The Energy Consumption Forecast Excel Template for Manufacturing Plants helps predict future energy usage by analyzing historical data and production schedules. This actionable forecast enables manufacturers to optimize energy management, reduce costs, and improve sustainability. Customizable features allow seamless integration with existing operational processes for accurate and efficient planning.

Daily Energy Usage Tracker Excel Template for Manufacturing Plants

The

Daily Energy Usage Tracker Excel Template for Manufacturing Plants is a structured spreadsheet designed to record and analyze daily energy consumption data across various production units. It enables precise monitoring of electricity, gas, and other energy sources, helping identify patterns and inefficiencies. Utilizing this tool supports cost reduction, enhances operational efficiency, and promotes sustainable energy management practices in manufacturing environments.

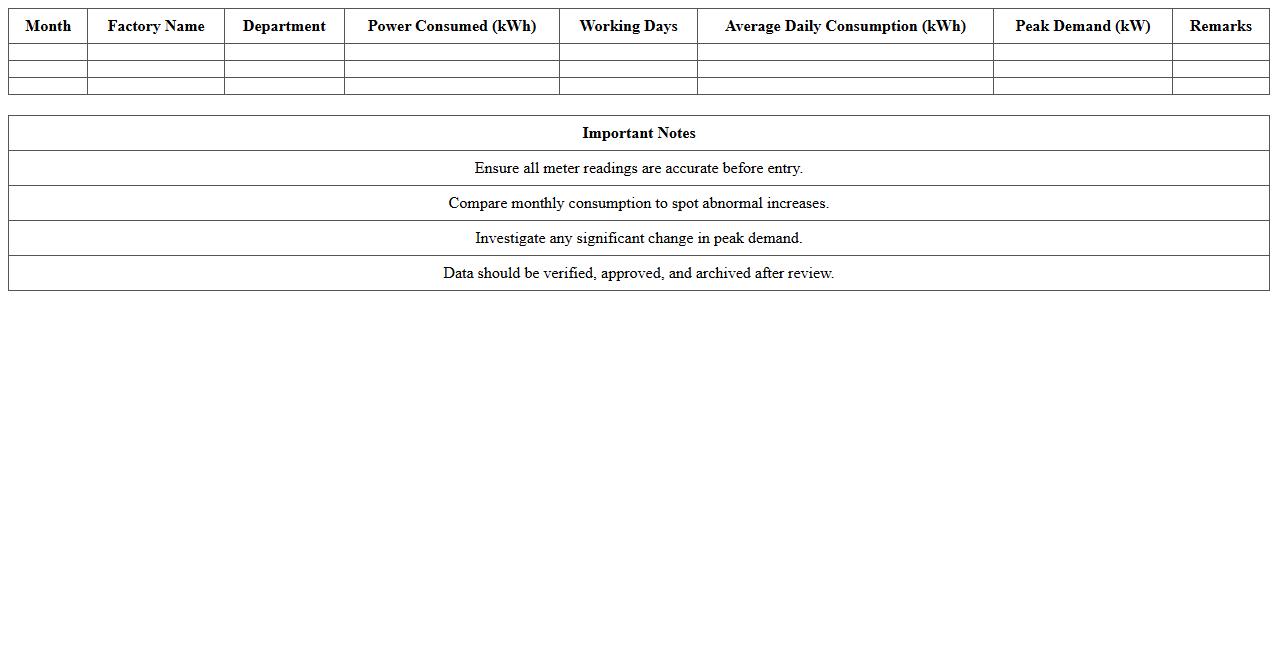

Monthly Power Consumption Analysis Excel for Factories

The

Monthly Power Consumption Analysis Excel for Factories document is a detailed spreadsheet designed to track, analyze, and visualize the electricity usage of manufacturing facilities over the course of a month. By organizing data on power consumption by machines, departments, or shifts, it enables factory managers to identify inefficiencies and opportunities for energy savings. This tool supports cost reduction strategies, enhances operational efficiency, and assists in meeting sustainability goals.

