The Equipment Maintenance Schedule Excel Template for Manufacturing Teams streamlines tracking of routine inspections and repairs, ensuring optimal machine performance. It allows easy customization of maintenance dates, tasks, and responsible personnel, enhancing operational efficiency. This template reduces downtime by providing clear schedules and timely reminders for preventive maintenance.

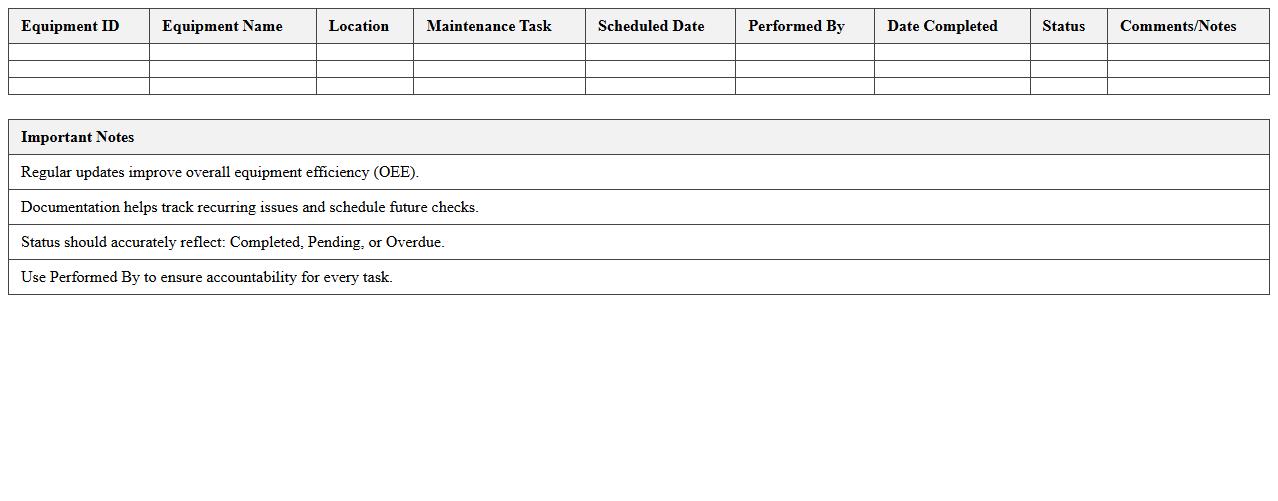

Preventive Maintenance Log Template for Manufacturing Equipment

A

Preventive Maintenance Log Template for manufacturing equipment is a structured document designed to systematically record all scheduled maintenance activities, inspections, and repairs performed on machinery. It helps track equipment performance, identify recurring issues, and plan timely interventions to prevent unexpected breakdowns. Utilizing this template improves operational efficiency, extends equipment lifespan, and reduces downtime costs in manufacturing processes.

Manufacturing Equipment Service Tracker Excel Template

The

Manufacturing Equipment Service Tracker Excel Template is a comprehensive tool designed to monitor and record maintenance schedules, repairs, and service history of manufacturing machinery. It helps optimize equipment uptime by providing organized data on service intervals, reducing downtime and preventing unexpected breakdowns. This template enhances operational efficiency by enabling timely maintenance decisions and streamlining resource allocation for equipment management.

