The Machine Downtime Report Excel Template for Manufacturing Plants enables precise tracking of equipment stoppages and operational inefficiencies. It helps identify downtime causes, monitor maintenance schedules, and improve overall plant productivity. This template's user-friendly format supports data-driven decision-making to minimize unplanned delays and optimize manufacturing workflows.

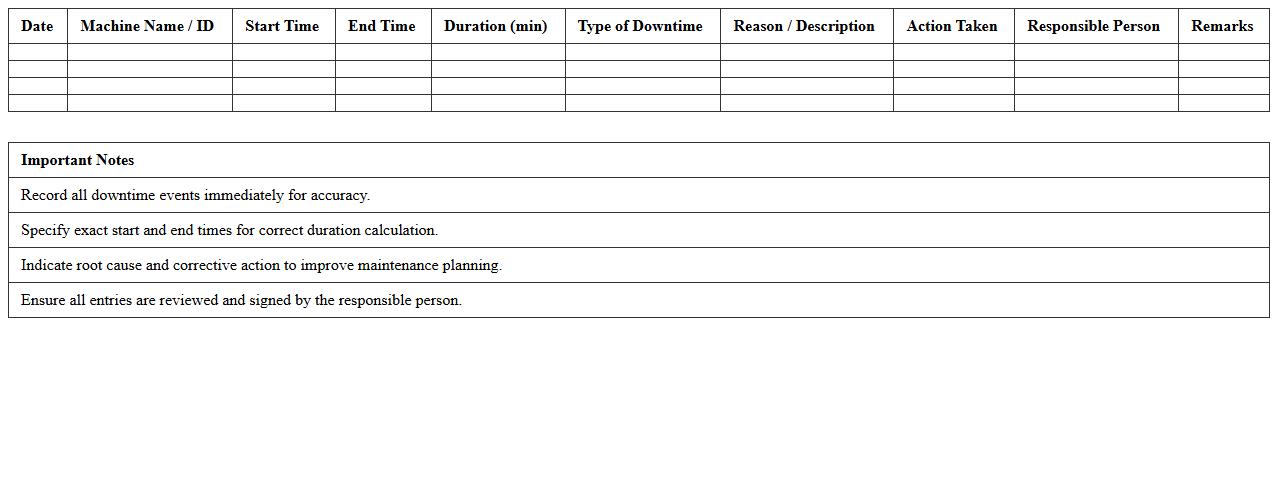

Machine Downtime Log Sheet Excel Template

A

Machine Downtime Log Sheet Excel Template is a structured document designed to record and analyze the duration, reasons, and frequency of machine stoppages in a manufacturing or production environment. It enables businesses to systematically track equipment performance, identify patterns of downtime, and implement targeted maintenance strategies to improve operational efficiency. Utilizing this template helps reduce unplanned interruptions, optimize resource allocation, and enhance overall productivity.

