified. This approach ensures that targets update automatically when shift parameters or production goals change.

What formula tracks downtime and its impact on line efficiency in the schedule?

Downtime tracking and its effect on line efficiency can be calculated using the formula: =1 - (Downtime / Total Available Time). This formula gives the actual operational efficiency during a production period by highlighting lost time. By incorporating real-time downtime inputs, managers can quickly identify efficiency bottlenecks and adjust schedules accordingly.

How does your schedule handle overlapping production orders for multiple SKUs?

Overlapping production orders for multiple SKUs are managed using conditional formatting and INDEX-MATCH formulas to prioritize orders based on deadlines and available capacity. The schedule flags conflicts by comparing production start and end times, helping planners sequence tasks effectively. This method reduces the risk of delays and optimizes machine allocation across different SKUs.

Which Excel function best highlights delays in the production line against planned dates?

The IF function combined with conditional formatting is ideal for highlighting delays by comparing actual completion dates to planned dates. For example, =IF(ActualDate > PlannedDate, "Delay", "On Time") provides a clear status indicator. This visualization helps production managers quickly spot and address lateness to keep schedules on track.

Can you integrate real-time machine utilization data into the production schedule Excel?

Integrating real-time machine utilization data is possible by linking Excel to external data sources via Power Query or APIs. This allows automatic updates of machine status and productivity, reflecting current operational conditions. With live data integration, production schedules become more responsive and accurate, enabling better decision-making.

More Schedule Excel Templates