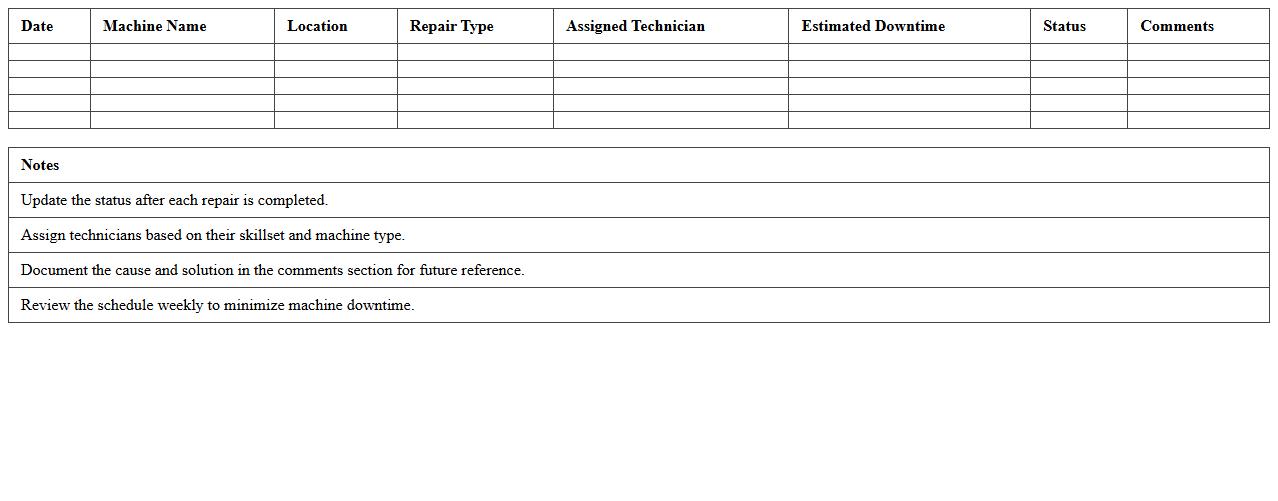

Machinery Repair Scheduling Spreadsheet Template

A

Machinery Repair Scheduling Spreadsheet Template is a structured document designed to organize and track maintenance tasks, repair dates, and machinery downtime efficiently. It allows users to plan repair schedules systematically, minimizing operational disruption and enhancing equipment longevity. By consolidating repair information in one place, the template improves resource allocation and helps prevent unexpected breakdowns.

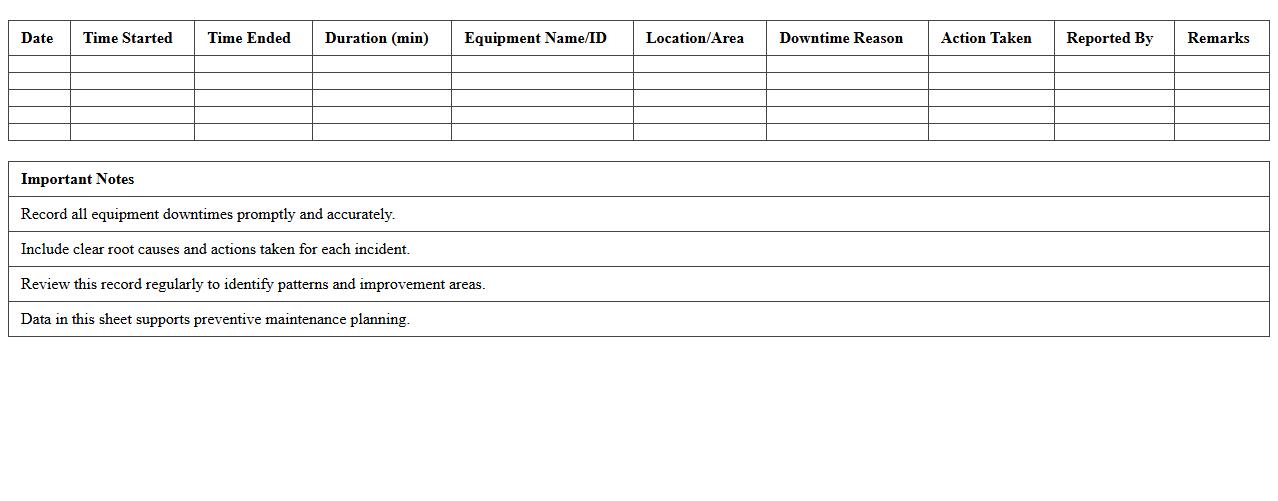

Factory Equipment Downtime Record Excel Sheet

A

Factory Equipment Downtime Record Excel Sheet is a structured document used to track and analyze periods when machinery is non-operational due to maintenance, breakdowns, or other interruptions. This tool helps identify patterns and causes of equipment downtime, enabling factories to implement preventive measures and improve overall productivity. By maintaining detailed records, businesses can reduce operational costs and enhance equipment efficiency.

