The Inventory Excel Template for Manufacturing Spare Parts streamlines tracking and managing spare parts efficiently, reducing downtime in production. It includes customizable columns for part numbers, quantities, locations, and reorder levels to ensure optimal stock control. This template helps manufacturers maintain accurate inventory records and improve supply chain management.

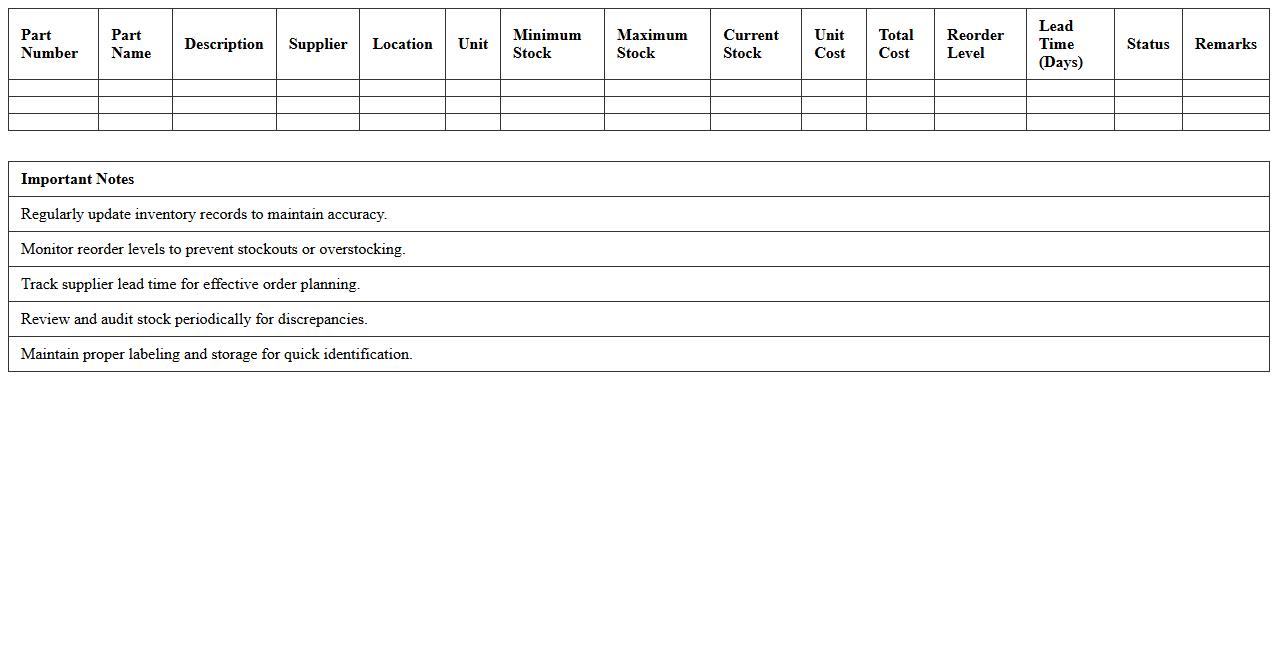

Manufacturing Spare Parts Stock Tracking Excel Template

The

Manufacturing Spare Parts Stock Tracking Excel Template is a specialized tool designed to monitor inventory levels, usage rates, and reorder points for spare parts in manufacturing operations. It helps businesses maintain optimal stock, reduce downtime by ensuring critical components are always available, and streamline procurement processes through accurate data management. This template enhances operational efficiency by providing clear visibility into spare parts inventory, preventing stockouts and overstock situations.

