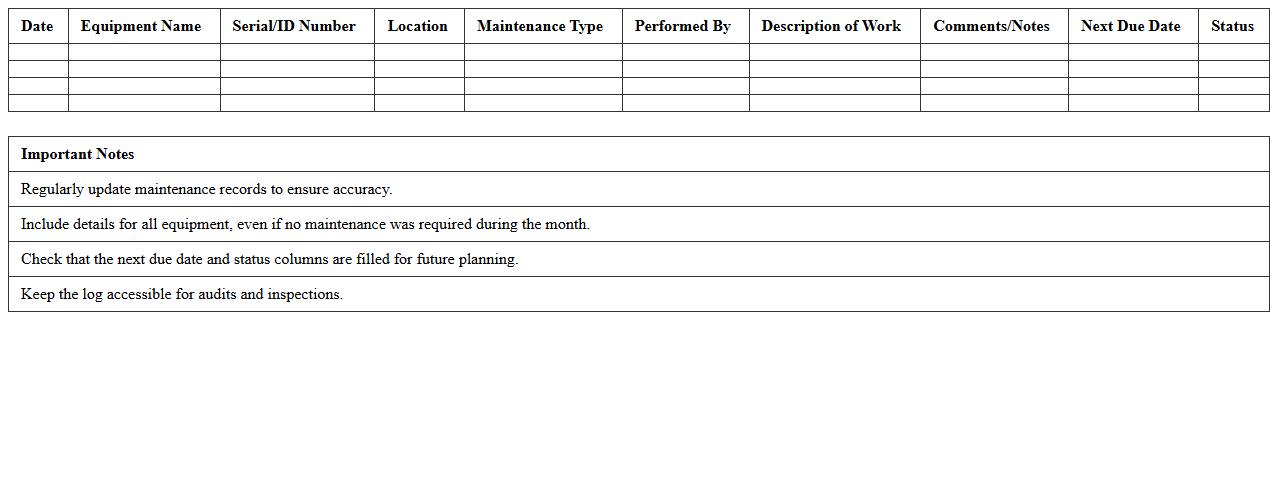

Monthly Equipment Maintenance Log Excel Template

The Monthly Equipment Maintenance Log Excel Template is a structured document designed to track and schedule routine maintenance tasks for machinery and equipment. It helps organizations ensure timely servicing, reduce downtime, and extend the lifespan of assets by recording inspection dates, maintenance activities, and technician notes. Using this

maintenance log improves operational efficiency and aids in compliance with safety standards.

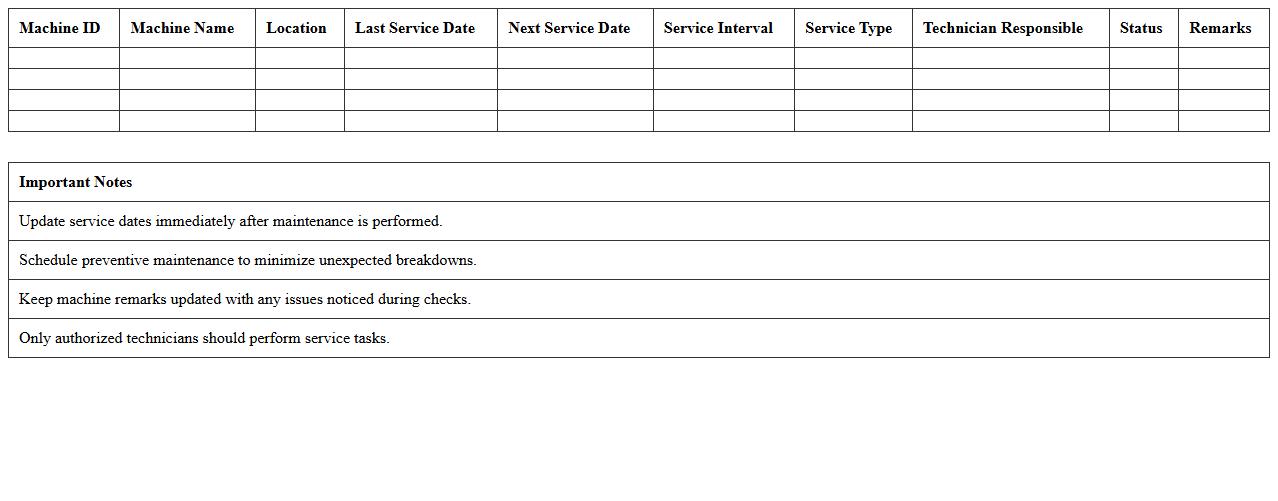

Factory Machine Service Schedule Spreadsheet

A

Factory Machine Service Schedule Spreadsheet document is a detailed tool used to organize and track maintenance activities for industrial machinery. It helps ensure timely servicing, reduces downtime, and extends equipment lifespan by scheduling regular inspections and repairs. This spreadsheet enhances operational efficiency by providing a clear overview of service history and upcoming maintenance tasks.

