The Production Forecast Excel Template for Manufacturing Plants provides a streamlined tool to predict manufacturing output based on historical data and current production capacity. It enables managers to optimize resource allocation, reduce downtime, and improve supply chain coordination through accurate demand projections. Customizable features allow for easy adaptation to various manufacturing processes and product lines, enhancing overall operational efficiency.

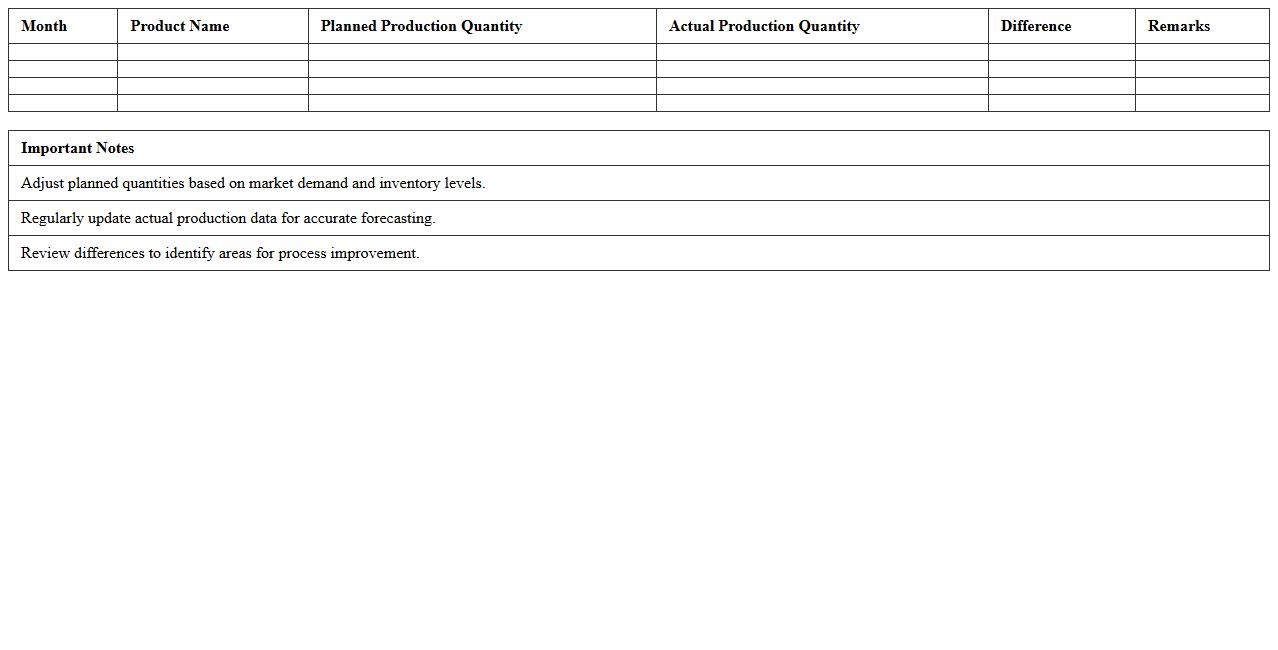

Monthly Production Forecast Excel Template

The

Monthly Production Forecast Excel Template is a structured spreadsheet designed to estimate future production levels based on historical data and market trends. It helps businesses efficiently plan resources, allocate budgets, and set realistic targets by providing clear visibility into anticipated output. This tool enhances decision-making by enabling accurate tracking of production performance against goals over a specified monthly timeline.

