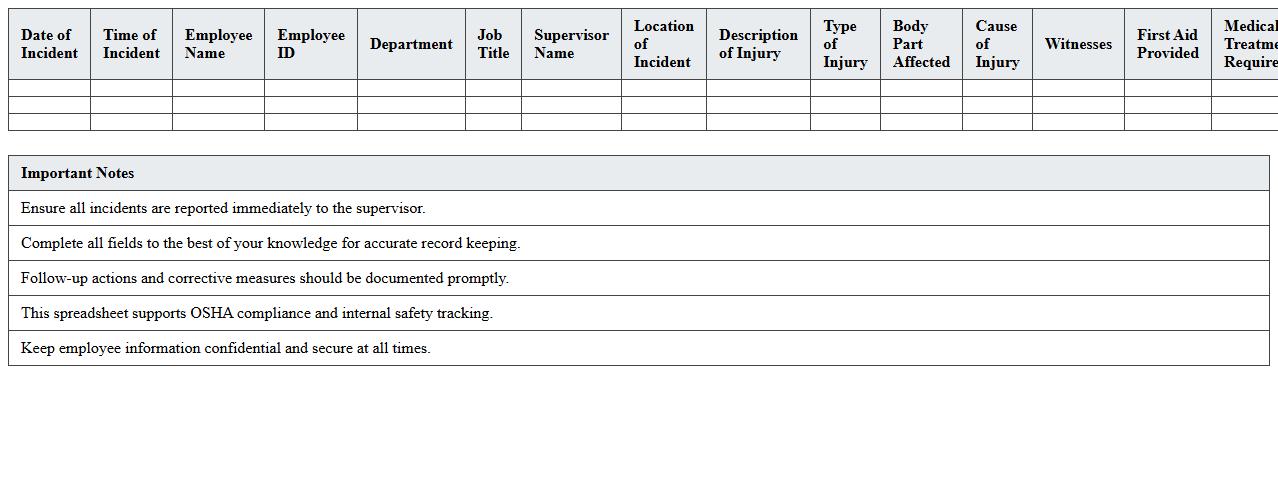

The Accident Report Excel Template for Manufacturing Plants streamlines the process of documenting workplace incidents by providing a structured format for capturing essential details such as time, location, cause, and corrective actions. This template enhances safety management by enabling clear tracking and analysis of accidents, helping to identify patterns and prevent future occurrences. Easy to customize and user-friendly, it supports compliance with safety regulations while improving overall plant safety performance.

Incident Tracking Log Excel Template for Manufacturing Plants

The

Incident Tracking Log Excel Template for manufacturing plants is a structured spreadsheet designed to record, monitor, and analyze workplace incidents efficiently. It enables plant managers and safety officers to document incident details, identify trends, and implement corrective actions to enhance workplace safety and regulatory compliance. This template streamlines incident management, reduces response times, and helps maintain a safer production environment by providing clear visibility into all reported incidents.

Workplace Injury Report Spreadsheet for Manufacturing Facilities

A

Workplace Injury Report Spreadsheet for manufacturing facilities is a detailed document that tracks incidents of employee injuries, including the type, cause, and severity of each case. This spreadsheet helps organizations identify patterns and high-risk areas within the production environment, enabling targeted safety improvements. By maintaining accurate injury records, facilities ensure compliance with occupational health regulations and enhance overall worker safety management.