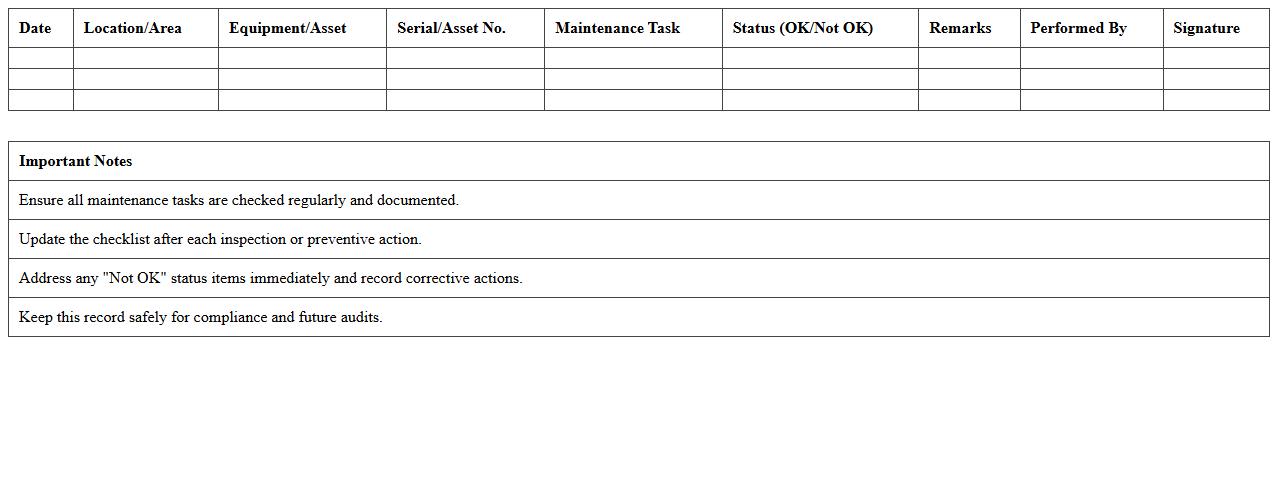

Preventive Maintenance Checklist Excel Sheet

A

Preventive Maintenance Checklist Excel Sheet is a structured document designed to schedule and track routine maintenance tasks for equipment and machinery, helping to avoid unexpected breakdowns. It provides a clear overview of maintenance activities, frequencies, and responsible personnel, ensuring systematic upkeep and compliance with safety standards. Using this checklist improves operational efficiency, reduces downtime, and extends the lifespan of assets by facilitating timely inspections and necessary repairs.

Equipment Downtime Tracking Excel Template

The

Equipment Downtime Tracking Excel Template is a structured spreadsheet designed to monitor and record periods when machinery or equipment is non-operational. This tool helps organizations identify downtime patterns, analyze causes, and implement maintenance strategies to enhance productivity. By providing clear visual reports and data-driven insights, it supports efficient asset management and reduces operational losses.