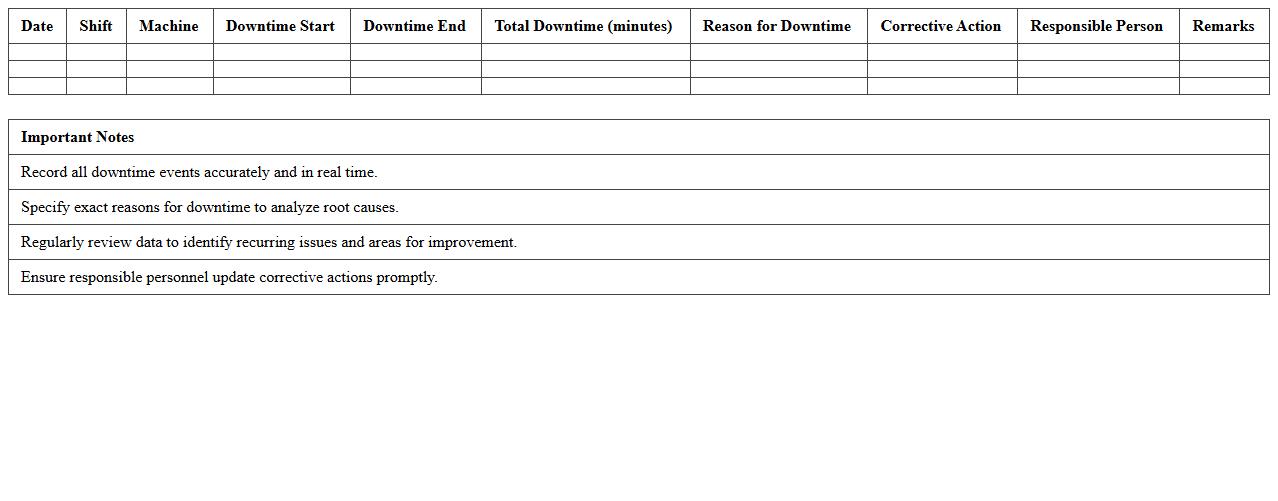

Manufacturing Plant Equipment Downtime Tracker

The

Manufacturing Plant Equipment Downtime Tracker document is a vital tool used to record and analyze periods when machinery is non-operational, enabling manufacturers to identify patterns and root causes of equipment failures. By systematically tracking downtime, this document helps optimize maintenance schedules, reduce unexpected breakdowns, and improve overall plant productivity. It serves as a data-driven foundation for decision-making aimed at enhancing operational efficiency and minimizing costly production delays.

Production Line Machine Downtime Analysis Spreadsheet

The

Production Line Machine Downtime Analysis Spreadsheet is a comprehensive document designed to track and analyze periods when machinery is non-operational, helping identify patterns and root causes of downtime. It organizes data related to machine stoppages, duration, and reasons, enabling manufacturers to pinpoint inefficiencies and prioritize maintenance activities. By utilizing this tool, companies can improve production efficiency, reduce unplanned downtime, and enhance overall equipment effectiveness (OEE).

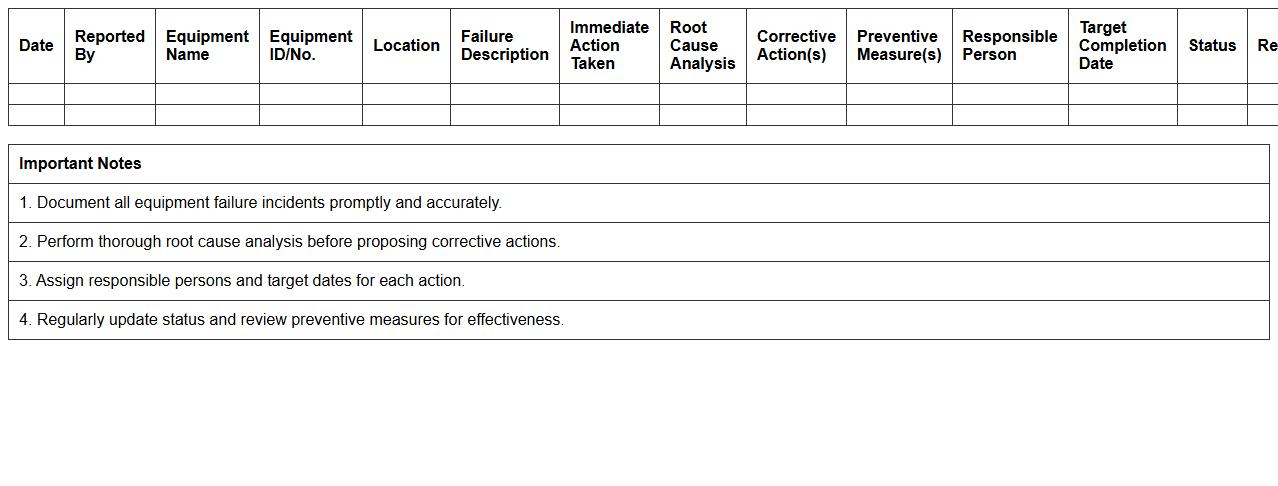

Equipment Failure Root Cause Report Excel Template

The

Equipment Failure Root Cause Report Excel Template is a structured document designed to systematically identify and analyze the underlying reasons behind equipment malfunctions. It allows users to log detailed information such as failure symptoms, inspection results, and corrective actions, enabling efficient tracking and resolution of issues. Utilizing this template improves maintenance processes by facilitating data-driven decision-making and reducing downtime through targeted preventive measures.