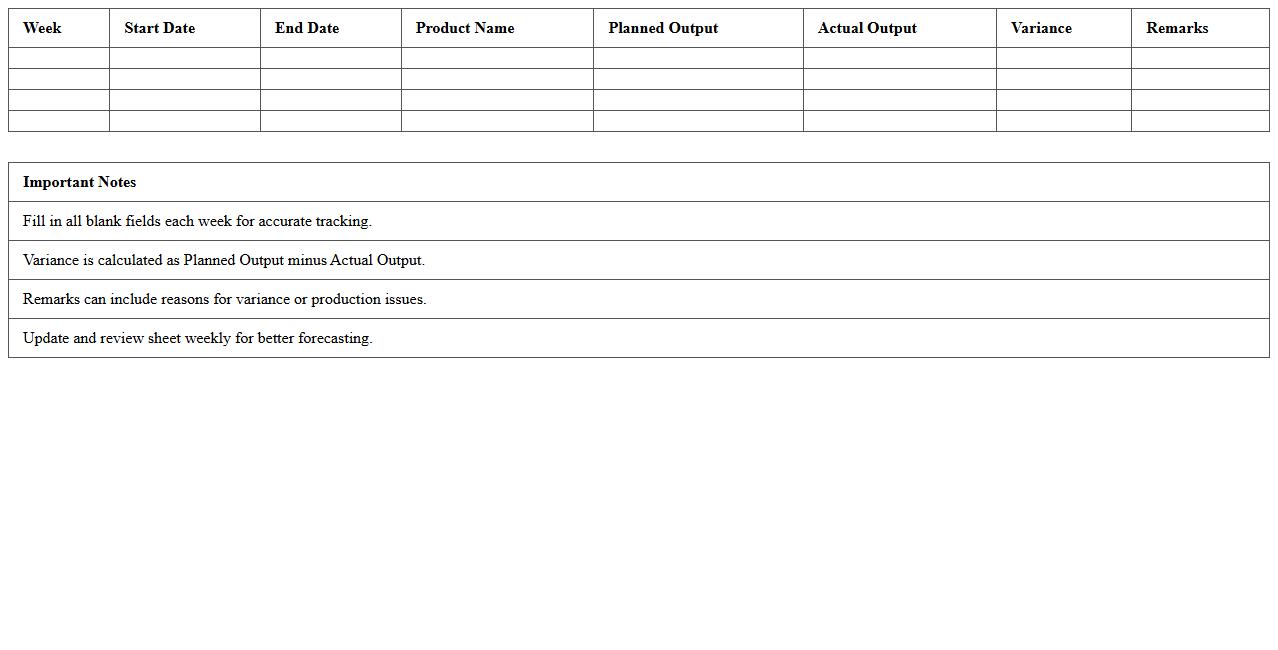

Weekly Manufacturing Output Prediction Sheet

The

Weekly Manufacturing Output Prediction Sheet is a strategic document that forecasts production volumes based on historical data, current capacity, and demand trends. It enables manufacturers to optimize resource allocation, manage inventory, and adjust workforce scheduling effectively. By providing accurate output predictions, it helps reduce downtime, minimize operational costs, and improve overall production efficiency.