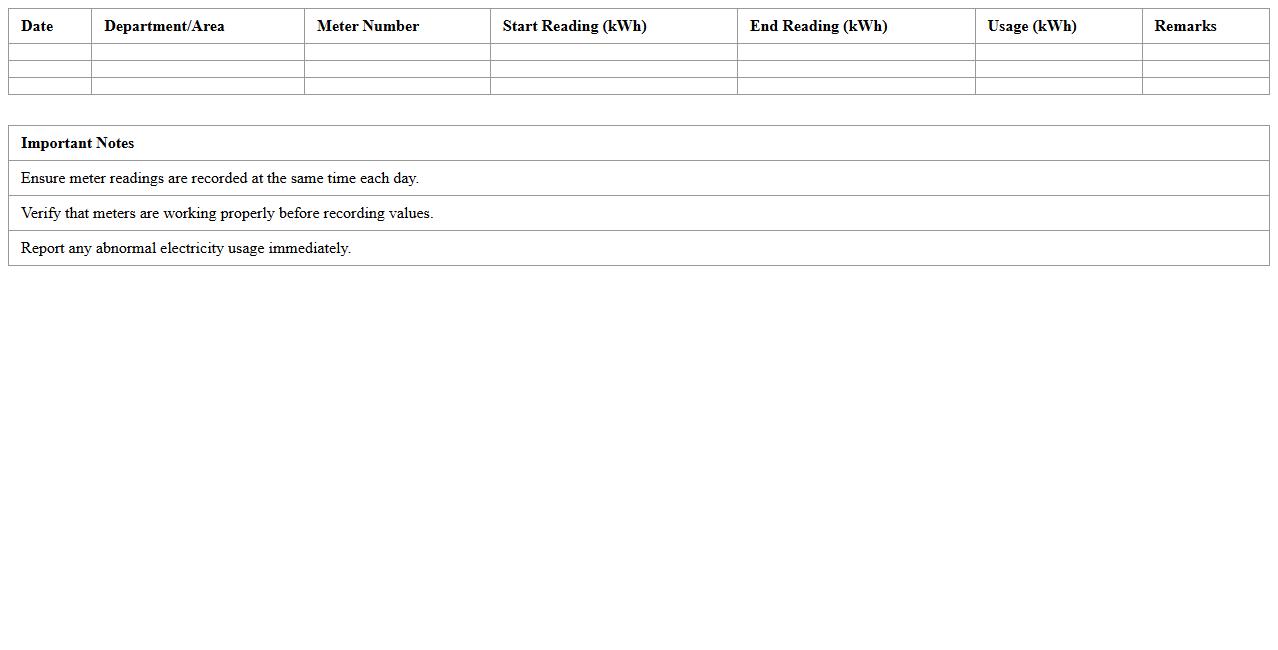

Plant Electricity Usage Report Template in Excel

The

Plant Electricity Usage Report Template in Excel document is a structured tool designed to track and analyze electricity consumption in industrial plants. It helps businesses monitor energy usage patterns, identify inefficiencies, and forecast electricity costs based on historical data. Using this template enhances operational efficiency by enabling data-driven decisions for reducing energy expenses and supporting sustainability goals.

