Using a List Excel Template for Inventory Reorder Points helps businesses efficiently track stock levels and automate reorder thresholds. This template organizes product details, current inventory, and reorder quantities, ensuring timely restocking and minimizing stockouts. Streamlining inventory management with this tool saves time and reduces errors in the replenishment process.

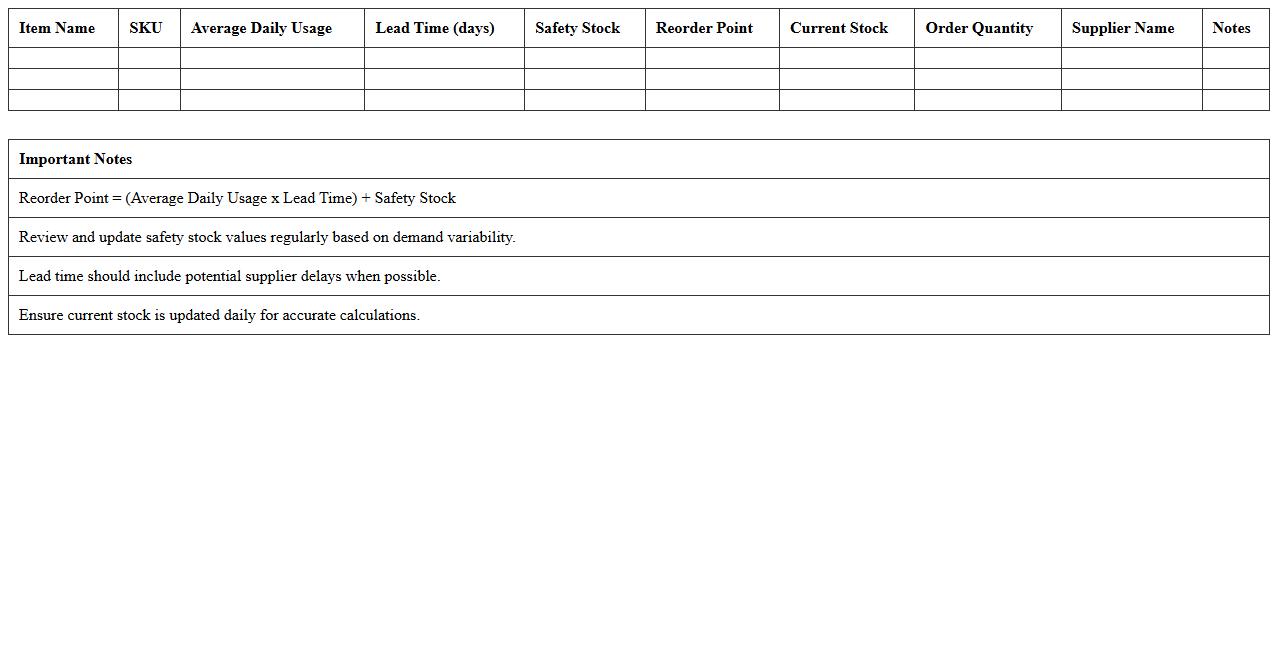

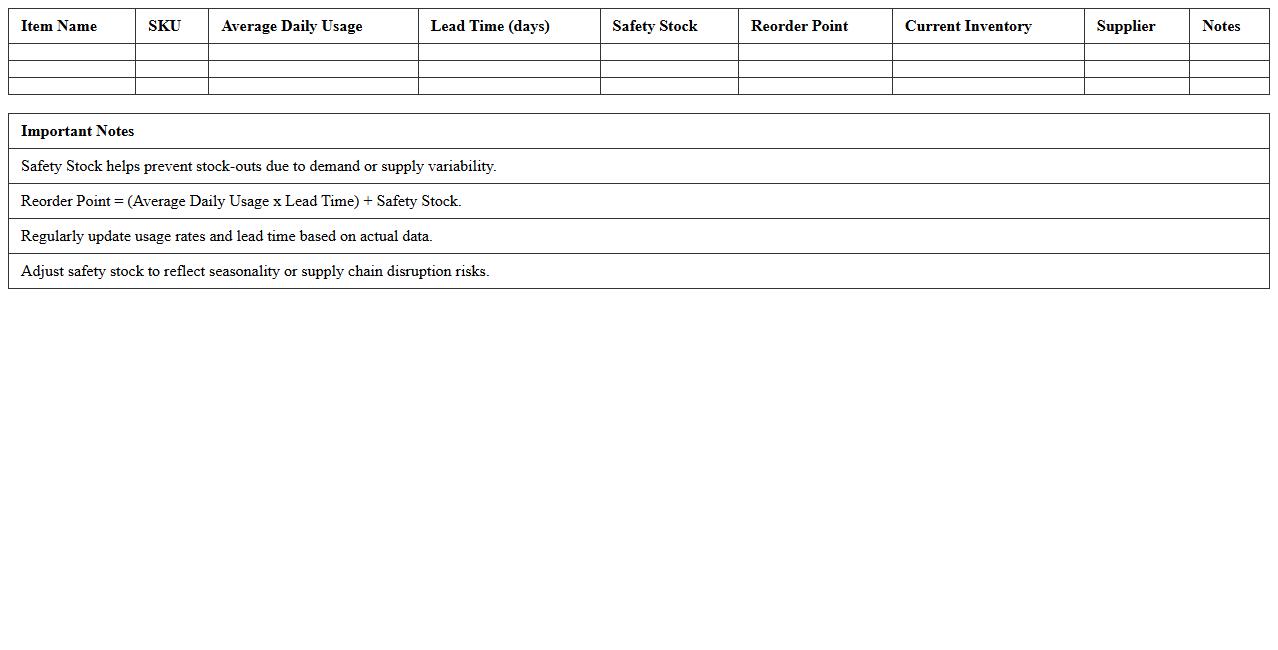

Inventory Reorder Point Calculation Template

The

Inventory Reorder Point Calculation Template is a tool designed to help businesses determine the precise stock level at which new inventory should be ordered to avoid stockouts and ensure smooth operations. By factoring in lead times, average daily usage, and safety stock, this template helps optimize inventory management and reduce holding costs. Using this document improves supply chain efficiency and supports data-driven decision-making for timely replenishment.