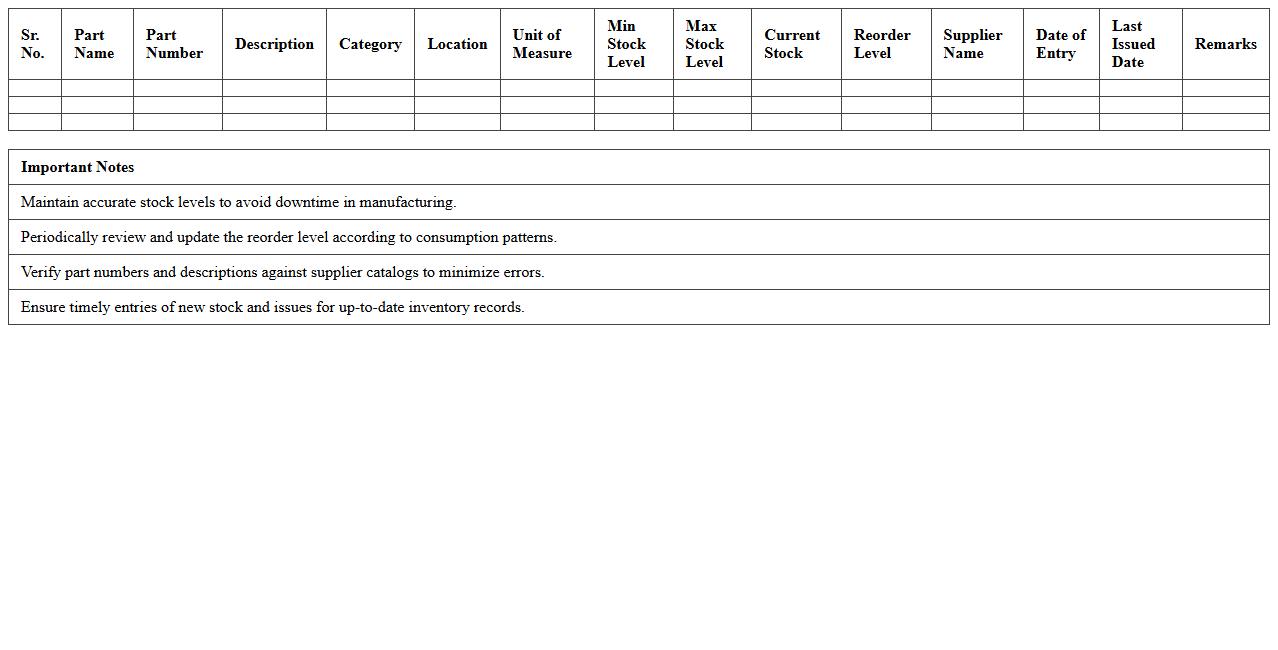

Spare Parts Inventory Management Sheet for Manufacturing

A

Spare Parts Inventory Management Sheet for manufacturing is a crucial document that tracks the quantity, location, and status of spare parts needed for machinery maintenance and repair. It helps streamline the procurement process, prevent equipment downtime, and optimize inventory levels by providing real-time data on available parts and reorder points. Using this sheet enhances operational efficiency, reduces unexpected production delays, and supports cost-effective inventory management.