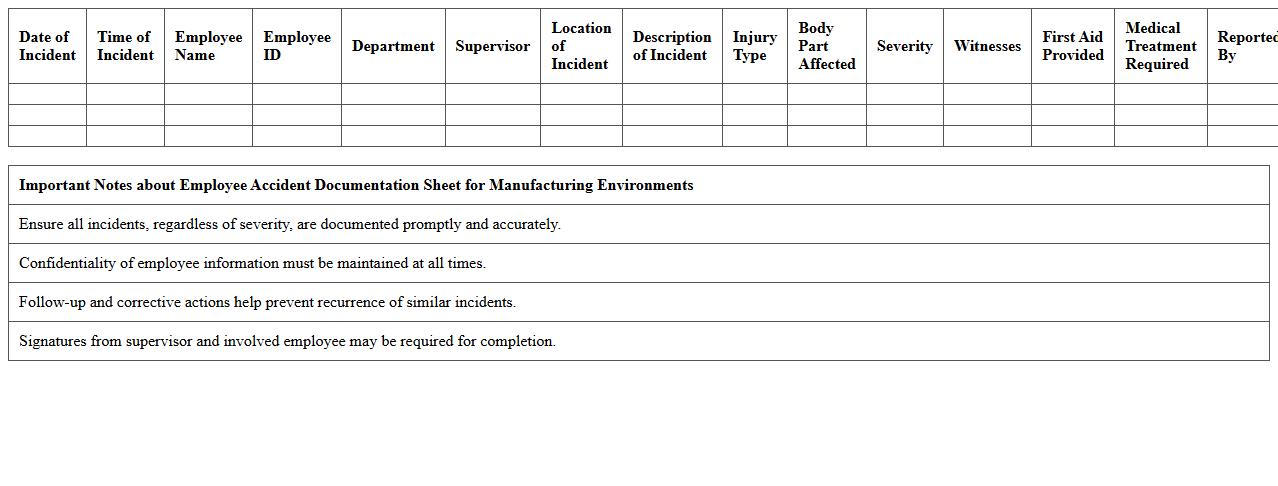

Employee Accident Documentation Sheet for Manufacturing Environments

The

Employee Accident Documentation Sheet for manufacturing environments is a critical record-keeping tool designed to systematically capture details of workplace accidents involving employees. It includes essential information such as the date, time, cause of the accident, nature of injuries, and witness statements, which are vital for incident analysis and legal compliance. Utilizing this document helps improve safety protocols, facilitates accurate reporting for regulatory agencies, and supports claims processing and risk management within manufacturing operations.

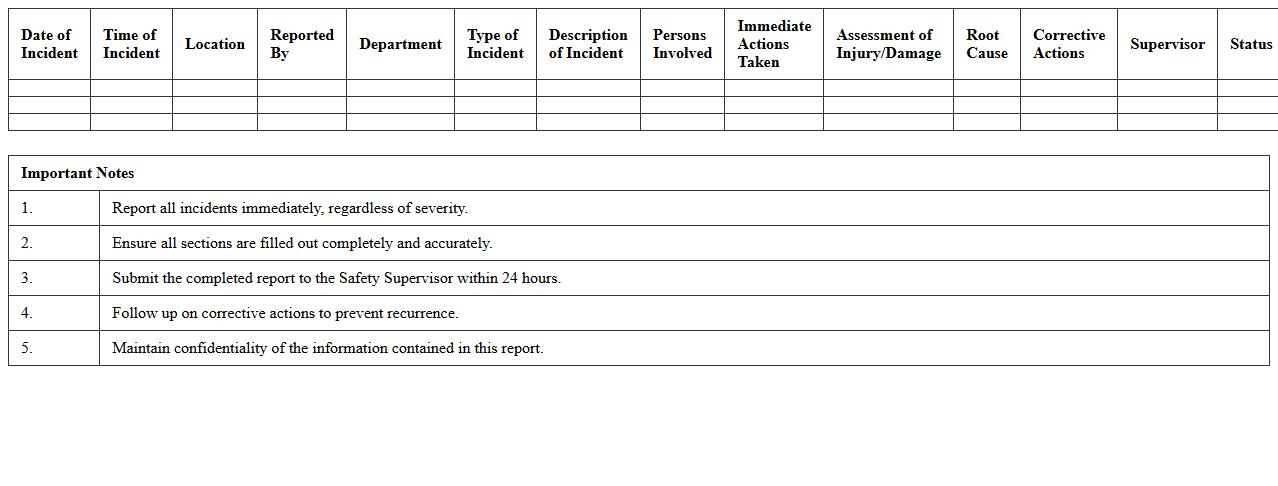

Production Floor Safety Incident Report Template

A

Production Floor Safety Incident Report Template is a structured document designed to record details of any safety incidents occurring on the production floor, including date, time, location, persons involved, and incident description. This template helps organizations systematically capture critical information for analysis, ensuring compliance with workplace safety regulations and facilitating timely corrective actions. Using such a report enables improved hazard identification, prevention strategies, and enhances overall workplace safety management.

