The Equipment Allocation Excel Template for Manufacturing Units streamlines the process of assigning machinery and tools to various production tasks, ensuring optimal utilization and minimizing downtime. This customizable spreadsheet allows managers to track equipment availability, maintenance schedules, and operational efficiency in real-time. By enhancing resource management, the template supports increased productivity and cost savings in manufacturing operations.

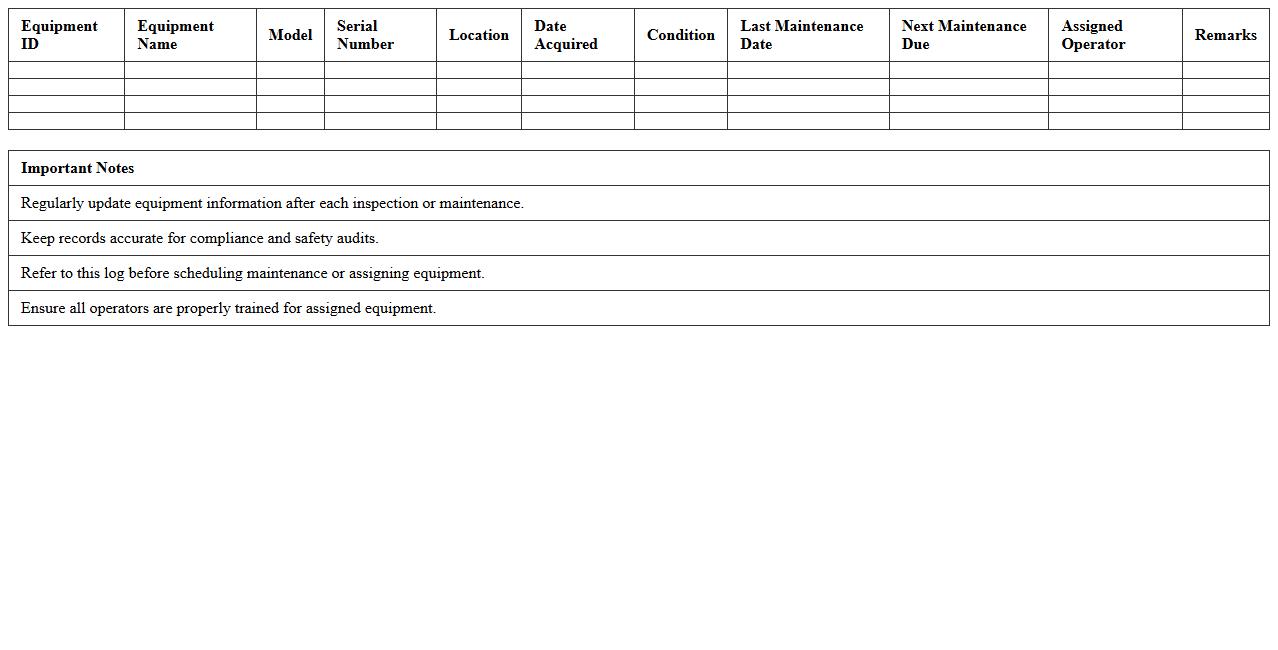

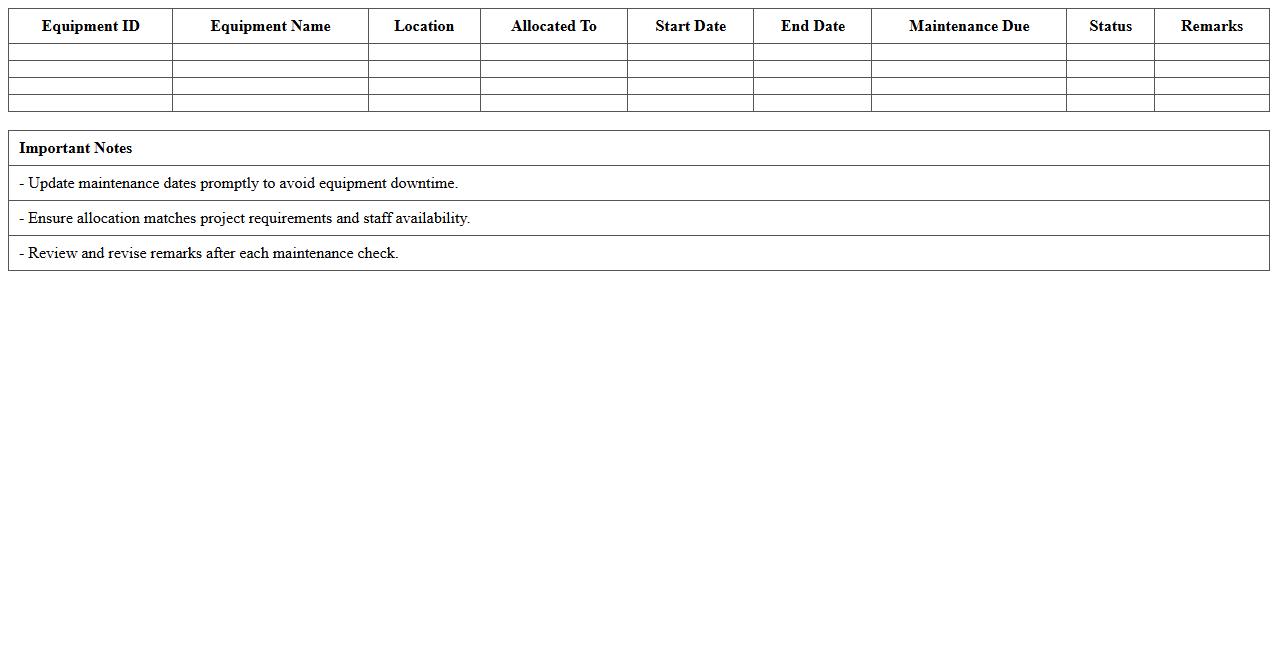

Production Line Equipment Inventory Log Template

The

Production Line Equipment Inventory Log Template document is a structured tool designed to systematically record and track all machinery and tools used in a manufacturing process. It helps organizations maintain up-to-date information on equipment status, maintenance schedules, and usage history, facilitating efficient resource management and minimizing downtime. Utilizing this template ensures accurate inventory control, better planning for repairs or replacements, and improved overall production line efficiency.

Machine Assignment Schedule Tracker Spreadsheet

A

Machine Assignment Schedule Tracker Spreadsheet is a digital tool designed to organize and monitor the allocation of machinery across various projects and tasks, ensuring efficient use of resources. It provides real-time visibility into machine availability, maintenance schedules, and operator assignments, thereby reducing downtime and avoiding scheduling conflicts. This spreadsheet enhances productivity by streamlining workflow management and supporting data-driven decision-making in equipment utilization.

