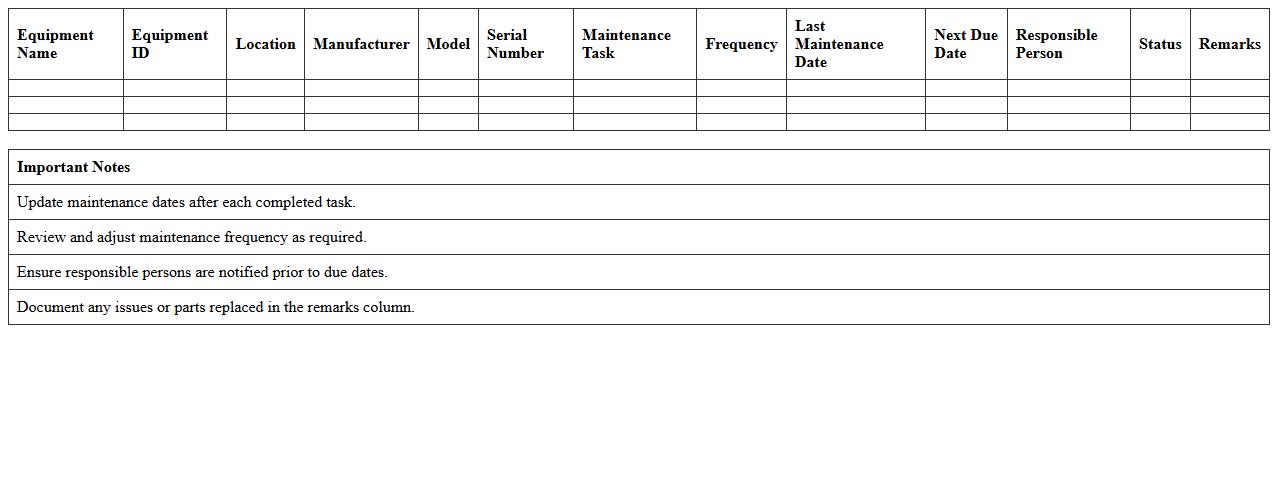

Preventive Maintenance Schedule Excel Template for Equipment

A

Preventive Maintenance Schedule Excel Template for Equipment is a structured spreadsheet designed to organize and track maintenance tasks, dates, and equipment details efficiently. It helps businesses minimize downtime, extend equipment lifespan, and reduce costly repairs by ensuring timely upkeep through systematic scheduling. This template streamlines maintenance planning, improves asset management, and enhances operational productivity by providing clear visibility into maintenance activities.

Equipment Repairs Log and Maintenance Tracker Excel Sheet

An

Equipment Repairs Log and Maintenance Tracker Excel Sheet is a comprehensive tool designed to record and monitor all repair activities and maintenance schedules for machinery or equipment. It helps in organizing detailed information such as repair dates, costs, equipment condition, and service history, ensuring timely maintenance and reducing downtime. Utilizing this document enhances asset management efficiency, prolongs equipment lifespan, and supports budgeting by tracking repair expenses accurately.