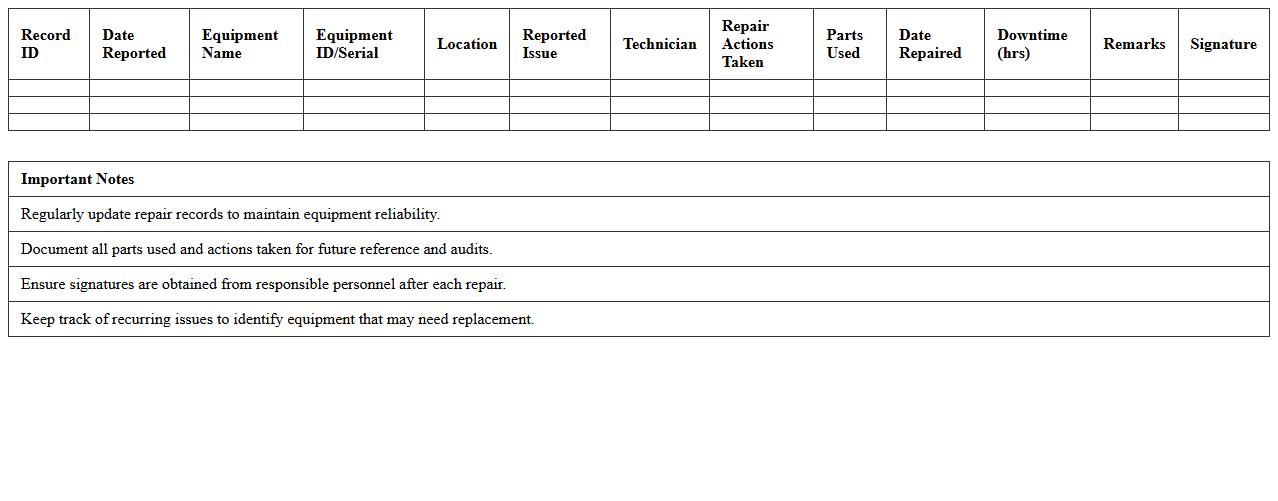

Industrial Equipment Repair Record Log

An

Industrial Equipment Repair Record Log document systematically tracks the maintenance and repair history of machinery, ensuring accurate documentation of service dates, issues addressed, and parts replaced. This log enhances equipment reliability by providing essential data for predictive maintenance, reducing downtime and repair costs. It also supports compliance with safety regulations and facilitates audit processes by maintaining a clear, organized record of all repair activities.

Maintenance Work Order Tracker Excel File

The

Maintenance Work Order Tracker Excel File is a structured document designed to log, monitor, and manage maintenance requests and tasks efficiently. It allows users to track the status, prioritize work orders, assign technicians, and maintain records of completed jobs, ensuring timely upkeep of equipment and facilities. By organizing maintenance activities in one centralized file, it enhances accountability, reduces downtime, and improves overall asset management.

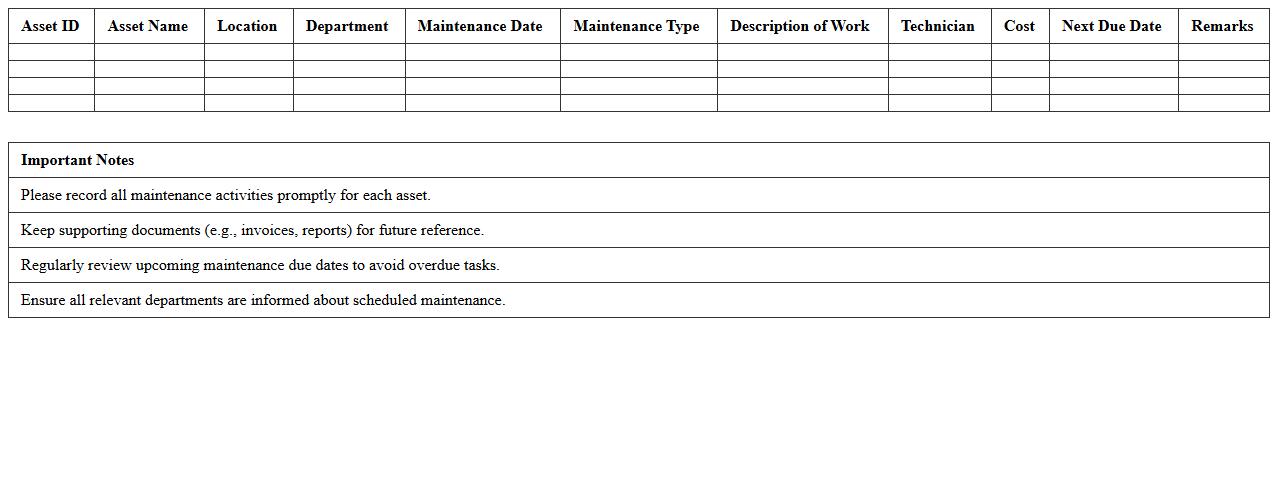

Asset Maintenance History Sheet for Factories

The

Asset Maintenance History Sheet for factories is a detailed record document that tracks all maintenance activities performed on factory equipment and machinery over time. It provides historical data on repairs, servicing dates, parts replaced, and maintenance costs, enabling effective monitoring of asset performance and lifecycle management. This document is useful for optimizing maintenance schedules, reducing unexpected downtime, and ensuring compliance with safety standards.