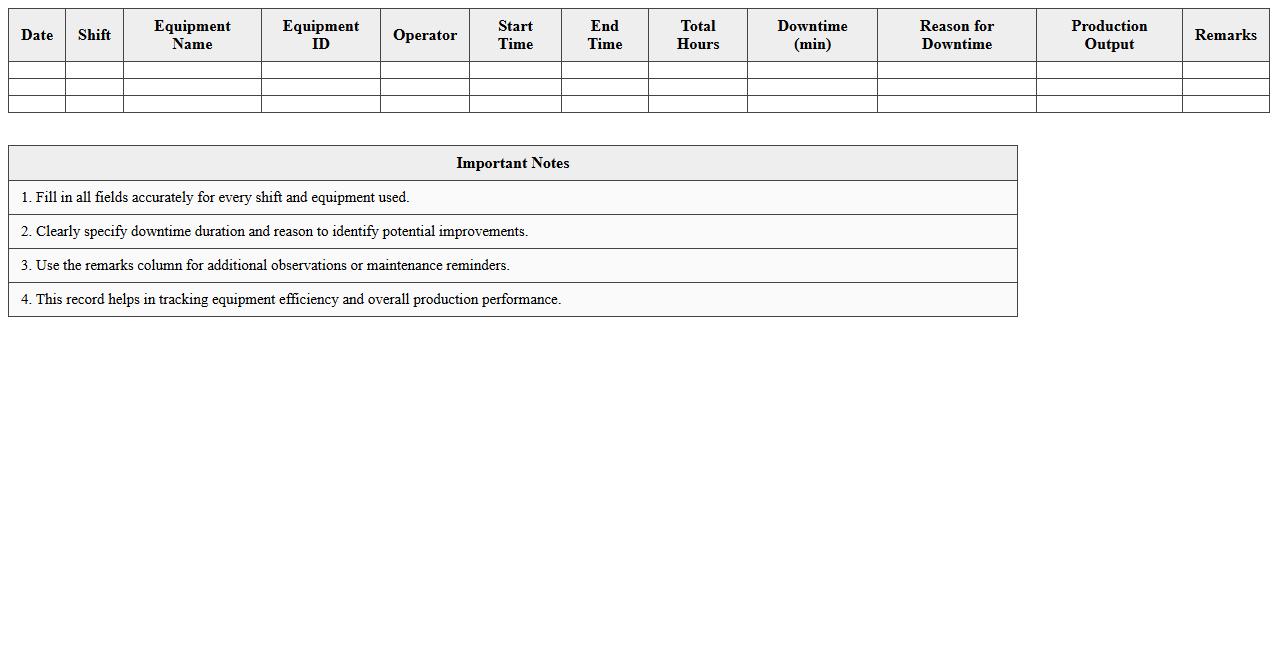

Manufacturing Equipment Utilization Record Sheet

A

Manufacturing Equipment Utilization Record Sheet is a document used to track the operational status, usage time, and maintenance activities of manufacturing machinery. It provides detailed data on equipment efficiency, downtime, and productivity, enabling better scheduling and resource management. This record sheet helps optimize equipment performance, reduces unexpected breakdowns, and supports informed decision-making in production planning.