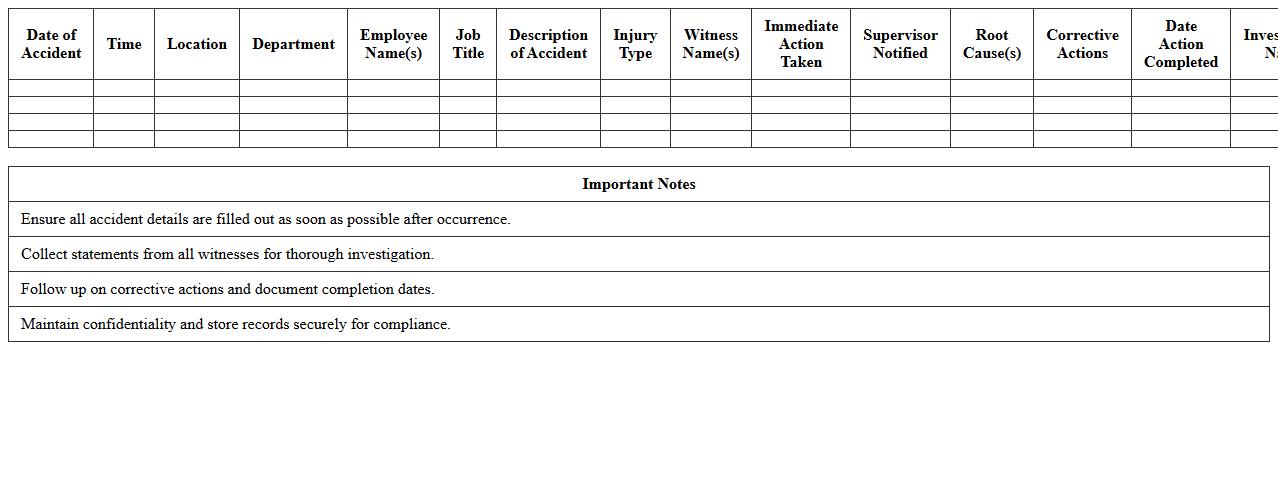

Manufacturing Plant Accident Investigation Excel Template

The

Manufacturing Plant Accident Investigation Excel Template is a structured document designed to systematically record and analyze workplace accidents in manufacturing environments. It organizes critical data such as incident details, root cause analysis, and corrective actions, enabling efficient tracking and reporting. Utilizing this template improves safety management by identifying hazards, preventing future accidents, and ensuring compliance with occupational safety regulations.