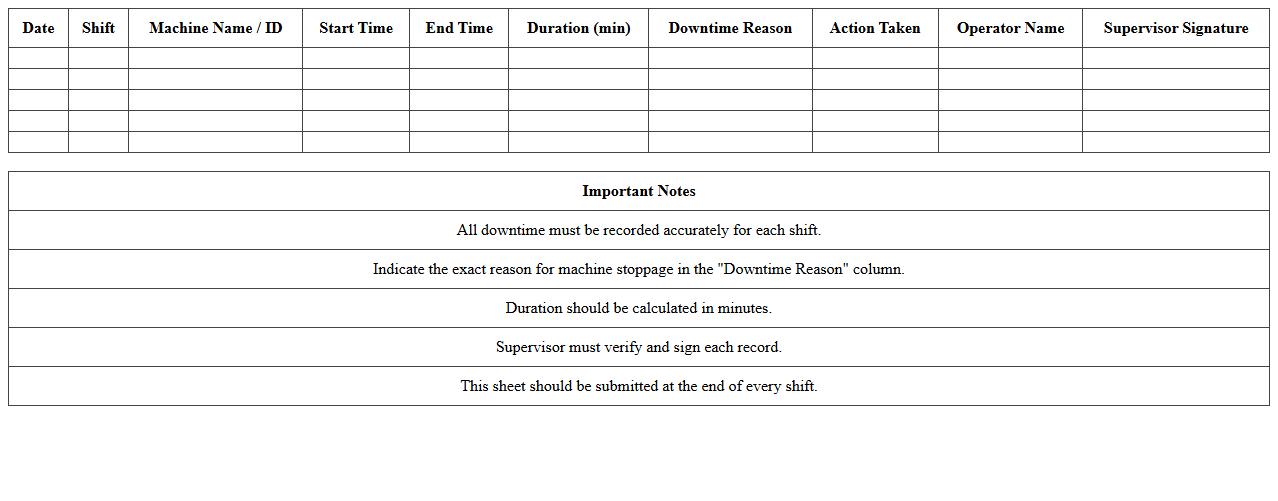

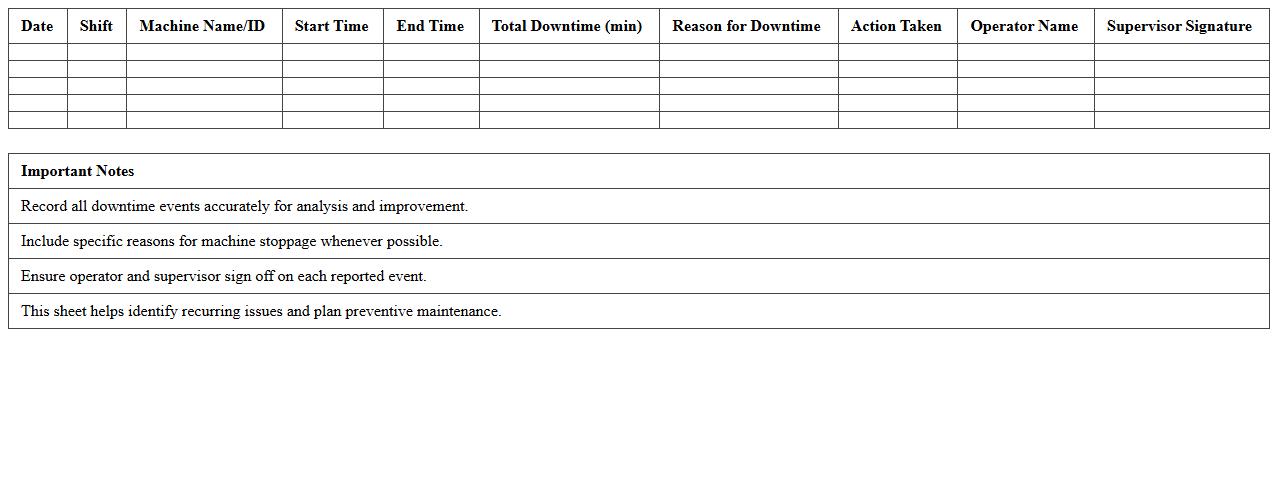

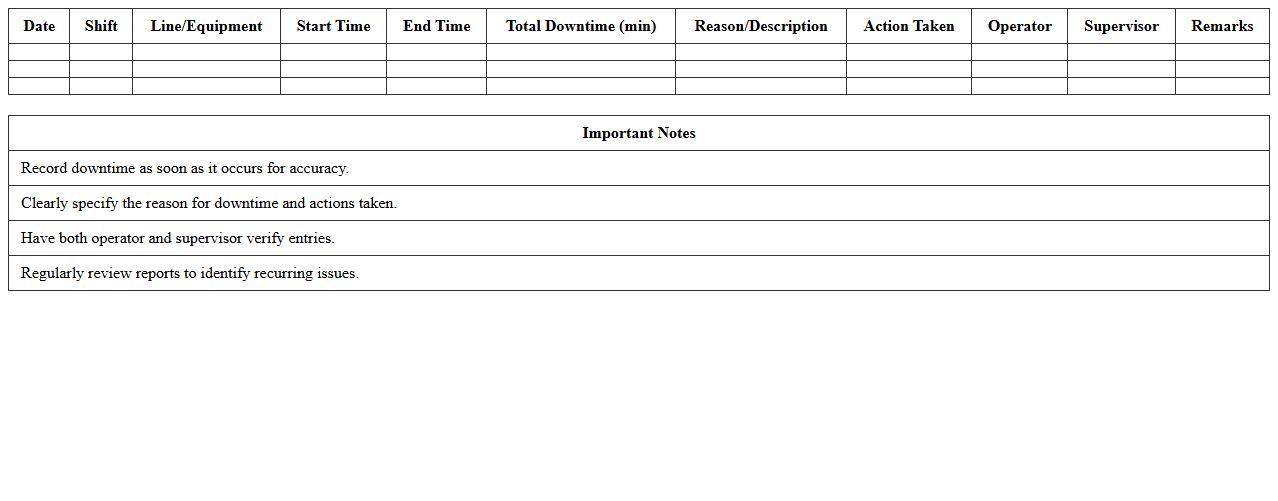

Shift-wise Machine Downtime Recording Sheet

The

Shift-wise Machine Downtime Recording Sheet is a document designed to track and document the exact times and reasons for machine stoppages during different work shifts. It enables production teams to identify frequent downtime causes, optimize maintenance schedules, and improve overall equipment efficiency. Recording downtime data shift-wise helps in pinpointing specific periods of inefficiency, facilitating targeted process improvements and minimizing production losses.