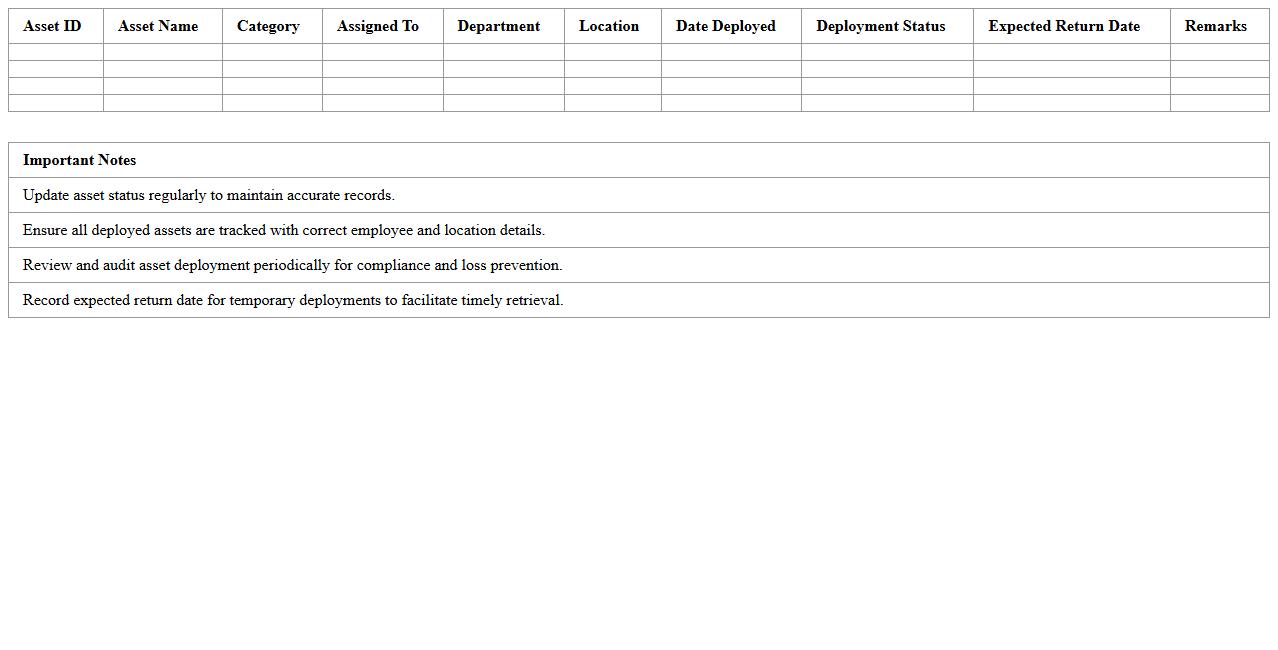

Asset Deployment Planning Excel Template

The

Asset Deployment Planning Excel Template document is a powerful tool designed to organize and streamline the allocation of resources across projects or departments. It enables precise tracking of asset utilization, availability, and scheduling to maximize efficiency and minimize downtime. Using this template improves decision-making by providing clear insights into asset deployment, resource forecasting, and cost management.

Equipment Maintenance and Allocation Calendar

The

Equipment Maintenance and Allocation Calendar is a vital document that schedules and tracks maintenance activities and the allocation of machinery or tools within an organization. It helps ensure timely servicing, reduces downtime, and optimizes resource utilization by clearly assigning equipment to specific tasks or departments. This calendar enhances operational efficiency, prolongs equipment lifespan, and supports proactive maintenance management.

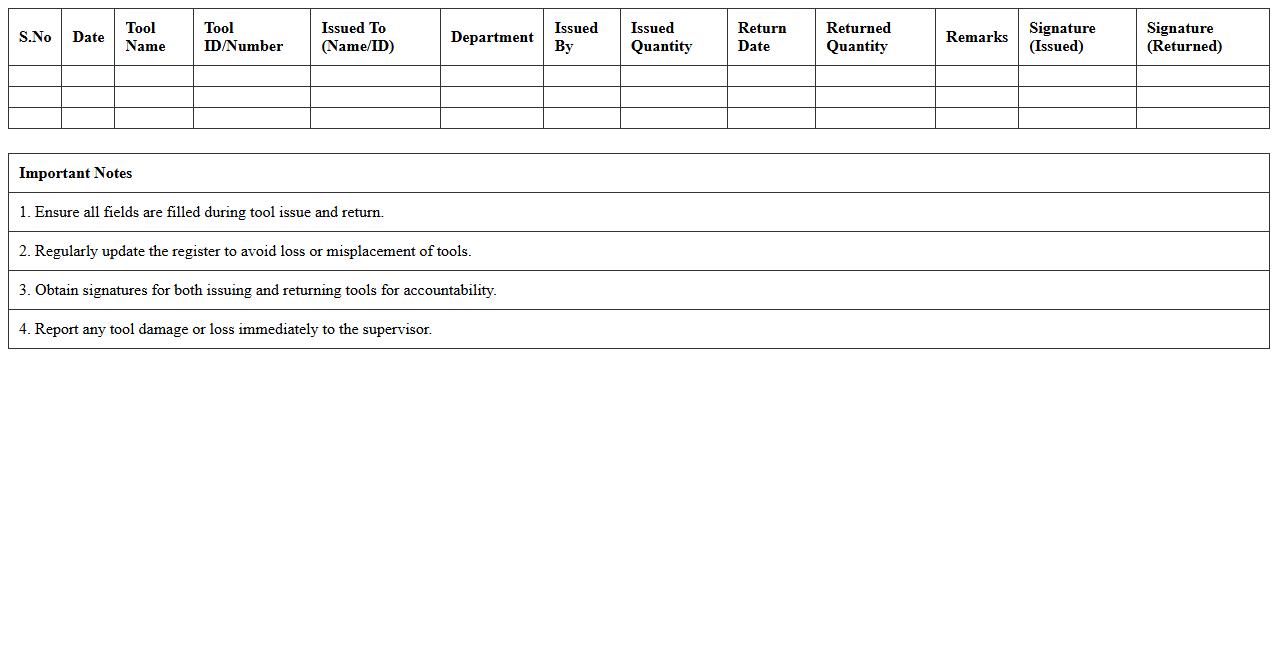

Workshop Tool Distribution Register Template

The

Workshop Tool Distribution Register Template is a structured document designed to systematically record the allocation and return of tools within a workshop environment. It helps track tool usage, prevent loss or theft, and maintain accountability among workers by providing clear documentation of who has each tool and when it was issued. This template enhances operational efficiency and ensures timely maintenance by keeping detailed logs of tool availability and condition.