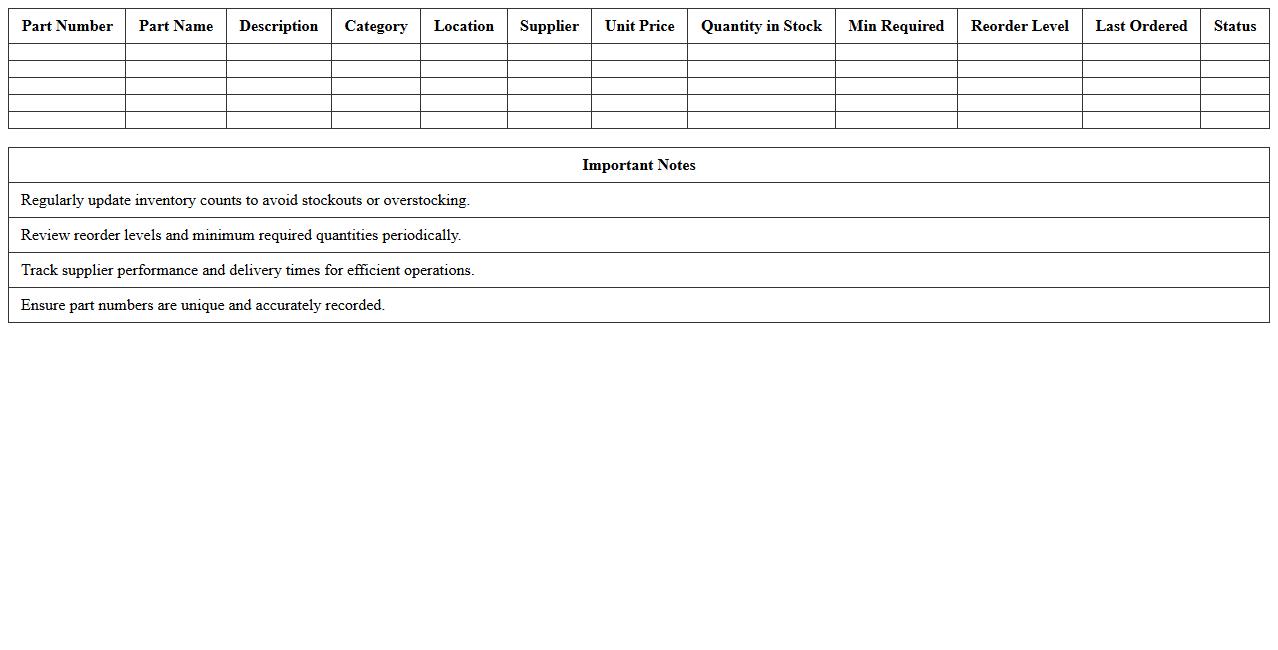

Excel Register for Manufacturing Spare Parts Inventory

An

Excel Register for Manufacturing Spare Parts Inventory is a detailed spreadsheet designed to track and manage spare parts used in manufacturing processes, including item descriptions, quantities, locations, and reorder levels. This document streamlines inventory control by providing real-time visibility into stock levels, reducing downtime caused by parts shortages, and improving procurement efficiency. Effective use of this register supports cost savings, minimizes excess inventory, and enhances overall operational productivity in manufacturing environments.

Manufacturing Parts Warehouse Inventory Excel Template

The

Manufacturing Parts Warehouse Inventory Excel Template document is a structured spreadsheet designed to track and manage parts inventory accurately and efficiently. It helps streamline inventory control by allowing users to monitor stock levels, reorder points, and part details in real-time, reducing downtime caused by shortages. Utilizing this template enhances organization, improves procurement decisions, and supports overall operational productivity in manufacturing environments.

Spare Parts Order and Reorder Excel Tracker

The

Spare Parts Order and Reorder Excel Tracker is a comprehensive document designed to monitor inventory levels, track orders, and manage reorder points for spare parts efficiently. It helps reduce downtime by ensuring timely replenishment of critical components and optimizes inventory costs through precise demand forecasting. By maintaining organized data on part numbers, suppliers, order dates, and stock availability, this tracker enhances procurement decisions and streamlines maintenance operations.