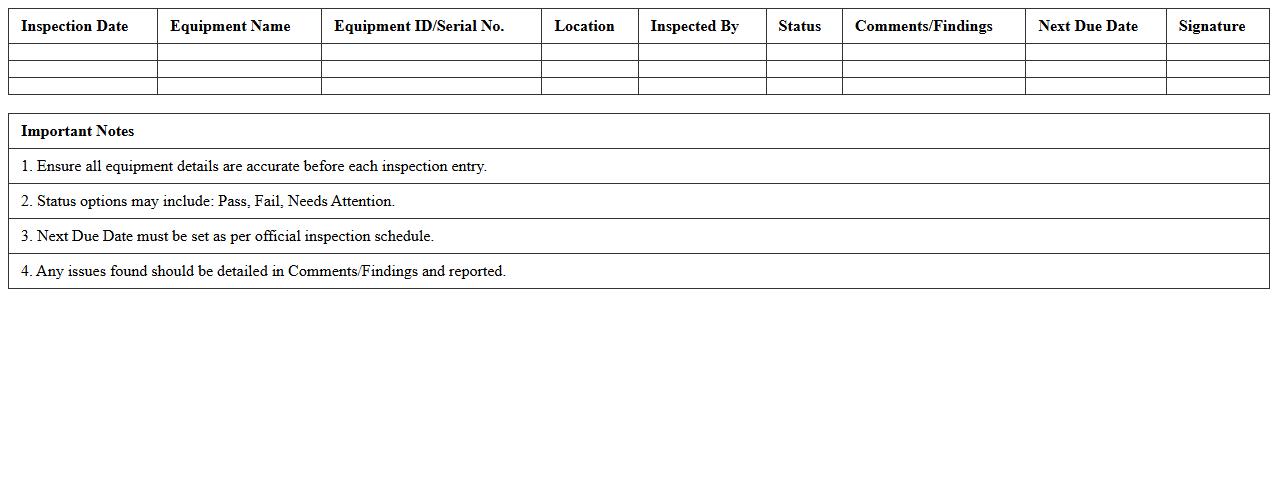

Equipment Inspection Register Excel Template

An

Equipment Inspection Register Excel Template is a structured spreadsheet designed to record, track, and manage the inspection status, dates, and maintenance details of various equipment. It streamlines equipment management by providing a centralized document that ensures compliance with safety standards and helps prevent breakdowns through timely inspections. Utilizing this template enhances operational efficiency, reduces downtime, and facilitates easy reporting and audit readiness for all equipment assets.

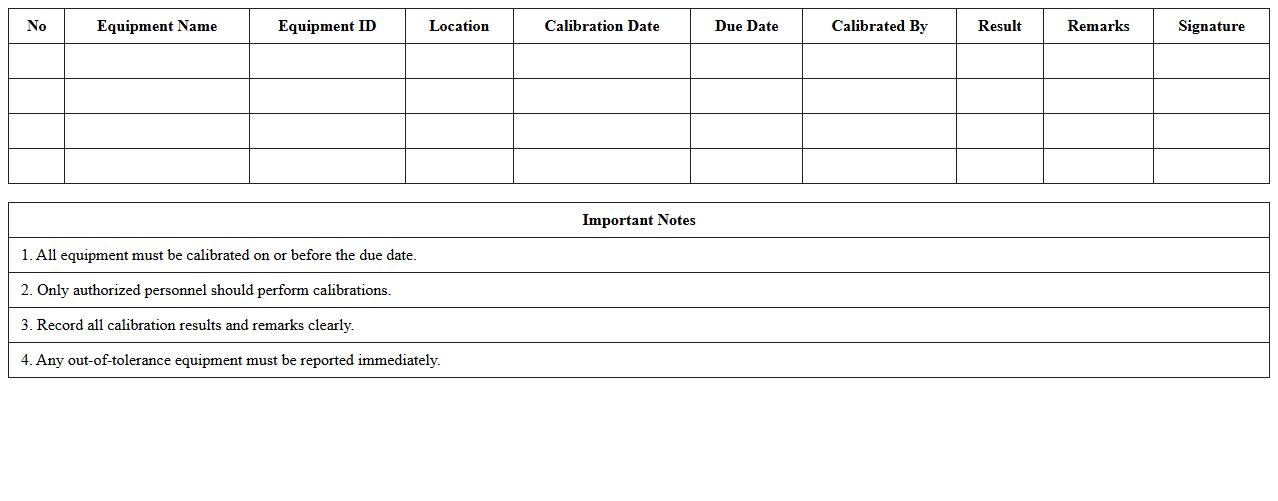

Factory Equipment Calibration Log Sheet

A

Factory Equipment Calibration Log Sheet is a document that records the calibration activities, dates, results, and technician details for factory machinery and instruments. This log sheet ensures accuracy, reliability, and compliance with industry standards by tracking the performance and adjustments of equipment over time. It is useful for maintaining quality control, preventing equipment failure, and meeting regulatory requirements in manufacturing processes.