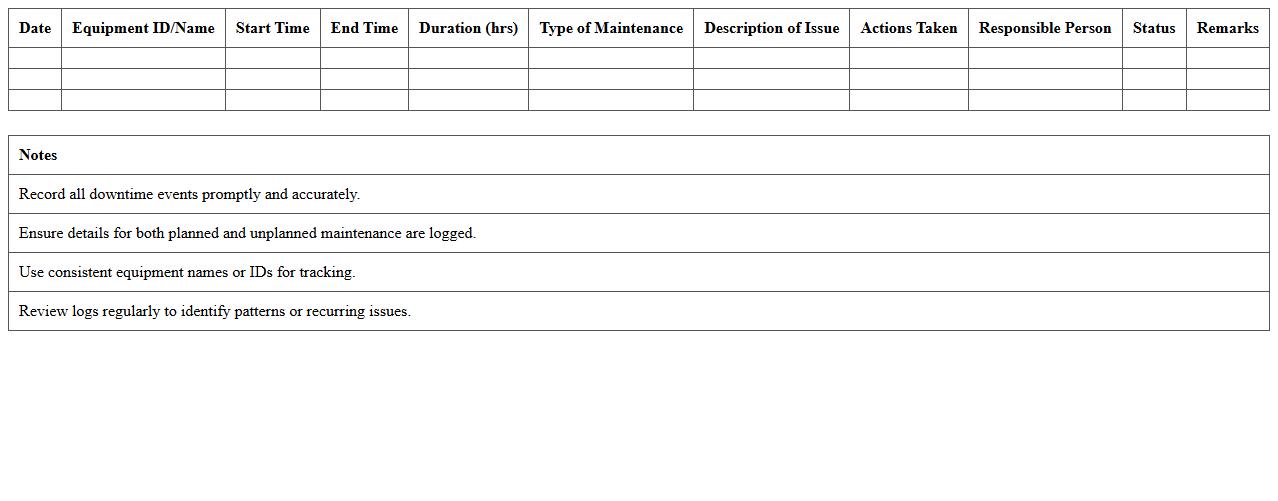

Maintenance Downtime Monitoring Excel Log

The

Maintenance Downtime Monitoring Excel Log document systematically records equipment or system downtime incidents, including duration, cause, and resolution details. This log enhances operational efficiency by identifying recurring issues and facilitating data-driven maintenance scheduling. It supports proactive decision-making, reducing unexpected breakdowns and optimizing resource allocation.

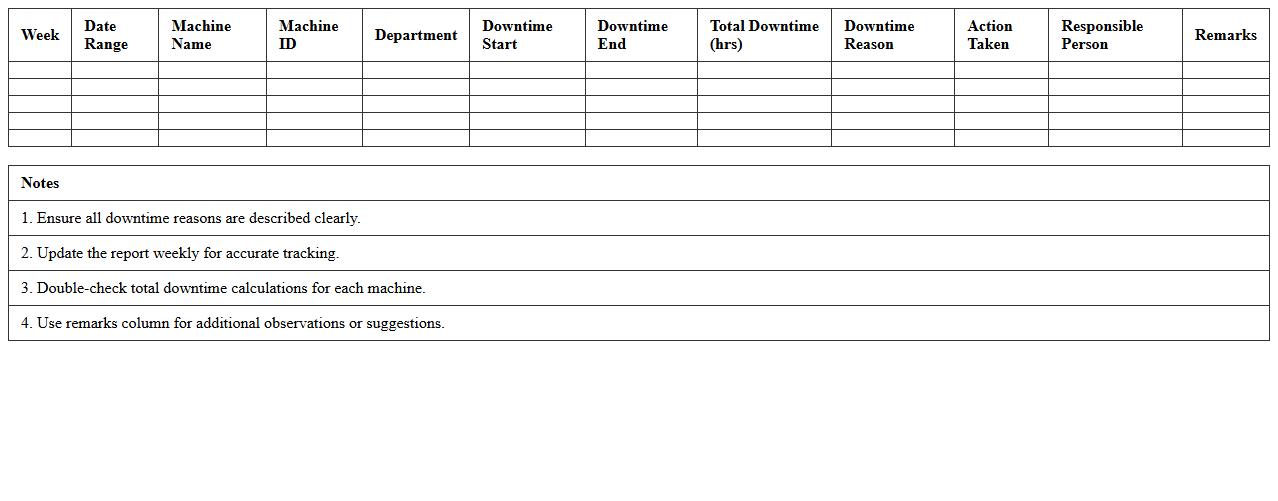

Weekly Machine Downtime Summary Report Template

The

Weekly Machine Downtime Summary Report Template document is a structured tool designed to track and analyze machine downtime on a weekly basis. It helps identify patterns in equipment failures, monitor maintenance effectiveness, and improve overall production efficiency by providing clear visibility into operational interruptions. Using this template enables teams to make data-driven decisions that reduce downtime and optimize machine performance.

Factory Machine Downtime Data Collection Sheet

A

Factory Machine Downtime Data Collection Sheet is a document designed to systematically record the duration and reasons for machine downtime in manufacturing environments. This sheet provides critical insights into equipment performance, allowing production managers to identify patterns, causes of delays, and inefficiencies. Utilizing this data enhances maintenance scheduling, minimizes unexpected breakdowns, and improves overall operational productivity.