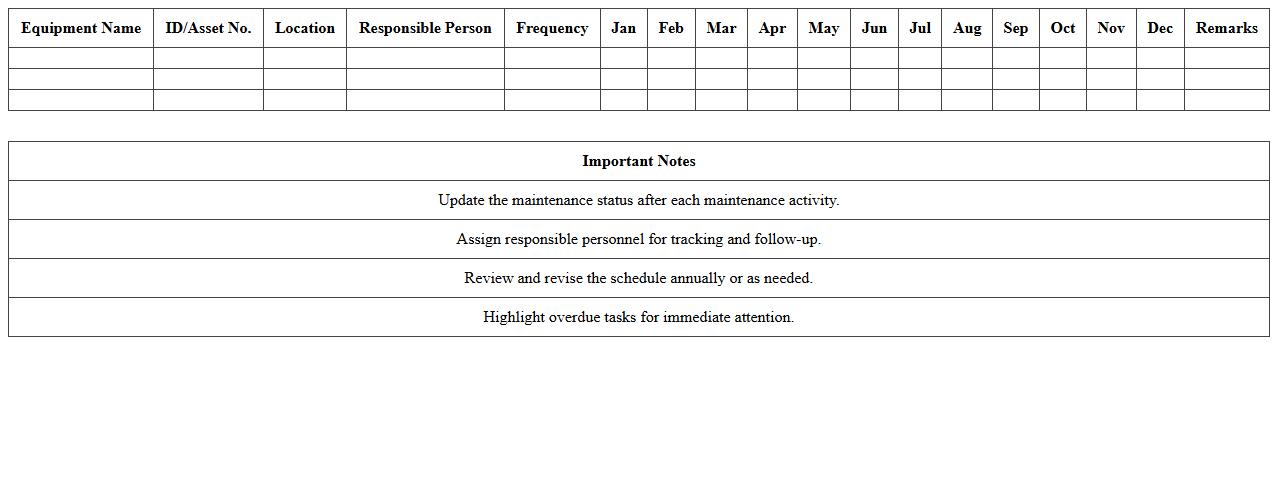

Production Equipment Maintenance Calendar Excel Template

The

Production Equipment Maintenance Calendar Excel Template is a structured tool designed to schedule and track maintenance activities for machinery and equipment in manufacturing environments. It helps ensure timely inspections, repairs, and upkeep, reducing downtime and enhancing operational efficiency. By organizing maintenance tasks visually, it aids in prolonging equipment lifespan and minimizing costly breakdowns.