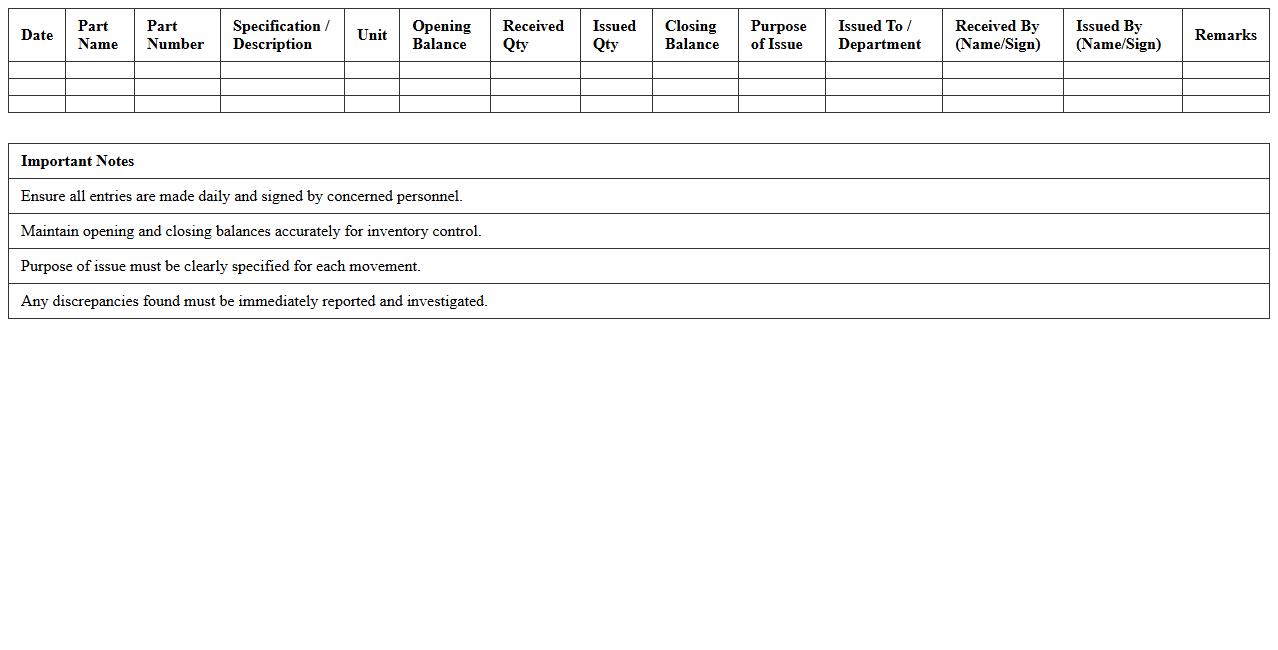

Manufacturing Plant Spare Parts Movement Log Sheet

A

Manufacturing Plant Spare Parts Movement Log Sheet is a detailed record that tracks the transfer, usage, and inventory status of spare parts within a manufacturing facility. This document helps maintain accurate inventory control, prevents stockouts or overstocking, and ensures timely availability of critical components for equipment maintenance. By logging every movement of spare parts, it enhances operational efficiency, reduces downtime, and supports seamless production workflows.

Excel Template for Spare Parts Location Tracking

An

Excel Template for Spare Parts Location Tracking is a pre-designed spreadsheet that helps organize and monitor the inventory of spare parts across multiple storage locations. It enables efficient tracking of part numbers, quantities, and exact storage sites, reducing the time spent searching for components and minimizing inventory discrepancies. This tool enhances inventory management accuracy and supports timely maintenance operations by providing real-time visibility into spare part availability and location.

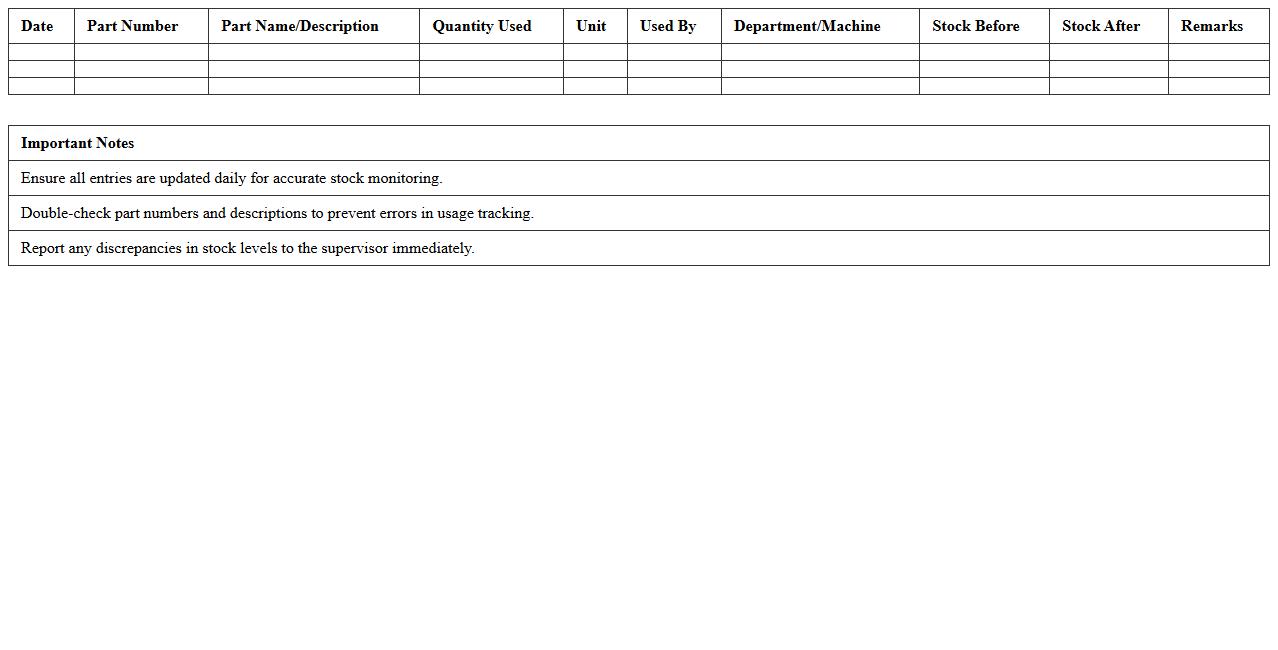

Spare Parts Usage and Consumption Log Excel

A

Spare Parts Usage and Consumption Log Excel document is a structured tool that tracks the quantity, date, and purpose of spare parts used in maintenance and repair activities. This log helps organizations monitor inventory levels, prevent stockouts, and optimize procurement processes by providing precise data on parts consumption trends. Maintaining accurate records in this Excel sheet enhances operational efficiency, reduces downtime, and supports cost-effective asset management.