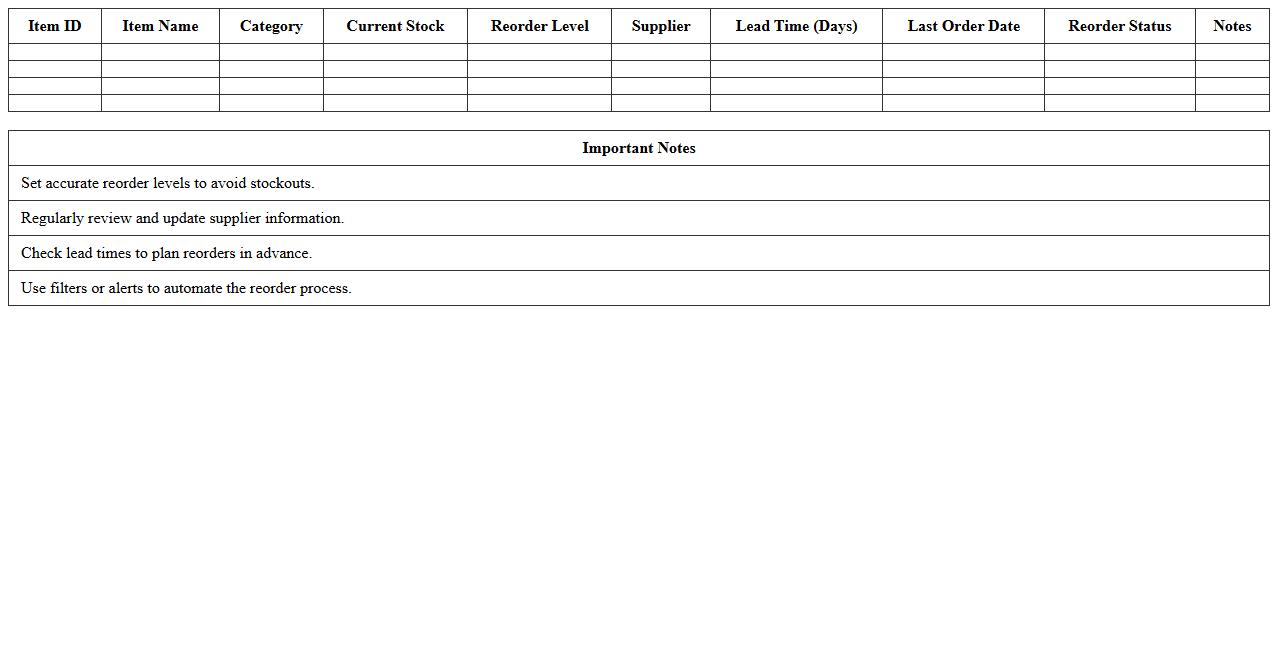

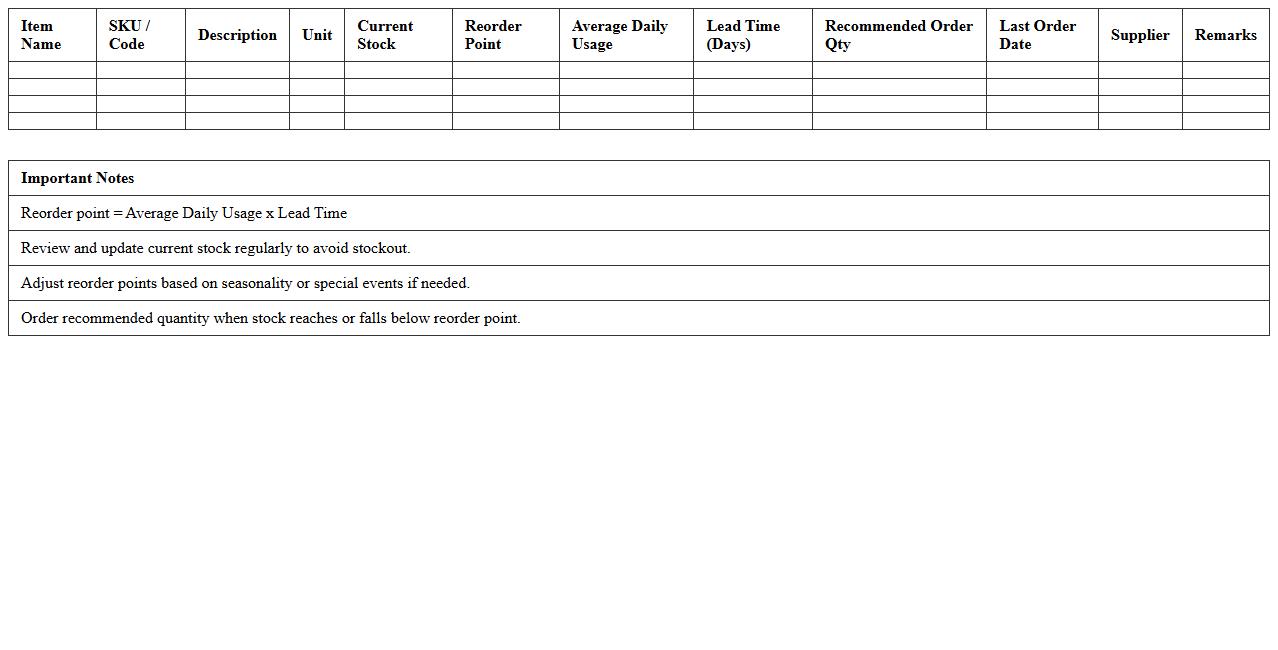

Stock Reorder Level Tracker Excel Sheet

A

Stock Reorder Level Tracker Excel Sheet is a document designed to monitor inventory levels and automatically signal when stock reaches the minimum reorder point. This tool helps businesses prevent stockouts and overstock situations by ensuring timely replenishment based on predefined thresholds. Using this tracker enhances inventory management efficiency and supports smooth operations by maintaining optimal stock levels.