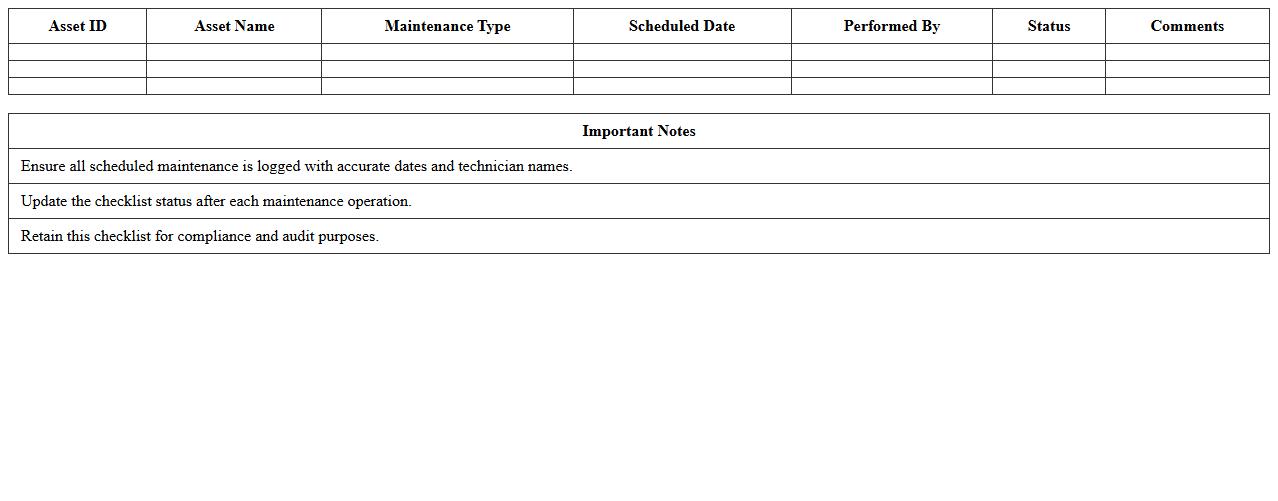

Manufacturing Asset Maintenance Checklist Excel Template

The

Manufacturing Asset Maintenance Checklist Excel Template is a structured document designed to track and manage the upkeep of manufacturing equipment and machinery. It helps ensure timely inspections, preventive maintenance, and repairs, reducing downtime and extending asset lifespan. Utilizing this template improves operational efficiency by organizing maintenance schedules, recording service details, and facilitating compliance with safety standards.

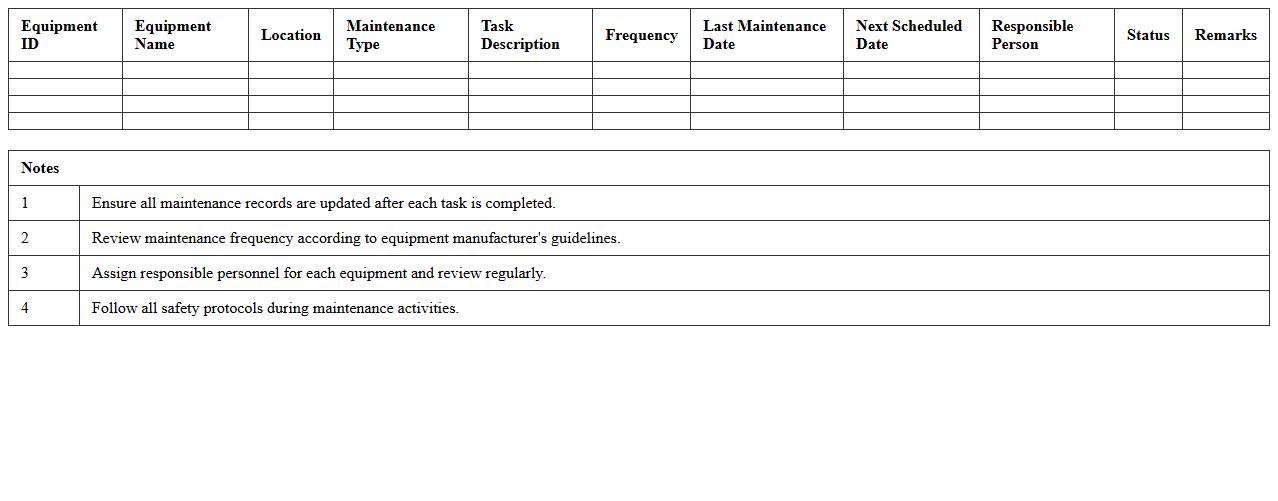

Plant Equipment Routine Maintenance Planner Template

The

Plant Equipment Routine Maintenance Planner Template is a structured document designed to schedule and track regular maintenance tasks for industrial machinery and equipment. It helps ensure timely inspections, lubrication, repairs, and part replacements to reduce downtime and extend equipment lifespan. By using this template, organizations can efficiently manage maintenance activities, improve operational reliability, and optimize resource allocation.