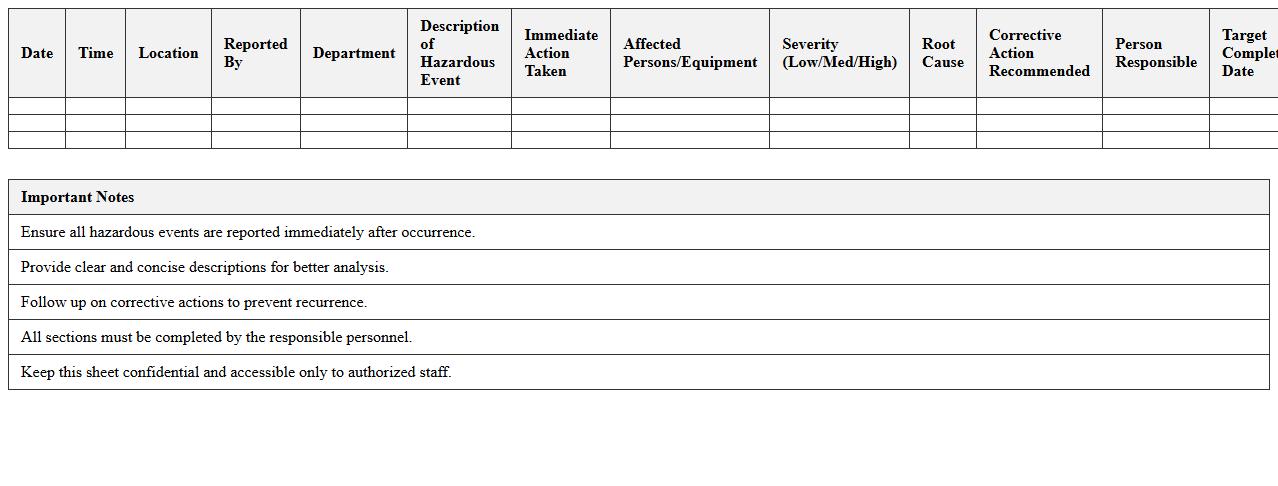

Hazardous Event Reporting Sheet for Factory Operations

The

Hazardous Event Reporting Sheet for factory operations is a critical document used to systematically record any incidents or near-misses involving potential hazards within the workplace. It helps identify the causes and impacts of hazardous events, enabling management to implement effective preventive measures. By maintaining accurate reports, factories enhance safety protocols, reduce the risk of accidents, and ensure compliance with occupational health and safety regulations.

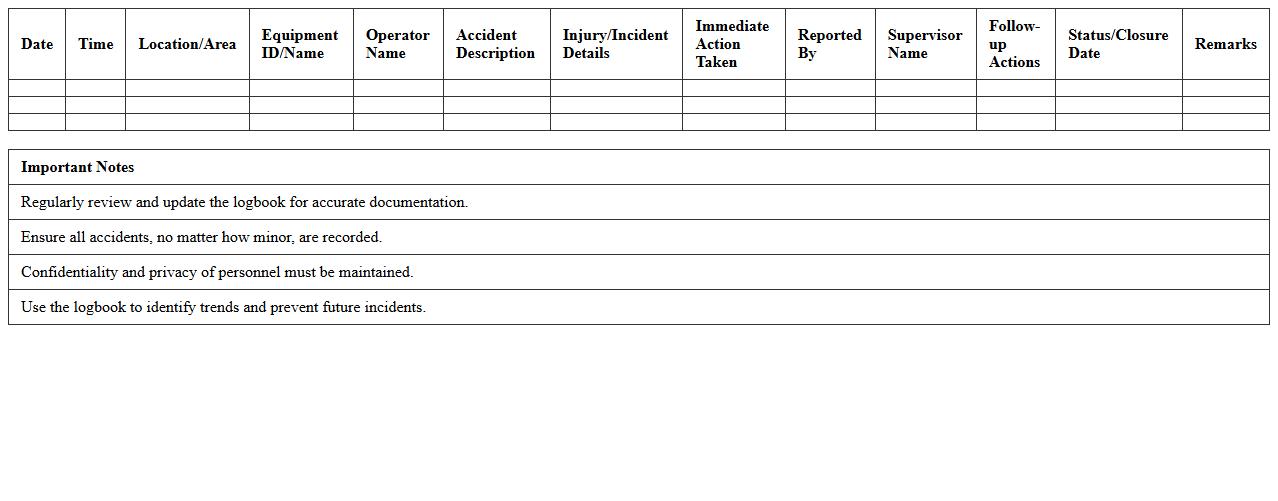

Equipment Accident Logbook Template for Manufacturing Sites

An

Equipment Accident Logbook Template for manufacturing sites is a structured document designed to record detailed information about incidents involving machinery or equipment. It helps track accident causes, affected personnel, equipment status, and corrective actions taken, ensuring compliance with safety regulations and facilitating incident analysis. This template improves workplace safety by enabling systematic monitoring, reducing downtime, and supporting preventive maintenance strategies.