Automated Inventory Reorder Alert Template

An

Automated Inventory Reorder Alert Template is a pre-designed document that triggers notifications when stock levels fall below a predefined threshold, ensuring timely replenishment of inventory. This system minimizes stockouts, reduces carrying costs, and enhances supply chain efficiency by providing actionable alerts to inventory managers. Using this template streamlines inventory management processes, improves order accuracy, and supports data-driven decision-making to maintain optimal stock levels.

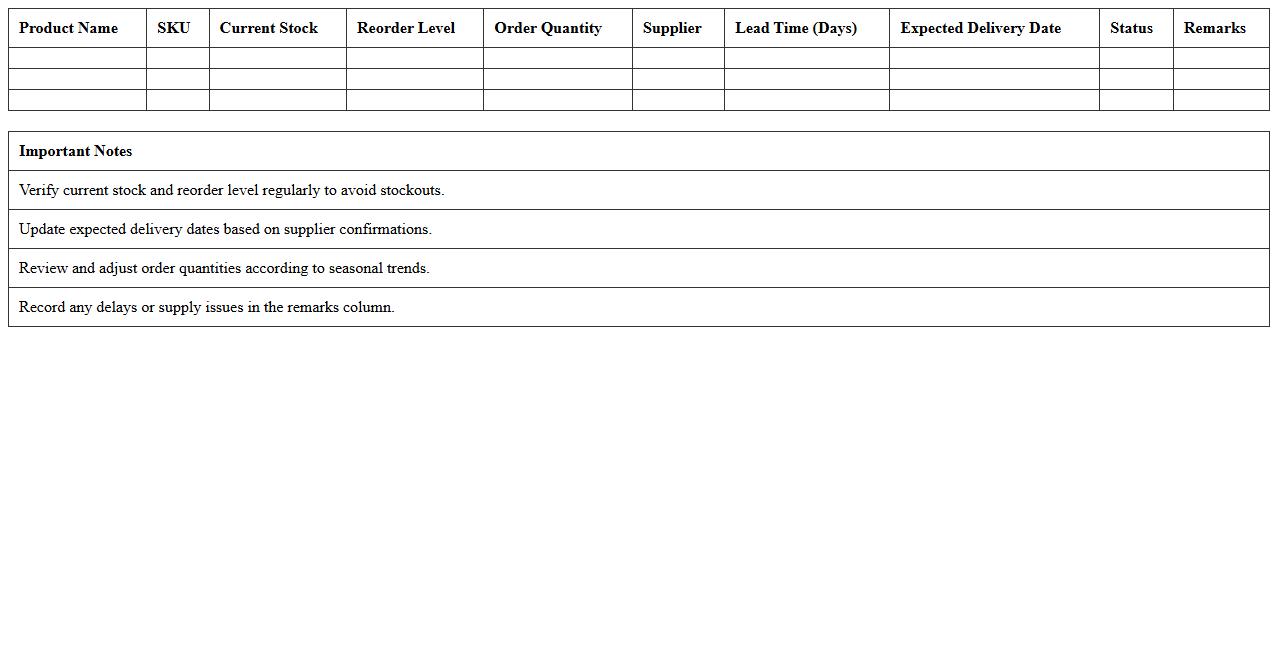

Product Replenishment Schedule Excel

A

Product Replenishment Schedule Excel document is a tool designed to track inventory levels, sales patterns, and reorder points to ensure timely restocking of products. It helps businesses avoid stockouts and overstock situations by providing clear visibility into when and how much to reorder based on historical demand and lead times. Using this schedule optimizes inventory management, reduces holding costs, and improves supply chain efficiency.

Safety Stock & Reorder Point Template

A

Safety Stock & Reorder Point Template document helps businesses maintain optimal inventory levels by calculating the minimum stock required to prevent stockouts during demand fluctuations or supply delays. This template incorporates factors like lead time, average demand, and safety stock to provide precise reorder points, ensuring timely replenishment. Using this tool enhances inventory management efficiency, minimizes holding costs, and improves customer satisfaction by avoiding stock shortages.