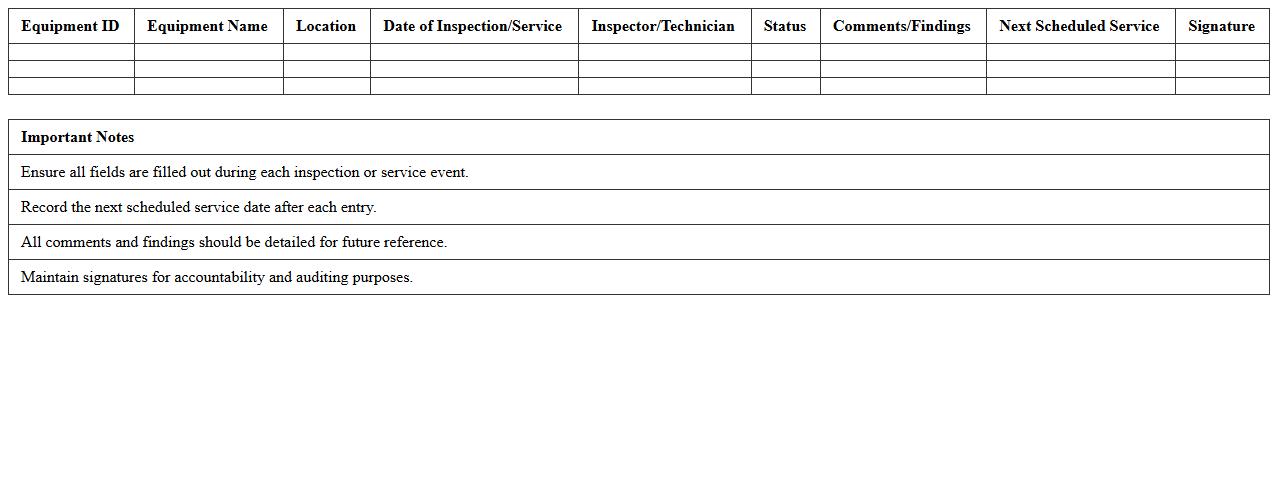

Equipment Inspection and Service History Log Excel

An

Equipment Inspection and Service History Log Excel document is a detailed record-keeping tool used to track the maintenance, inspection dates, and service activities of various equipment. It enables organizations to monitor the condition and performance of assets, ensuring compliance with safety standards and reducing machinery downtime. This log helps in scheduling timely maintenance, identifying recurring issues, and extending the lifespan of critical equipment through well-documented service histories.

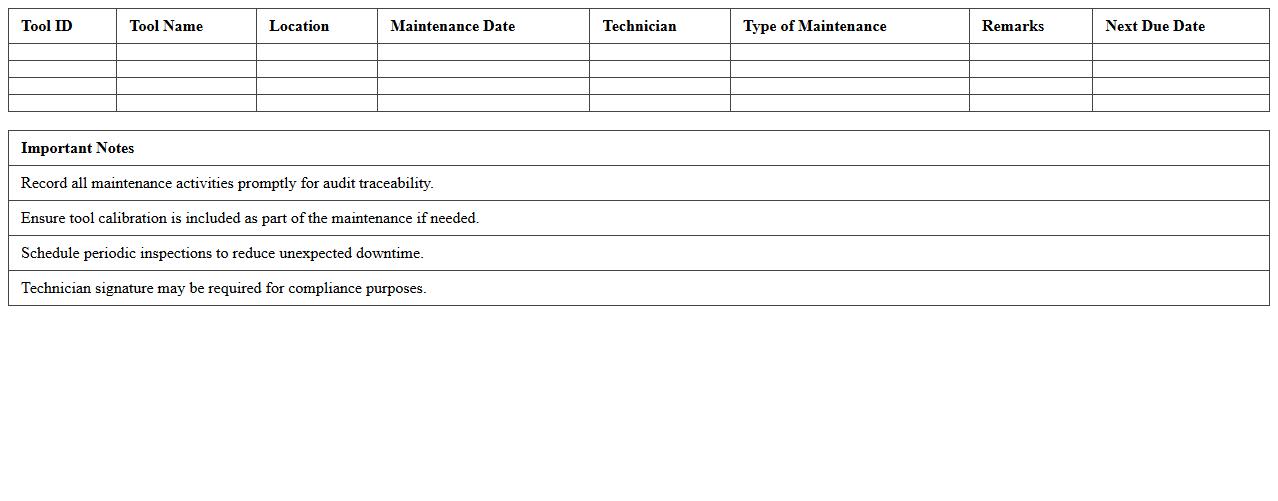

Manufacturing Tools Maintenance Register Spreadsheet

A

Manufacturing Tools Maintenance Register Spreadsheet is a detailed document that tracks the maintenance schedules, repair history, and usage data of manufacturing tools. It helps ensure timely servicing, reduces downtime, and extends the lifespan of equipment by providing organized, accessible records. This register enhances operational efficiency and supports proactive maintenance strategies in manufacturing environments.