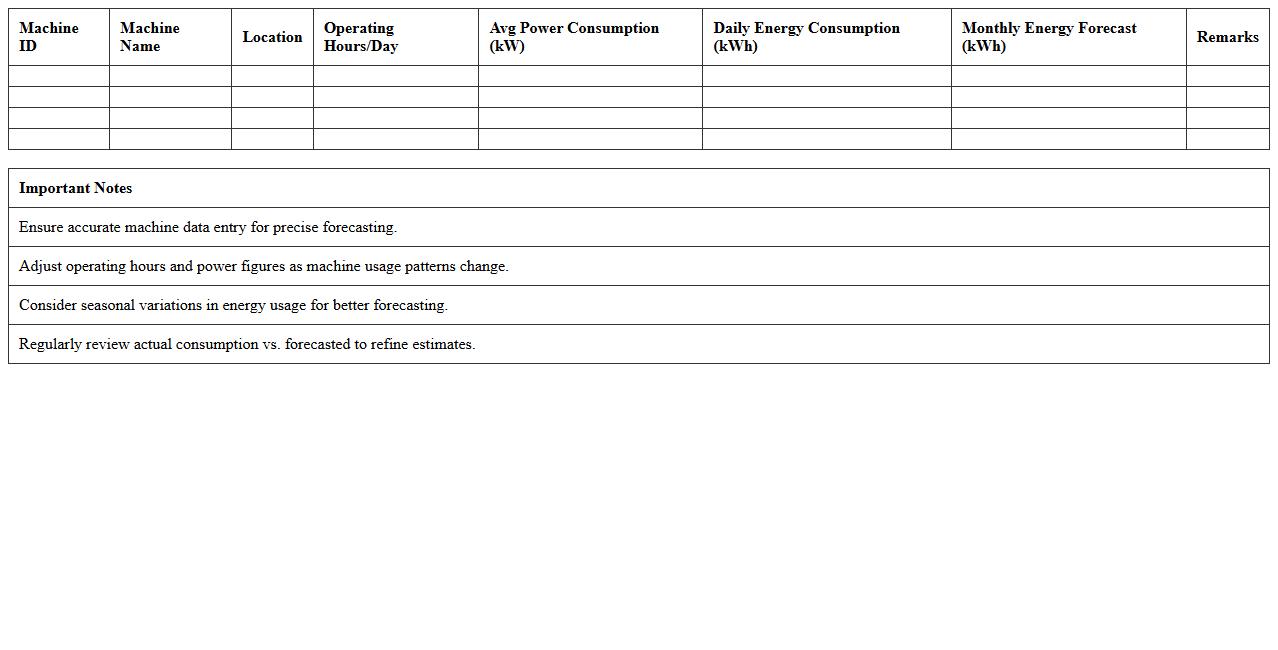

Industrial Machine Energy Forecasting Spreadsheet

The

Industrial Machine Energy Forecasting Spreadsheet document is a data-driven tool designed to predict energy consumption patterns of industrial machinery, enabling businesses to optimize energy use and reduce costs. By analyzing historical energy data alongside machine operational parameters, it facilitates accurate forecasting and supports strategic planning for energy management. This spreadsheet enhances decision-making processes by providing actionable insights into energy efficiency and sustainability efforts in industrial operations.