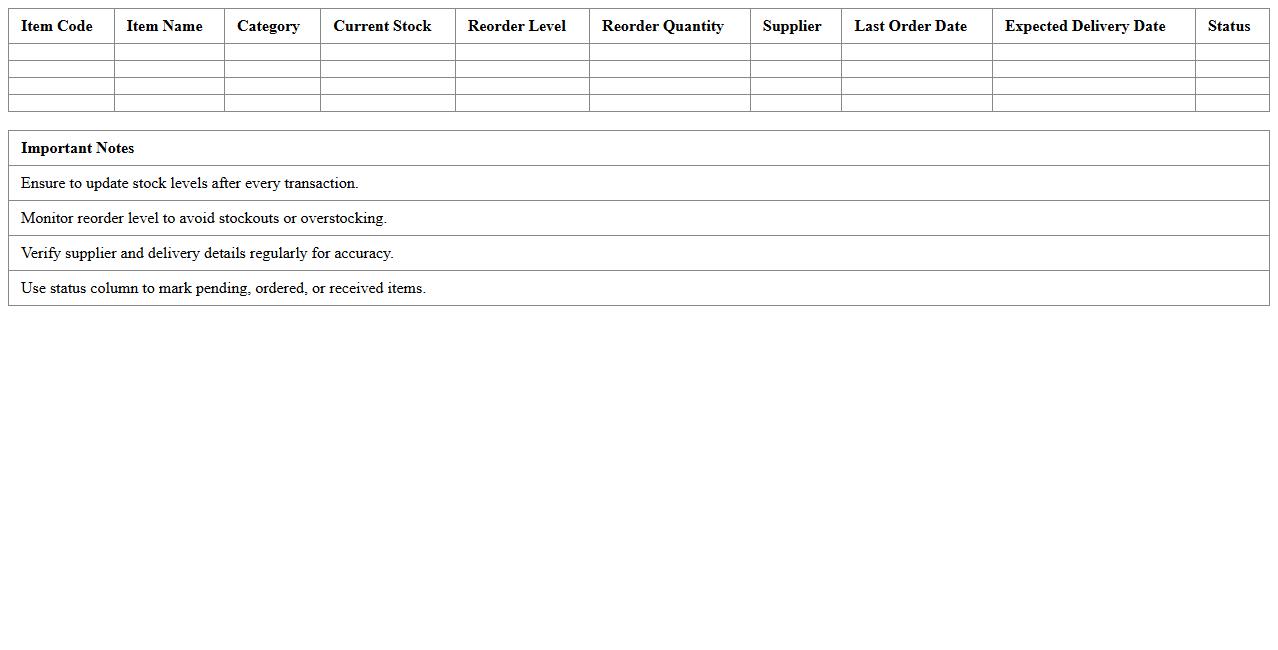

Item Restocking Threshold Tracker

The

Item Restocking Threshold Tracker document monitors inventory levels to signal when stock reaches a predefined minimum threshold, ensuring timely replenishment. It prevents stockouts and overstock situations by providing clear data-driven insights for inventory management decisions. This tool is essential for maintaining optimal stock levels, reducing carrying costs, and improving supply chain efficiency.

Simple Reorder Point Monitoring Sheet

A

Simple Reorder Point Monitoring Sheet is a tool designed to track inventory levels and signal when stock reaches the predefined reorder point, ensuring timely replenishment. By monitoring usage rates and lead times, it helps prevent stockouts and overstock situations, optimizing inventory management. This document is essential for maintaining operational efficiency and reducing carrying costs in supply chain processes.

Warehouse Inventory Replenishment Excel

The

Warehouse Inventory Replenishment Excel document is a powerful tool designed to track stock levels, forecast demand, and schedule timely restocking to prevent stockouts or overstock situations. By automating calculations and providing clear visibility into inventory status, it streamlines supply chain management and improves order accuracy. This document enhances operational efficiency, reduces carrying costs, and supports data-driven decision-making in warehouse management.