Manufacturing Equipment Lifecycle Maintenance Chart Excel

The

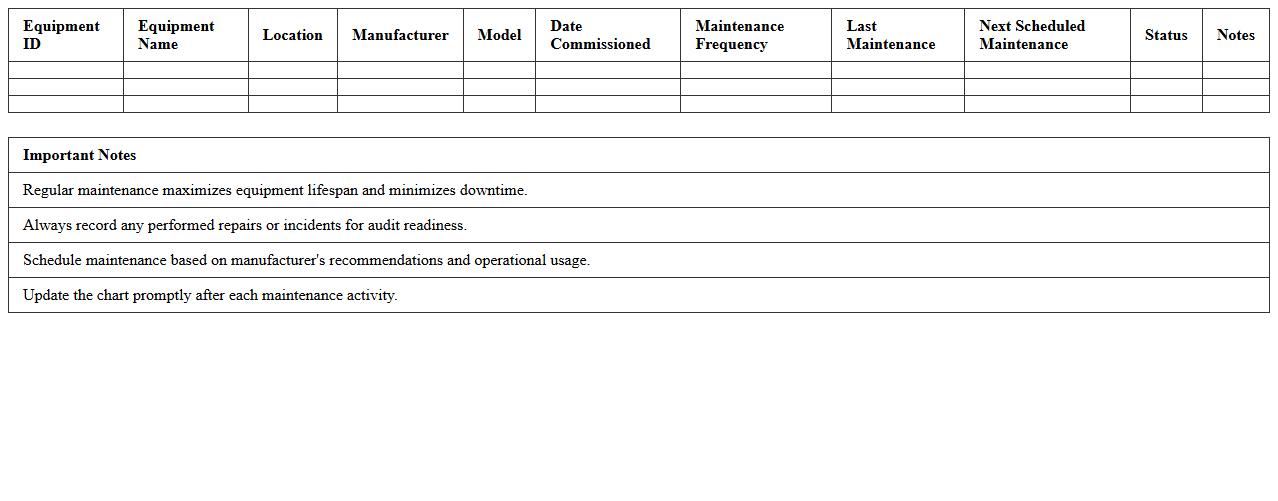

Manufacturing Equipment Lifecycle Maintenance Chart Excel document is a strategic tool designed to track the maintenance schedule, performance, and lifespan of manufacturing machinery. It helps organizations optimize equipment uptime by providing clear timelines for preventive maintenance, repairs, and replacements. Using this chart in Excel enhances decision-making by consolidating vital data into an accessible format to minimize downtime and extend equipment longevity.

How can I automate maintenance reminders in an Equipment Maintenance Schedule Excel for manufacturing teams?

Automating maintenance reminders in Excel can be achieved using conditional formatting and formulas like TODAY() to highlight upcoming tasks. You can set up alerts by creating rules that notify users when a maintenance date is approaching or overdue. Additionally, combining Excel with Outlook or Power Automate enables automated email notifications for manufacturing teams.

What custom columns are essential for tracking downtime causes in Excel maintenance sheets?

Key custom columns to track downtime causes include 'Downtime Reason', 'Start Time', 'End Time', and 'Duration'. These columns help categorize and quantify equipment stoppages for better analysis. Adding a 'Corrective Action Taken' column enhances documentation and future prevention strategies.

How do you integrate QR code scanning for equipment ID in an Excel maintenance schedule?

Integrating QR code scanning involves generating QR codes linked to equipment IDs and using a mobile device or scanner to input data. The scanned equipment ID can be imported directly into Excel, streamlining data entry. This method improves accuracy and speeds up equipment identification within the maintenance schedule.

What formulas help monitor compliance status for scheduled maintenance tasks in Excel?

Formulas like IF(), AND(), and COUNTIF() are essential for tracking compliance status of maintenance tasks. For example, using IF(TODAY()>ScheduledDate, "Overdue", "On Time") helps indicate the task status. Combining these with conditional formatting visually represents compliance across the schedule.

How can I visualize maintenance trends using pivot charts in an Excel equipment schedule?

Creating pivot charts from maintenance data allows you to analyze trends like breakdown frequency and downtime duration. By grouping data by equipment type or time periods, you uncover patterns that aid decision-making. Pivot charts dynamically adjust with your data, offering an interactive visualization of maintenance performance.

More Schedule Excel Templates