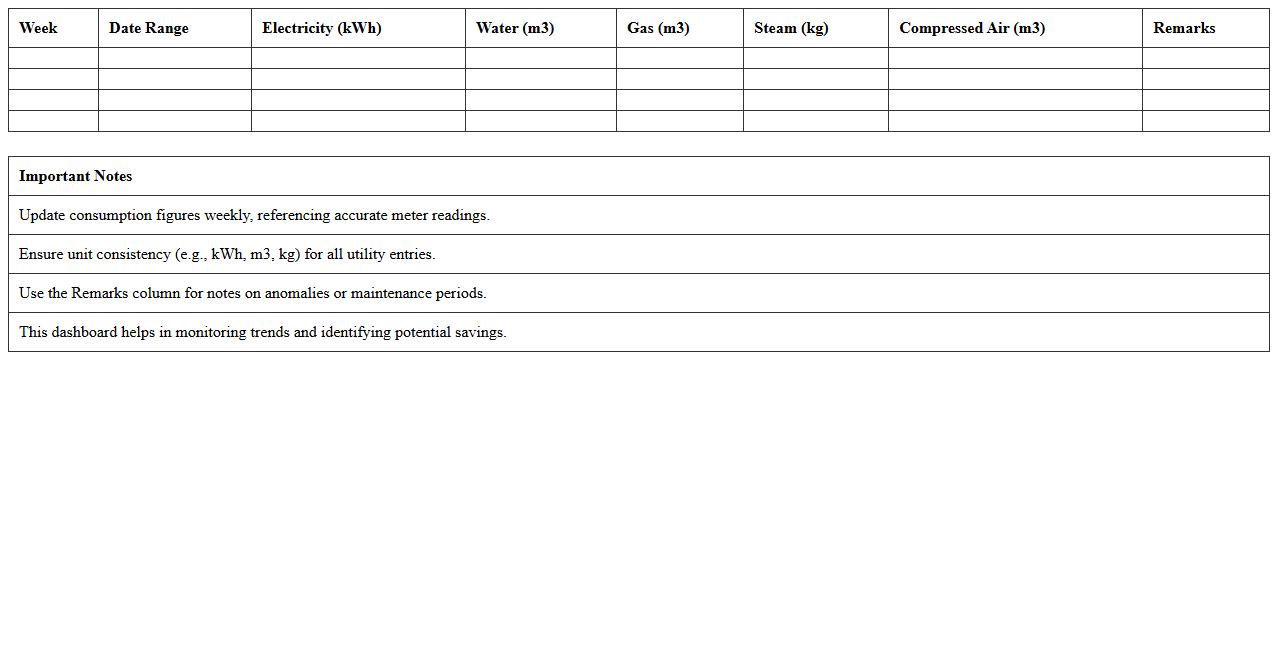

Weekly Utility Consumption Dashboard Excel for Manufacturing

The

Weekly Utility Consumption Dashboard Excel for Manufacturing is a powerful tool that tracks and visualizes energy usage, water, and other utility consumption across manufacturing processes on a weekly basis. It enables managers to identify trends, detect inefficiencies, and optimize resource allocation to reduce operational costs and improve sustainability. This dashboard supports data-driven decisions by consolidating utility metrics into comprehensible charts and summaries, enhancing overall manufacturing performance.

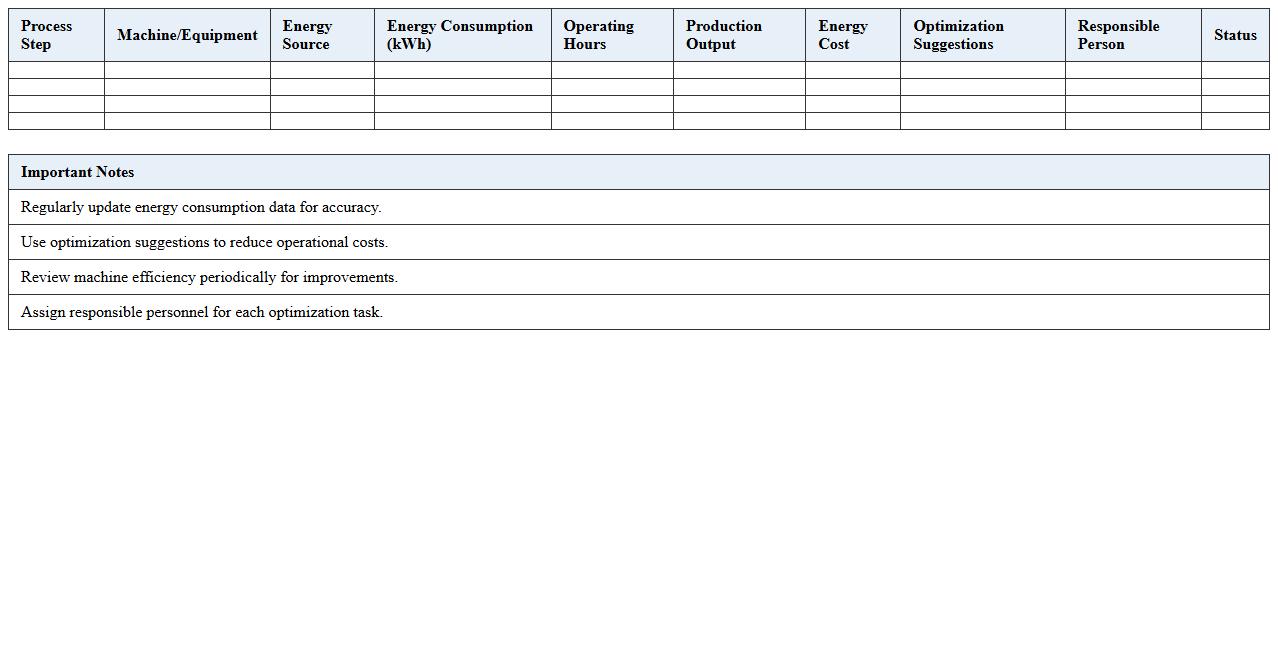

Production Line Energy Optimization Excel Template

The

Production Line Energy Optimization Excel Template is a comprehensive tool designed to analyze and reduce energy consumption across manufacturing processes. It enables users to input energy usage data, identify inefficiencies, and calculate potential savings by optimizing equipment operation schedules and workflow. This template supports informed decision-making, leading to cost reduction and enhanced sustainability in production environments.