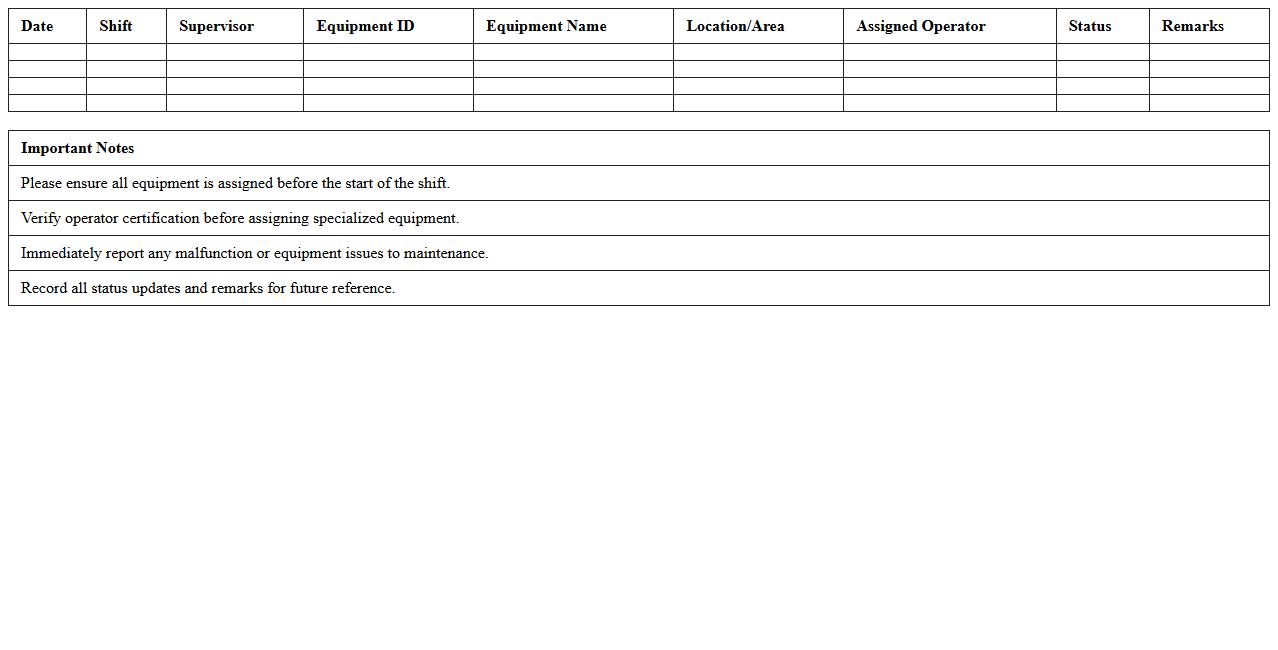

Production Floor Equipment Assignment Sheet

A

Production Floor Equipment Assignment Sheet is a detailed document that tracks the allocation and usage of machinery and tools on the manufacturing floor. It helps in optimizing resource management by clearly assigning equipment to specific tasks, operators, or production lines, ensuring efficient workflow and reducing downtime. This sheet is essential for monitoring equipment availability, maintenance schedules, and improving overall productivity in the production process.