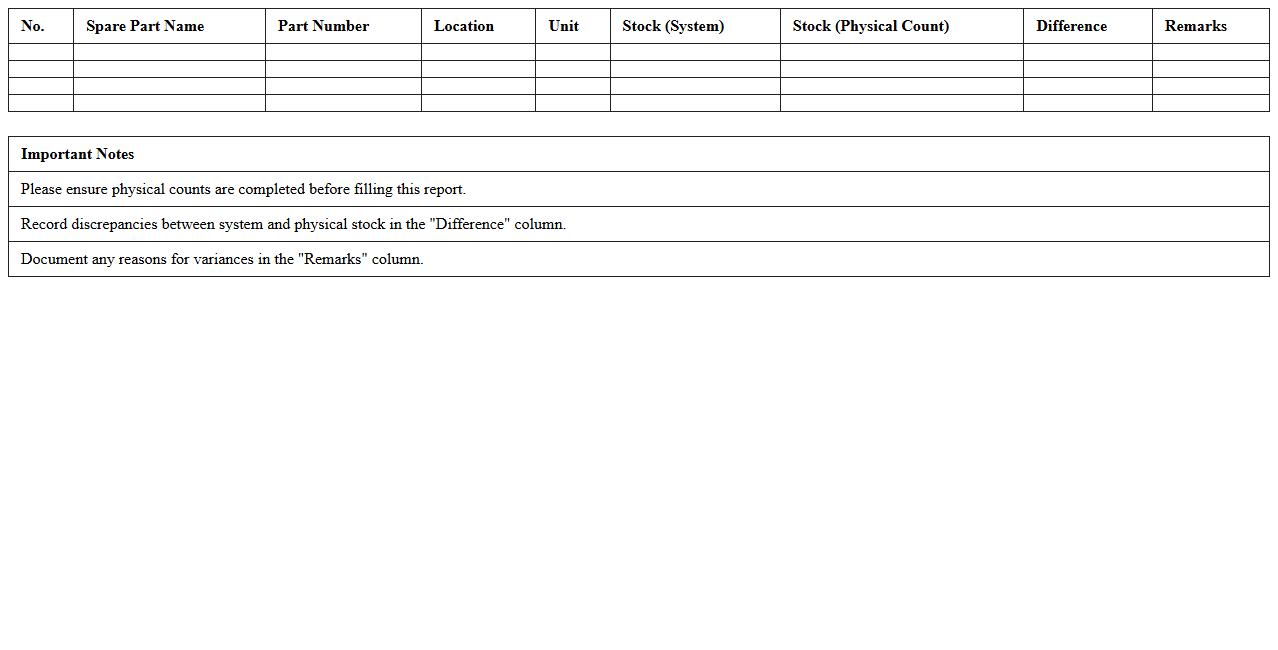

Manufacturing Spare Parts Stocktaking Excel Report

The

Manufacturing Spare Parts Stocktaking Excel Report document is a detailed inventory tool designed to track and manage spare parts within manufacturing operations. It provides accurate data on stock levels, usage rates, and reorder points, ensuring efficient inventory control and minimizing downtime caused by part shortages. Utilizing this report enhances decision-making, reduces excess inventory costs, and improves overall maintenance planning in manufacturing environments.