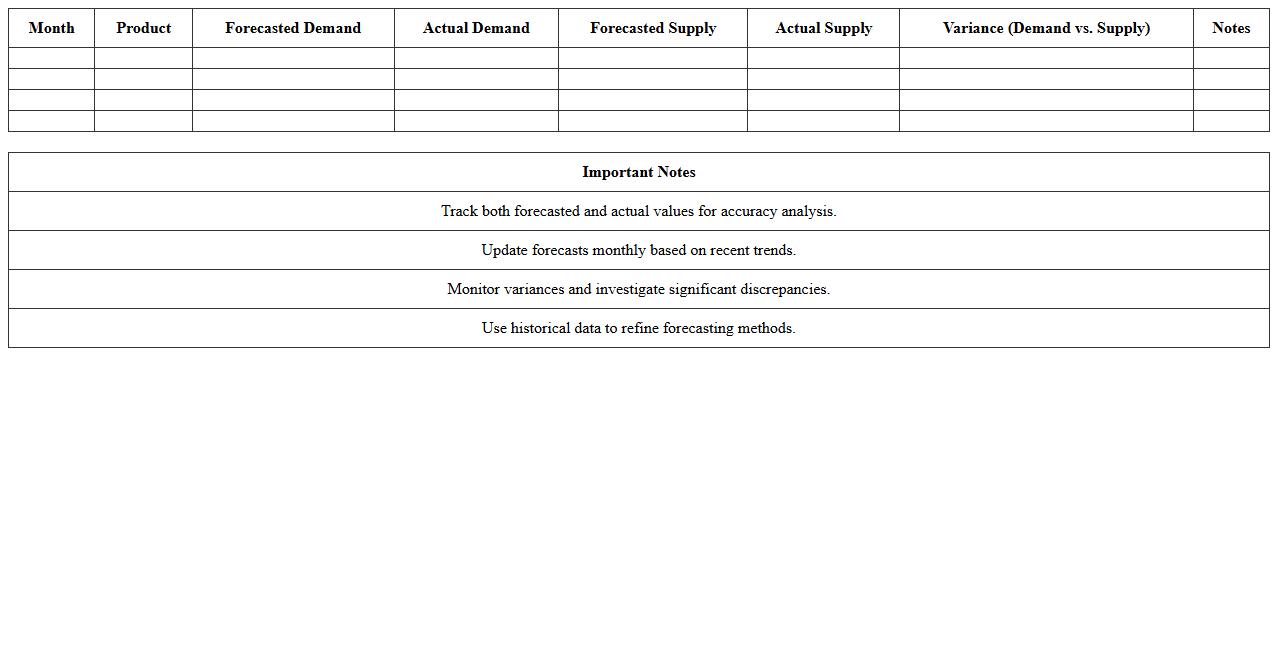

Demand vs. Supply Forecast Spreadsheet

A

Demand vs. Supply Forecast Spreadsheet is a data management tool that compares projected customer demand with available inventory or production capacity over a specified period. It helps businesses identify potential shortages or surpluses, enabling proactive adjustments in procurement, manufacturing, or sales strategies. By providing clear visibility into market dynamics and resource allocation, this document supports optimized decision-making and efficient supply chain management.

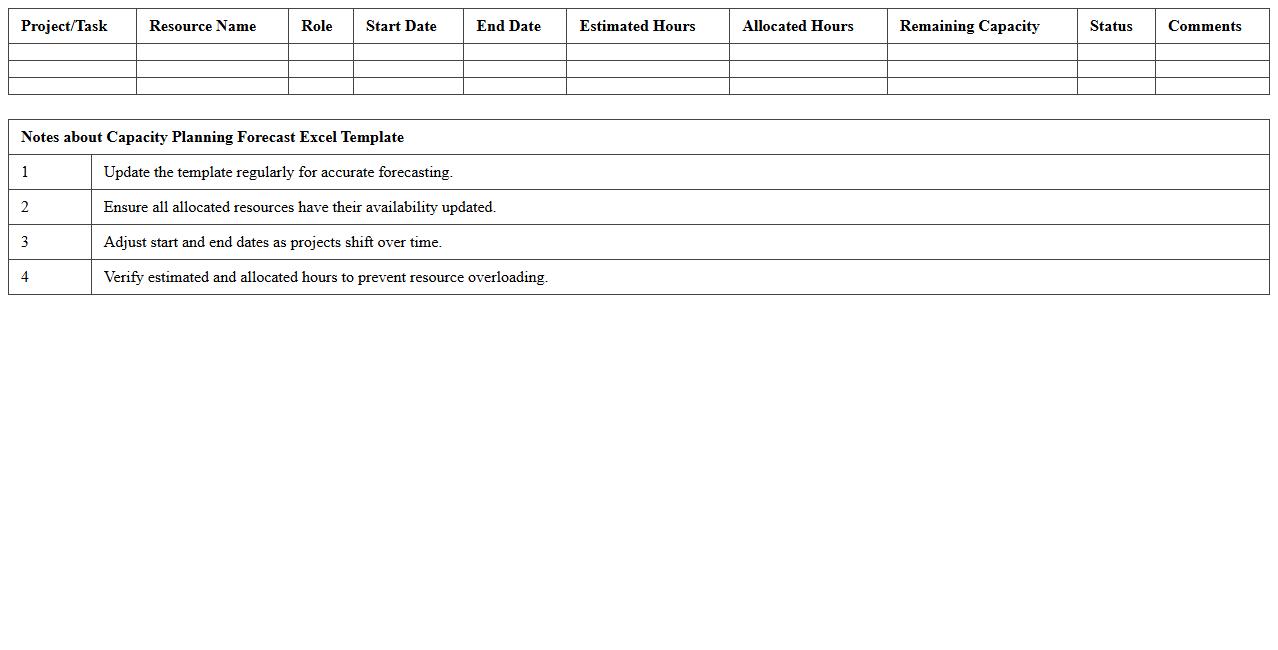

Capacity Planning Forecast Excel Template

Capacity Planning Forecast Excel Template is a powerful tool designed to help organizations predict and manage resource requirements effectively. It enables tracking of workforce, equipment, and production capacity against future demand, ensuring optimal utilization and minimizing bottlenecks. Using this template improves decision-making by providing clear visibility into capacity constraints and future workload projections, making it essential for operational efficiency and strategic planning.