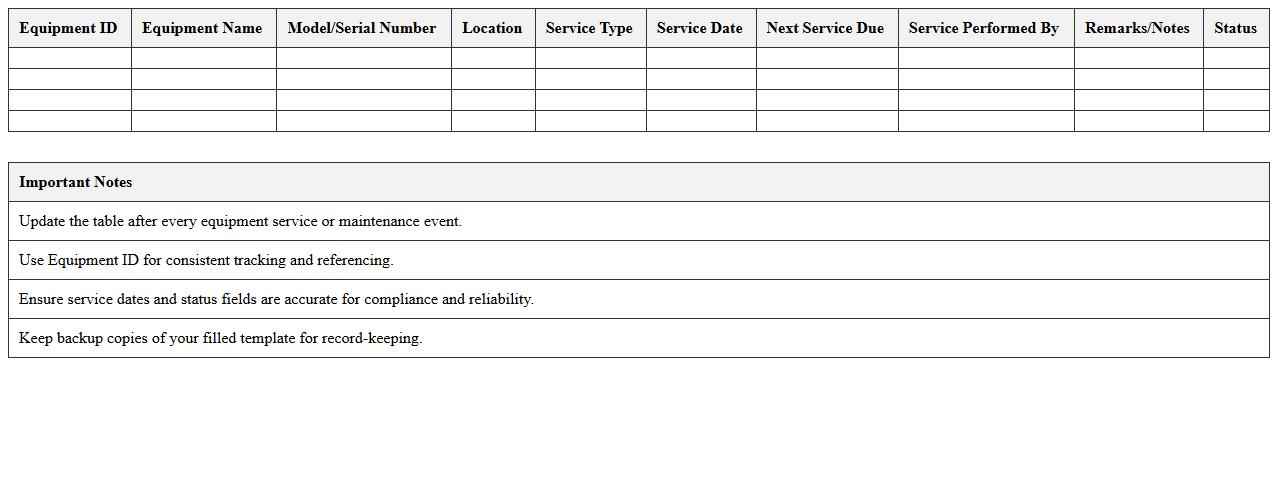

Excel Template for Equipment Service and Maintenance Records

An

Excel Template for Equipment Service and Maintenance Records is a structured spreadsheet designed to log, track, and manage the maintenance history and service schedules of various equipment efficiently. This template helps organizations maintain accurate records of service dates, costs, technician details, and equipment condition, facilitating timely maintenance and minimizing downtime. By centralizing maintenance data, it enhances asset management, prolongs equipment lifespan, and ensures compliance with industry standards and safety regulations.

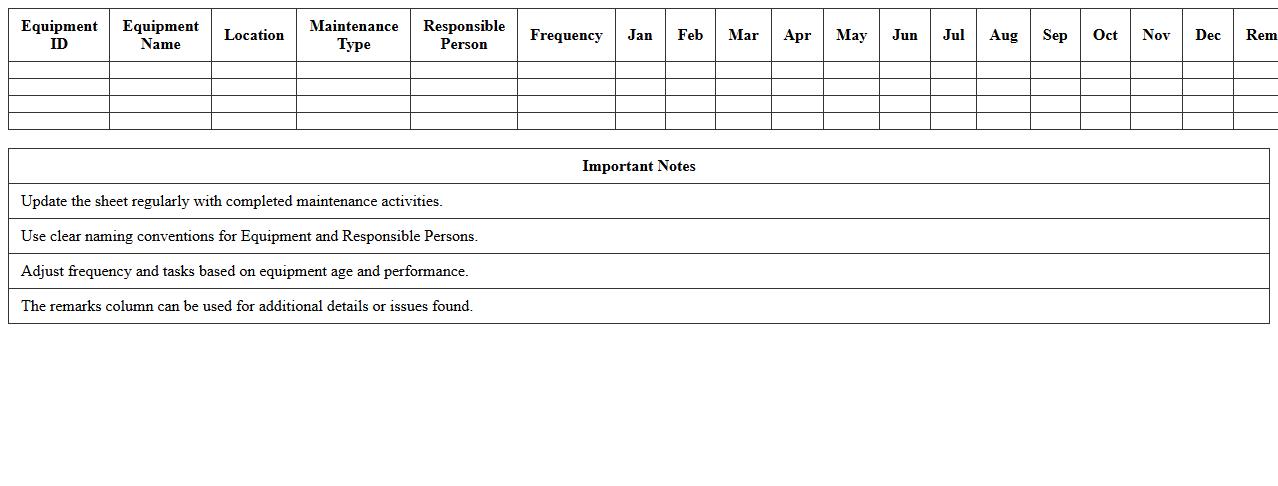

Annual Equipment Maintenance Planning Sheet in Excel

An

Annual Equipment Maintenance Planning Sheet in Excel is a structured document designed to schedule, track, and manage the regular maintenance activities of equipment over a year. It helps ensure timely servicing, reduces downtime, and extends equipment lifespan by organizing maintenance tasks, frequencies, and responsibilities in one accessible location. This tool enhances operational efficiency and supports preventive maintenance strategies by providing clear visibility into upcoming and completed maintenance activities.

Equipment Breakdown and Repair Tracking Excel Template

The

Equipment Breakdown and Repair Tracking Excel Template document is designed to systematically record and monitor the maintenance history, repair schedules, and breakdown incidents of various machinery and equipment. It helps organizations prevent costly downtime by providing clear insights into repair trends, maintenance costs, and equipment performance. This template enables efficient tracking of repair timelines and parts usage, optimizing the maintenance process and supporting informed decision-making for equipment management.