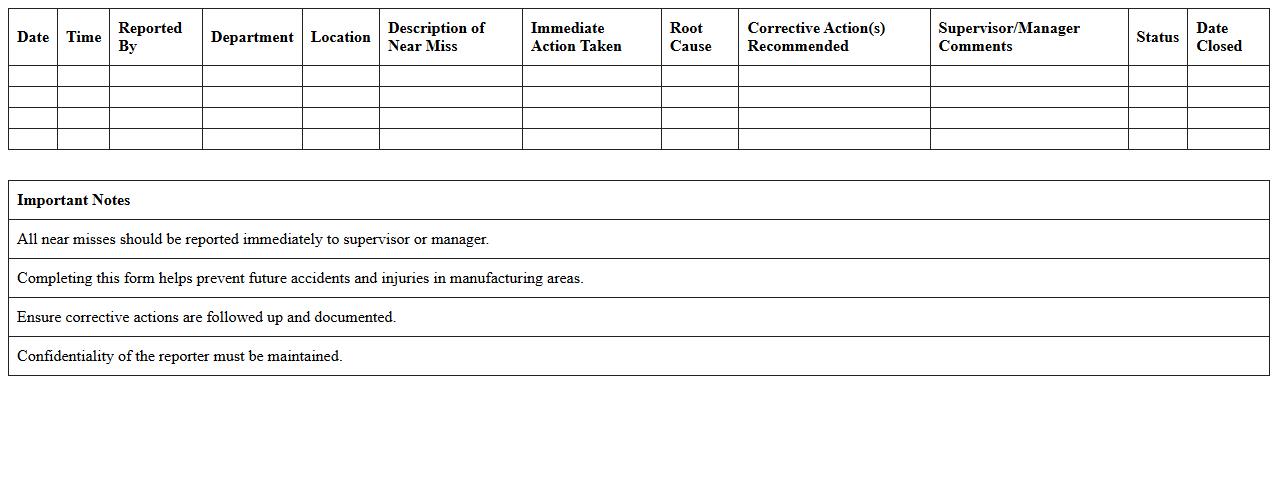

Near Miss Report Excel Template for Manufacturing Departments

A

Near Miss Report Excel Template for manufacturing departments is a structured document designed to record and analyze incidents where accidents were narrowly avoided. It helps identify potential hazards and unsafe conditions before they result in injuries or damage, enabling proactive safety improvements. Using this template enhances workplace safety by promoting timely reporting, tracking trends, and facilitating data-driven decision-making in manufacturing environments.

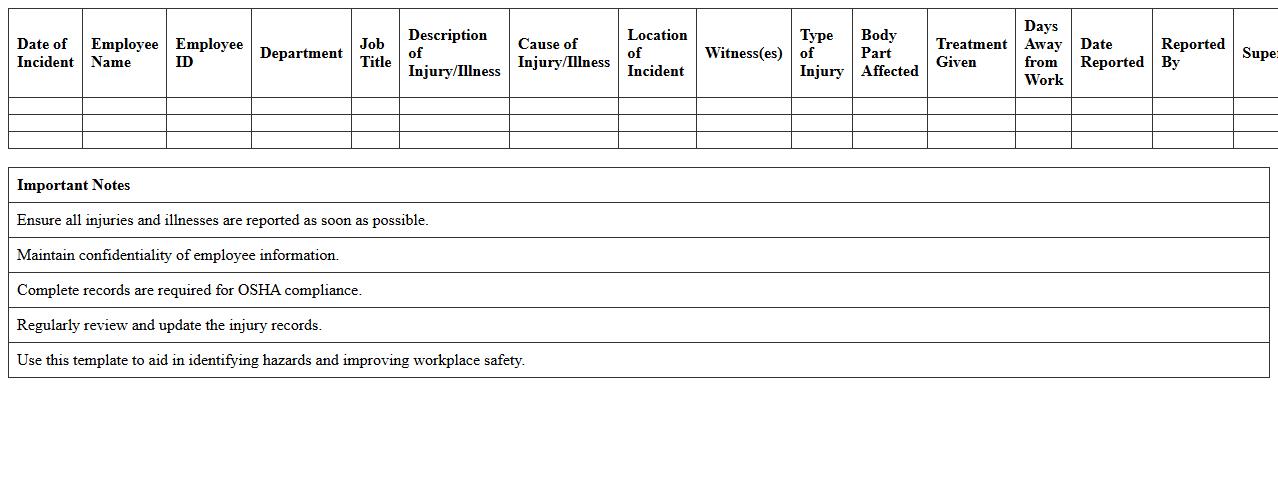

Occupational Injury Recordkeeping Template for Manufacturing Workplaces

The

Occupational Injury Recordkeeping Template for manufacturing workplaces systematically documents work-related injuries and illnesses, ensuring compliance with OSHA regulations. It helps employers track incident patterns, identify hazards, and implement safety improvements to reduce workplace accidents. Utilizing this template streamlines reporting processes and supports maintaining a safer work environment in manufacturing settings.