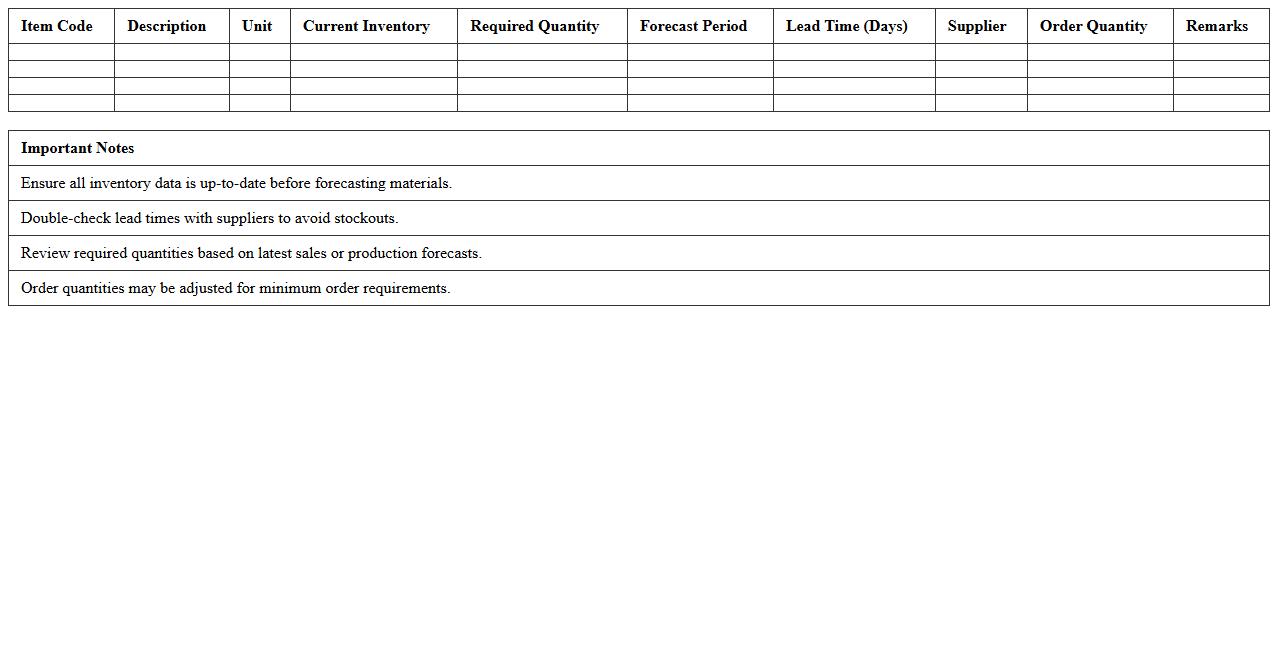

Production Volume Planning Template

A

Production Volume Planning Template is a structured document designed to forecast and organize the quantity of products to be manufactured within a specific timeframe. It enables efficient resource allocation, helps maintain inventory levels, and ensures timely order fulfillment by aligning production capacity with market demand. Utilizing this template enhances operational efficiency, reduces costs, and supports strategic decision-making in manufacturing processes.