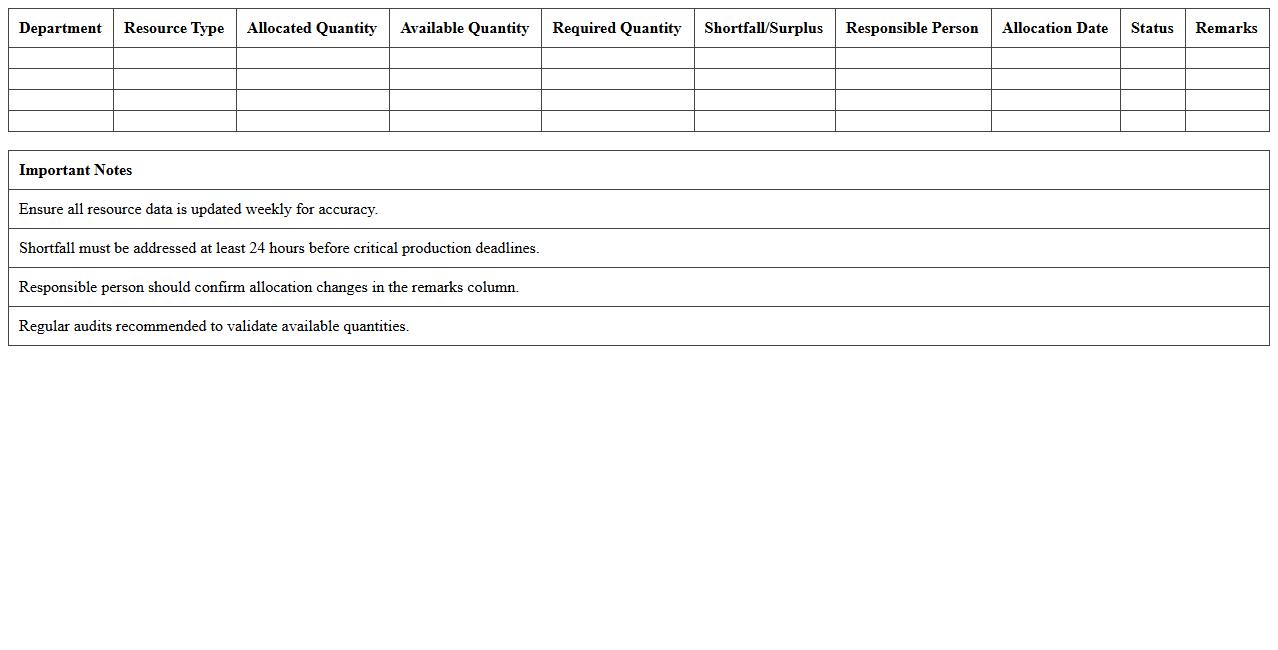

Factory Resource Allocation Dashboard Excel

The

Factory Resource Allocation Dashboard Excel document provides a comprehensive overview of resource distribution across manufacturing operations, enabling efficient tracking of labor, machinery, and materials. It consolidates real-time data into visual charts and tables, helping managers identify underutilized assets and optimize production scheduling. This tool enhances decision-making by offering clear insights into resource availability, utilization rates, and potential bottlenecks.

Plant Equipment Checkout and Return Tracker

The

Plant Equipment Checkout and Return Tracker document is a vital tool for managing the allocation and retrieval of machinery and tools on-site, ensuring all equipment is accounted for and maintained efficiently. It helps reduce loss, prevent unauthorized usage, and streamlines maintenance scheduling by keeping detailed records of who checked out equipment, the time of use, and its return condition. Utilizing this tracker enhances operational productivity, supports safety compliance, and improves inventory accuracy across plant operations.

Manufacturing Unit Asset Allocation Log

The

Manufacturing Unit Asset Allocation Log document systematically records the assignment and distribution of assets within a manufacturing facility, ensuring accurate tracking of equipment, machinery, and tools. It enhances operational efficiency by providing clear visibility into asset utilization, preventing downtime caused by misplaced or unavailable resources. This log aids in maintenance scheduling, budget planning, and audit compliance, thereby supporting effective asset management and cost control.

How do you track equipment allocation changes over time using Excel pivot tables?

To track equipment allocation changes in Excel, use pivot tables to summarize data across different time periods. Incorporate date fields into your pivot table rows or columns to display allocation changes chronologically. Refresh the pivot table regularly to update the view with the latest equipment assignments and reallocations.