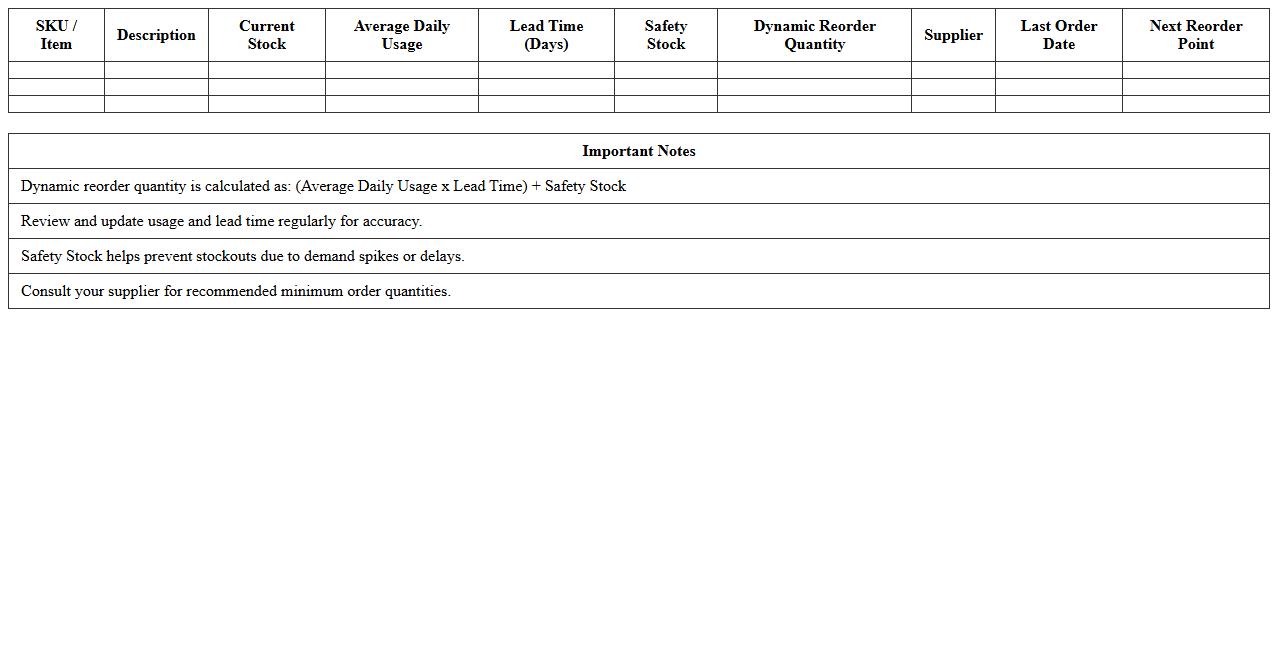

Dynamic Reorder Quantity Calculator

The

Dynamic Reorder Quantity Calculator document outlines a method for determining optimal reorder points and quantities based on fluctuating demand, lead times, and inventory levels. This tool enhances inventory management by minimizing stockouts and excess inventory, leading to improved cash flow and operational efficiency. Businesses can use this calculator to adapt reorder strategies in real-time, ensuring responsiveness to market changes and better supply chain performance.

Inventory Minimum Level Notification Sheet

The

Inventory Minimum Level Notification Sheet is a crucial document that tracks stock quantities and alerts when inventory falls below predetermined minimum thresholds. This sheet helps businesses avoid stockouts and ensures timely replenishment, maintaining smooth operations and preventing production delays. By providing real-time visibility into inventory levels, it supports efficient inventory management and cost control.

How do I automate reorder point alerts in an Excel document list?

To automate reorder point alerts in Excel, use conditional formatting combined with formulas that compare current stock levels against reorder points. Set rules that highlight cells when inventory falls below these points to capture attention immediately. Utilize Excel's notification features or VBA macros for advanced alerts, such as sending emails or messages.

What Excel formula calculates inventory reorder points for multiple SKUs?