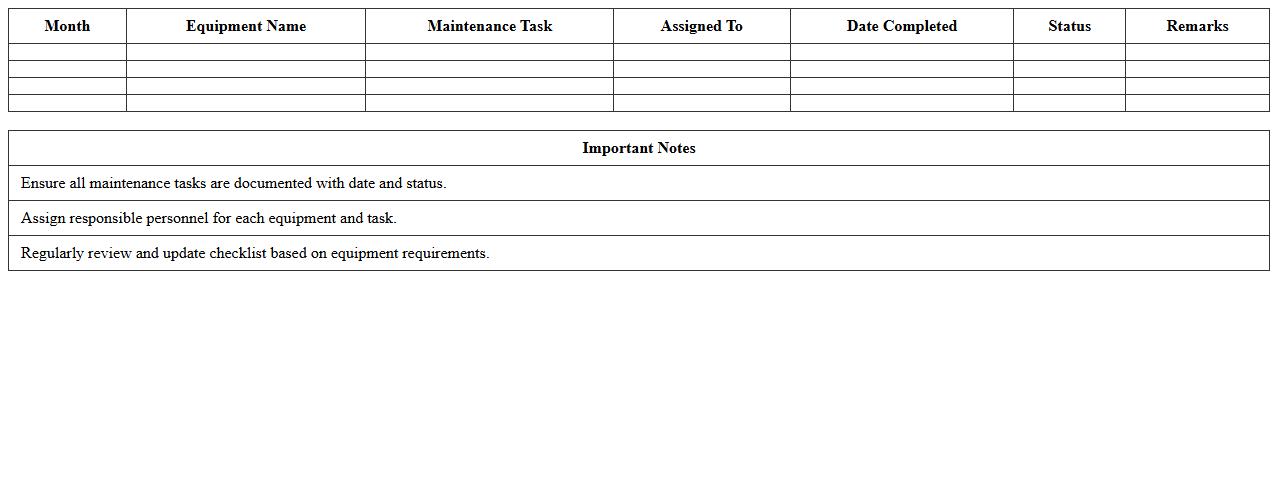

Monthly Preventive Maintenance Checklist Excel Template

The

Monthly Preventive Maintenance Checklist Excel Template is a structured document designed to organize and track routine maintenance tasks for equipment or systems to prevent breakdowns and ensure operational efficiency. It enables users to schedule, monitor, and record maintenance activities, helping to reduce downtime and extend the lifecycle of assets. By using this template, businesses can improve maintenance consistency, optimize resource allocation, and enhance overall productivity.

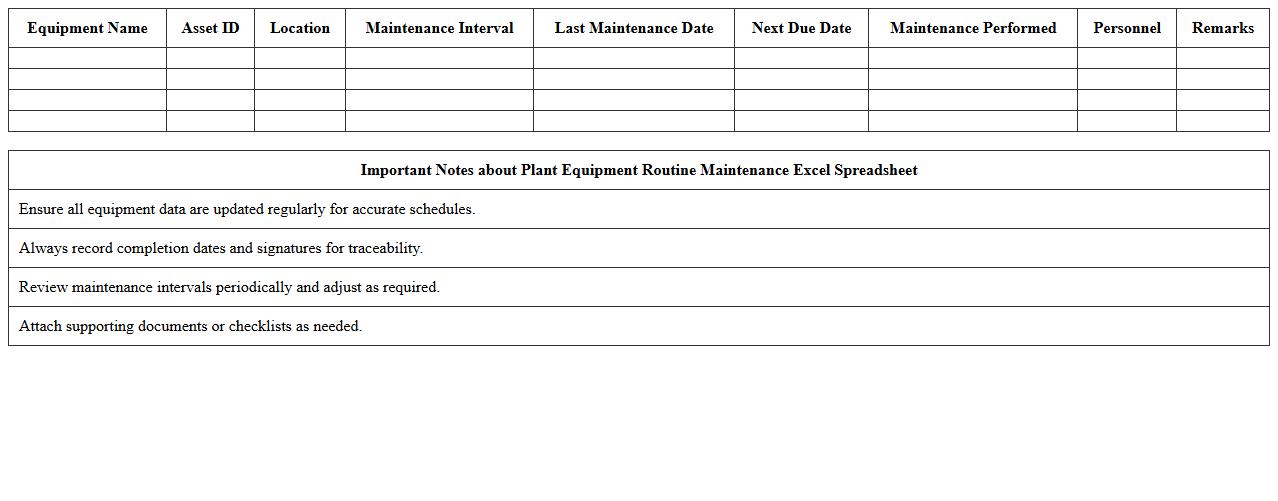

Plant Equipment Routine Maintenance Excel Spreadsheet

The

Plant Equipment Routine Maintenance Excel Spreadsheet document is a structured tool designed to schedule, track, and record maintenance activities for machinery and plant equipment. It helps ensure timely inspections, reduce downtime, and extend equipment lifespan by providing clear visibility into maintenance tasks and history. This spreadsheet facilitates efficient resource allocation and compliance with safety standards by keeping all maintenance data organized in one accessible location.