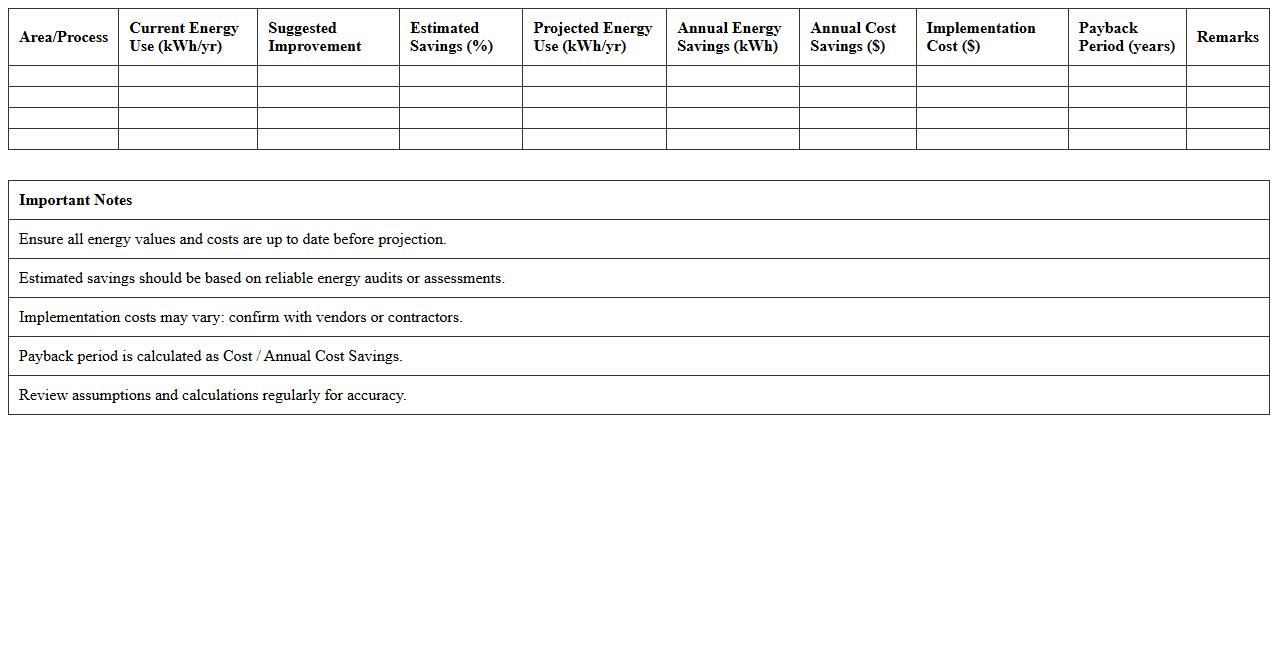

Plant-Wide Energy Savings Projection Excel Sheet

The

Plant-Wide Energy Savings Projection Excel Sheet is a comprehensive tool designed to quantify and track potential energy savings across an entire manufacturing facility. It enables accurate forecasting of energy consumption reductions by analyzing operational data and efficiency improvements, helping facilities identify cost-saving opportunities. This document supports strategic planning and sustainability goals by providing clear, data-driven insights into energy management initiatives.