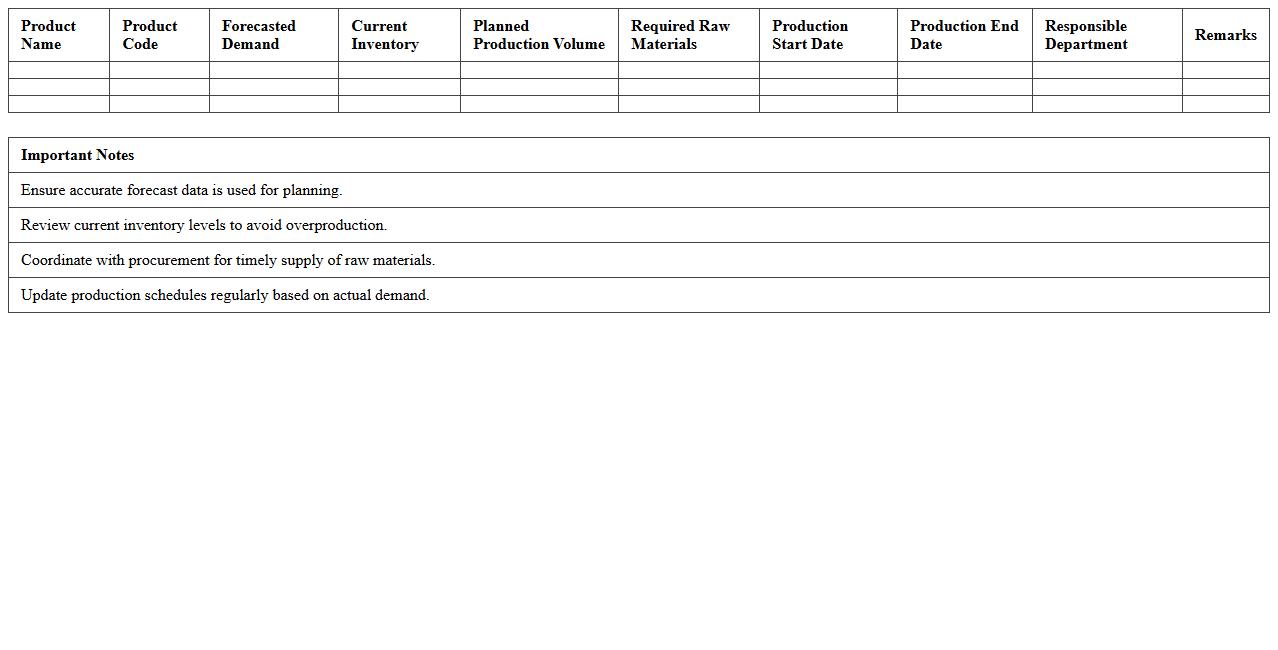

Material Requirement Forecast Spreadsheet

A

Material Requirement Forecast Spreadsheet is a document designed to predict the quantity and timing of raw materials needed for production processes. It helps businesses manage inventory efficiently by aligning material procurement with anticipated demand, reducing carrying costs, and minimizing stockouts. This tool supports accurate planning, improves supply chain coordination, and enhances overall operational productivity.