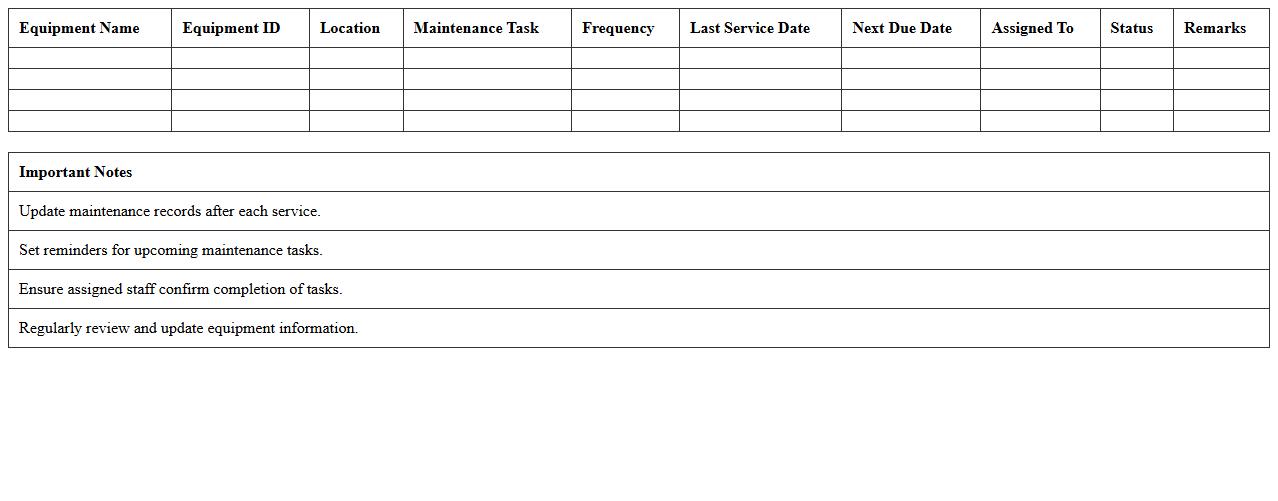

Scheduled Maintenance Planner Spreadsheet

A

Scheduled Maintenance Planner Spreadsheet is a systematic document used to organize, track, and manage maintenance activities for equipment or facilities. It helps ensure timely inspections, repairs, and preventive tasks, reducing downtime and extending asset lifespan. By providing a clear overview of maintenance schedules, it enhances operational efficiency and resource allocation.

How can conditional formatting in Excel highlight overdue equipment maintenance tasks?

Conditional formatting in Excel uses dynamic rules to visually identify overdue maintenance tasks by comparing due dates against the current date. Applying a rule that highlights cells in red when the maintenance date is less than today instantly flags delays. This method enhances task visibility and helps prioritize equipment maintenance schedules effectively.

What are the best practices for tracking equipment downtime in an Excel maintenance log?

Accurate tracking of equipment downtime requires setting up structured columns for start and end times to calculate the total downtime automatically. Using drop-down lists ensures consistent inputs for reasons behind downtime, improving data accuracy. Regular updates and summarizing downtime by machine provide actionable insights for maintenance planning and reducing overall equipment unavailability.

How can you automate email reminders for scheduled equipment maintenance using Excel?

Automating email reminders involves linking Excel with Outlook through VBA scripts that trigger emails based on scheduled maintenance dates. Setting a macro to check due dates daily allows sending timely notifications directly from the maintenance log. This integration minimizes missed maintenance events and supports proactive equipment management.

Which Excel formulas efficiently calculate maintenance costs per machine over time?

Using the SUMIFS function enables aggregating maintenance costs filtered by machine and specific time periods. Incorporating date ranges as criteria helps track expenses monthly, quarterly, or yearly within the log. This formula-driven approach provides transparent cost analysis essential for budgeting and cost control in equipment upkeep.

What data validation methods prevent incorrect maintenance entries in factory logs?

Implementing data validation rules such as dropdown menus, date restrictions, and numerical limits ensures maintenance logs contain only correct and consistent data. Custom error messages guide users to input valid information when entering dates, technician names, or cost figures. These validation controls significantly reduce data entry errors and improve the reliability of maintenance records.