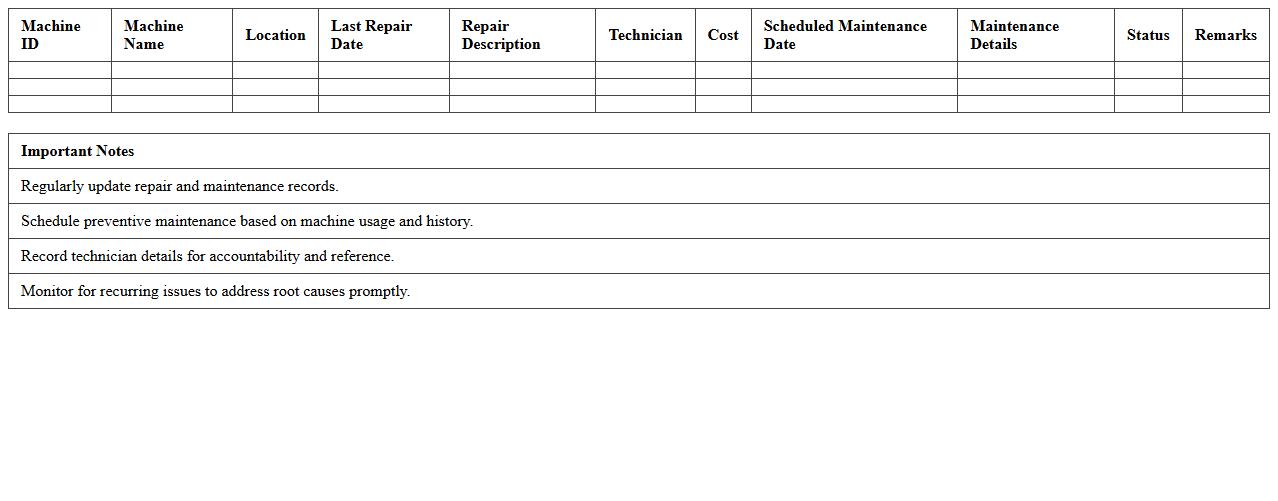

Machinery Repair History and Scheduled Maintenance Template

The

Machinery Repair History and Scheduled Maintenance Template document records detailed information about past repairs and planned maintenance activities for equipment, ensuring comprehensive tracking of machinery performance and issues. It provides a systematic approach to monitor repair frequency, identify recurring problems, and schedule timely preventive maintenance, which enhances equipment reliability and lifespan. Utilizing this template helps reduce downtime, optimize maintenance costs, and improve overall operational efficiency.

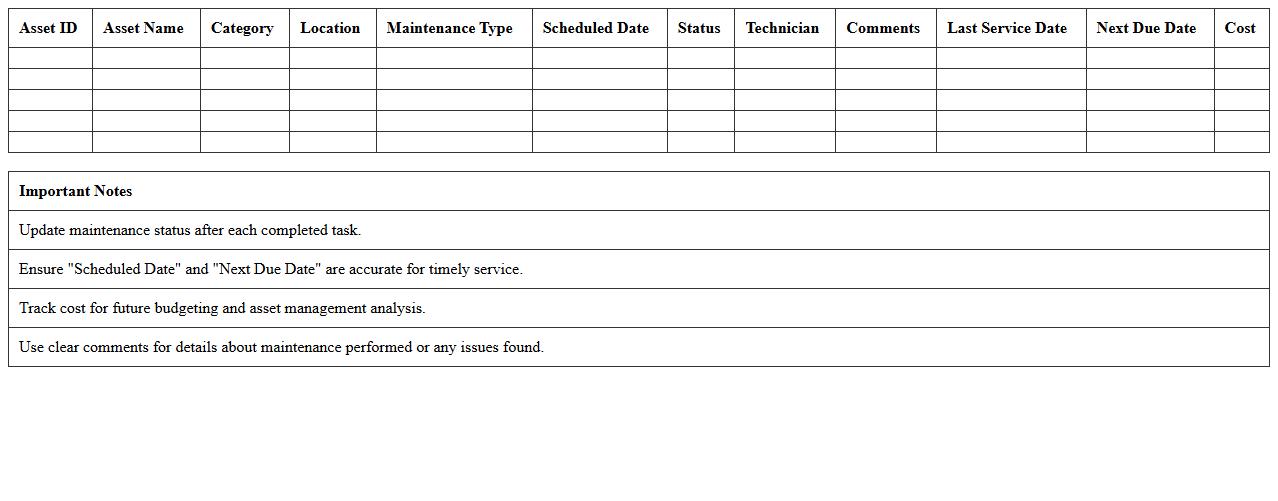

Excel Sheet for Asset Maintenance Scheduling and Reporting

An

Excel Sheet for Asset Maintenance Scheduling and Reporting is a structured tool designed to organize, track, and manage maintenance activities for various assets. It helps streamline maintenance tasks by providing clear schedules, capturing maintenance history, and generating reports that enhance decision-making. This document improves operational efficiency, reduces downtime, and supports proactive asset management through real-time data analysis and visualization.