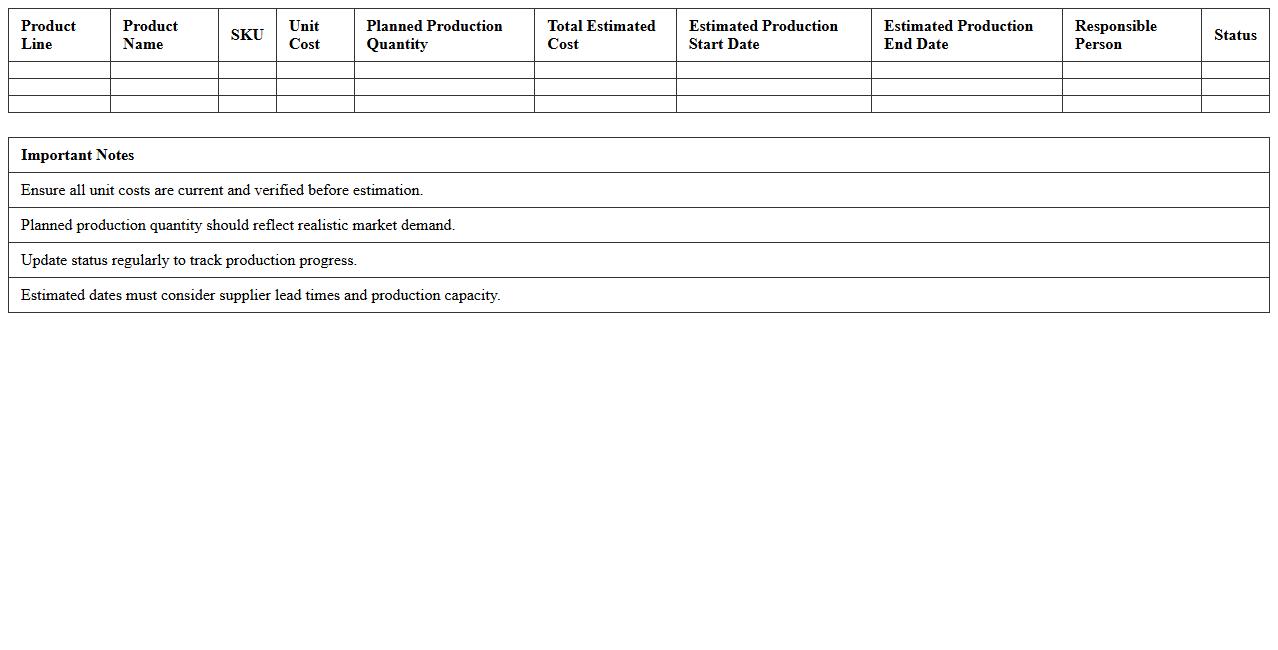

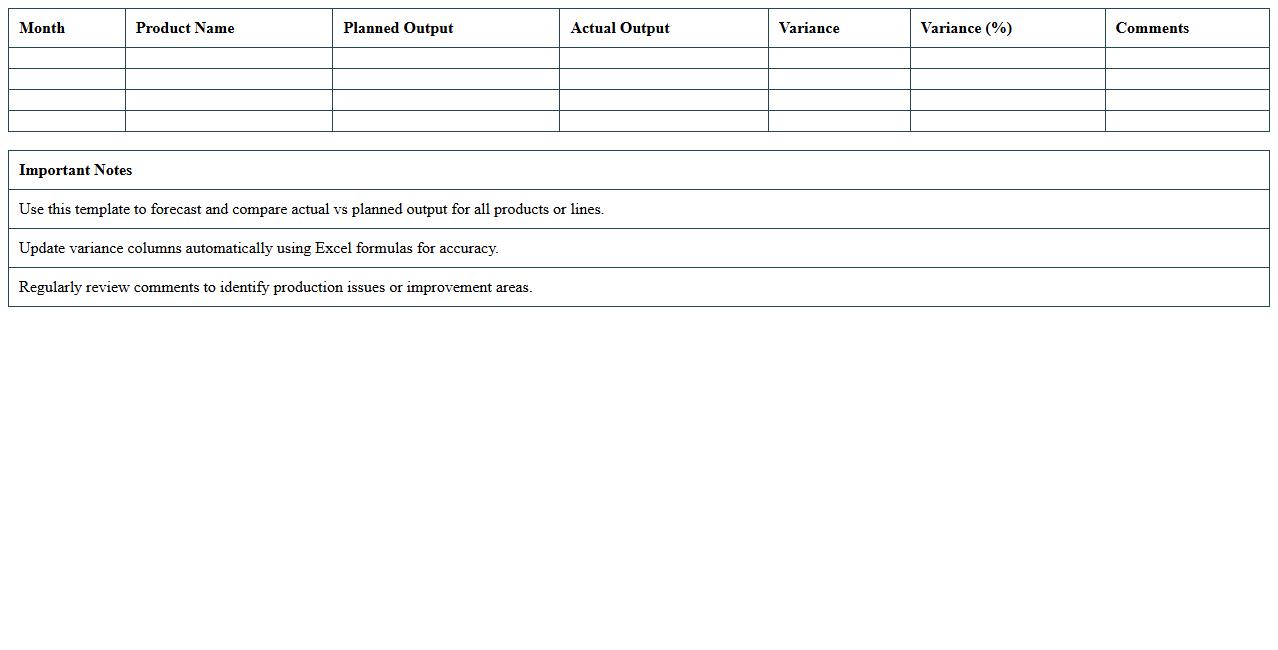

Product Line Production Estimate Template

A

Product Line Production Estimate Template document provides a structured framework to forecast manufacturing output, costs, and timelines for multiple products within a production line. It enables businesses to optimize resource allocation, manage inventory levels, and plan capacity effectively by consolidating production data into a clear, actionable format. Using this template helps improve decision-making accuracy and enhances operational efficiency through better visibility into production estimates.