Which Excel formulas best automate equipment assignment to manufacturing units?

Formulas like VLOOKUP, INDEX-MATCH, and IF statements are essential for automating equipment assignment in Excel. These formulas help dynamically match equipment to the correct manufacturing unit based on predefined criteria. Combining these with data validation ensures consistent and automated equipment allocation workflows.

How can conditional formatting highlight under-utilized equipment in the allocation sheet?

Conditional formatting can be set to flag under-utilized equipment by applying color rules based on allocated hours or usage metrics. For example, cells with usage below a threshold can turn red, drawing immediate attention. This visual cue makes it easier to identify equipment that may require reassignment or maintenance.

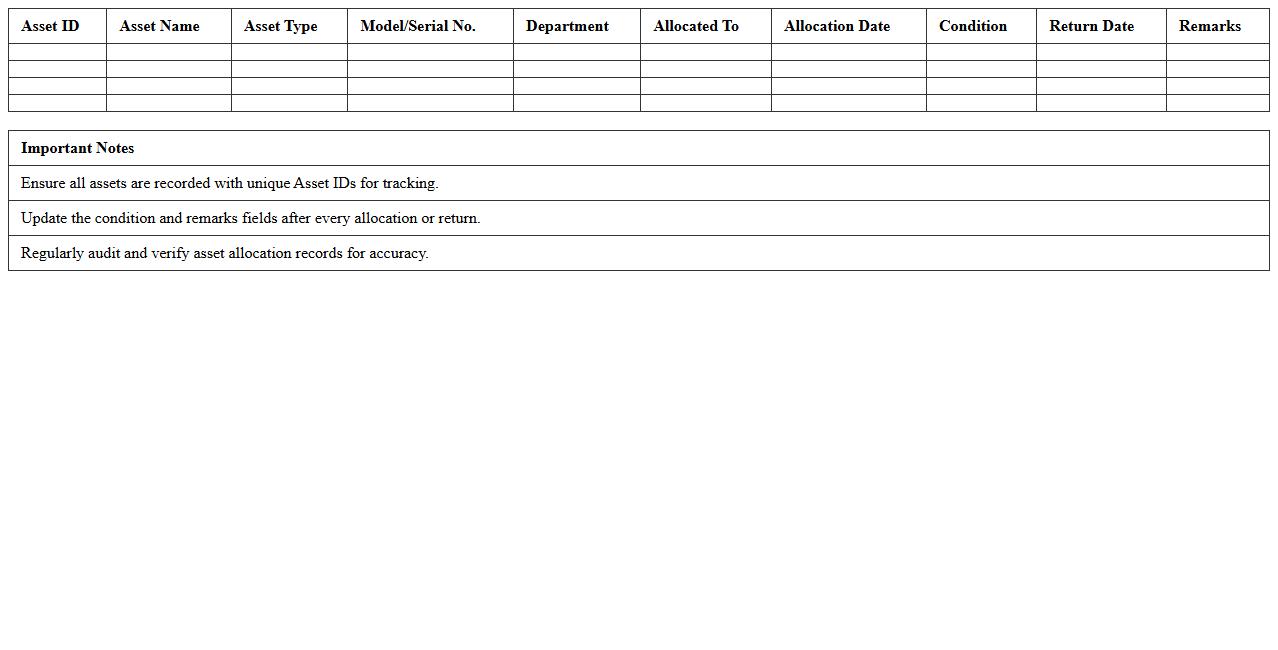

What columns are critical for an effective Equipment Allocation Excel template in manufacturing?

Essential columns include Equipment ID, Manufacturing Unit, Date of Allocation, Usage Hours, and Status. These fields capture key details necessary for tracking and managing equipment deployment accurately. Additional columns like maintenance dates and operator information enhance the template's effectiveness.

How do you integrate maintenance schedules into an equipment allocation Excel document?

Integrate maintenance schedules by adding columns for next maintenance date and last service performed. Use formulas or conditional formatting to alert when maintenance is due based on the schedule. Linking maintenance data with equipment allocation helps prevent downtime and optimize operational efficiency.

More Allocation Excel Templates