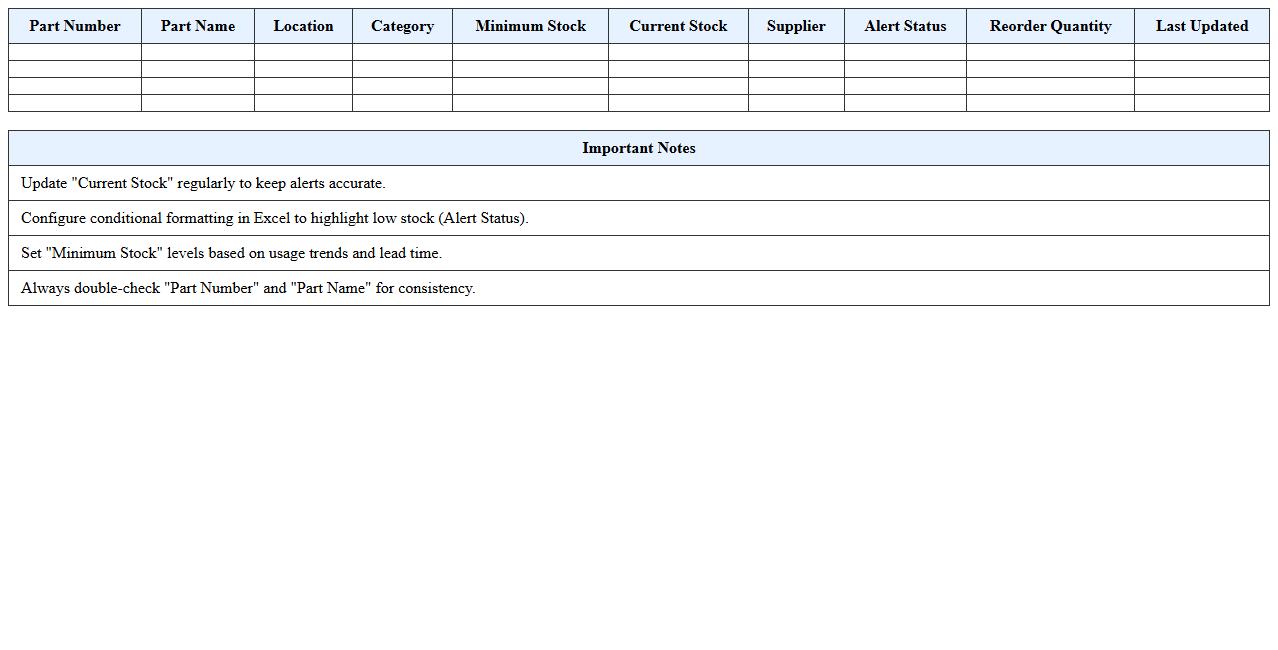

Excel Template for Spare Parts Minimum Stock Alert

An

Excel Template for Spare Parts Minimum Stock Alert is a structured spreadsheet designed to monitor inventory levels of spare parts and trigger notifications when stock falls below a predefined threshold. This template helps businesses maintain optimal inventory by preventing shortages and reducing excess stock, ensuring smoother operations and cost efficiency. By automating stock alerts, it minimizes manual tracking errors and supports timely reordering decisions for critical spare parts management.

How do you structure an Inventory Excel template specifically for tracking manufacturing spare parts?

To structure an Inventory Excel template for manufacturing spare parts, organize data columns for part identification, quantity, and location. Use separate sheets for different machine categories to maintain clarity and efficiency. Incorporate sections for supplier details and reorder information to streamline procurement processes.

What are the essential columns to include in an inventory Excel sheet for spare parts management?

Essential columns in an inventory sheet include Part Number, Description, Quantity on Hand, Reorder Level, and Supplier Name. Additional important columns are Location, Unit Cost, and Lead Time to monitor stock value and replenishment timing. These columns provide comprehensive data for efficient spare parts tracking and management.

How can you automate reorder level alerts in an Excel document for spare parts inventory?

Automate reorder level alerts in Excel by using conditional formatting to highlight items below the reorder point. Create formulas that compare stock on hand to reorder levels and trigger visual cues like color changes. You can also use Excel's built-in alert functions or macros for more advanced notifications.

What is the best method to categorize and filter spare parts by machine type in Excel?

The best method to categorize spare parts by machine type is to add a dedicated column specifying the machine each part belongs to. Use Excel's filtering or Table feature to quickly sort and display parts by machine category. Implementing PivotTables can also help summarize and analyze parts distribution across different machines.

How do you monitor stock aging and slow-moving spare parts using Excel formulas?

Monitor stock aging by recording the date each part was added and using formulas like DATEDIF to calculate storage duration. Use conditional formatting to identify slow-moving parts that exceed a certain age threshold. Combining these insights helps prioritize inventory reviews and optimize spare parts turnover.

More Inventory Excel Templates