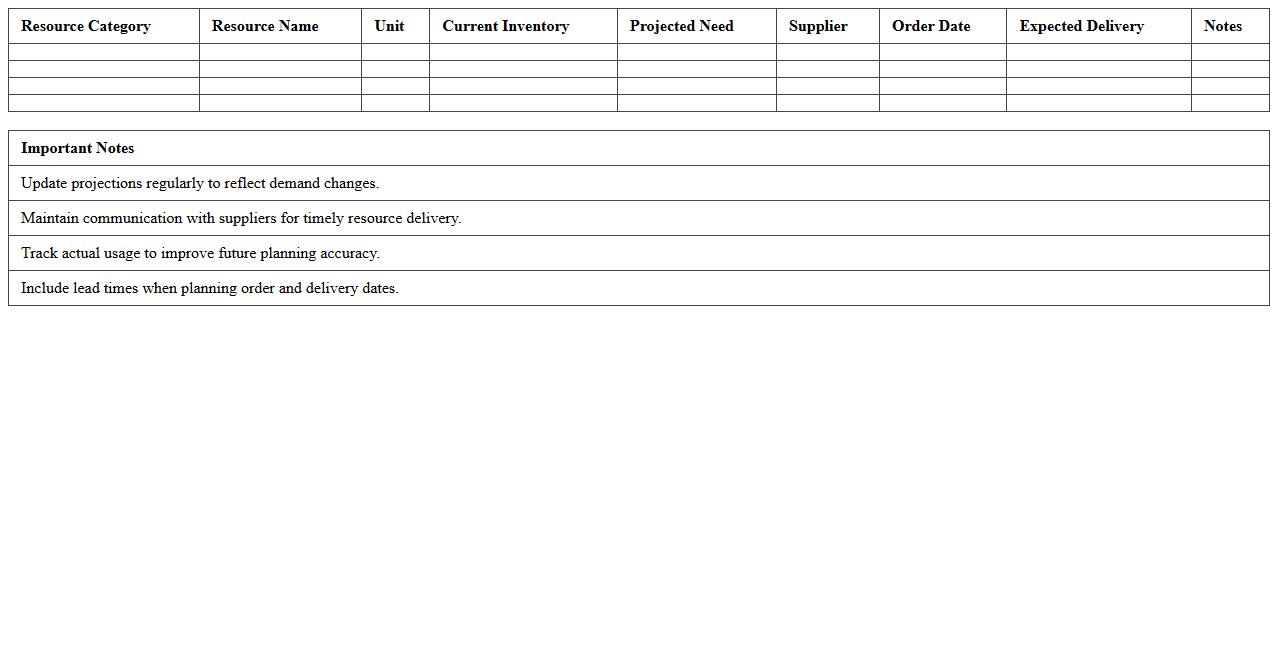

Manufacturing Resource Needs Projection Sheet

The

Manufacturing Resource Needs Projection Sheet is a critical document that estimates the required materials, labor, and machinery to meet future production goals. It helps streamline operations by aligning resource allocation with projected demand, reducing waste and bottlenecks. This projection sheet enhances decision-making accuracy, ensuring efficient inventory management and timely procurement.

Plant-wide Output Forecast Excel Template

The

Plant-wide Output Forecast Excel Template is a comprehensive tool designed to predict and analyze production output across an entire manufacturing facility. It consolidates data from multiple production lines, enabling accurate demand forecasting, resource allocation, and capacity planning. By utilizing this template, businesses can optimize operational efficiency, reduce downtime, and improve overall production management.