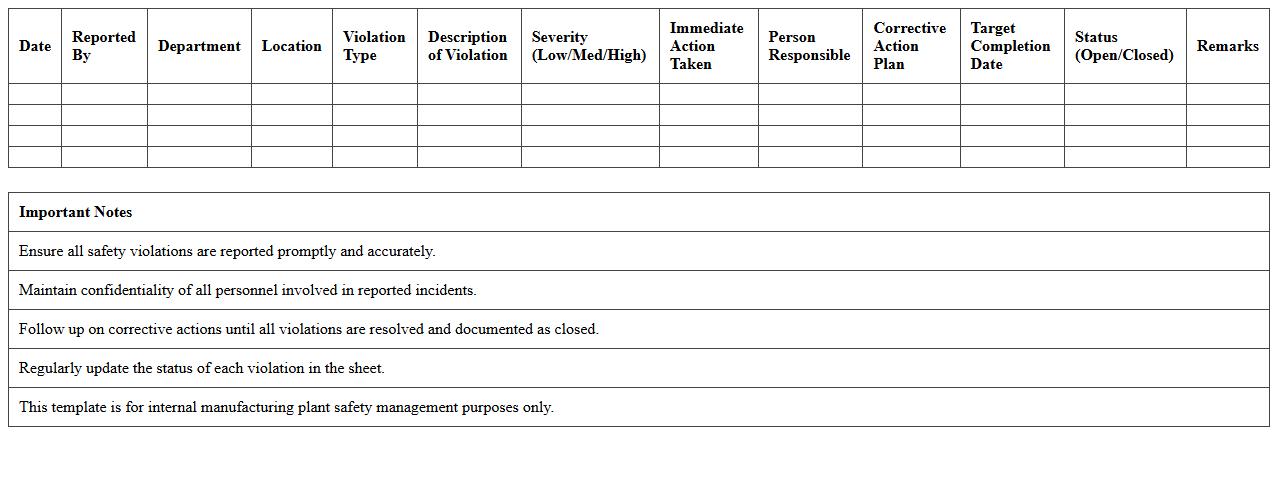

Manufacturing Plant Safety Violation Report Excel Sheet

The

Manufacturing Plant Safety Violation Report Excel Sheet document is a detailed record-keeping tool designed to track and document safety violations within manufacturing facilities. It helps identify patterns and recurring issues by organizing violations by type, date, location, and responsible parties, enabling proactive risk management. This organized data improves compliance with safety regulations and supports continuous improvement in workplace safety standards.

What key data fields should be included in an accident report Excel sheet for manufacturing plant incidents?

An effective accident report Excel sheet must contain incident date and time to track when accidents occur. It should include employee details such as name, job title, and department for accountability. Additionally, key fields like accident description, location, injury type, and severity level are crucial for comprehensive documentation.

How can accident severity levels be categorized effectively in a manufacturing accident log?

Accident severity levels can be categorized using predefined risk classification tiers such as minor, moderate, serious, and fatal. Implementing a numerical scale aligned with OSHA or company-specific standards ensures consistency in reporting. Clear severity categories help prioritize corrective actions and resource allocation effectively.

What formulas automate injury frequency rate calculations in Excel accident reports?

The formula to calculate Injury Frequency Rate (IFR) is (Number of Injuries x 1,000,000) / Total Hours Worked. Use an Excel calculation like = (COUNT(InjuryRange) * 1000000) / Sum(HoursWorkedRange) to automate this metric. This formula provides a standardized measure of injury incidence adjusted for workforce exposure.

Which conditional formatting highlights recurrent accident types in a manufacturing plant Excel report?

Applying color scales or duplicate value highlighting in Excel emphasizes frequently occurring accident types. Use conditional formatting rules such as Highlight Cells Rules > Duplicate Values to flag repeated incidents. This visualization aids in quickly identifying patterns and areas needing urgent attention.

How can Excel track corrective action follow-up status after manufacturing plant accidents?

Excel can track follow-up status by adding drop-down lists with options like pending, in progress, and completed in a dedicated status column. Incorporating date fields for assigned, due, and completion dates allows timeline monitoring. Using conditional formatting or progress bars visually indicates the current corrective action status at a glance.

More Report Excel Templates