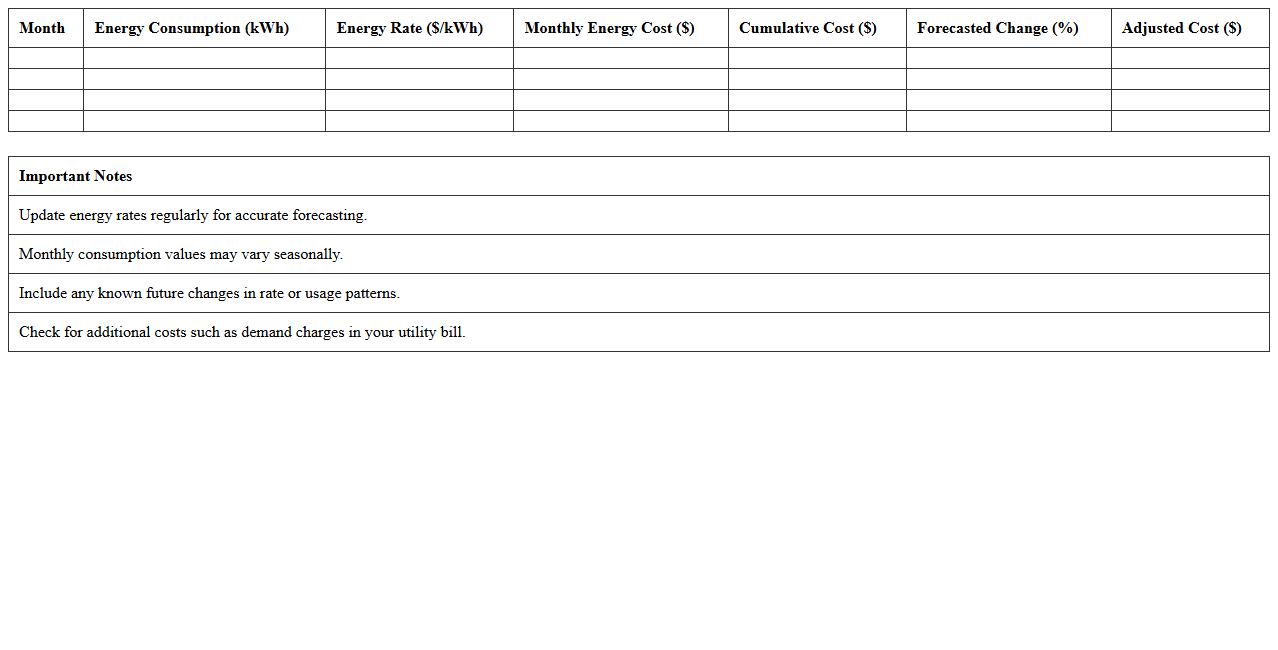

Energy Cost Forecast Calculator Excel for Plants

The

Energy Cost Forecast Calculator Excel for Plants is a powerful tool designed to estimate and predict future energy expenses for manufacturing facilities based on historical usage data and variable energy rates. By inputting key parameters such as energy consumption patterns, rate fluctuations, and operational schedules, this calculator enables accurate budgeting and financial planning. It helps plant managers identify cost-saving opportunities, optimize energy usage, and improve overall operational efficiency.

Factory Energy KPI Tracking Excel Template

The

Factory Energy KPI Tracking Excel Template is a structured spreadsheet designed to monitor and analyze energy consumption metrics within manufacturing facilities. It enables businesses to track key performance indicators such as energy usage per unit produced, cost savings from energy efficiency initiatives, and overall carbon footprint reduction. By utilizing this template, organizations can identify energy wastage, optimize resource allocation, and improve sustainability efforts, ultimately leading to reduced operational costs and enhanced environmental performance.