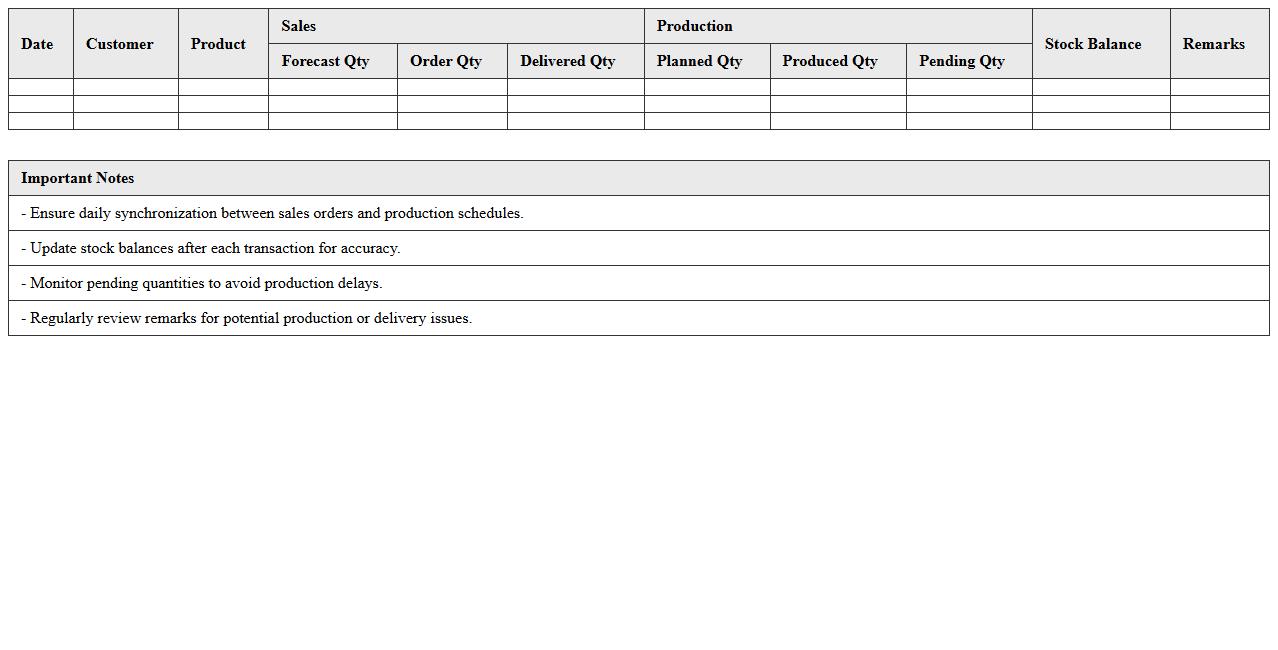

Sales and Production Synchronization Sheet

The

Sales and Production Synchronization Sheet is a critical document that aligns sales forecasts with production planning to ensure inventory levels match customer demand accurately. By integrating real-time sales data with manufacturing schedules, it helps reduce overproduction, minimize stockouts, and optimize resource allocation. Utilizing this sheet improves operational efficiency and enhances the ability to respond swiftly to market fluctuations.

How can I automate monthly production forecast updates using Excel formulas?

You can automate monthly production forecast updates by using dynamic Excel formulas such as OFFSET, INDEX, and MATCH to pull updated data ranges automatically. Incorporating the EOMONTH function helps in adjusting formulas to reflect month-end dates efficiently. Additionally, leveraging array formulas or the newer XLOOKUP function enhances the real-time updating capability without manual intervention.

What Excel template optimizes raw material tracking for production scheduling?

An Excel template designed for raw material tracking should include columns for inventory levels, reorder points, lead times, and supplier details. Combining this with conditional formatting highlights critical stock levels to prevent production delays. Integrating pivot tables and data validation ensures easy data input and real-time visibility into supply status, optimizing production scheduling.

How do I incorporate demand variability in a manufacturing plant's forecast model?

Incorporating demand variability requires using statistical functions like STDEV.P or VAR.P in Excel to measure demand fluctuations over time. You can enhance forecast models by applying moving averages or exponential smoothing techniques to smooth out irregularities. Implementing scenario analysis with Data Tables helps anticipate different demand outcomes and plan production accordingly.

Which Excel functions best visualize production forecast accuracy for stakeholders?

Excel functions such as CHARTS, including line and scatter plots, effectively visualize accuracy by comparing actual versus forecasted production. The use of statistical metrics like FORECAST.LINEAR and calculating Mean Absolute Percentage Error (MAPE) highlights deviations in data. Conditional formatting and sparklines add intuitive visual cues, making complex data easily understandable for stakeholders.

How can I link inventory levels to forecast outputs in one dynamic worksheet?

Linking inventory levels to forecast outputs in a dynamic worksheet involves using cell referencing combined with logical functions like IF and SUMIFS to relate inventory data directly to predicted demand. Utilizing Excel Tables ensures data is structured properly, allowing formulas to automatically adjust with new data entries. Adding drop-down menus with Data Validation enables users to interactively select parameters, keeping inventory and forecast connected seamlessly.

More Forecast Excel Templates