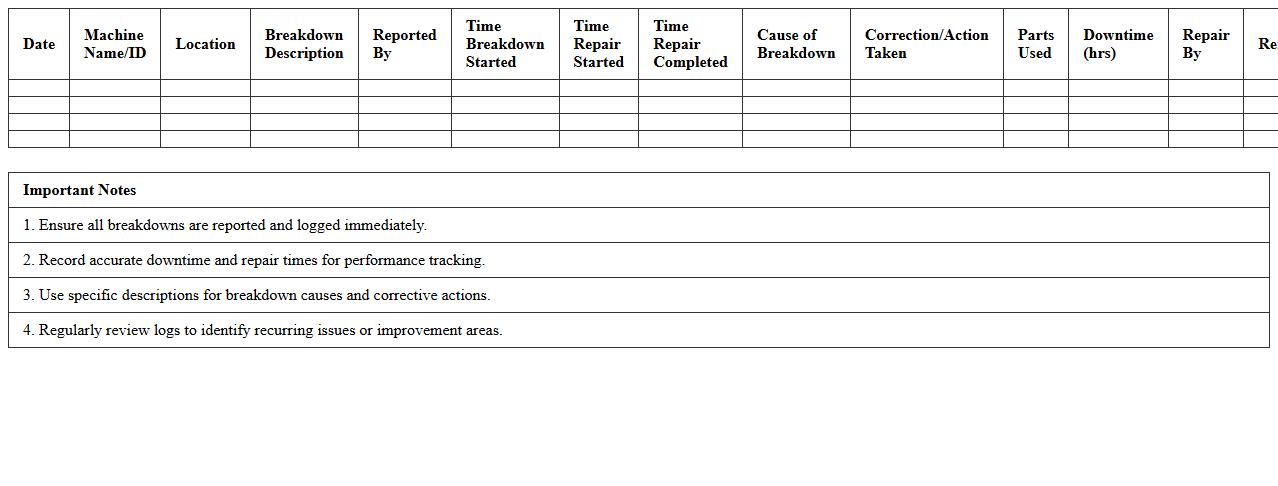

Machine Breakdown and Repair Excel Log

A

Machine Breakdown and Repair Excel Log document is a structured spreadsheet used to record details of equipment failures, repair activities, downtime duration, and maintenance costs. It helps in tracking machine performance, identifying recurring issues, and scheduling preventive maintenance to minimize unplanned outages. This log enhances operational efficiency by providing clear data insights for decision-making and resource allocation.

Plant Operations Downtime Reporting Template

The

Plant Operations Downtime Reporting Template document systematically records periods when machinery or production lines are non-operational, capturing critical data such as downtime duration, causes, and affected equipment. This template enables plant managers and maintenance teams to analyze downtime patterns, identify recurring issues, and implement targeted improvements to reduce unplanned stoppages. By optimizing downtime tracking, it enhances overall operational efficiency and supports data-driven decision-making in manufacturing environments.

How can conditional formatting in Excel highlight critical machine downtime events in the report?

Conditional formatting in Excel can highlight critical machine downtime events by applying color codes based on set thresholds. Use rules to format downtime durations that exceed a specific limit, such as turning cells red if downtime exceeds 30 minutes. This visual aid allows quick identification of problem areas in the report, streamlining analysis.

What formulas best calculate average downtime per machine section in a manufacturing plant?

To calculate average downtime per machine section, use the AVERAGEIF function to average downtime values that meet specific section criteria. For example, =AVERAGEIF(SectionRange, "SectionA", DowntimeRange) computes the average downtime for Section A. This formula provides accurate downtime insights grouped by each machine segment.

How can you automate downtime reason categorization using data validation lists in Excel?

Automate downtime reason categorization by creating a data validation list with all possible causes, allowing consistent entries across the downtime report. Link the data validation dropdown to a predefined reason list to standardize inputs and reduce errors. This automation facilitates easier filtering and analysis of downtime root causes.

Which Excel pivot table setup reveals recurring downtime patterns by work shift?

Create a pivot table with work shifts as row labels and downtime events as values summarized by count or duration. Add downtime causes as columns or filters to analyze the patterns for each shift. This setup helps identify which shifts experience the most frequent or longest downtimes.

What is the most efficient way to track maintenance response times linked to machine downtime entries?

Track maintenance response times by calculating the difference between downtime start and maintenance action timestamps using formulas like =EndTime-StartTime. Store these times in a dedicated column and summarize using Excel functions such as AVERAGE or MAX for analysis. Integrating this with downtime logs enhances performance monitoring and accountability.

More Report Excel Templates