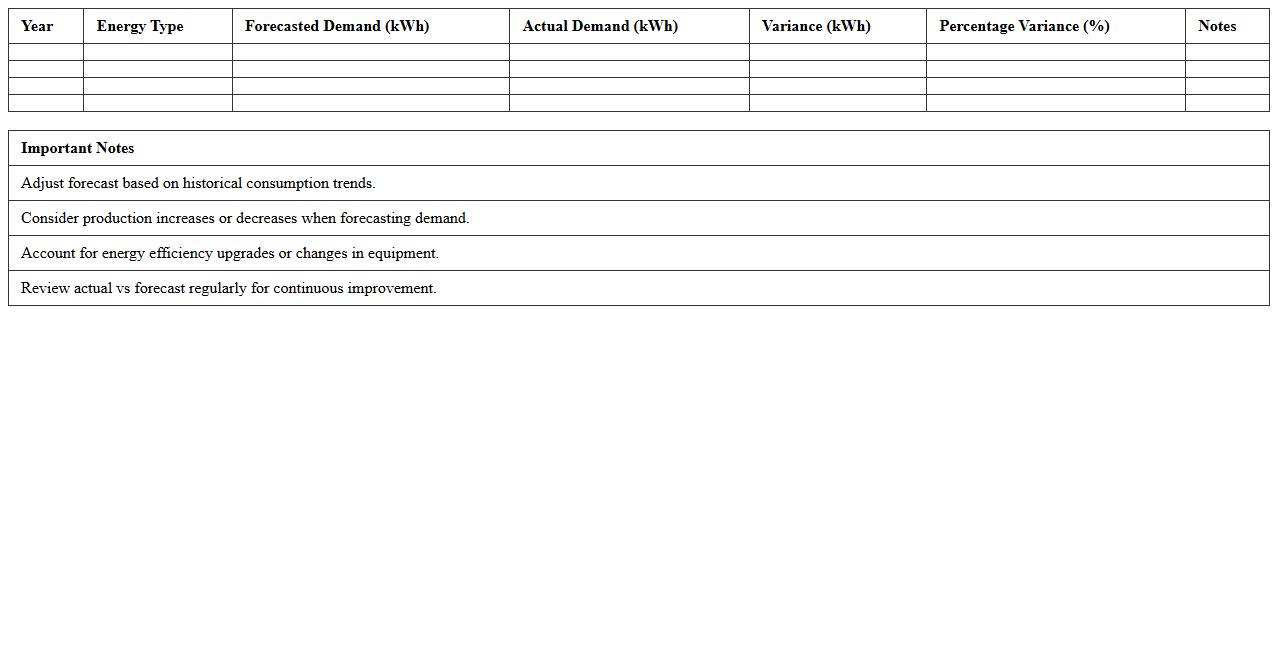

Yearly Manufacturing Plant Energy Demand Forecast Excel

The

Yearly Manufacturing Plant Energy Demand Forecast Excel document provides a detailed projection of energy consumption patterns based on historical data and planned production schedules. It helps manufacturing facilities optimize energy procurement, reduce costs, and improve sustainability by anticipating peak demand periods and identifying efficiency opportunities. This tool supports informed decision-making for budgeting, resource allocation, and compliance with environmental regulations.

What advanced Excel formulas can automate hourly energy consumption forecasts for manufacturing equipment?

Using the FORECAST.ETS function in Excel allows for accurate time series forecasting based on historical hourly energy data. Combining this with ARRAYFORMULAS and dynamic named ranges can automate continuous data updates without manual adjustments. Additionally, integrating SUMPRODUCT with conditional filters helps calculate weighted averages for predicting consumption under various operational scenarios.

How can you integrate real-time sensor data into an Excel energy forecast model for plant operations?

Real-time sensor data can be integrated into Excel using Power Query to fetch live data streams from IoT platforms or databases. Incorporating dynamic data connections ensures the forecast model updates automatically as new measurements come in. Using Excel's Data Model and linked PivotTables then helps analyze and visualize incoming sensor data within the energy forecast framework.

Which VBA macros enhance batch data import for weekly energy tracking in Excel?

VBA macros that automate importing multiple CSV or TXT files into a consolidated worksheet significantly improve batch data handling. Implementing a macro to loop through selected files and append data with error handling ensures seamless weekly energy tracking. Additionally, VBA scripts can standardize data formats and timestamps, which is crucial for consistent energy data analysis.

How do you visualize peak vs. off-peak consumption trends using Excel charts for manufacturing plants?

Creating clustered column charts with distinct colors for peak and off-peak hours highlights consumption differences effectively. Using dynamic named ranges adjusted by slicers allows interactive exploration of specific time periods or equipment. Overlaying a line chart to show average consumption trend provides clear visual insights into fluctuating energy usage patterns.

What custom dashboard KPIs are most effective for monitoring energy efficiency improvements in Excel?

Key custom KPIs include Energy Usage Intensity (EUI), comparing energy consumed per unit of production, and Peak Demand Reduction metrics. Real-time calculation of Cost Savings from implemented efficiency measures offers immediate feedback on performance. Integrating these KPIs in an interactive dashboard with slicers and conditional formatting improves decision-making for plant energy management.

More Forecast Excel Templates