The reorder point (ROP) formula typically is: ROP = (Average Daily Usage x Lead Time) + Safety Stock. For multiple SKUs, structure the Excel sheet so each SKU has columns for daily usage, lead time, and safety stock, then apply formulas dynamically. Use arrays or structured references to efficiently compute reorder points across all SKUs.

How can I track low stock items dynamically in an inventory letter template?

Dynamic tracking of low stock items can be achieved by linking your inventory data to the letter template using Excel functions like FILTER or conditional logic. Automate the template to extract only those SKUs that fall below reorder points. This method ensures your letter highlights critical stock shortages without manual updates.

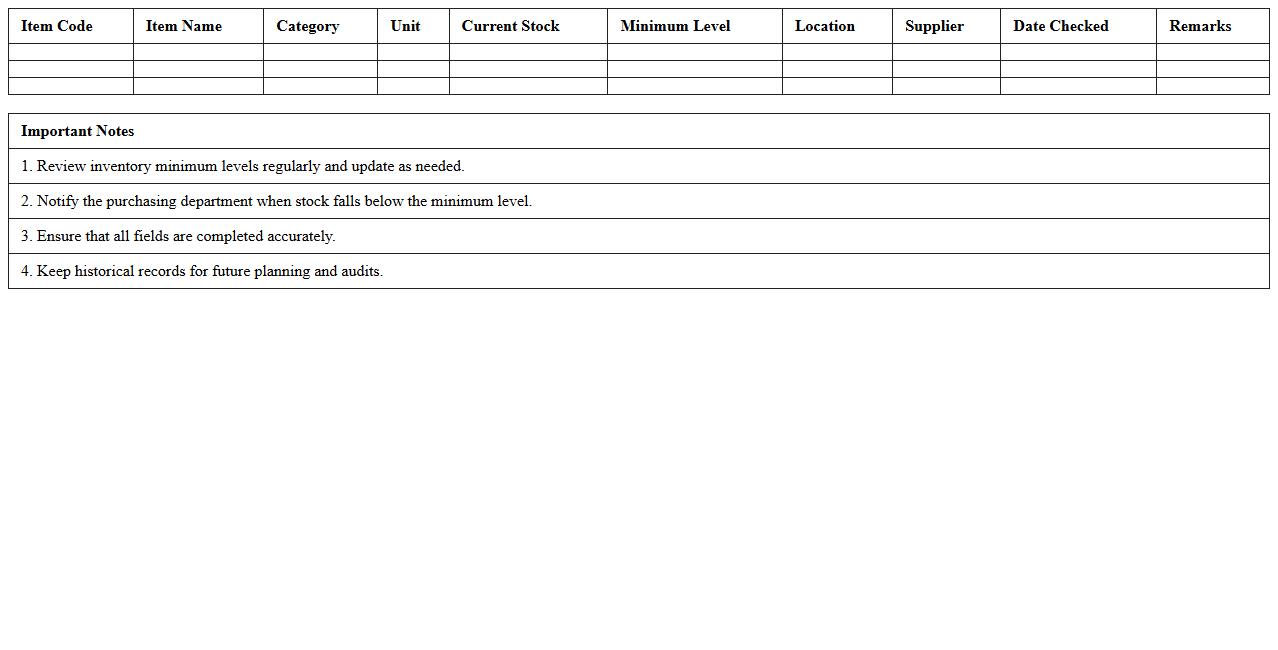

Which columns are essential in an Excel inventory reorder points list?

Essential columns include SKU or Item ID, Current Stock, Reorder Point, Lead Time, Average Daily Usage, and Safety Stock. These columns provide a comprehensive overview to calculate when to place new orders accurately. Including Supplier Info and Last Order Date can further enhance management efficiency.

How do I integrate supplier lead time into an Excel reorder point document?

Incorporate supplier lead time as a critical variable within your reorder point formula by assigning a dedicated column for lead time in days. This value directly influences the reorder point by extending the buffer needed to replenish stock before exhaustion. Ensure that lead time data is regularly updated to reflect supplier performance for accurate inventory planning.

More List Excel Templates