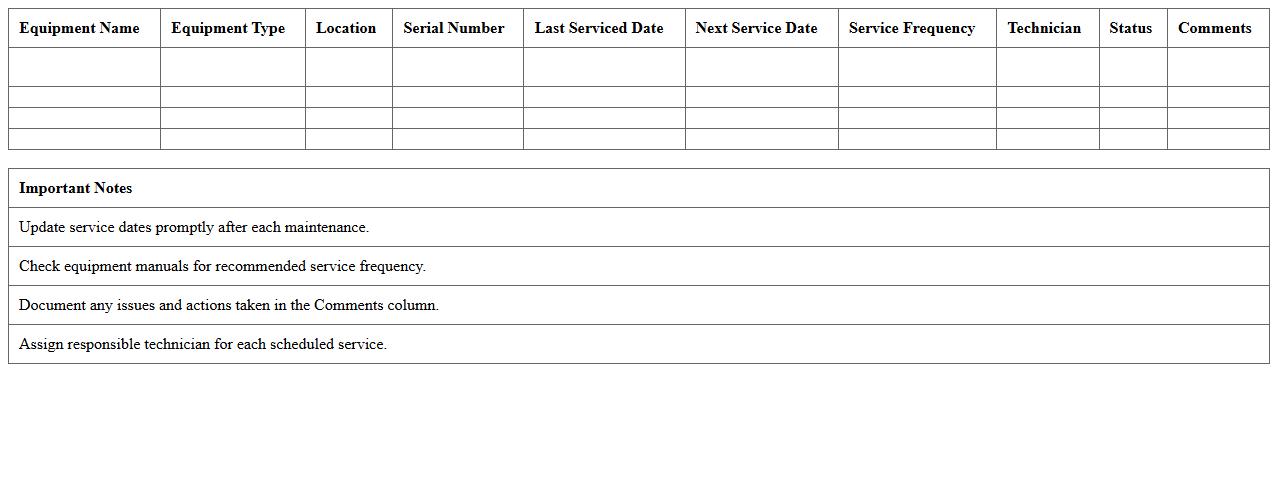

Industrial Equipment Servicing Calendar Excel Template

The

Industrial Equipment Servicing Calendar Excel Template is a structured tool designed to schedule and track maintenance activities for machinery and equipment in industrial settings. It helps ensure timely servicing, reduces downtime, and improves operational efficiency by providing clear visibility of upcoming service dates and maintenance history. Using this template streamlines maintenance management, supports compliance with safety standards, and extends the lifespan of critical industrial assets.

How can you automate recurring maintenance tasks in an Excel maintenance schedule?

To automate recurring maintenance tasks in Excel, use the DATE and IF functions to generate future task dates automatically. Set up dynamic reminders by combining formulas with conditional formatting, which alerts users of upcoming tasks. Additionally, macros can be created to update schedules periodically, ensuring maintenance tasks appear without manual input.

Which formula tracks overdue equipment repairs in an Excel sheet?

The formula =IF(TODAY()>DueDate, "Overdue", "On Time") effectively tracks overdue equipment repairs by comparing the current date with the repair due date. This logical test highlights which tasks need immediate attention, improving maintenance responsiveness. Integrating this formula with filter and sorting features allows quick identification of overdue equipment.

How do you link maintenance history to specific equipment IDs in Excel?

Link maintenance history to equipment IDs by using the VLOOKUP or INDEX-MATCH functions to fetch relevant records associated with each ID. Structuring data into tables with a unique Equipment ID column ensures accurate and efficient retrieval of history details. This method creates a dynamic database that updates automatically with added maintenance entries.

What Excel template layout best visualizes monthly repair workloads?

An ideal Excel template for visualizing monthly repair workloads uses a Gantt chart or calendar-style layout that displays tasks across days or weeks. Incorporating color-coded bars and task status indicators enhances clarity and work distribution visibility. This approach aids in balancing repair assignments and forecasting resource needs effectively.

How can conditional formatting highlight urgent repairs in a maintenance schedule?

Conditional formatting highlights urgent repairs by applying color scales or icon sets based on criteria such as due dates or issue severity. Setting rules like "cell value less than or equal to today's date" visually flags priority tasks in bold colors like red. This instantly draws attention to high-priority repairs, streamlining maintenance workflow management.